Insulating a home is the primary task of a homeowner who wants to use their home as efficiently as possible. Insulating both a wooden and a stone house from the outside will allow the developer to significantly reduce heating costs, save usable space inside the house and protect the house from the negative effects of atmospheric phenomena and precipitation.

One of the most popular and in demand methods of thermal insulation of housing is the technology of insulating the facade with mineral wool under plaster. You can familiarize yourself with the features, rules, tools and stages of installing mineral wool under plaster below.

What is mineral wool?

Unlike wool for interior work, façade mineral wool is denser and hydrophobic (repels water). Mineral wool for insulating the outside of a wooden, brick and other house is produced exclusively in the form of slabs with dimensions of 0.6x1.2 m and 0.5x1 m. The thickness of the material can be 5, 10, 15 cm. The most popular type is 10-centimeter mineral wool slabs .

Mineral wool is available in three varieties:

- basalt;

- fiberglass;

- slag.

At the same time, basalt glass wool, due to its record low thermal conductivity, is considered the best option for insulating the outside of a wooden house.

Plastering process

When façade mineral wool for plaster has been selected, you can begin exterior finishing work.

First, you will need to prepare hand tools for plastering work, as well as a knife for cutting insulation, which will also most likely come in handy.

Having chosen basalt insulation or another type of mineral wool, you need a competent and effective approach to finishing.

A prerequisite is surface preparation. To do this, you need to clean it of dirt, remove the old finish, if any, and also treat it with a primer.

Several main stages can be distinguished. Separately about each of them.

Reinforcement

Typically, mineral wool for facades under plaster requires reinforcement.

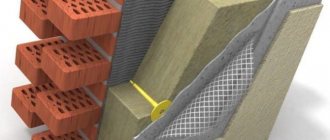

Once again, we won’t talk about how the cotton wool itself is attached. Everything is standard here. The sheathing is made, slabs are laid in the cells, a protective film is attached, and so on.

When the thickness of the plaster layer is more than 20 mm, reinforcement is required.

And for this, a façade reinforcing mesh is used, which is attached in two ways:

- First, a layer of adhesive solution is applied, and the mesh is pressed into it, and then leveled;

- The mesh is fixed with an overlap using self-tapping screws and washers.

In this case, the overlap should be about 10 cm. Otherwise, at the points of contact of the mesh, if it is attached end-to-end, cracks may begin to appear.

Pros and cons of using mineral wool for external thermal insulation of a house

The popularity of insulation is primarily due to:

- low thermal conductivity of the material, and therefore high thermal insulation characteristics;

- excellent sound insulation;

- good level of fire safety (after all, mineral wool does not support combustion);

- vapor permeability (provides “breathing” of the house, which is especially important if the house is not wooden, but stone);

- resistance to fungi and rodents;

- relative environmental friendliness and safety of the material (harmful substances are released only when heated to more than 300 ° C);

- simplicity of installation technology.

Thermal insulation of the facade using mineral wool can be done independently.

As disadvantages, it is worth noting:

- change in the volume of insulation and the appearance of cracks in it (occurs only when there is no reinforcing layer);

- If mineral wool is not treated with a hydrophobic solution, all its thermal insulation characteristics will come to naught, because it almost instantly absorbs moisture.

Technology of applying decorative finishing to insulation

Work on thermal insulation of the facade begins with priming the walls and installing guides. The insulation boards are fixed simultaneously with glue and umbrella dowels. After completing the installation of all the thermal insulation material, finishing begins.

The technology for applying decorative coating provides for certain temperature conditions from +5º to +30ºC. Work should not begin in rain or windy weather.

The solution is applied with a metal spatula, and to level the plaster you will need a rubber tool and a trowel.

The process includes several stages:

- The surface of the insulation is covered with glue used to fix it to the wall.

- The fiberglass reinforcing mesh is pressed into the adhesive layer and remains until it dries.

- The surface is treated with a primer, the composition is applied with a roller or brush.

- Apply decorative plaster with a wide spatula or metal float.

- The size of the layer depends on the size of the filler fraction.

Drying of the composition takes 48-72 hours, but the exact time depends on weather conditions.

Facade surface preparation

Before starting to work with insulation and plaster, it is necessary to clean the surface of the walls from oil stains and dirt and level them. According to technology, all metal elements that may rust must be removed from the walls outside. If these are strategically important metal elements, then it is necessary to ensure the flow of oxygen under the plaster, i.e. this immediately excludes the use of acrylic-based plaster.

The insulation material must have low thermal conductivity. Therefore, mineral wool, namely its variety with a density of 140 kg/m², is ideal.

If there are remnants of the old coating on the walls, be it paint, plaster or anything else, then insulation cannot be placed under the plaster.

Before starting insulation, it is worth using sags to mark the boundaries of the zones. Sags are strong nylon cords pulled between the reinforcement pins (these pins must then be removed, so do not drive them in too tightly), fixed at a designated point in a vertical, horizontal position and diagonally.

Sags are installed to assess the geometry of the wall

Once the sags are in place, it becomes much easier to evaluate the wall geometry. The sags must be attached so that they retreat at least 1 cm from the mineral wool. After the wall is marked, you can begin installing the guide profiles.

How to choose the right plaster composition?

Silicone putty for facade finishing

In order to plaster mineral wool, you can use different mixtures. It is important that the raw material fits well and does not create difficulties during the work process.

To obtain a durable layer 3 mm thick, the following types of solution are used:

- Silicone plaster. The mixture is sold in finished form. Plastering this mineral wool insulation has many advantages. It is not susceptible to mechanical damage, is waterproof and does not fade in direct sunlight. The surface finished with this method allows steam to pass through well and is also capable of self-cleaning during the rainy season.

- Composition based on white cement. Sold dry. The solution has good vapor permeability, which is very important for mineral wool. It should also be noted the durability and low cost of the composition.

- Polysilicon (silicate). This plaster is perfect for finishing mineral wool. Sold ready-made.

The acrylic mixture is used less often. This is due to poor vapor permeability. In addition to its disadvantages, such plaster has a number of advantages. It is highly resistant to mechanical damage and cannot fade in the sun.

In order to save money, owners often resort to applying cement mixtures to mineral wool. Since such compositions have a gray tint, they are subsequently required to be painted in the desired color.

Final wall decoration

Decorative plaster decorates the building and protects its walls from the appearance of fungus and mold. It is applied in one of three ways:

- Stamping. The plaster is applied with a regular roller covered with a patterned mesh;

- Trimming. To apply the plaster, use a sponge soaked in water. The surface after trimming imitates natural stone;

- Bouffant. A metal brush with bristles is used. It is used to comb the wall after applying the plaster.

After the procedure, the insulated surface should be protected from rain and snow for at least a day.

Other wall insulation technologies

Companies producing construction and finishing materials offer innovative methods of surface cladding. Plaster with insulation is inferior in performance to classical technology, but can be used in warmer latitudes. The most widespread type of finishing material is one in which foamed vermiculite is used as a filler.

Insulating plaster with granulated polystyrene foam is suitable for external and internal work. The main parts of such mixtures, in addition to the heat insulator of this composition, are binding components: gypsum, cement or lime and fillers made from sifted and washed sand or other minerals.

Advantages of plaster over other materials

When choosing a finish for facade insulation, the following advantages can be noted:

- Protects the building from precipitation;

- High vapor permeability prevents moisture from accumulating in building materials - it is constantly removed naturally;

- A thin layer of plaster weighs significantly less than other finishing materials, which minimizes the load on the house;

- Using a combination of “thermal insulating materials + plaster” allows you to insulate almost any material from brick to concrete;

- The result of insulation is smooth, smooth or textured surfaces, which guarantees an attractive exterior and the ability to implement a wide variety of architectural solutions.

Cost per square meter of work

Installation specialists can offer professional execution of wet finishing of the building facade. Labor costs are calculated as follows:

- Preparing the base of the walls;

- Installation of slabs;

- Application of a reinforcing layer;

- Formation of plaster texture;

- Finishing window slopes;

- Installation and dismantling of scaffolding, etc.

For example, Stroy-Continent has a cost of 1 sq. m of facade insulation starts at 350 rubles, and the group’s price for installing slabs is slightly higher - from 390 rubles per 1 sq. m. m. "LuxElitStroy" for such work puts forward a price of 380 rubles, and the "Brigade of Private Craftsmen" set a price of 300 rubles per square.

Note! It must be taken into account that the cost of facade insulation does not include the remaining stages of work.

High-quality work will provide housing with savings on heating costs, and will also protect it from climate “surprises” for many decades. After all, with proper installation of insulation, the service life of the building increases by 30 years.