The AGV boiler is a simple, but quite reliable and efficient heating device. The units have been produced since Soviet times, the products were called the Zhukovsky Machine-Building Plant. However, gradually all domestic autonomous gas devices began to be called by such an abbreviation.

Installation

The outer part of the chimney and the part located in the attic must be thermally and waterproofed.

It is necessary to install an inspection in the chimney designed to collect debris that has entered the chimney. Modern gas water heating installation.

Gas heaters can be connected to the gas pipeline and registered only by representatives of the regional gas industry. It is imperative to thermally insulate the pipeline through which the coolant will flow to the radiators. But it is not necessary to subject the return circuit to this procedure. If the house uses a heating circuit with natural circulation of coolant, the device should be mounted below the place where the radiators are installed. It is recommended to install it in the basement.

Installation of harness

In the process of installing gas heating, it is important to correctly set the angle of inclination of horizontal sections of the pipeline. The requirements include 1 cm of slope per 1 m of pipeline length

This allows for more efficient fluid circulation, reducing the likelihood of air locks. Providing the required slope will help drain water from the system if it is intended to preserve or repair individual elements.

AGV installation process.

The heating system will have a shorter service life if the temperature exceeds +50 °C, as this will cause condensation to form on the walls of the pipes and boiler. To improve the performance of systems using gas heat sources, heating can be supplemented with a circulation pump.

How it all began

At one time, gas boilers of the AGV-80 or AGV-120 brand were used to heat a private house. This equipment had low productivity, but given the low cost of gas, this fact did not bother anyone.

AGV gas boilers for private homes were equipped with primitive automation, which failed in the first year of operation. However, the equipment functioned normally without it.

Installation of pipes for distribution is carried out outside around the perimeter of the house. However, this issue was not relevant at that time, and heat was supplied to the house in full. Pipes were used with a diameter of 2 inches, since a smaller diameter could cause the formation of air pockets that impede the natural circulation of the coolant.

After a slight modernization, gas boilers for heating AOGV and AOKGV appeared on the market, but this equipment was characterized by the same shortcomings (low performance and unreliable automation).

Despite this, boilers of this type have held up quite confidently on the market due to a serious advantage: the AGV heating stove operates without being connected to a power supply.

Other advantages of a heating system using AGV include the following:

- If we compare imported equipment and AGV, we note the affordable cost of the latter option.

- In contrast to the AOGV and the gas boiler produced by domestic manufacturers, the efficiency of the AGV can be noted.

The listed characteristics help in deciding what is better: an AOGV or a boiler.

Criterias of choice

When buying boilers for a private home, several aspects are taken into account:

- The area of the heated room.

- Possible heat losses (depending on the materials from which the walls of the building are constructed, the floors and ceilings, windows and doors are made).

- Equipment power (the required figure is calculated based on 1 kW for every 10 m² of area). But if the house is located in a region with harsh winters or is built from materials with high heat loss, the resulting figure is increased by 25%.

- Functional features of the boiler.

AGVs are produced in different capacities, but the standard indicator is enough to heat a house up to 120 m². For large buildings, foreign autonomous boilers are purchased. Additionally, an improved AOGV or AKGV boiler is being considered as an alternative solution.

The latter is a complex water heating apparatus. These are double-circuit boilers that operate independently of the electrical network. The units provide heating and hot water supply.

However, experts believe that it is not advisable to install such equipment in houses with an area of 200 m² or more, since it is impossible to create stable natural draft. You will have to buy an additional circular pump, and a UPS and a generator for it to ensure operation. Such disadvantages offset the advantages that the autonomy of boilers provides.

Scheme of water heating of a country house

To heat country houses, heating systems are installed in which water or antifreeze acts as a coolant.

The system consists of the following components:

- Water heating boiler (with two or one circuit).

- Polypropylene or metal fittings and pipelines.

- Bypasses that allow you to turn off individual radiators without stopping the entire system.

- Cast iron, steel, bimetallic or aluminum batteries.

- Expansion tank.

- Circulation pump (only in systems with forced circulation of the coolant).

- Gas heating equipment must be equipped with a safety system, which includes a thermocouple and a solenoid valve.

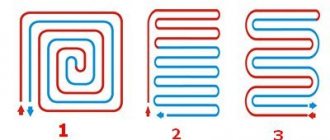

Depending on the wiring diagram, such systems can be single-pipe or double-pipe. In the first case, heating devices are connected in series, so the temperature of the coolant in each subsequent device decreases. This wiring is suitable for small one-story houses.

With two-pipe wiring, coolant with the same temperature is supplied to each radiator, which ensures uniform heating of the entire house. If necessary, individual radiators can be disconnected from the general circuit. This wiring is ideal for a large house with several floors.

Depending on the principles of coolant flow, systems come with forced and natural circulation. With forced current, a circulation pump is responsible for the movement of liquid through the pipes, and natural circulation occurs due to the different densities of cold and hot liquid.

The expansion tank can be open or closed. For systems with natural circulation, an open type container is used. A closed tank with two sealed parts separated by a membrane, used in systems with forced liquid flow.

For small one-story buildings, systems with natural current are sufficient, but for buildings with several floors, a pump will have to be installed. In this case, the length of the circulation circuit is limited to 30 meters, because the pump will not be able to supply water over a greater distance.

You can also install combined heating. In such systems, the pump is installed on the bypass. It starts up when you need to quickly warm up the premises. If there are interruptions in the power supply, then by simply switching the levers you can switch to heating with natural circulation.

How to choose a boiler for installation in a private house

When choosing a boiler, you need to familiarize yourself with the passport data of each of the “candidates” and focus on compliance with safety standards. To choose the right gas boiler, you need to consider some nuances:

- The dimensions of the room in which heating is expected. This is one of the most important criteria when choosing an AGV system. The power of the boiler depends on the heated area. There are certain standards in the production of a water heater. A rough calculation is carried out using a simple formula - 1 kW of power x 10 m2 of room.

Choose the boiler power according to the area of the house - Geographical location and climatic conditions. If your city is located in a cold region, then you need to add 20-25% of the power to the design power of the boiler.

- Taking into account the heat loss of the materials used and the dilapidation of window and door units. If the heating system is designed in an old building, then 15-20% must be added to the initial AGW power.

- System load. Here you should take into account the number of circuits (circulation rings) of the boiler. If it is planned to only heat the room, then a single-circuit boiler is installed, and if hot water is supplied to a private house, a double-circuit boiler is installed.

If you take into account each of these points and approach the heating problem responsibly, then choosing a boiler for the heating system will not be difficult. To simplify the task, you can consult a specialist.

Composition of the AGV system

The AGV system for heating devices consists of the following main elements:

- AGV boiler;

- pipelines;

- heating elements (radiators, registers);

- expansion tank, which is mounted above all other elements (necessary when starting the AGV heating system).

The basis of the AGV is the AGV boiler. It is a tank mounted in an iron casing, inside of which a pipe for burning gas is mounted. It looks like a samovar. The combusted gas heats the water flowing inside the tank. Gas combustion products are released into the atmosphere through the chimney.

The heated water enters the heating system, where, in accordance with the known laws of physics—hot water is lighter than cold—it flows through pipelines into heating radiators. There, having given up thermal energy, it cools and again enters the AGV for heating. This creates a closed circuit through which the coolant flows by gravity. Its driving force is the difference in height between the heating (AGV) and cooling devices (radiators). The greater this difference, the more intense the water circulation. Such a heating system is called a thermosiphon or a system with natural circulation of coolant. However, recently heating systems with forced water circulation have become increasingly used. In this case, a circulation pump is installed at the outlet of the AGW into the pipeline, which significantly increases the rate of water circulation and, as a result, reduces the time for heating the premises at a given temperature and the consumption of gas consumed. In this case, automation is used that maintains the specified parameters and monitors the fulfillment of basic safety requirements (switching off the gas supply when the water pressure in the line decreases or the burners go out).

New generation of AGV devices

The main model produced at Russian factories is AOGV-23.2-1 (domestic gas heating apparatus). It is designed to heat houses with an area of 140-200 square meters. There is a device with less power, designed to heat areas of 100-140 m2. In appearance, these two brands are practically no different from each other.

Not so long ago, manufacturers began to offer a new combined model AKGV-23.2-1 with a water circuit. This unit can be used both for heating the house and for organizing the supply of hot water. Its filling has also changed. Instead of a pipe running inside the boiler, manufacturers began to install three steel sections. They are made by stamping and are hollow inside. The sections are mounted vertically, connecting into one chimney, through which gas combustion products enter a separate chimney pipe.

The most amazing thing is that water for domestic needs is heated using a coil that encircles the entire circuit inside the boiler. Water flows through it, which is used for everyday life. And in the boiler itself the water for heating is heated. An excellent device, so to speak, two in one. By the way, the coil is made of copper pipe.

An injection burner has been added to the kit of the new model, ensuring efficient combustion of gas without residue. This type of burner works great even if the gas pressure in the pipeline drops.

AKGV-23.2-1 with water circuit

Special conversation about the automation of the new AGV. This is a unique system that completely controls the entire water heating process. The automation unit consists of:

- Thermal sensor that controls the water temperature;

- An electromagnet responsible for controlling the main gas supply valve;

- Thermocouple, which is installed near the igniter. It is heated by a constantly burning torch, thereby creating an electric current in the circuit. And the current guarantees that the gas supply valve will always be open;

- A draft sensor, which is mounted in the chimney and monitors the effective draft of the pipe.

In general, the automation unit will never give you the opportunity to play a cruel joke on you if one of the indicators of the boiler’s efficient operation suddenly goes wrong. There will be no fire or gas leak. The most important thing is that the automation is correctly adjusted.

Model overview

Any AOGV is a single-circuit floor-standing device designed for heating a room. There is no second circuit in them. If you need hot water supply, you need to connect an indirect heating boiler. Based on AOGV, AKGV is produced - they have a built-in heat exchanger for hot water supply.

The burner is designed for natural gas. To convert the device to liquefied gas, you will need to change it and need a special nozzle. The manufacturer produces heaters with power from 11 to 29 kW. You can choose a modification for heating an area from 45 to 250 m². The estimated cost of ZhMZ boilers is 18-23,000 rubles.

AOGV-11.6 Economy

Floor-standing version. Household versions - 11-29 kW. Features of version 11.6:

- Efficiency 90%

- Open camera.

- Heats 100 m².

- 11,600 W.

- One circuit.

- Mechanical control.

- Convection type.

- Weight - 45 kg.

AOGV-23.2-3 Comfort

- Efficiency 88%

- Open firebox.

- Heats 200 m².

- 23.2 kW.

- One circuit.

- Mechanical control.

- Convection type.

- Weight - 52 kg.

But 23 Universal can be made in two variations: single-circuit and double-circuit. The non-volatile device is equipped with imported automatic equipment. Works on any type of gas. Modest dimensions, light weight - an ideal solution for creating autonomous heating.

AOGV-17.4-3 Universal

AOGV 17 belongs to the convection type. Floor-standing version. Open firebox.

- Efficiency 88%

- Area - 140 m².

- Power - 17.4 kW.

- Weighs 49 kg.

The abbreviation stands for “Gas Water Heating Apparatus”. The Zhukovsky plant is not their only producer. They are released:

- JSC "Borinskoe" (Moscow region). It produces devices in an expanded power range; there are models for 5, 6, 7, 9 and 11 kW. Next: from 11 to 23 kW.

- CJSC "Rostovgazoapparat" Produces options 11.6-35 kW.

- There are also imported versions - Beretta (Italy).

Zhukovsky MZ does not produce parapet boilers, but they can be found from other domestic manufacturers, for example, a device from the ROSS company. Parapet models have a closed combustion chamber, so they can be installed in an apartment. They do not require a separate room.

Example of a parapet device: ROSS AOGV-13P. This is a 2-circuit option. Heats up to 130 m². 13 kW. Efficiency - 90%.

AOGV-23.2-3 Comfort: Timofey U., Istra

It has been operating for six years now. Very cheap compared to what the Europeans offer. Quickly heats a house of 180 sq.m. It starts without problems. Over the 5 years of operation, the thermocouple had to be replaced once.

AOGV-11.6-3: Elena P., Kotlas

Cheap, that's why we bought it. Pros: compact, relatively quiet. Cons: everything is cheap, poor, as if it was assembled in a barn. Automation is just one name. The very next year it started to turn off on its own. And sometimes, on the contrary, it starts to “blaze” - something is burning inside, it smells of burnt plastic. And the masters cannot do anything. If I have money, I’ll buy something better, but not ZhMZ.

ZhMZ gas boilers are simple and reliable equipment, time-tested. They are adapted to Russian conditions and have an affordable price. In addition to the products of the Zhukovsky Metallurgical Plant, there are a lot of other manufacturers on the market that produce similar equipment, including double-circuit and parapet models. Everyone can choose the power that suits their home.

Foreign autonomous gas water heaters

Non-volatile boilers are popular. Imported units differ from AGV in a wide variety of models. However, more often these are floor heating devices. Wall-mounted options are rare.

But there is a variety like parapet non-volatile boilers. They can be installed on the floor or hung on the wall (but not higher than the window sill). There are models mounted on a vertical surface.

Imported non-volatile devices also differ in the materials from which the heat exchanger is made. For example, stainless steel, cast iron or copper. The latter is considered expensive, but also the most reliable and durable option. Copper is not used for the production of AGV.

The equipment of the Slovak brand Protherm is popular. The models are named after animals. The Protherm Bear 20 TLO boiler is considered practical and powerful. The device is equipped with a heavy cast iron heat exchanger.

The unit has a higher efficiency compared to AGV - about 90%. This model is suitable for heating a house with an area of up to 200 m² (excluding heat loss), although the power is 18 kW.

Among foreign devices, the Baxi boiler is popular. SLIM EF 1.22. The device is characterized by a high power of 22 kW, but the efficiency is lower than that of other imported units - 88%.

Operating principle

All AOGV boilers look like a single-circuit mechanism, which is equipped with an internal atmospheric burner. The maximum coverage of the heated surface in such boilers is ensured by the energy of the combustion gas. This happens thanks to special micro-torch burners.

At the bottom of the boiler, directly under the tank with the heat exchanger, there is a gas burner, with the help of which the water is heated. With a slight modernization of the device, it can be operated using liquefied gas.

The steel heat exchanger has a tubular configuration, which ensures high efficiency of the equipment. In the rear area of the gas boiler there are outlet and inlet fittings with a diameter of approximately 4 cm, intended for connecting a heat carrier. At the bottom of the device there is a return line, and at the top there is a so-called “direct” line.

The chimney has a diameter of about 120 mm and is connected to the top of the device.

The unit is controlled using a valve with electromagnetic properties and a thermostat lever. Sometimes boilers with piezo ignition or automatic start are produced. A thermocouple and a draft sensor are connected to the valve. The copper thermocouple controls the presence of fire at the igniter and is considered an important component of the boiler. The draft sensor is capable of shutting off the flow of gas if the draft decreases.

DEVICE AND PRINCIPLE OF OPERATION.

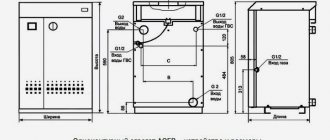

The device consists of the following components and parts: a heat exchanger tank, a main burner, an ignition burner unit with a thermocouple and an ignition electrode installed in it, a combined gas valve (multifunctional regulator), a draft stabilizer, and cladding parts.

In the upper part of the tank-heat exchanger there is a thermostat sensor connected by a capillary tube to the actuator of the thermostatic valve (bellows-thermal balloon system), and a thermometer sensor

A special feature of the design of the 630 EUROSIT combination valve is the presence of a device for stabilizing the gas outlet pressure, as well as the combination of valve control in one handle with the designation of positions by the corresponding symbols and numbers at its end and an indicator on the valve cover. The dependence of the temperature of the heated water on the position of the control handle scale is presented below:

| Scale numbers | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Water heating temperature, °C | 30 | 40 | 50 | 60 | 70 | 80 | 90 |

The operating principle of the temperature controller is based on the expansion of liquid when heated. The working fluid, heated in the sensor (thermal cylinder) from the water in the tank - heat exchanger, heated by the combustion of natural gas, expands and flows through the capillary tube into the bellows, which converts the volumetric expansion into linear movement of the mechanism that drives the system of two valves (instantaneous and metering). ). The design of the mechanism provides protection against thermal overload, which protects the bellows-thermal cylinder system from damage and depressurization.

- When setting the required water temperature in the device using the control handle to increase, first the instantaneous (click) valve opens, then the dosing valve.

- When the water temperature in the apparatus reaches the set value, the dosing valve smoothly closes, switching the main burner to the “low gas” mode.

- When the temperature rises above the set value, an instantaneous (click) valve is activated, completely shutting off the gas to the main burner.

- In the absence of draft in the chimney, the gases leaving the firebox heat the draft sensor, the sensor is triggered, opening the normally closed contacts of the thermocouple circuit. The electromagnetic (inlet) valve closes and blocks the access of gas to the main and ignition burners. The draft sensor is designed to be activated during a period of no draft for at least 10 seconds.

- When the gas supply from the network is stopped, the pilot burner instantly goes out, the thermocouple cools down, and the solenoid valve closes, blocking gas access to the main and pilot burners. When the gas supply is restored, the passage through the apparatus is completely blocked.

- When the gas pressure in the network decreases below 0.65 kPa, the gas pressure at the ignition burner will also drop, and the emf of the thermocouple will decrease to a value insufficient to hold the valve. The solenoid valve will close and block gas access to the burners.

Design Features

- Fire adjustment is made in two ways: automatically and manually. The models differ not only in power, each of them has a certain range of capabilities.

- Some models have a pump to circulate water in the pipes. This allows you to effectively heat the room due to uniform heat distribution. Cheaper modifications do not have pumps, and water circulates according to the laws of physics. Therefore, when installing such boilers, the pipes are mounted at an angle.

- All modifications have an expansion tank. It allows you to achieve optimal pressure in the system, and if the liquid expands due to strong heating, it stores its excess.

Varieties

All boilers at the Zhukovsky Plant are floor-standing. There are three modifications:

In the first case, automation manufactured in the Russian Federation was used, in the other two - foreign ones. The brand presents only single-circuit versions - for heating buildings; double-circuit versions are not produced at ZhMZ.

Device

The efficiency of the equipment is 89%, which is quite good for domestic products. This productivity can be achieved due to the original design of the heat exchanger. The cast iron heat exchanger is equipped with turbulators. The burner is atmospheric, air comes from the room. Thanks to automation, continuous operation for a long time is ensured.

Heaters from the Zhukovsky Plant have a number of innovations that increase their environmental friendliness. Developers are trying to keep up with global trends, but still, domestic products are far from achieving the indicators of European and some Asian competitors. But Russian products have an undeniable advantage - a low price that satisfies all consumers.

Cost and Savings

The average cost of equipment varies over a wide price range. The cheapest are models that are not equipped with an automatic shutdown system and thermal sensors. Also, the price depends on the volume of the main tank and the power of the device.

Choose a reliable boiler model that will work properly

Responsible manufacturers include maintenance of manufactured equipment in their list of services; cost formation also depends on this. The price is also affected by the use of different materials. The country of origin and the promotion of the brand can affect the increase in the market value of the product, but the quality, as a rule, is different for imported boilers, especially from northern countries.

Advice! Boilers from domestic manufacturers are adapted to local conditions. When choosing, this fact should also be taken into account.

When choosing equipment, do not rush to a product with a low price. The cost of each device is calculated and justified. In addition, in a few years even the most expensive water heater will pay for itself, taking into account the modernizing equipment installed on the boiler (automation, temperature sensors and circulation pump).

Advantages and disadvantages of AGV

Like any device, AGV also has its advantages and disadvantages. Its main advantages are:

- reliability and safety during operation;

- independence from power supply;

- possibility of heating automation;

- the use of various installation methods (wall or floor);

- simplicity of design, which allows for high-quality and reliable maintenance of the equipment;

- low cost and economical operation.

There are two main disadvantages:

- some massive equipment, which occupies about 1 m3. Therefore, AGVs are often installed in a separate room.

- deterioration of the design of heated rooms (pipes, radiators or registers), which forces the use of additional elements when arranging the interior.

Modern heating AGV

Compared to Soviet models, manufactured devices have become convenient and functional. They are equipped with automation, which makes the operation of the boilers comfortable for the user.

Modern models have a temperature sensor necessary to control the set temperature. Often a component is installed that regulates the draft in the chimney. The operation of the automation is carried out due to the electric current generated by a thermocouple. The latter produces it due to heating. This ensures the activity of the electromagnet, which makes it possible to control the gas valve. This also increases operational reliability.

To choose a suitable model, take into account the characteristics of the equipment.

SAFETY INSTRUCTIONS

Persons who have examined this passport are allowed to service the device.

Installation and operation of the devices must comply with the requirements of the “Rules for the design and safety of operation of hot water boilers, water heaters and steam boilers with excess pressure”, as well as the requirements of the “Safety Rules for Gas Distribution and Gas Consumption Systems. PB 12 - 529", approved by the State Mining and Technical Supervision of Russia.

The operation of the devices must be carried out in accordance with the “Fire Safety Rules for residential buildings, hotels, dormitories, administrative buildings and individual garages PPB - 01 - 03”.

Operation of the device is only permitted with properly functioning automatic safety and thermal control.

Gas safety automatics must provide:

- Reducing the gas supply when the water temperature in the heating system reaches the set value.

- Shutting off the gas supply to the main burner when the set heating temperature is exceeded.

- Turning off the gas supply to the device in the following cases:

- when the gas supply to the device is stopped (within no more than 60 seconds);

- in the absence of draft vacuum or in the boiler furnace (for a period of no less than 10 seconds and no more than 60 seconds);

- when the pilot burner flame goes out (within no more than 60 seconds).

When operating the device, the hot water temperature should not exceed 95 °C.

Prohibited:

- operate the device with the heating system partially filled with water;

- use other liquids instead of water as a coolant**;

- install shut-off and control valves on the supply line and pipeline connecting the heating system to the expansion tank;

- operate the device if there is a gas leak through the gas pipeline connections;

- use an open flame to detect gas leaks;

- operate the device if there is a malfunction of the gas network, chimney or automation;

- independently eliminate malfunctions in the operation of the device;

- make any design changes to the apparatus, gas pipeline and heating system.

When the device is not working, all gas valves: in front of the burner and on the gas pipeline in front of the device, must be in the closed position (the valve handle is perpendicular to the gas pipeline).

Any malfunctions when operating the device on gas must be immediately reported to the emergency service of the gas operating company.

If gas is detected in the premises, you should immediately stop supplying it, ventilate all premises and call emergency or repair services. Until the malfunction is eliminated, it is prohibited to light matches, smoke, or use

** It is allowed to use household coolant “Olga” (manufacturer: ZAO Organic Products Plant) according to the instructions for use. After a period of operation, the coolant must be drained and disposed of.

The manufacturer reserves the right to make changes to the design and appearance of the product. This technical documentation may differ from the description above; see the operating manual enclosed with each boiler upon purchase.

This page uses materials from the site

User manual

The main thing to remember is that such boilers do not have a built-in circulation pump. Good natural traction is required. This is only possible if ventilation is established in the room where the AGV is installed, and the chimney is arranged according to all the rules.

The installation features are as follows:

- the height of the air duct is at least 5 m with a total length of horizontal sections of up to 3 m;

- the diameter of the pipe corresponds to the size of the outlet pipe of the device;

- equipment must not be connected to exhaust ventilation ducts;

- a small hatch is installed under the vertical part of the chimney to clean the system from condensate;

- When installing the AGV, you need to make sure that there is a free passage of at least 1 m in front of the device.

The recommended distance from the unit to the nearest wall is 2 m or more; this is the only way to ensure fire safety. The finishing of the vertical surface must be made of non-combustible material. If the owner doubts its properties, it is better to install a screen made of sheet asbestos.

Installation of AGV necessarily involves connecting the equipment to gas networks. You cannot do this on your own; you need to contact specialists from a company that has a license to carry out the work.

As for the operating rules, the equipment is started in the following sequence:

- First you need to check whether the heater tank is filled with water.

- Then they look for the presence of draft in the chimney. This can be done using a thin paper flag. If there is no traction, it will remain motionless. This is important because there is a risk of poisoning from unburned fuel.

- Open the valve mounted on the gas pipeline.

- Light the burner (with a match or piezo ignition handle - depending on what type is provided on the model). Then only the igniter turns on. After this, you can open the tap in front of the main burner. It should work from the igniter. It is recommended to read the instructions first.

- After turning on the AGV, check again for the presence of draft in the chimney.

- Close the firebox door.

If the igniter goes out, it can only be re-ignited after a few minutes. When the water heater is running, it should be on constantly.

The AGV is also switched off sequentially. First you need to close the gas valves. They are installed in front of the main burner and appliance. The AGV 120 gas boiler is characterized by the fact that the pilot valves in front of the boiler are closed separately.

The units do not require special care. The main thing is to provide protection from mechanical damage and liquid ingress if the device is installed in such a way that splashes from a shower stall or water tap reach it.

The operation of the device should be monitored. The flame has a bluish tint and the length of the tongues is 30-40 mm. If it starts to smoke, you need to open the windows slightly to allow oxygen to enter the system. When you smell gas in the air, call specialists immediately. Before the emergency team arrives, turn off the tap in front of the equipment and ventilate the room. At the same time, turn off electrical appliances and lights so that there is no spark anywhere.

What is AOGV: decoding

Mechanical automation.

AOGV (interpretation: gas hot water heating apparatus) is a gas boiler that does not contain a single volatile element. That is, the unit can operate autonomously without electricity. They are usually installed where there is a central gas pipeline, but even in the absence of gas, you can change the burner, which will run on propane-butane. In the heater marking there are always numbers after the abbreviation - this is the maximum power. For example, AOGV 17 means that the maximum thermal power of the unit is 17 kW.

Main elements of the heater:

- automation;

- thermocouple;

- combustion chamber;

- heat exchanger;

- chimney.

The operation of the AOGV boiler is controlled by mechanical automation. Domestic heaters can be equipped with automatic equipment of their own (in cheaper models), European or American production. This is the heart of the heater; without automation, the boiler cannot operate. The second important element of the heater is a copper thermocouple. It is responsible for activating the solenoid valve, which shuts off the gas supply if the burner wick goes out.

Unlike modern parapet heaters, AOGV gas boilers are equipped with an open combustion chamber. The disadvantage of such chambers is that they take air from the room in which they are located to maintain the fire. The advantage is the ability to exhaust smoke through a regular chimney with natural draft; there is no need for an energy-dependent fan.

The heat exchanger is located at the top of the combustion chamber, directly above the burner. Each circuit has its own heat exchanger; the fluids in them do not intersect. That is, if the heater is intended not only for heating the room, but also for preparing hot water, then there will be two heat exchangers.

What is the difference between AGV and AOGV

The autonomous heating gas water heater is a 1-circuit independent boiler. The main difference from the AGV is that the device is considered more reliable and safe to use. The unit is equipped with advanced automation.

To install AGV, a separate room is required, since combustion air is taken directly from the room. Good sound insulation is necessary, because when the device is turned on, a loud bang is heard. In AOGV this drawback has been eliminated.

When the water reaches its maximum temperature, the burner switches to minimum flame mode, but does not turn off completely. A separate room for the AOGV is also not required, since a chimney with a size of 140 mm or more is laid through the wall, and the air is taken from outside. It is only important to install a special garbage container under the pipe for waste that accidentally ends up in the channel.

Model overview

Any AOGV is a single-circuit floor-standing device designed for heating a room. There is no second circuit in them. If you need hot water supply, you need to connect an indirect heating boiler. Based on AOGV, AKGV is produced - they have a built-in heat exchanger for hot water supply.

The burner is designed for natural gas. To convert the device to liquefied gas, you will need to change it and need a special nozzle. The manufacturer produces heaters with power from 11 to 29 kW. You can choose a modification for heating an area from 45 to 250 m². The estimated cost of ZhMZ boilers is 18-23,000 rubles.

AOGV-11.6 Economy

Floor-standing version. Household versions - 11-29 kW. Features of version 11.6:

- Efficiency 90%

- Open camera.

- Heats 100 m².

- 11,600 W.

- One circuit.

- Mechanical control.

- Convection type.

- Weight - 45 kg.

AOGV-23.2-3 Comfort

- Efficiency 88%

- Open firebox.

- Heats 200 m².

- 23.2 kW.

- One circuit.

- Mechanical control.

- Convection type.

- Weight - 52 kg.

But 23 Universal can be made in two variations: single-circuit and double-circuit. The non-volatile device is equipped with imported automatic equipment. Works on any type of gas. Modest dimensions, light weight - an ideal solution for creating autonomous heating.

AOGV-17.4-3 Universal

AOGV 17 belongs to the convection type. Floor-standing version. Open firebox.

- Efficiency 88%

- Area - 140 m².

- Power - 17.4 kW.

- Weighs 49 kg.

The abbreviation stands for “Gas Water Heating Apparatus”. The Zhukovsky plant is not their only producer. They are released:

- JSC "Borinskoe" (Moscow region). It produces devices in an expanded power range; there are models for 5, 6, 7, 9 and 11 kW. Next: from 11 to 23 kW.

- CJSC "Rostovgazoapparat" Produces options 11.6-35 kW.

- There are also imported versions - Beretta (Italy).

Zhukovsky MZ does not produce parapet boilers, but they can be found from other domestic manufacturers, for example, a device from the ROSS company. Parapet models have a closed combustion chamber, so they can be installed in an apartment. They do not require a separate room.

Example of a parapet device: ROSS AOGV-13P. This is a 2-circuit option. Heats up to 130 m². 13 kW. Efficiency - 90%.

The best condensing gas boilers

These boilers are considered the most economical because they can use the energy of not only gas combustion, but also condensing steam. As a result, their efficiency is almost close to the coveted 100%.

Vaillant ecoTEC plus VUW

89%

buyers recommend this product

Stuffed with intelligent electronics and eBus switching, the unit works not only for efficient heating, but also for preparing hot water, that is, it also belongs to double-circuit units. The capacitor system is more environmentally friendly compared to the traditional one, and also provides a very high efficiency of 98%.

The combustion chamber is equipped with a modulating burner with wide power adjustment capabilities (from 28 to 100 percent). With such efficiency and equipment, the dimensions of the boiler are quite acceptable: 720x440x372 mm. The ecoTEC line itself consists of three models with a maximum power of 24, 30 and 34 kW.

Advantages:

- Digital control and diagnostic system;

- The most informative panel;

- Possibility of control from a mobile phone and connection to a “smart home”;

- The burner can receive air both from the room and from the street;

- Short-term increase in power for quick water heating;

- Removal of condensate outside.

Flaws:

- Difficult to repair;

- High price.

ecoTEC Plus boilers still scare off many due to their high cost. But there is minimal hassle with them, and the fuel savings will pay off the investment over time.

Viessmann Vitodens 100-W

88%

buyers recommend this product

An expensive boiler, capable of operating at a power of 4.7-35 kW, saves not only blue fuel, but also electricity - due to the adjustable operation of the fan. This model also has other highlights. We are talking about a cylindrical MatriX burner, consisting of many micro-nozzles, which practically does not allow heat loss. A ring heat exchanger made of stainless steel works no less efficiently.

Advantages:

- Compact housing 400x400x350 mm;

- Two ways to prepare hot water;

- Maximum efficiency and energy efficiency;

- High efficiency (98%);

- Intelligent automation;

- Remote control – from a touch panel or smartphone;

- Possibility of working on LNG and biogas;

- Easy access for repairs and maintenance.

Flaws:

Price.

If your home is equipped with a smart home system, the equally smart Viessmann Vitodens will be the best solution for creating a heating and hot water system.

Viessmann Vitopend 100-W A1HB003

Baxi Eco Four 1.24 F

Vaillant AtmoTEC Plus VU 240/5-5

Heating power 34 kW 24 kW 24 kW Type single-circuit single-circuit single-circuit Efficiency 90% 92.9% 91% Combustion chamber closed closed open

Features of installation of the AGV heating system

Installation and connection of AGV can only be carried out by specialists from the gas service of your locality. After installation, your gas water heater will be registered.

If you plan to install AGV heating, then you must provide for the following features:

- The heating boiler is installed in a separate room (boiler room);

- The pipe for exhaust gases must be installed outside, at a height not lower than the roof.

- The minimum diameter of the chimney pipe must be 135 mm;

- The outer part of the chimney must be insulated and insulated;

- The chimney is equipped with a special channel for collecting waste.

When using a system with natural heat circulation, it is necessary to ensure that the unit is located below the installation level of the radiators.

If you already know how to choose AGV heating, then you should be aware that the diameter of the pipes is selected based on the technical documentation of the equipment.

When laying heating system pipes, it is necessary to lay them at a certain angle of inclination. The slope should be 10 millimeters per 1 meter of pipe. The condition with a slope is necessary in order to avoid the appearance of air locks in the system, as well as to improve water circulation. Plus, it’s convenient when draining water from the system.

When the temperature reaches 50 degrees C, gas condensate may appear on equipment elements. Because of this, the service life of some system components may be reduced. Also, at this temperature, the coolant itself stops circulating.

Disadvantages of the AGV gas system

- The layout and installation of pipelines when using the AGV system requires strict adherence to the rules.

- It is not possible to automatically regulate and control the temperature in each individual room. This may be the reason for not the most efficient fuel consumption.

If the AGW system is used in a country house and you leave it in winter, then it is important not to forget to drain the water from the heating system. In principle, this can be avoided if you use special antifreezes that do not freeze even at sub-zero temperatures. Be careful when using such chemicals as they can be toxic.

You should be careful when using such chemicals as they can be toxic.

It is possible to significantly improve the AGV heating system by installing a circulation pump, which will increase the efficiency of your heating system.

Improvement of AGV by the manufacturer

The obvious advantages of gas water heating units became the reason for their further production.

But the equipment required serious modifications and improvements, so the design underwent the following changes:

- Fragile glass thermometers were replaced by more reliable Italian instruments.

- American automation from Honeywell began to be used.

- The device is turned on using a piezo ignition system.

- Changing the appearance thanks to the application of coatings using new technologies.