Regular participants of our portal know that in the Moscow region, as part of the “HOUSE IN A YEAR” project with FORUMHOUSE, construction work is underway to build a modern and comfortable country cottage. The key characteristic of this project is the use of modern building materials and technologies, which we describe in detail in the history of the project.

In particular, extruded polystyrene foam (EPS) was used to insulate the USHP foundation on which the house is being built. But insulating the foundation is only one of the technological stages in building an energy-efficient house. Therefore, in this article, a specialist in a master class format will talk about how to properly insulate the blind area and basement of a country cottage, and answer the following questions:

- Why is it necessary to insulate the blind area and the basement of the house?

- What are the requirements for heat and waterproofing materials?

- How to carry out work correctly.

Insulation technology

Thermal insulation of the blind area and basement helps reduce heat loss and protects the foundation from destruction caused by temperature changes. The insulation technology for these elements is different.

Tools and materials for creating an insulated blind area

To build an insulated blind area around the house with your own hands, you will need the following tools:

- Shovels (bayonet and shovel) - for digging a pit as when insulating the base with polystyrene foam;

- Wheelbarrow - to transport soil;

- A vein, fishing line, or twine - for marking the territory;

- Level - to set the blind area to the required slope;

- Concrete mixer or container for preparing the solution;

- Buckets, trowel.

From the materials we will need the insulation itself - extruded polystyrene foam, clay, sand and fine crushed stone - to create a layer of bedding, wooden blocks and bitumen mastic, cement grade M300-M400, reinforcing mesh, waterproofing - you can use ordinary roofing felt.

Insulation of the blind area

Insulation of the blind area is carried out according to the following scheme:

Penoplex is the best option for insulation

- The soil around the foundation is selected to a width of about a meter to a depth of 0.45 m with a slight slope - from 3 to 5%;

- A leveling sand layer is laid and thoroughly compacted, after which the layer thickness should be at least 150 mm;

- Penoplex or extruded polystyrene foam is laid as tightly as possible;

- Lay geotextiles with a minimum density of 150 mm and a width of 2 m in the trench;

- Take a drainage pipe, lay it on geotextiles along the edge of the trench with an outlet into the drainage ditch;

- Pour crushed stone over the pipe and into the gap between it and the edge of the insulation;

- Wrap the drainage pipe in geotextile together with crushed stone, first placing the edge lying on the insulation, and then covering it with the second edge;

- Cover the slabs and pipe with coarse sand to a height of 300 mm and level it, and then compact the surface using a tamper. Markings are made for the curbs, for which a thread is pulled level at a distance of 70 cm from the foundation;

- Storm water inlets are installed by installing a plastic receiving tray under the drainpipe and connecting to it a sewer pipe for external use with an outlet into the gutter;

- Install and concrete curbs on 2 sides;

- Fill the internal space with the required amount of sand and compact it again;

- Paving is done with paving slabs, concrete stone or other material. The height of this layer is 600 mm;

- Add soil along the outer perimeter of the border.

Base insulation

It is best to insulate the base with penoplex or extruded polystyrene foam when laying the foundation, but if this moment is missed, then you can do this during the operation of the house.

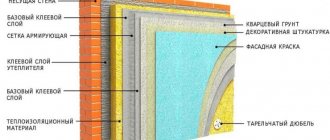

Base insulation scheme

Let's consider the option when the base and walls of the house are in the same plane. Warming is carried out in 10 consecutive steps:

- Make horizontal markings along the entire perimeter, taking into account that the insulation should protrude several centimeters beyond the waterproofing layer;

- They cut the heat-insulating material, focusing on the markings;

- Clean the walls from dirt and dust, prime them;

- Apply a layer of special glue to the base using a notched trowel, choosing a corner as the starting point;

- Apply glue to the slabs and attach them to the surface of the base, seal the joints;

- Drill holes for dowels using a hammer drill and hammer in the fasteners;

- Attach a metal corner around the perimeter of the wall, using the same glue as for the slabs;

- Apply a layer of soil to the slabs;

- Cut the reinforcing mesh according to the dimensions of the slabs, lubricate it with glue and glue it to the heat insulator;

- The base is puttied or covered, and flashings are installed.

Waterproofing

When externally insulating the foundation of a house, it is also important to provide reliable protection from moisture. Therefore, the waterproofing material is laid in two layers: first bitumen mastic, then Technonikol sheets

In the first case, we apply it with a roller in a small layer of up to 5 mm on all walls of the foundation and plinth, allowing time to dry.

After this, you can proceed to the second stage - attaching the sheets. We do this from the bottom up and with an overlap of 10 cm. Lightly melt the front part with a gas burner. Each element must be smoothed to release excess air from it.

It is the combination of these two materials that will prevent excess moisture from getting onto the surface of the foundation.

How to do it yourself?

Insulation of the blind area can be done in the summer, when the ground is dry. To complete the work, it is advisable to choose several days without precipitation. When installing a blind area, you should calculate the required width.

It is worth remembering that it should be 0.3 m more than the roof overhang of the walls. This is necessary for proper removal of precipitation from the foundation. When constructing a blind area, cold bridges should not be allowed.

Technology for creating a warm structure:

- Thermal insulation should be carried out not only on the blind area, but also on the foundation. This way, the soil under the house will not freeze.

- Attach waterproofing to the walls of the trench. For example, cellophane.

- Membrane device. It is recommended to use Technonikol. The material has a long service life and high strength.

- Construction of a cushion of crushed stone and sand 0.1-0.3 m each.

- When insulating a structure yourself, you should level the surface with sand and crushed stone. Then, according to the level, you can lay polystyrene foam in a checkerboard pattern. All cracks must be thoroughly foamed. If cracks appear on the material, they also need to be eliminated.

- The membrane fabric is laid on expanded clay.

- For the concrete layer, formwork is made from boards. For thermal expansion of the structure, cross members are used every 0.2 m.

- To obtain resistance to loads and increase service life, it is recommended to reinforce the blind area. You can use a metal mesh with cells from 3 to 5 cm.

- For tightness, a damper tape is used around the perimeter of the foundation.

- Pouring concrete 0.1 m thick. The slope of the structure is from 2 to 3 degrees.

- If necessary, you can paint the structure after complete hardening.

You cannot use the blind area for 2 weeks, i.e. walk on it.

The video will show you how to insulate a blind area with penoplex with your own hands:

What material to choose as insulation?

To insulate the blind area, various thermal insulation materials are used. But the most common are the following:

- Extruded polystyrene foam.

- Expanded clay.

Each of these materials has certain advantages and disadvantages. You need to know about both the first and the second in order to make the right choice.

Expanded polystyrene is one of the most common types of foam used in the construction industry. It has extremely low thermal conductivity, is durable, has low moisture absorption and is highly durable; it is not afraid of frequent and severe temperature changes. As a result of the research, it was found that its service life is 60-80 years. To insulate the blind area, it is better to select a material with a higher density; it will be stronger, have lower water absorption, hygroscopicity, vapor and air permeability.

Expanded clay is also a fairly high-quality material. It is cheap, simply poured into a pit near the foundation, is not chemically active, and is not afraid of moisture and temperature changes. The only drawback is the relatively low efficiency - you need to pour a thick layer to provide the required level of thermal insulation to the blind area.

Having studied the basic properties of these materials, you can easily choose the one that is best suited for you. After this, you can safely get to work, having first learned how to insulate the blind area with different materials.

Briefly about the next steps

After this, it is necessary to start implementing drainage located along all edges of the installed blind area. This can be done in several different ways.

First option. Asbestos-cement pipes, the diameter of which should reach 100 mm, are laid close to the blind area on an underlying layer of crushed stone or sand. They must first be cut in half.

Second option. A special monolithic concrete trench is installed over the crushed stone bed. To ensure the most suitable shape, you can use a small piece of metal pipe or a pre-sanded log.

Drainage arrangement

It is very important to properly insulate the blind area, because the preservation of heat in the house, its stability and service life directly depend on it.

Insulation of the blind area with foam plastic

Insulating the blind area is a way to protect the foundation from moisture and freezing. It is laid around the perimeter of the building in the form of a pedestrian path. To learn how to do this work using foam plastic as thermal insulation, read this article.

Features of thermal insulation of the blind area with foam plastic

One of the important aspects of building construction is the installation of a blind area, which serves as the main barrier to the penetration of melt or rain water from the roof to the foundation. In the absence of this element, moisture saturates the concrete of the house’s supports, and when it freezes, it can cause its destruction with all the ensuing consequences.

Pros and cons of foam insulation

Polystyrene foam is a fairly common thermal insulation material. It differs from other insulation materials, first of all, in cost. But, despite the low price, foam boards have excellent insulating properties and do not absorb moisture.

No need to lay a deep foundation;

These advantages serve as a good reason for installing an insulated blind area.

Preparatory work for insulating the blind area with foam plastic

It is recommended to insulate the blind area during the warm season of the year. This greatly simplifies the excavation work that precedes the main process.

Technology of insulating the blind area with foam plastic

Before insulating the blind area with polystyrene foam, you need to prepare all the materials and necessary tools. The materials you will need are foam sheets, sand, water, crushed stone and cement, asbestos-cement pipes, slats, bitumen mastic, plastic film, boards for making formwork, reinforcing mesh or individual metal rods. The tools needed for the job are very simple: a shovel, a plaster trowel or spatula, a sharp knife, a building level and a tamper.

That's all. We hope that the presentation of our material will help you to efficiently perform a foam-insulated blind area. Good luck with your work!

Why and when do you need to insulate?

The blind area performs 4 functions:

- Removal of precipitation from the base of the house;

- Acts as thermal insulation in case of insulation, protecting the soil from freezing;

- Serves as a decorative element;

- Provides more comfortable movement around the site.

If it is carried out according to all the rules, then it will drain water from the foundation even without insulation, but it will not protect against soil heaving, which is observed during seasonal temperature changes. When, during severe frosts, soil water becomes ice, the volume of soil increases and begins to put pressure on the blind area and foundation.

These structural elements are subject to destruction, manifested in the form of cracks. This happens especially quickly with the blind area due to its small thickness. When it is insulated, the soil under it and near the foundation does not freeze. It is important to provide high-quality drainage in parallel with insulation.

Advantages of an insulated blind area

Each owner must decide for himself the issue of insulating the basement and blind area, but experts strongly recommend doing this in cases where the house where they live permanently stands on heaving soil on one of the following types of foundation:

- Shallow;

- Swine;

- Columnar;

- Plitny.

It is better to insulate the blind area even when there is a basement floor, and if the foundation, located below the zero level, was not insulated during construction.

The feasibility of performing work on insulating the blind area is determined by the purpose of the structure. If people live in the house permanently, then thermal insulation is necessary, but if it is a dacha where people come only in warm weather, then there is little point in investing a lot of money in it . It is enough to simply make a good drainage system from the foundation.

Many developers carry out the blind area after the construction of the house is completed, and this is their main mistake. Ideally, everything should be done in 2 stages. The first is the installation of a rough blind area after vertical insulation of the foundation and before the final finishing of the base.

It includes excavation, preparatory work, concreting, and digging a trench to drain water from the house. All this does not exclude the possibility of installing an insulated structure around the building in use.

Note! The trench for water drainage should be covered with plastic film, secured with boards. Thus, the soil in the area of the foundation will not be saturated with moisture. All work must be completed before the onset of winter.

The second stage - the installation of a finishing blind area - begins after finishing the finishing work of the facade and basement. Advantages of this approach:

- The appearance of the base does not suffer;

- Such a phenomenon as winter soil heaving is excluded;

- Provides reliable support for scaffolding.

There are many recommendations regarding the width of the blind area. Many consider it an axiom that it should protrude at least 20 cm in relation to the roof overhang. But one can argue with this, because the drainage system removes water from the roof, and it practically does not fall onto the blind area, so the minimum width of the blind area should be 80 cm.

Insulation scheme for the blind area

The width of the structure plays a huge role on subsidence soils. The value recommended by the standards is from 1.5 to 2 m.

Such a wide blind area can cost the owner more than the building itself, but one cannot ignore the subsidence of the soil, because the integrity of the structure depends on this. But there is a way out - a combination of the open part of the structure with a hidden blind area.

What is included in the insulation layer for the blind area

A foundation blind area insulated in the correct way is a layered structure that includes:

- waterproofing material;

- drainage outlet;

- directly the insulation material itself.

To prevent the soil from being washed away, and to ensure that the walls and foundation remain intact, they must be equipped with a permeable layer.

When we insulate a blind area with our own hands, the layers of insulation are laid in the following order:

- We put geotextiles below. It will be the base on which the entire insulating structure will be formed, and it will also separate the upper bulk fraction and the lower soil;

- bulk clean sand (river or quarry) comes in bulk up to 15 cm;

- insulation is laid on top of a sand cushion (expanded clay, penoplex, polystyrene foam and others);

- PVC layer;

- sand, poured in a layer of 15 cm to level the load on groundwater. Sand, scattered evenly, will prevent failure of the lower layers in dangerous places;

- a separating layer of geotextile between the sand and the final layer;

- the last soft layer based on fine crushed stone will protect the structure from damage. You can also use decorative tiles as a finishing layer, then the blind area will also perform an aesthetic function.

How to calculate the required amount of building materials?

If polystyrene foam is used as insulation, it is laid in several layers, since the standard thickness of 5 cm is not enough to maintain the temperature in the ground.

For central Russia, 2 layers are enough, that is, 10 cm thick. For northern regions 3 layers. The quantity is calculated by square meters, taking into account overlaps on the wall of the building.

Example : the perimeter of a building is 8*4 meters = (8+4)*2 = 24 m. With a standard blind area width of 1 m, it turns out that only this part requires 24 m2 of polystyrene foam. The overlap on the wall is equal to the same perimeter, but its height is 30 cm.

We count 24*0.3 = 7.2. With a reserve of 8 m2. A total of 32 m2 of polystyrene foam is needed for laying in 1 layer. For a double bottom layer you need 24+24 = 48 m2. And 8 m2 for the walls. A total of 56 m2 of polystyrene foam will be required.

For foam plastic, the calculation follows the same scheme , but depends on the thickness of the material.

If the tiles are initially larger than 10 cm, then the insulation is placed in one layer. This means, if you look at the example above, 32 m2 including the walls. Penoizol is calculated based on consumption per 1 m2. The layer thickness should not be more than 25 cm; at standard air temperatures and normal winter (not northern or southern regions), up to 15 cm is sufficient. According to manufacturers’ calculations, 1.3 liters per 1 m2 is required.

Example : similar to the previous calculation. The blind area itself requires 24 * 1 * 1.3 = 32 liters of mixture. On the wall 24*0.3*1.3 = 10 l. Total 32 l. Here it is also recommended to take with a reserve of 35 liters. Expanded clay is sold in cubic meters, consumption is calculated based on the height of the layer.

Example: a layer of expanded clay is 10 cm, the building parameters are still the same. 0.01 m3 is consumed per 1 m2. We calculate 10*24 (area of the blind area)*0.01 = 2.4*1000 = 2400 liters. Total: according to the given parameters, you will need 2400 liters of expanded clay. It is packaged in 50 liter bags. Divide 2400 by 50. This means you need 48 bags of expanded clay.

To each calculation you need to add a few more units in case of errors or omissions. If the building has a porch, near which there is no blind area, then its length must be subtracted from the perimeter.

Indications for insulation

Among experienced builders, there is still no clear opinion as to whether it is worth insulating the blind area at all. The following considerations are given as arguments against:

- the blind area is an auxiliary element that serves to drain the foundation and improve the waterproofing of the basement;

- heat loss through the blind area is insignificant in the overall heat balance of the building;

- the costs of materials and work on thermal insulation of the blind area do not justify the resulting savings on heating costs.

All these arguments in themselves do not contradict the facts. However, such an analysis of the situation is incomplete and does not take into account all the factors affecting the strength and longevity of building structures. This can be argued in relation to houses operated in warm regions. There, even in winter, the soil does not freeze to a more or less significant depth, and there is no soil deformation associated with the freezing and thawing of groundwater.

In regions with severe and prolonged cold periods, an uninsulated blind area will be subject to seasonal fluctuations in the soil adjacent to the foundation. They will inevitably sooner or later lead to stress in the concrete screed material, the appearance of cracks and microdefects and, ultimately, to destruction.

Insulating the blind area shifts the freezing point away from the foundation by several tens of centimeters. The crushed stone soil poured into a pit next to the foundation does not freeze in winter, turning into a monolith. It retains the ability to filter and remove moisture to the drainage and does not place additional pressure on the recessed walls of the basement.

As a result, the balance of arguments shifts in favor of insulating the blind area around the house. This set of works is performed every few decades. It allows you to significantly extend the service life of the foundation.

Expenses

Average prices for insulation in Russia:

- Expanded polystyrene. The price depends on the thickness and volume of purchase. Piece by piece 2 cm - from 55 rubles/piece, 5 cm - from 115 rubles/piece, 10 cm - from 250 rubles/piece. The standard plate size is 118.5*58.5.

- Styrofoam. 1 cubic meter from 220 rubles.

- Penoizol. The work is carried out by specialists from 140 rubles/cubic meter. They bring the mixture ready for application and spray it, creating a thermal insulation layer.

- Expanded clay. Bag 50 l from 120 rub.

You will find a lot of important and useful information about insulating the blind area around the house in this section.

The principle of insulation of building elements

A feature of any foundation is operation in aggressive environments, periodic changes in loads (force, direction) with uneven frost heaving of clay soils. Heaving forces arise exclusively when several conditions are present:

- clay in the soil;

- presence of moisture;

- negative temperatures leading to expansion (volume increase by 9%).

By eliminating any condition, it is possible to minimize or completely eliminate buoyancy forces and bending moments affecting underground reinforced concrete structures. Moisture is removed by drains at the level of the base of the foundation. Clay is removed by replacing 40–80 cm of soil layer with non-metallic material (sand, crushed stone). Expanded polystyrene laid around the house at a depth of 30 - 40 cm allows you to retain geothermal heat.

The diagram shows the heat distribution when insulating the entire depth of the foundation and blind area.

Base insulation solves other problems:

- preventing freezing of concrete, which can crack when saturated with moisture;

- protection of the waterproofing carpet when backfilling the sinuses of the pit;

- reduction of tangential swelling forces along the side faces of the foundation strip.

The benefits of exterior insulation for basement walls include moving the dew point outward. After that, moisture is guaranteed not to appear on the inner walls of the basement. Expanded polystyrene is attached to the outer edges of concrete structures, then laid horizontally at the bottom of the trench. The width of the strip around the foundation is 0.6 - 1.5 m, depending on the roofing, the size and design of the blind area, as well as climatic conditions.

All of the recommendations given apply exclusively to heated houses. Buildings for seasonal/periodic residence protect against swelling in a slightly different way:

- continuous thermal insulation carpet (expanded polystyrene XPS) under MZLF, slab foundation;

- warm blind area of increased thickness or width.

The characteristics of the heat insulator are determined according to the tables of the SGT organization standard 36554501-012 dated 2008. If density is practically unimportant for the vertical insulation of the base and the horizontal layer of polystyrene of the blind area, when laying thermal insulation sheets under monolithic structures, preference should be given to high-density XPS modifications to avoid subsidence.

We recommend reading: Insulation of strip foundations from the outside.

Do you need a vertical thermal protection belt?

Proper insulation of the blind area is not limited to placing thermal insulation under the concrete covering; the thermal protection must be combined with the vertical insulation belt of the foundation. This is necessary in order to prevent heat leakage through the concrete itself, which has high thermal conductivity.

Therefore, parallel to the installation of insulation of the blind area, polystyrene foam slabs are fixed to the above-ground part of the foundation with glue and disc-shaped dowels, which are subsequently hidden under the finishing of the base. It is extremely important that the thermal protection of the foundation and blind area has a continuous contour. The best option is when a horizontal belt is first laid, and then the base thermal insulation slabs rest on it with their lower end.

Expanded polystyrene as EPS or XPS insulation

Today, mainly two types of expanded polystyrene are used as thermal insulation: foamed (EPS) and extruded (extruded, XPS). They differ not only in production technology, but also in properties. For foundation insulation, it is preferable to use XPS. Compared to it, EPS has a higher heat transfer coefficient (less effective as a thermal insulation material), is hygroscopic, and less durable. But at the same time, foamed polystyrene foam stands out for its comparatively low price. Its shortcomings can be mitigated by installing an additional layer of waterproofing that protects the material from wet soil, as well as foundation drainage, which helps lower the groundwater level.

How wide should the thermal protection be?

The outflow of heat from the soil occurs not only from the surface, but also through the colder adjacent layers of the soil. Therefore, the width of the thermal protection under the blind area is determined by the depth of soil freezing in a particular area. It also makes no sense to make the width of the thermal protection larger than the width of the blind area required for effective water drainage.

The thermal protection belt must have such a width that the distance from its edge to the bottom of the foundation exceeds the freezing depth. The exact width value can be obtained by squaring the freezing depth, subtracting from it the square of the height of the underground part of the foundation and taking the root from the resulting value. At the same time, practice shows that making a thermal protection belt wider than 120 cm, even if there is a basement floor, is irrational.

Which blind area is better - made of paving slabs or concrete?

Each of the above types of blind area has its own advantages, disadvantages and construction features. According to statistics and reviews, today the most popular (most often used) blind areas are poured from concrete and laid out from tiles. Therefore, it would be correct within the article to consider what is better, concrete or paving slabs for the blind area?

This question is asked by many craftsmen and users. Practical operating experience indicates the effectiveness of the tiles. The advantages are as follows:

the ability to create a continuous, strong and stable blind area. At the same time, ensuring the integrity of a concrete blind area is much more difficult than a tiled one;

maintainability. The tiles can be dismantled completely or partially. Thus, the process of repairing a blind area or laying communications is significantly simplified. In the case of concrete, it is necessary to destroy part of the blind area, dispose of the concrete fractions, and restore it again after laying. Eliminating tile subsidence or replacing a defective element in a tile blind area is not difficult and will not take much time. And most importantly, the tiles can be reused;

reliability. The tiled blind area drains water well due to the large number of seams. This allows us to assert that it does not deform as a result of soil heaving or water freezing. Water that has frozen on the surface of a concrete blind area can lead to local cracking of the material. At first, these cracks will not pose a threat, but each subsequent flooding will cause the crack to expand and the blind area to collapse. Another nuance is the location where the blind area adjoins the house. As you know, the blind area should not form a single structure from the foundations (should not be connected to it). Soil movement and freeze/thaw cycles will inevitably cause this bond to break. When laying tiles it is easier to ensure the required technological gap. In addition, the destruction of concrete most often occurs precisely at the place where it adjoins the foundation or plinth (the blind area comes off);

insulation of the foundation. The technology for laying paving slabs involves the arrangement of several layers, incl. the use of clay and the possibility of laying insulation. An insulated foundation blind area is an additional protection for the basement and ground floor, which reduces heat loss and ultimately leads to savings on heating the house;

reducing the height of the base. With a rigid blind area (made of concrete), the minimum height of the plinth should be at least 500 mm. For soft (tiles, paving stones, gravel, natural stone), a height of 300 mm will be sufficient. This reduces the cost of installing a plinth;

ease of work, no need for a reinforcing frame, minimum waste, minor dustiness of the work;

additional waterproofing of the foundation blind area. While a concrete blind area protects the foundation only from the influence of surface water (rain or melt), a clay hydraulic lock, which is made to form a cushion for laying paving slabs, allows you to protect the base of the building from groundwater;

more aesthetically pleasing appearance compared to a concrete blind area. A variety of installation options, designs, sizes and colors allows you to create a unique blind area.

The main advantage that led to the use of concrete as a material for the blind area is its low cost. Buying paving slabs and materials for laying them will cost more, even if you do the installation yourself.

General arrangement of the blind area around the house

To solve operational and decorative problems, the path along the foundation of the house can be covered with a large number of different materials. The most widespread include the following:

Blind area device

- asphalt,

- concrete,

- paving slabs,

- a natural stone.

The exploited surface of the blind area is not its main component. What is hidden from view is of particular importance. The blind area with or without insulation is designed, no less, to significantly increase the service life of the entire house. To lay the main layers, a trench is made along the entire perimeter of the building, into which they are installed. The scheme for insulating the foundation and blind area with penoplex and other types of insulation will be discussed below in more detail.

The technology of making a house is multifaceted and complex. Some builders do not consider it necessary to make an insulated blind area, considering this an unnecessary waste of materials and effort. It is believed that finishing the foundation with insulation of one type or another fully contributes to reducing heat loss from the base. Let's look at this problem in more detail.

Blind area technologies

When covering the outer surface of the foundation, the surrounding soil freezes completely in winter. Thus, negative temperatures approach directly to the foundation of the house, significantly increasing heat loss from the interior. If an insulated blind area is installed around the house, the soil near the base does not freeze, which helps reduce heating costs, which has become increasingly important in recent years.

Based on what was described above, we can say for sure that the blind area insulation technology is much more advantageous in terms of reducing the heat loss of a building. The sequence of work will be discussed in detail below. After reading our review, you will learn how to properly insulate the foundation and make a blind area, spending a minimum of materials, time and effort.

Insulation under paving slabs

If paving slabs are used as the final finishing of the blind area, then it is enough to ensure a slope of 3%. Place it on a layer of cement-sand mixture, spread in a layer of 2 to 3 cm.

Final finishing with paving slabs

During the laying process, the tiles are tapped with a rubber hammer to level the surface flat. Upon completion of the work, the DSP is scattered over the surface, then passed over with a broom, sweeping away the excess. Next, pour water so that the mixture located below and caught in the seams between the tiles sets.

Note! The height of the border must be flush with the tiles, otherwise it will retain water. As you can see, only work done correctly will give a positive result.

As you can see, only work done correctly will give a positive result.

Finishing the blind area with polystyrene foam

Finishing of the finished blind area can be done with various materials - clinker, porcelain stoneware, special paint, cobblestones, paving slabs, etc. Paving slabs are the best option in terms of price and quality.

After insulating the blind area with polystyrene foam under the paving slabs on the concrete blind area, you need to form a layer of mortar 3-5 cm thick, with a slope of 3% from the wall. You need to control the thickness of the layer using wooden beacons that determine the surface level.

Tiles on a cement substrate must be laid using a special adhesive or mortar. The gaps between the elements of the tile covering should be established using plastic crosses. Two days after polymerization of the solution, you need to grout the joints.

How to insulate a blind area with polystyrene foam - watch the video:

According to many owners of private houses, finishing blind areas and garden paths with the same material is the most effective and practical option. If you do everything according to technology, the work done will give excellent results, and your home will be warm and reliable.

What tools are required for installation?

It is best if the junction unit is carried out together with the blind area device. In this case, the home craftsman will need to have a set of tools to perform concrete work. Since the concrete will not wait for anyone, it is best to prepare the tools in advance.

Most of the necessary tools and materials are standard and will not require significant investment:

- Protective clothing: suit, gloves, goggles, respirator, rubber boots.

- Construction rule, cord, pegs and level.

- Wheelbarrow for transporting solution.

- Mixer, shovels and bucket.

- Hammer.

- Boards for formwork

- Fasteners

- Damper tape or other insulator.

What is required to create a warm structure?

To build a blind area outside the house you will need:

- shovels, shovels and bayonets;

- gloves;

- vibrator;

- plumb line, tape measure, thread, pegs;

- sharp knife;

- boards for formwork;

- rule.

Materials:

- sand;

- crushed stone;

- clay;

- waterproofing;

- thermal insulation;

- geotextiles;

- covering: concrete, paving slabs, granite chips, lawn, etc.

Depending on the type of blind area, some of the listed materials and tools may not be needed.

Handmade insulation of the blind area

The process of insulating a blind area yourself is simple. It is recommended to strictly follow the recommendations of specialists. Penoplex will not be difficult. It's easy to work with him.

Scheme of thermal insulation of the blind area

Schematic thermal insulation of a blind area with penoplex:

- The area is being prepared. Space is cleared and a trench is dug. The top ball of fertile soil is removed.

- Sand is poured into the bottom of the pit. Watered with water. It is carefully compacted.

- A layer of crushed stone is poured. Compacts.

- Penoplex sheets are laid.

- Reinforcement is being carried out.

- The gap between the wall and the sheets is filled with polyurethane foam.

- Formwork made of boards is being installed.

- The surface is concreted and asphalted. It is necessary to control the slope of 10 degrees.

Marking, excavation work

The marking is done with a metal rod and several wooden pegs. The corners are marked. Marking material is driven in. A cord is stretched around the perimeter of the building. Additional pegs are being installed. The resulting straight line is the main guideline.

You can seal a foundation with a high edge of the blind area. It is recommended to use polyurethane sealant and damping insulating tape.

During the excavation process, you need to correctly set the slope of the future trench. The bottom of the pit is carefully compacted. A regular tamper and log are used.

Installation of formwork

Structurally, the formwork is boards, 4-5 mm thick. They are raised to a height equal to the thickness of the blind area, with an addition of 5 cm. In the corners, individual elements are secured with bolts. This will make it easy to disassemble the structure after the concrete solution has hardened. Additionally, retaining elements are used to prevent the concrete from bursting. Mounted on the outside of the formwork.

Self-created formwork must be done so that expansion joints are formed along the perimeter of the concrete surface. If you do not follow the recommendations, cracks will appear in the foundation over time. The reason is the influence of the soil on the structure due to temperature changes. The distance between individual expansion joints should be up to two meters. Boards 2 cm thick are installed across the blind area. If pouring a concrete screed is not intended, there is no need to make seams.

Is it possible to lay insulation on open ground?

Despite the fairly high strength and elasticity of polystyrene foam, it should only be laid on a leveled and prepared surface. Otherwise, due to soil subsidence, the slabs may bend and even collapse, which will lead to an increase in the thermal conductivity of the entire pie.

In the optimal option, a substrate of 30–50 cm of compacted and leveled sand, thoroughly spilled with water, is prepared under the insulation. To prevent erosion of the bedding, the sand is separated from the soil with one layer of needle-punched geotextile.

Advantages and disadvantages of insulating blind areas with penoplex

- The material practically does not absorb moisture. After a long stay in water, it increases by only 0.4% of the panel's weight.

- The samples are superior to competitors in moisture-repellent and heat-insulating properties.

- The insulation has a long service life, which is comparable to the operation of the entire building.

- Penoplex eliminates the main problems associated with frost heaving of the soil in the immediate vicinity of the foundation. The temperature near the base of the house does not fall below zero degrees, so the reasons leading to the destruction of the protective structure or its displacement relative to the base disappear. The foundation will not be subject to load from frozen soil.

- The product is not afraid of harmful aggressive elements, which are abundant in groundwater. Cement mortar and other mixtures are not capable of destroying it.

- The material is easy to cut and modify, despite its high density. The blocks are manufactured with high precision, which speeds up installation work. The heat-insulating layer under the blind area made of this product will reduce the cost of insulating the house.

- Penoplex preserves the integrity of the auxiliary structure, prevents soil subsidence in spring and swelling in winter.

What mistakes can there be and how to avoid them?

Main mistakes:

- laying polystyrene foam in one layer - there is no need to save money, the more reliable the thermal insulation, the more durable the entire structure will be;

- the overlap on the wall is done for greater thermal insulation efficiency and protection of the foundation from freezing - you should not forget about it;

- The lamellar insulation is laid in even layers, the seams are connected as tightly as possible - if you put the material overlapping, cracks will form.

Insulation is recommended for all types of blind areas in Russia, since most regions experience severe winters.

The absence of this detail is detrimental to the foundation of the building; the cold quickly destroys it, making the house uninhabitable. If errors occur with the installation of insulation, the blind area is completely disassembled and the procedure is repeated correctly.

Insulation of strip foundations, work algorithm

The order of work is as follows:

- The foundation is dug around the entire perimeter. The width of the trench must be at least 1/3 of the overhang of the roof slope. The depth should reach the base of the foundation.

- The foundation is thoroughly cleaned of dirt and soil residues.

- The following work is carried out in stages:

- Waterproofing the foundation in one of the ways;

- Drainage for drainage of groundwater;

- Foundation insulation work;

- Insulation of the blind area.

- After installing the insulation, the trench is filled with crushed stone.

When insulating a strip foundation, you should remember that:

- Sheets of insulation are mounted on the foundation walls using construction adhesive mixtures.

- Under no circumstances should additional fastening be carried out using dowels, since drilling concrete violates the integrity of the structure.

- The coating must be continuous; for this, all joints between the sheets are additionally filled with polyurethane foam.

- Types of waterproofing are selected according to the specific situation on the site. Coating, pasting, plastering and others can be used.

We insulate the foundation ourselves

The high cost of the required materials and the simplicity of the process make it possible to insulate the foundation yourself, minimizing the total cost of this type of work. We will dwell on the features of each option for installing a penoplex foundation in more detail, which will allow us to avoid inevitable mistakes in the future.

We insulate the slab foundation

The technology for insulating the foundation with penoplex with your own hands is not complicated and is similar to working with the simplest version of a children's construction set. The slabs are laid on a pre-prepared base, tightly joining them to each other. As a rule, no additional fastening is required for this. A prerequisite is the laying of a polyethylene sheet to prevent the concrete mixture from leaking into the seams.

Penoplex for slab foundation

Calculating the required quantity will also not be difficult for any home craftsman who has not yet forgotten the elementary school mathematics course. The area of a standard Penoplex foundation slab with dimensions of 1200x600 mm is 0.72 m2. Therefore, to determine the required amount of material, it is enough to divide the total area of the future slab by 0.72, rounding to the nearest integer. When making calculations, do not forget to determine the amount of Penoplex insulation for the side walls of the slab base of the house.

Often, to determine transportation costs, it is necessary to calculate the number of packages of material. To do this, in addition to the total number of slabs, you also need to know their required thickness. This is due to the different configurations of penoplex packs, which have a standard thickness of 400 mm. Thus, the package will contain 8 pieces of slabs with a thickness of 50 mm, and 20 pieces of slabs with a thickness of 20 mm.

We insulate the strip foundation

Since the strip type of base is the most common, the technology of its insulation should be discussed in more detail. Penoplex slabs allow you to finish the walls of the foundation of a new house or one that has stood for several decades. The sequence of work will look like this:

Penoplex for insulating strip foundations

- It is necessary to completely remove the soil from the strip base at a distance convenient for two people to move. Typically, this value is 1 meter.

- The surface of the belt is thoroughly cleaned of various debris and lagging parts of the concrete mixture. This is especially true for foundations with a long service life. Plastic brushes, mounted in a drill chuck or on a grinder, are recommended as tools.

- If deep depressions form on the surface of the foundation walls, they must be filled with fresh cement mortar and plastered.

- Before attaching foam boards to the foundation, it must be insulated from moisture. To do this, the dried walls of the tape are covered with coating mastic, onto which roofing material is glued. Waterproofing the foundation with penoplex, even taking into account its low moisture permeability, is not recommended.

- Having decided on the basis of preliminary calculations which penoplex for the foundation is suitable in your conditions, we install it. In the lower, underground part, a special adhesive for slabs is used, sold in the form of a dry mixture and prepared directly at the construction site. For the above-ground part, builders recommend using dowels and nails.

- The outer surface of the insulation must be coated with one or another composition. Before closing the penoplex on the foundation, wait until the adhesive has completely cured. The best option is plastering using plastic reinforcing mesh.

The described technology has wide application, and, for example, correctly insulating the foundation of a bathhouse with penoplex, as well as the outer surface of a country pool, will now not pose any problems for you. By maintaining consistency and striving for high quality work, it is not difficult to get the result you are going for.

This may be useful:

- Construction technology for a rubble concrete foundationInstallation of a foundation for a fireplace - types, technology, featuresInsulation for the foundationDrilling wells for piles: equipment and technology

Additionally, we recommend reading:

Material selection

It is optimal to choose extruded polystyrene foam in slabs for insulating the blind area. They are produced in different brands, thicknesses and dimensions. Most of the properties of a material are determined based on its density: the higher it is, the correspondingly higher the strength, less hygroscopicity, moisture absorption and air permeability. Extruded polystyrene foam has the best density and waterproof characteristics. The size of the slabs is 600x1200 mm with a possible thickness of 30 to 100 mm. At the same time, sheets of standard polystyrene foam have a thickness of 20 mm, and for insulation of the middle part of the blind area it is preferable to choose EPP from 50 mm, and for corners from 60 to 120 mm, since in these zones there is always maximum freezing.

Insulation thickness

Extruded polystyrene foam is produced in slabs. They have different brands, thicknesses and dimensions.

| Brand | Thickness, mm | Length, m | Width, m |

| PSB S-35, 20 | 20 | 1,24 | 0,64 |

| PSB S-35, 30 | 30 | 1,2 | 0,6 |

| PSB S-35, 40 | 40 | -«- | -«- |

| PSB S-35, 50 | 50 | -«- | -«- |

| PSB S-35, 60 | 60 | -«- | -«- |

| PSB S-35, 70 | 70 | -«- | -«- |

| PSB S-35, 80 | 80 | -«- | -«- |

| PSB S-35, 90 | 90 | -«- | -«- |

| PSB S-35, 100 | 100 | -«- | -«- |

| PSB S-35, 120 | 120 | -«- | -«- |

| PSB S-35, 150 | 150 | -«- | -«- |

Note! For a blind area, the most suitable option is a slab 50 mm thick and 0.6 m wide. A tape emerges from it, insulating the soil around the house to a width of 60 cm.

Installation of EPS

When the waterproofing is finished and the bitumen has finally cooled down, insulation of the foundation with polystyrene foam proceeds to the main stage. The thickness of the insulation is determined in accordance with the parameters of the foundation and the climatic characteristics of the region. For example, if the winter in the area where you live is harsh and long, it would be reasonable to lay the thermal insulation in two layers, five centimeters each.

Expanded polystyrene sheets are available both corrugated and smooth. To ensure optimal adhesion to glue, the former are better suited. But if you nevertheless purchased smooth slabs, immediately before installation, treat them with a needle roller.

How to attach?

Fastening polystyrene foam below ground level requires the use of exclusively special glue that does not contain organic solvents. It is applied to the insulation with dotted strokes in the corners and in the center of the sheet. Then the insulation sheet should be firmly pressed against the foundation and held until the glue sets.

Under no circumstances should you fix the thermal insulation in the basement using dowels, as they will damage the moisture-resistant layer. Above ground, the sheets are attached to the wall with hardware three days after installation, when the glue has completely dried. Each sheet contains approximately five dowels, which are driven into holes drilled through the insulating material.

How to lay it?

EPS sheets should be laid from the corner of the house, checking the correct installation using a level. At the corners, it would be better to lay the material in two layers, with a meter extending in each direction from the corner. The slabs are mounted to each other using a connecting locking system at the edges. If there are gaps between the sheets, they are sealed with polyurethane foam sealant.

Thermal insulation protection

Thermal insulation must be protected from rodents and unexpected ground movements. There are two main protective technologies: using geotextiles and roofing felt or reinforced fiberglass mesh. The cost of the glue on which the mesh is attached is quite impressive, so it is permissible to use cement mortar instead.

Backfilling the trench

The trench dug around the perimeter of the house, after completing the insulation work, should be filled in only when all the materials are dry, including the cladding of the basement floor.

This process occurs in several stages:

- the bottom of the trench is covered with a layer of sand up to 150 mm thick;

- the sand should be moistened, leveled and compacted well;

- Expanded clay or gravel is laid on top of the sand layer, the layer thickness is from 200 to 300 mm;

- the excavated soil is poured on top of the gravel cushion and compacted very carefully;

- The trench should not be completely buried; approximately 300 mm should remain to the ground level for the blind area.

How to fill the screed correctly?

When pouring screed over XPS slabs, it is possible that separated liquid will seep between the expanded polystyrene slabs, which will lead to their displacement or even floating. It is not enough to simply lay the insulation on the ground; it must be carefully adjusted at the joints, immobilized and waterproofed.

All elements of the thermal protection belt must be carefully adjusted to each other without the formation of gaps. Temporarily the insulation is attached to the ground with knitting needles made of 4 mm wire, bent in the shape of the letter “L”, in an amount of at least 3 pieces. on the stove. Next, you should roll out a plastic film over the insulation, after which you can start pouring concrete.

Possible variations of thermal insulation material

The market for building materials that perform a thermal insulation function is wide. Popular:

- expanded polystyrene;

- Styrofoam;

- penoizol;

- expanded clay

Let's take a closer look at their characteristics.

Extruded polystyrene foam

It is characterized by high density and low thermal conductivity. The material is strong enough to allow the use of thin sheets. Ecologically pure. Does not harm the body or the environment. Does not absorb water. Resistant to sudden temperature changes. The building material is easy to work with. No specialized set of tools is required for processing.

Penoplex

The main disadvantage is the fire hazard. It does not flare up on contact with fire, but burns well. A leveling coating is required to eliminate the possibility of mechanical influence.

Styrofoam

Shows good thermal insulation qualities. Easy to install, affordable. Can be cut into elements of any shape or design.

Styrofoam

Of the negative properties:

- short service life compared to other insulation materials;

- sheets of low density actively absorb liquid;

- produced in sheets. Butt joints require additional processing;

- instability to mechanical influence. Reinforcing mesh required;

- flammability.

Penoizol

Shows low thermal conductivity. They note the durability of use. Shows resistance to combustion. It is applied by spraying, forming a continuous, seamless layer of material. Requires equipment and specialist help. The cost of insulation is high.

Penoizol

The downside is destruction from excess moisture levels. Presence of toxic compounds in the composition.

Expanded clay

It is durable, fireproof, and moisture resistant. Harmless. Does not have a toxic component. Made from clay and slate. Accessible. Working with building materials is easy. You need to pour expanded clay into the trench.

Expanded clay

Suitable sand, crushed stone, gravel. The last type is optimal for blind areas. Absorbs less liquid, frost-resistant.

The best choice is penoplex

Penoplex is superior to analogues in operational and technical parameters. The structure is porous. But unlike polystyrene foam, the cells do not break down into granules. Each is filled with gas and insulated, providing a high degree of thermal insulation. The building material is dense and durable.

Has a small mass. Easy to cut. Doesn't crumble. The sheets are joined using the tongue-and-groove method, which simplifies working with the material. Available in several variations.

Features of penoplex

The operational and technical characteristics of penoplex allow us to call it the most effective insulation material available on the market today.

It is essentially an advanced foam made by extruding polystyrene. During the production process, polystyrene granules with the addition of foam are placed in a high-temperature chamber. The mixture melts and foams due to the fact that the blowing agents, when heated, release a large amount of gases - carbon dioxide, nitrogen and others. Through molding nozzles, a mass resembling whipped cream is squeezed onto a conveyor, hardens and cut into panels.

The result is a porous material. But, unlike polystyrene foam, it has a single fine-cellular structure that does not break down into granules. Each cell is gas-filled and fully insulated, providing high thermal insulation performance. Penoplex is characterized by a higher density and greater strength than polystyrene foam.

EPS insulation is lightweight, cuts well and does not crumble. The sheets have a tongue-and-groove joint, which prevents even the slightest cold from leaking in. It is convenient to use for independent insulation of any building elements.

Several types of penoplex are available. For thermal insulation of blind areas and basements, grades 35, 45 and “Foundation” are suitable.

Dense fine-cell structure of penoplex

When can you insulate yourself, and when should you turn to professionals?

The blind area is one of the simplest elements in the construction of a private house. Any homeowner who knows how to work with their hands can handle it themselves. The main thing is to follow the technology of the device and correctly create a “layer cake” from building materials inside the structure.

There are 3 types of blind area:

- Tough. It is based on pouring concrete or paving. The participation of specialists is recommended here, since the technology is labor-intensive and will require hiring equipment and auxiliary tools.

- Semi-rigid.

The final covering here is made of paving slabs, which lie on a concrete base. Laying out the material and pouring the base require certain skills; it is not always possible to carry out the process efficiently the first time on your own. - Soft blind area. The technology does not involve concrete, so this process is easier to do yourself.

Accordingly, you can insulate the blind area with your own hands with a soft coating that does not require the participation of equipment and concrete work. For other types of coating, the intervention of professionals may be required, but if you act carefully and according to the instructions, insulation and installation of the coating yourself is possible for everyone.

Device

If we talk about the construction of the blind area, then it should be said that the concrete blind area itself is not warm. Usually the insulated version has several layers.

- Waterproofing. This layer allows water to be retained on one side, which prevents it from seeping into the ground and thereby having a destructive and negative impact on the foundation of the house.

- Layer of clay. This layer is used to transmit moisture and retain some of it, so that the waterproofing can handle the removal of the remaining moisture normally.

- Insulation layer. This structural element does not allow the ground to give off cold and take away heat from the building. That is, this is where the transition to the ground is separated from the ground part. It must be added that the material is not only laid under concrete, but is located between the wall of the house and the foundation on one side and the blind area on the other. This makes it possible to minimize the heat loss of the building.

- Layer of concrete. This material will already directly form the structure. In fact, this is a node that connects the underground and above-ground parts of this structure with waterproofing.

- A couple of layers of roofing felt. They are designed to partially retain moisture, which should have a minimum negative impact on concrete.

- Paving slabs will perform a unique decorative function and hide the blind area from prying eyes as much as possible.

In general, as you can see, the installation of an insulated blind area cannot be called complicated. The only thing that should be said is that all the mentioned components that such a pie has must be present.

Otherwise, its effectiveness will decrease significantly.

Do or pay?

Now you know enough to decide what kind of blind area you need. Further material will help you understand the details, and in order to decide whether to take on the work yourself or order it from builders, we inform you: the price of just the work of constructing a blind area in Central Russia ranges from 2000-2500 rubles / sq. m. m for soft crushed stone up to 3300-4200 rub./sq. m for concrete monolithic. We emphasize: this is only work, the purchase of materials with delivery is the owner’s, so there is no need to count on wholesale discounts.

This is due to the fact that a normal customer, a normal designer and normal builders make the blind area at the same time as the entire structure. A finished house without a blind area is unfinished, but how much do builders like to finish unfinished projects and whether such work is profitable for them, you can ask any of them. Perhaps expand your knowledge of Russian, in parts not reflected in general-purpose dictionaries.

How to carry out excavation work correctly?

When installing an insulated blind area, it is necessary to remove the top fertile layer of soil, in which insects and rodents can settle. Soil excavation is carried out with a reserve, adding an additional 10–15 cm to the actual width of the blind area, necessary for the correct installation of gravel backfill.

The minimum excavation depth is 150 mm, and it must be taken into account that the surface of the finished blind area must rise above the adjacent soil by at least 5 cm. To reduce the cost of concrete and bulk material, the bottom of the pit selected for the blind area can be raised with a clay bed.

Thermal insulation of a columnar foundation with polystyrene foam

Before you insulate a columnar foundation with your own hands, you will need to purchase a heat insulator and suitable glue for it. Then you should perform all the following types of operations in turn:

- Dig the foundation to its depth, making a trench around it.

- Cover the foundation with EPS at least to the depth of freezing of the soil.

- Clean the foundation, removing all crumbling or chipping concrete particles.

- Cover the surface of the foundation with a penetrating primer (2 layers) and let it dry until it is completely absorbed into the concrete.

- Waterproof the foundation with bitumen mastic.

- Apply glue onto the slab in spots.

The polystyrene foam is attached to the foundation 1 minute after applying the glue. If the size of the polystyrene board is 120x60 cm, you need to apply more than 8 strips of glue 1 cm wide. For this, a comb spatula is used. You need to start from the bottom, rising in rows.

If the polystyrene foam insulation does not have special locks, then after 3 days polyurethane foam is injected into the seams between its plates for sealing. Dowels can be used for fastening, so holes for them are drilled along the edges of the slabs and in the center of each of them.

When insulating a columnar foundation with your own hands, coating waterproofing can be used if protection from capillary water is required. The level of hydrostatic pressure can reach up to 0.1 MPa.

The technique of coating waterproofing is quite simple. It is performed using bitumen or polymer mastics that cover the surface of the foundation with a film with waterproof properties. The use of coating technologies is typical for vertical waterproofing of foundations.

When carrying out horizontal coating waterproofing, it is necessary to take into account the fact that due to their low strength they are used only as auxiliary waterproofing layers. After treating each hole with a small amount of foam, dowel nails are driven into them. Then waterproofing is applied to the heat insulator with polymer mastic, and after it dries, the trench is covered with earth.

Are there differences for different types of bases?

When installing a slab version of the USHP type construction, thermal insulation is laid under the foundation in 2-3 layers of 100 mm each (you can learn about the construction technology of installing a slab foundation with your own hands here). The formwork is also assembled from extruded PPS slabs. USHP is suitable for houses made of timber, aerated concrete and frame structures.

Calculation of thermal insulation

To insulate the foundation with penoplex with your own hands, you should calculate the thickness of the slab. The nature of the soil and the climatic conditions of the region determine the parameters of thermal insulation. Manufacturers, as a rule, indicate the recommended thickness of the material in the instructions. To be more reliable, you can do the calculations yourself using the following formula:

- R - heat transfer resistance. The required value for each region can be found in the reference book. The thickness of the material must be such as to create resistance;

- H1 - foundation thickness;

- H2 is the desired thickness of the foam board;

- L1 - thermal conductivity coefficient of the foundation;

- L2 is the thermal conductivity coefficient of the insulation.

By substituting reference data for your region, you get the required slab thickness. This value is the minimum. When selecting penoplex, you need to round its value up.

For reliable thermal insulation, the material is laid in two layers so as to overlap the joints of the plates. Therefore, if the calculated value is, for example, 100 mm, then the foundation must be sheathed with slabs 50 mm thick, but in two layers.

What is the advantage of extruded polystyrene foam

In order to save money, you should not choose the method of insulating the foundation with foam plastic for several reasons. If moisture gets into the gaps between the cells, the insulation will begin to crumble at the first frost. The foam will crumple under soil pressure, as it can withstand a compressive load of only 100 - 200 kg/m². Mice love to make their burrows in this kind of insulation. The only way to eliminate the shortcomings is to protect the foam with brickwork. But then the price of insulation will be several times higher than the option with EPS for the foundation.