Your gas heater won't light and you want to call a technician? We assure you that many malfunctions and breakdowns can be dealt with on your own, without the help of specialists.

And the simpler the geyser, the easier it is to repair it. In this review, we will not only talk about the malfunctions, but also give recommendations on how to eliminate them - after which you will be able to light up your speaker.

In the general list of situations why a gas water heater does not light up, three main points need to be highlighted:

- A situation where a gas water heater is working properly, but cannot work due to external factors - loss of draft, lack of water pressure or low gas pressure.

- A situation when a gas water heater does not ignite well under normal external factors, that is, problems arise directly with ignition.

- Cases when an automatic geyser does not heat water after normal switching on and the start of hot water supply.

- It takes a long time for the automatic dispenser to light up. The electric automatic system runs on batteries: when you open the tap, they are activated and produce a spark that ignites the burner. At the same time, the equipment should crack. If there is no spark, you need to replace the batteries, it is better to install batteries. They are located at the bottom of the body.

All these cases, although generally similar to each other, indicate that there are completely different reasons why the geyser does not turn on when turned on.

At the same time, the reason that the column has stopped igniting or is taking a long time to ignite are quite standard situations typical for most water heaters.

Reasons for the lack of flame on the wick of a gas water heater

- The air supply hole in the wick is clogged. This hole allows air to flow in to ensure combustion of natural gas at the igniter tip.

- The solenoid valve coil has burnt out. An electric magnet holds the valve stem; if it breaks, the valve will close.

- The thermocouple has failed. The thermocouple, while in the flame, generates voltage that is supplied to the electromagnet.

- The sensors for monitoring the water temperature and the state of the chimney (presence of draft) are faulty. At values up to + 82 0C, the sensor is in the closed position; above this temperature, its bimetallic plates diverge and the circuit opens. The normal contact between the two plates can be disrupted by surface oxidation, mechanical or thermal damage.

- The electrical circuit of the flame control system is broken. All elements of the flame control system are interconnected by wires. Their malfunction will inevitably lead to disruption of the entire system.

- The nozzle or gas supply tube to the wick is clogged. The inner diameter of the tube is 2.5 mm (external 4 mm) and the nozzle outlet diameter is 0.1 mm. These elements can become clogged with soot, dust, etc.

- The operation of the piezoelectric element is disrupted, the spark from which ignites the gas.

Fault prevention

The device requires preventive inspection from time to time

In conclusion, a few words about simple operating rules that will allow you to avoid most malfunctions. So, what operating rules must be followed:

- Provide a sufficient amount of air; if there is insufficient oxygen supply, the column does not work. Open windows and vents while the unit is operating;

- Do not turn on cold water at the same time as hot water. If the water supplied by the column is too hot, it is better to adjust the water temperature than to dilute it with cold water.

- Carry out periodic inspections and preventive maintenance, this will help to identify problems in a timely manner and quickly repair them;

- Do not install flexible hoses longer than three meters; this can significantly reduce the gas supply pressure, which will lead to interruptions in the operation of the column.

Remember that gas appliances require a responsible approach. If you are not confident in your abilities, then call a specialist - a very serious problem that can lead to disastrous consequences.

Eliminating the problem

Temporary. To reduce the temperature in the room, you can open the window slightly. At the same time, due to the decrease in temperature, the relay protection against overheating will stop turning on and the water heater will not go out.

Final. You can completely get rid of the problem only by replacing the bad relay.

Malfunction of the ignition system.

One type of ignition system for geysers is a pilot burner. But more modern models are equipped with an electronic ignition system for switching on. To create a spark, there are two options: using batteries (batteries); using a piezoelectric element, which is turned on by a device in the form of a turbine placed in a water system.

water heater

If batteries are used to generate the spark, then perhaps they should simply be replaced. Despite manufacturers' assurances of trouble-free battery life for a long time, experience shows that they have to be replaced approximately every year.

Weak or completely absent cold water pressure.

To start a gas water heater, sufficient pressure of cold water entering its system is required. When the cold water pressure decreases, the Oasis heater will simply go out. The protection will work, turning off the column, as if the tap is closed and the column will go out. In this case, you should find out the cause of the problem. Open any cold water tap:

- If the water pressure is weak there, then you will not be able to do anything, since such pressure comes from the city system.

- If water flows normally from the tap, the filter will probably need to be cleaned or replaced. If the problem is not in the filter, then you will have to clean the gas water heater radiator.

The procedure looks like this:

- Close the gas supply valve;

- Unscrew the pipes;

- Remove the water heater from its hinges;

- Turn it upside down and, in this position, place it on the table;

- We draw the washing liquid previously purchased from a specialized store into a syringe and inject it into the column;

- Leave in this state for two to three hours;

- After this, drain the liquid, rinse with water and install in the reverse order.

Some models are equipped with a special handle that regulates the amount of water passing through. If the water pressure in the tap is good, but it is not enough to start the water heater, then the handle is moved to the extreme left position and moved to the right until the water heater turns on. As a rule, the flow has to be adjusted once during startup.

Membrane damage.

One of the reasons why a gas water heater does not ignite is a faulty membrane. If it has mechanical damage or has lost elasticity, then normal operation of the column becomes impossible.

This fault falls into a more complex category. To determine whether the membrane is faulty, it must be disassembled, remembering the location of all parts. To do this, you need to remove the water block from the water heater, disassembling it to remove the membrane. When purchasing a new membrane, you should opt for the silicone version, since such parts have a longer service life.

How to care?

Care instructions:

- Take care of the cleanliness of the water heater - regularly wipe off dust and remove dirt found on the body.

- Do not use cleaning products containing solvents or abrasives.

- To prevent scale formation, it is recommended to limit the temperature to 55 °C.

- Every year – cleaning of the ignition group. If necessary, replace the cold water filter. Cleaning or replacing the membrane.

- Check water connections for leaks. If detected, compaction occurs. Check for leaks using a soap solution.

Column does not light up

Let's look at the reasons that precede this problem.

Lack of traction. Typically, the malfunction occurs as a result of a foreign object entering the exhaust duct, which prevents the correct functioning of the air flow in the system. The second reason for the problem is the accumulation of a large amount of combustion products. As a result, the circuit breaker is automatically triggered.

To check the draft in the system, you need to bring a match to the ventilation. If it is present, the direction of the flame will be towards the channel; if it is absent, the fire will not flutter.

In the second case, it is important to clean the channel as quickly as possible, and also vacuum the column, since some of the soot settles directly on its surface. For uninterrupted operation of the device, you should periodically ventilate the room in which the gas water heater is installed, since if there is a lack of oxygen, the system may not work for long and go out, as a result there is a risk of gas poisoning

- Old batteries. One of the most common reasons why a water heater does not turn on is the end of its battery life. To fix the problem, it is enough to replace the batteries in the device.

- Weak cold water pressure. In this case, you need to call technical support and leave a request. As a rule, within 3-4 hours an authorized person will arrive to identify the cause of the malfunction.

- Shower clogged. There are times when hot water suddenly disappears after switching from the tap to the shower, and as a result the water heater quickly goes out. To eliminate the problem, it is worth inspecting the aerator, as well as the flexible hose, followed by cleaning it if necessary.

Remember, when the igniter is functioning correctly, its flame has a bluish color, and it lights up in a timely manner, evenly. If an orange tint forms, it is necessary to clean the nozzle, the tubes through which the gas is supplied.

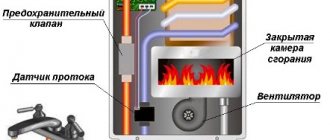

Unit design

Before you decide why the gas water heater does not ignite and what are the causes of this malfunction, it is necessary to study the design and operating principle of this unit. Currently, there are two types of devices that differ from each other both in design and operating principle. They are divided into the following types:

- With an open combustion chamber (atmospheric) - in these devices, air for fuel combustion is supplied naturally through a special intake. The most famous models: Termet AquaHeat, Dion, Zanussi, Neva Comfort, Ariston, etc.

- Turbocharged or with a closed combustion chamber - in these devices the air is supplied using a fan. Popular brands: Lemax Alpha Turbo, Selena SWH 20 SE3, Ariston NEXT EVO SFT 11, etc.

From this video we learn about some reasons for the malfunction of geysers:

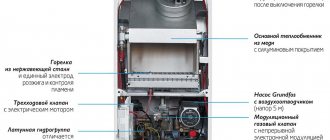

In addition, the water heaters produced differ in the method of igniting the gas burner. Gas can ignite from a piezoelectric device, an ignition electrode from batteries, or automatically from a hydrogenerator or electrical network . The main elements of gas burners are:

Lights up but goes out

Let's consider several moments when the column fades out some time after ignition and what ways there are to solve this problem:

One of the reasons is insufficient draft due to the lack of air movement inside the room where the device is located.

Checking the traction force

This happens when windows and doors are tightly closed. For this reason, the protective relay overheats and the overheating sensor is triggered.

You can eliminate it by opening a window or vent, creating a draft in the room. A gas heater burns a very large amount of oxygen during operation, so it requires a constant supply of fresh air to operate.

The second reason for the column to fade out may be the insufficient time of holding the ignition button. It should be held for at least 20 seconds; if held for less time, the column will go out.

A malfunction of the combustion products exhaust sensor is the next point. To check the sensor, you need to ring it by connecting two terminals. Normally, the resistance should show infinity. If the reading is different, the sensor will have to be replaced.

Strong cold water pressure and low hot water pressure - this situation also often causes the water heater to fade. This happens when you use hot water and open a cold tap. To eliminate this problem, you need to adjust the water supply in such a way that you do not have to open cold water in order to dilute the hot one. In addition, this is incorrect operation of the device and can lead to damage to the heater.

High water pressure can lead to attenuation. This problem is especially typical for the Lux Eco model, which is designed to work with low water pressure. In this case, the strong pressure of the flow bends the membrane of the water unit, the membrane moves the rod in the gas supply. It is necessary to adjust the gas supply or, if possible, adjust the water pressure.

The temperature sensor has activated, protecting the device from overheating.

Column temperature sensor Vector

The heater works for some time after ignition, then goes out again. If you try to turn on the device right away, there will be no result. After some time, about 25 minutes, the burner lights up, but then goes out again. The problem is that the sensor is too sensitive. In this case, only replacing it will help.

Poor contact between thermocouple and solenoid valve.

If the thermocouple is working, you need to clean the contacts and the automation unit.

The design of the igniter itself (device for generating an electric spark). The electrode is mounted in such a way that the spark hits the comb, which is welded to the edge of the gas burner at a distance of about 12 mm from its outlet. Provided that the gas supply is adjusted to low water pressure, the gas leaves the burner in a small volume and at a low speed.

Taking into account the fact that a small reverse draft is almost always formed inside the system, a weak level of gas goes down under the pressure of this draft, not reaching the spark. This situation can be corrected by bending the electrode from the comb to a level at which the spark does not fall on the comb, but through the gas exactly in the center of the burner. After performing such manipulations, the device almost always lights up, ignition is fast, stable and soft.

The formation of holes between the gas exhaust pipe, the connecting pipes of the gas exhaust device and the chimney, between individual sections of the gas exhaust pipe. Determined visually, to eliminate it, it is necessary to seal the gaps with self-adhesive heat-resistant tape or other materials that are resistant to high temperatures.

Reasons for column attenuation after ignition

When identifying the cause of a malfunction, it is important to pay attention to two points: how the igniter goes out (are any extraneous sounds heard); this happens immediately after ignition or already during the combustion process.

Reason #1 - failure of the flame ionization sensor

If the device turns on and goes out, the ionization sensor is 70% to blame.

This element is constantly in contact with the flame. The ions produced during the combustion process are attracted to the sensor and produce a current. If there are enough ions, the device works. If there are few of them, the column does not function.

The ionization sensor is a thermocouple that is heated by a flame. It is also called a gas sensor because it prevents the device from leaking when the burner is turned off

Signs of malfunction:

- the burner went out 3-5 seconds after ignition;

- when restarted, the device operates longer;

- You just need to start the device several times and it is already functioning normally;

- problems appear only after a long break.

It is necessary to inspect the wiring that runs from the part to the control board. Why do we check all contacts? Then unscrew the holding screws and place the heating electrode at the hottest point of the flame.

This technique can extend the life of the sensor by another year. If everything is in order with the contacts and connections, the element needs to be replaced.

Reason #2 - the membrane of the water unit is worn out

A polymer part must have sufficient elasticity. Over time, this property is lost - the element becomes hard, cracks, and becomes overgrown with scale.

A water block or “frog” is a fairly simple device. The cover is held together with screws, by unscrewing which you can get to the membrane

If the element becomes unusable, the heater will go out. It is necessary to inspect and replace the membrane, if necessary, with a more durable silicone one.

Reason #3 - the wick is clogged with dust

In models with an igniter, this part often becomes clogged. The flame becomes weak and a yellow tint appears. But a change in the color of the flame may also indicate a lack of air in the gas-air mixture.

The result is that the device is either completely unable to ignite the burner, or performs its function after a large volume of fuel has been supplied. In the latter case, a characteristic bang is heard.

To clean the element you will need two screwdrivers (Phillips, slotted) and an adjustable wrench.

The algorithm is as follows:

- We remove the case - pull out the adjustment knobs, unscrew the bolts in the corners from the bottom, lift and remove the cover.

- We unscrew the draft sensor tube and the one that supplies fuel to the wick.

- We unscrew the screws and disassemble the structure.

- We clean the nozzle, blow out the tee, and assemble it.

There may also be a blockage in the draft sensor, which causes the igniter to smoke. After removing dust and dirt, the pilot light should burn with a stable blue flame.

After cleaning, the device may make a slight noise. The sound is produced by air that is sucked in through the slots in the wick guide housing. There is no danger, but the noise can be eliminated if you slightly tighten the wick with screws

If desired, all parts of the structure can be washed. But don't forget to dry them well before assembling.

Problem: the heat exchanger is clogged with scale

The most common malfunction of geysers lies in the heat exchanger (radiator) being clogged with scale. Hard water is to blame for scale build-up on pipes. Scale deposition occurs at water temperatures above 80 degrees, and at 82 degrees this process begins to occur more intensely.

To prevent scale formation, you should not use too hot water. For swimming, a water temperature of about 42 degrees is enough, for removing grease when washing dishes - about 45 degrees, since grease removers can cope with it in cold water, and for washing in an automatic machine - no more than 60 degrees.

Many people leave the gas water heater running on the igniter because it is convenient and there is no need to light and adjust the water heater every time. However, even an hour is enough for the temperature in the heat exchanger to rise to 90 degrees - hence the scale. Therefore, do not be lazy to turn off and turn on the column as necessary, and also do not alter the heater’s automation; if you have low pressure, it is better to install an intensifying pump in this case.

Well, if you have a problem, you need to repair the Chinese gas water heater by flushing the heat exchanger

To do this, you need to understand that the heat exchanger of the column is really clogged, paying attention to the following symptoms: low pressure in the heated water tap, when the pressure in the cold water tap is good; the column does not turn on at all; or turns off immediately after turning on. Of course, the tap at the entrance to the gas water heater may have broken, but if it is working properly, proceed to disassembling the water heater

To flush the column, you will need: a Phillips and flat-head screwdriver, a set of open-end wrenches, a set of paranit gaskets and a rubber hose. In addition, you must purchase anti-scale agent in advance from a hardware store, which is sold in a plastic bottle and in the form of a dry powder. You can also use vinegar essence because it is the most accessible.

First, remove the accessories from the speaker, and then the casing. After this, it is necessary to shut off the water supply at the inlet and open any of the heated water taps closer to the column. Next, unscrew the supply tube from the heat exchanger and move it to the side. After you unscrew the nut from the heat exchanger, water will begin to flow out of the heat exchanger. It needs to be drained about a liter.

Next, put a hose on the inlet of the heat exchanger, lift it higher than the column, insert a funnel into the hose and pour the prepared solution into it in a thin stream. Pour slowly, otherwise a reaction will begin and the anti-scale will be pushed back. The solution should remain in the heat exchanger for a couple of hours. The substance can also be heated on a burning igniter so that the reaction occurs faster and takes less time.

Place a basin or plastic bucket under the tap and slowly open the water supply to the gas water heater. See what comes out of the hose. If there is a lot of sludge and after washing the pressure becomes good, then everything worked out, if not, then the procedure will have to be repeated again. But when using anti-scale, this will not be necessary.

EE error codes in a gas water heater

| Error code | Description of the causes of errors and solutions |

| H1 | Insufficient water heating. Reason: high water pressure, contamination of the burner nozzles. |

| E0 | Gas is not supplied to the burner device. Reason: closed tap or failed servomotor. |

| E1 | The burner does not ignite. A spark is supplied, but if there is no flame, the automation gives a signal to shut down. |

| E2 | No flame or blocked chimney. Cause: Insufficient air circulation leading to malfunctions. |

| E3 | Automation failure. The solenoid valves are activated, although there is no signal from the water pressure sensor. |

| E4 | Premature switching on of the gas burner. The ionization sensor gives a signal about the presence of a flame, although the flow sensor does not work. |

| E5 | There is no signal from the water pressure sensor. Reason: open circuit between the electronic unit and the gearbox. |

| E6 | The water unit has failed. The membrane has ruptured and the gasket needs to be replaced. Additional signs of malfunction: leakage from the water unit, the appearance of condensation. |

| E7 | Unsuccessful ignition attempt. There is a spark. The main burner is ignited, after which the column turns off. Cause: low or insufficient gas pressure. |

| E8 | No traction. The flue gas sensor is triggered. The column turns off after 2-5 minutes of operation and turns on only after cooling. |

| E9 | The water overheating sensor is triggered. There are several reasons. From insufficient pressure in the pipeline to oxidation of contacts. |

When to turn on the column

- Columns with a constantly burning wick - ignition is performed at the beginning of the day. Most consumers light the wick in the morning and leave it running throughout the day. After ignition, the column is completely ready for use. The first switching occurs with the opening of the hot water tap.

- Columns operating in automatic mode (without a wick) turn on independently after opening the DHW tap. Classic models refuse to work if there is no pressure in the pipeline. In modern water heaters, they turn on at low water pressure (0.3 atm).

Instantaneous gas water heaters, regardless of type, have a common drawback: time passes from the moment the hot water tap is opened until hot water is supplied to the user. It takes several minutes to reach the set temperature.

Malfunctions of gas water heaters

The operating principle of a device designed to heat water is to pass liquid through a heat exchanger. The latter, in turn, is presented in the form of a ribbed copper tube. The process of increasing the water temperature is carried out through the operation of a gas heating pad.

Thanks to the built-in protection system, you can automatically control the temperature and water pressure, as well as the intensity of the gas supply.

In order to minimize the cost of the family budget, replacing worn out parts, done yourself, will be much cheaper than buying a new device or calling a specialist to your home.

However, remember, before you begin restoring a water heater, you should familiarize yourself in detail with its design, identify the cause of the breakdown, study the technology for troubleshooting, prepare the necessary materials and tools, and only then begin repairing the product.

Unfortunately, manufacturers have not yet invented the “ideal” model of a gas installation. That is why each water heater model has several classic disadvantages that appear during the operation of the device.

Let's look at the main device failures and the reasons for their occurrence.

- Scale in the heat exchanger. It is not difficult to recognize this breakdown, since it has the following characteristic features: when turned on, the device operates for only a few seconds or there is no reaction at all to commands from the control system, while the water pressure in the cold and hot taps is minimal.

- Radiator leak. As a rule, a sign of this problem is the inability to obtain water at the desired temperature.

- The water heater does not heat water well. This is due to the fact that the gas supply and liquid throughput are not adjusted.

- The burner does not light. This problem can occur for the following reasons: lack of traction, old batteries, weak water pressure, clogged shower.

In addition, the service life of the device is directly affected by the quality of tap water and natural gas.

Let us consider in more detail the methods for eliminating these faults.

Repair

There are several types of problems that occur most often. Those that are directly related to gas have already been mentioned above - eliminating them is not within your competence. Accordingly, further we will analyze cases that a home handyman can easily handle without spending money on paying for the work of someone who repairs water heaters professionally.

Geyser does not light up

The most common reason that a gas heater does not ignite may simply be a lack of draft in the ventilation well. It is possible that over time the chimney simply became clogged with soot or a foreign object got into it. In this case, the protection system located inside the column is triggered, and the gas is automatically shut off directly in the device.

Gas water heater installation diagram.

Check the draft in the chimney. This is done quite simply: you need to bring a lit match to the well, if the flame deviates in its direction, it means there is a draft, everything is fine.

It is enough to eliminate the cause, and the gas water heater will work properly again. You can clean the well yourself or call a professional.

Another reason for the malfunction of geysers in this case may be a simple discharge of the batteries, but this applies exclusively to devices with automatic ignition (from batteries or generators). Despite the assurances of manufacturers who claim that the batteries have a service life of 1 year, they should be replaced much more often.

Debugg:

- check the gas water heater on and off keys;

- replace the batteries.

Thirdly, the gas water heater does not ignite simply due to insufficient water pressure. It's easy to check - you just need to open the cold water tap. If the pressure is low, it is quite possible that the reason lies not in the column, but in the water supply itself or in a separate section of it.

If the pressure in the cold water tap is stronger than in the hot tap, then perhaps the reason lies in the water unit of the gas water heater (the membrane is deformed or the filters are clogged). Quite often the cause is additionally installed coarse filters.

Debugg:

Diagram of the gas water heater.

- first you need to call the utility service to find out the reason for the lack of pressure;

- wash the cleaning filters or replace them in the mixer;

- You can leave a request at the utility service to clean the pipes supplying hot water;

- flushing the gas column from soot and combustion products;

- replace the column water assembly membrane.

Fourthly, it often happens when a gas water heater lights up and immediately goes out. In this situation, it is necessary to adjust the water supply (cold and hot).

Please note: under no circumstances should hot water be diluted with cold water; this will lead to immediate extinguishing of the flame, and such actions violate the rules for operating the column. Troubleshooting: it is necessary to reduce the water supply from the cold tap

Troubleshooting: it is necessary to reduce the water supply from the cold tap.

Another reason for the burner not to fire may be wear of the water membrane. Over time, the membrane deforms from constant loads, and when water is supplied, the burner switching device loses sensitivity and does not work. Nothing can be done about this; even in the speakers of serious imported manufacturers, the membranes should be changed every 5-7 years.

Open the water tap to maximum, if the column turns on at maximum pressure, it means that the problem is just in the membrane, it will have to be replaced.

Device of a frog instantaneous water heater

In order not to carry out repairs blindly, you need to understand how this or that unit works. For a better understanding of the purpose of the parts and the principle of operation, let’s consider the design of the water block of a gas water heater used in everyday life. Let's do this using the example of one of the most common columns - Neva .

The water reducer is colloquially called the heart of the water unit. The body of the “heart” consists of two parts – the base and the cover, connected with screws. In Neva the body is made of brass. In modern drives, gearbox housings are also made of silumin, polyamide or high-strength plastic.

In the lower part of the base there are inspection holes for draining water, plugged with screws.

The regulator body is made of brass. The base and cover are connected by 8 screws, which, before screwing in during reassembly, it is advisable to lubricate with graphite grease or lithol

The internal structure of the water unit gearbox is thought out to the smallest detail. Everything is simple and reliable, so it can only be dismantled to replace consumables.

The base has two pipes. According to the introduction, water flows into the frog. Using a union nut, the pipe is connected to the water supply pipe. There is also a sealing gasket installed here that protects against leaks, and a filter mesh that protects the insides of the frog from debris particles getting in with the water. The presence of a filter extends the life of the membrane, which is especially sensitive to the presence of debris, which acts like an abrasive when the water flows and the membrane moves.

The outlet pipe is equipped with a Venturi fitting . The pipe is connected to the tube through which water from the reducer goes to the heat exchanger coil with a union nut. A sealing gasket is also installed here. Above the narrowed part of the Venturi fitting, a bypass hole is made in the body of the base, through which water from the lower cavity of the regulator, through the fitting, enters the upper cavity separated by a membrane - under the cover.

The gearbox cover is shaped like an inverted bowl. In its center there is a channel for passing the rod and installing a sleeve equipped with a nut. At the lower end of the rod (on the inside of the cover) there is a disc of a plate in contact with the membrane (diaphragm). The upper end of the rod mechanically transmits a signal to the gas block valve.

On the side of the cover there is a bypass channel equipped with an adjusting screw and a retarder ball made of metal or plastic. The lower hole of the channel (when connecting the halves of the housing) coincides with the bypass hole of the base. The channel with the ball works like a ball valve.

Design of the water part of the water-gas unit of the Neva Group of Companies. The numbers indicate: 1 – base, 2 – cover, 3 – membrane, 4 – plate, 5 – rod, 6 – inlet pipe, 7 – outlet pipe, 8 – filter mesh, 9 – union nut, 10 – fastening screw connecting GU and VU, 11 – rod bushing, 12 – bypass channel, 13 – , 14 – Venturi fitting, 15 – gas block pipe, 16 – rod spring, 17 – rod seal, 18 – sealing gasket, 19 – water flow limiter, 20 – hole for draining water with a plug, 21 – water flow regulator

Between the lid and the base there is a membrane - which performs the main function of the block. Previously, membranes were made of rubber. Of the modern materials, silicone is the best. There are also combined rubber-metal diaphragms. Along the edge of the membrane disk there are holes for fastening screws, as well as a bypass hole.

Operating principle of the Venturi fitting

To understand in detail the principle of operation of the frog, we understand how the individual parts of the device work. Let's start with the Venturi fitting. It is a tubular cylinder, in the channel of which an artificial narrowing is made. The narrowing of the channel causes an increase in flow velocity and a decrease in pressure at the bottleneck.

The result is a difference in fluid pressure:

- before narrowing, the water presses on the walls with greater force;

- in a narrow place where the flow speed is maximum, the pressure is reduced.

Where the pressure in the fitting is minimal when the tap is opened, a bypass channel begins, through which water from the lower cavity of the frog enters the upper. When the tap is closed, there is no water flow to the coil. There are also pressure differences in the fitting and in front of it. The pressure in both communicating cavities of the gearbox is the same. The membrane occupies a position in the middle.

The design of the Venturi fitting is responsible for the appearance of the pressure difference. Pressure with closed (a) and open (b) hot water taps. How does a ball valve work?

The water pressure in the lower cavity is a constant value, equal to the water pressure in the water supply. The water pressure in the upper cavity of the frog is a variable value. The maximum pressure in it, equal to the water pressure in the water supply system, is achieved when the hot water tap is closed. When the valve is fully open, the flow velocity at the narrowing point of the fitting is maximum. The pressure in the bypass channel drops to a minimum, followed by a decrease in water pressure in the upper cavity of the gearbox.

How does the frog membrane work?

When you open a hot water tap and a pressure difference appears, the membrane, trying to bend upward, presses with force on the plate rigidly fixed to the rod. The rod extends outward and transmits force to the gas block valve, which is responsible for turning on the gas supply to the burner. The pressure difference is sufficient to generate the necessary force due to the membrane area, transfer it through the plate to the rod and overcome the elasticity of the spring installed on the rod.

When you close the tap, the flow of water in the column stops and the pressure difference disappears. The membrane returns to its original position, ceasing to put pressure on the rod. The spring pushes the rod back and the gas valve closes.

Membranes can be made of rubber, plastic or silicone. Their shape corresponds to the configuration of the frog, so sometimes it can be difficult to find the right model to replace

From all that has been said above, it becomes clear that the membrane is one of the most important parts of the unit, ensuring its automatic operation and working “for wear”. It is the violation of the integrity of the membrane that most often causes the water unit to fail.

Purpose of the retarder ball

If you remove and shake the cover of the water reducer, you can hear a metal ball rolling around inside it with a knock. You can see it if you unscrew the adjusting screw. When the column is turned on and off, a small steel (or plastic) pea rolls along the bypass channel, either partially blocking its lumen or freeing up more space for the flow of water.

Rolling back in the direction of the screw when the tap is turned on, the ball partially blocks the lumen of the channel. Water leaves the upper cavity slowly, so the gas valve opens smoothly. When the tap is closed, the pea moves in the opposite direction, the lumen is quickly cleared, and the pressure drop is eliminated. Therefore, turning off the gas water heater occurs quickly.

The retarder ball can be purchased together with the repair kit. Removing the ball or incorrect adjustment may cause the gas to turn on quickly, accompanied by a popping noise.

In this way, the smooth opening of the gas and its rapid shutoff are also carried out automatically, which is why the channel with the ball is also called a ball valve. The smoothness of the gas opening is adjusted using an adjusting screw hidden under a screw cap. This is done in extreme cases, since usually the gearbox is well adjusted by the manufacturer.

About the role of the plate and rod

When assembled, these two parts look like a mushroom with a cap. The rod is a metal rod that extends toward the gas block when the hot water tap is turned on.

A plastic plate is attached to one end of the rod, which, bending, is pushed by the membrane; with the other end of the rod, it presses on the valve of the gas unit, which opens the gas supply to the burner.

To prevent water leaks into the gas supply channel and onto the microswitch platform, several seals are installed in the rod connections.

The picture shows the most common rod configuration. On the axis (1) of the rod are strung (in order of priority from the water to the gas unit): a nut (2) with a sleeve (4), with which the rod is attached to the gearbox perpendicular to the membrane; stem seal (not visible), built into the bushing; rod bushing oil seal (3); rod skirt (5) – used to control the position of the microswitch platform foot (MS); the rod spring (6) ends with a small skirt; rod seal (7)

In some models of water reducers, the plate and membrane are combined in one part - a reinforced membrane. The reinforced membrane has a strict orientation relative to the axis of the rod, so the rod seal lasts longer, and the membrane is more durable

In modern models, the gas valve control mechanism is duplicated. Switching on is done mechanically (by pressing the stem on the valve) and using a microswitch. In the latter, when the tab is retracted (by the retractable rod), a closure is made and a signal is given to open the valve.

Bypass and other gearbox innovations

In modern water heaters, for example, the Electrolux brand, you can find improvements - a bypass with a water flow regulator . This is a channel parallel to the Venturi tube through which the flow of water is controlled.

When the bypass regulator closes, all the water flows through the fitting, therefore, the pressure drop is maximum, the gas opens to full capacity. When the bypass is opened, the flow of water through the Venturi decreases, at the same time the pressure drop decreases and the gas valve opens less. The heating temperature of the liquid decreases.

In the same columns, the base of the body is equipped with a valve that regulates the flow of water through the frog (feedback device). If the pressure in the water main increases, the valve will partially close and open wider as the pressure decreases.

Water reducers of modern dispensers are equipped with several regulation and protection systems. Water flow valve eliminates surges in water pressure

Another protective device for the water unit is a safety valve , which relieves pressure and thereby protects against rupture of the column pipe. It consists of a tube, the end of which is closed with a stopper, and inside there is a spring-loaded (with a spring, the compression force of which is regulated by a pressure screw) retaining valve. If there is a leak in a given place, tighten the clamping screw a little tighter.

Problem: the gas heater does not ignite

1. The first reason for the flame to go out when igniting a gas water heater may be the lack of draft in the ventilation duct. If a foreign object gets into the chimney or it is clogged with combustion products of the column, the protection system in the water heater is activated and the gas in the device is automatically shut off. Checking whether there is draft in your chimney is quite simple: with the window open, place your palm or a lit match on the chimney opening. If the draft is good, the flame will deviate strongly or you will feel a puff.

Debugg:

— it is necessary to clean the ventilation duct. To do this, you should call the management company, leave a request and call the chimney sweeps.

2. The next reason for the lack of flame in the column may be the discharge of the power elements. This reason only applies to speakers with automatic ignition from batteries (batteries or generators). Manufacturers may convince you that batteries will have to be changed at least after a year, but practice shows that the service life is shorter.

Debugg:

— check the speaker on/off key;

— buy and change batteries.

3. The column may not light up due to low water pressure. You can find out the reason by opening the cold water tap. If the pressure of cold water turns out to be as insufficient as in the hot water tap, then the reason is in the entire water supply.

If the pressure of cold water is much stronger than in a hot water tap, then the reason is in the water unit of the column. Most likely, the filters at the inlet of the water unit are clogged or the membrane is deformed. The hot water pipes themselves can become clogged. The reason for the lack of water pressure can also be deep water filters installed additionally in the system.

Debugg:

— call the utility service to find out the reason for the lack of water pressure;

— wash the water purification filters or replace the filter in the mixer;

— leave a request to the utility service for flushing hot water pipes;

— clean the column from soot and combustion products;

— replace the membrane on the water assembly of the column.

4. There are times when the column lights up and immediately goes out. In this case, the supply of hot and cold water should be adjusted. There is no need to dilute hot water with cold water - this not only leads to the extinguishing of the heater flame, but is also an incorrect operation of the gas appliance.

Debugg:

- reduce the supply of cold water to the tap.

Rules for dismantling and disassembling the gearbox

Regardless of the modification of the geyser, before starting repairs or preventive maintenance, turn off the supply of gas and cold water to the unit.

To drain water from the system, open the hot water tap, located below all water taps powered from the column. We place a wide container (basin or bucket) under the dismantled water unit, where the remaining water from the gearbox will be drained.

Removing the gearbox from the column

Often the frog can be removed separately. But in some columns this is impossible, so you will have to dismantle both blocks together. There are models of instantaneous water heaters in which, in order to gain access to the insides of the frog, it is not at all necessary to dismantle it - just remove the cover.

Dismantling the frog of the Neva 3208 water heater

In the Neva 3208 column, it is easy to dismantle the gearbox, as in other similar devices. To do this, you need to unscrew the union nuts on the inlet and outlet pipes of the housing, and also unscrew the three screws that secure the frog to the gas unit. When unscrewing the nuts and screws securing the water regulator, hold the unit being removed with your hand so as not to accidentally deform the parts of the gas unit.

When dismantling the water regulator, use a wrench to unscrew the 2 union nuts of the pipes in the indicated order, then unscrew the 3 screws with a screwdriver

The procedure for removing the Neva-Transit gearbox

To repair the water reducer, it must be removed from the column housing. Let's look at how to do this using the example of dismantling the Neva-Transit dispenser, since the fastening of gas-water units in many modern models is very similar. First, remove the adjusting knobs on the front panel. They are simply put on stock.

After that, unscrew the screws and remove the front panel. Please note that the digital display on the front panel is connected using detachable terminals to the electronic devices of the column. Therefore, by pulling the panel towards you, we disconnect the terminals and only after that we remove the panel completely.

Next, we will consider the process of extracting the water unit in the next photo selection.

Image gallery

Photo from

Step 1 - unscrewing the first two screws

Step 2 - Disconnecting the Ground Terminal

Step 3 - disconnecting the frog and column burner

Step 4 - carefully remove the water unit

Do you have a Neva gas water heater? We recommend reading in more detail about typical faults and how to fix them.

Disassembling the water regulator

Having freed the frog and drained the last water from it, unscrew the lid. Often the screws are soured. To make the work easier and to avoid tearing off the splines, we use the special tool WD-40. After unscrewing the screws, remove the cover, remove the membrane and inspect the condition inside.

We replace parts that have become unusable, clean and rinse the insides (surfaces, channels, if necessary, clean the outside of the body), install the parts in place and reassemble the frog in the reverse order.

Reassembling the frog

It is especially important to set the aperture correctly. The bypass hole must exactly coincide with the holes of the same name in the cover and base. If the channel connecting the cavities of the base and cover is blocked, the column will not work.

After installing the cover on the base, tighten the screws. We install the assembled gearbox in place (also in reverse order), not forgetting about the sealing gaskets on the pipes and on the connection of the water-gas unit with the gas burner leg platform.

The screws should be tightened and tightened without any misalignment. To do this, they are installed and baited in pairs, crosswise, and similarly screwed in until it stops.

A gasket is installed in this place (between the burner and the gas unit). Be careful - the safety of the gas water heater is ensured by the tightness of this unit

Testing a repaired unit

After installing the repaired frog, we check the operation of the water part without connecting the gas by opening the hot water tap.

We observe:

- whether drops have appeared on the connections;

- Is the flow rate the same when turning on hot and cold water separately;

- does the burner igniter click?

- Does the rod move normally when opening and closing the tap?

If not everything is going as it should, you should double-check your work. However, sometimes the reason may lie not only in the water node.

Only after the mounted frog has passed the test can gas be supplied to the column. But do not forget about the safety rules when using the speaker. And if you smell gas, you should immediately turn off its supply, arrange ventilation and call the gas workers.

Weak water pressure at the outlet

Gas boiler chimney diagram.

If gas is supplied, therefore, the water pressure in the water intake device is normal, the problem lies in the heat exchanger being clogged with scale. One of the reasons may be the igniter burning idle for a long time. The igniter manages to heat the heat exchanger, thereby causing intense evaporation of the remaining water. The accumulated scale is not washed away due to the lack of water flow and has time to set before the next time the column is turned on. As a result, the column does not work.

Scale fouling of pipes can also occur due to hard water. At water temperatures above 80°C, scale deposits occur, and at 82°C this process begins to become more intense. To avoid scale build-up, do not use too hot water. Repair consists of replacing or cleaning the heat exchanger.

With certain skills, you can wash the heat exchanger yourself. To do this you will need:

Diagram of the gas water heater.

- set of open-end wrenches;

- Phillips and flat head screwdriver;

- rubber hose;

- set of paronite gaskets;

- anti-scale or vinegar essence;

- basin or plastic bucket.

First, remove the accessories from the column, and then the casing. After this, you should turn off the water supply at the entrance and open any of the heated water taps closer to the column. Then unscrew the supply tube from the heat exchanger and move it to the side. After unscrewing the nut from the heat exchanger, water will begin to leave the heat exchanger. About a liter needs to be drained.

After this, put a hose on the inlet of the heat exchanger, lift it slightly above the column, insert a funnel into the hose and pour the prepared solution into it in a thin stream. You need to pour slowly, otherwise the anti-scale will be pushed back. The solution must be left in the heat exchanger for a couple of hours. To make the reaction go faster and require less time, the substance can also be heated with a burning igniter.

Place a plastic bucket or basin under the tap and slowly open the water supply to the gas water heater

Pay attention to what will come out of the hose. If a lot of sludge comes out and the pressure after flushing becomes good, then everything worked out, but if not, then the procedure must be repeated again

This is not required when using anti-scale.

Malfunctions of the Termet column

Most often, in Thermet devices with electric ignition, it happens that the gas water heater does not ignite. If you do the diagnostics yourself, the first thing you need to do is check the functionality of the batteries. If the geyser does not turn on when you turn on the water, and the spark plug stops clicking, then you need to replace the batteries.

R20 elements are used for devices such as Termet, Dion, Ariston and many others . Experts recommend using alkaloid batteries, as they have a fairly long service life. In Termet speaker designs, batteries are installed in the lower left side.

In semi-automatic water heaters, for example, Termet Termag G 19-01, the ignition nozzle may become clogged, which is why the gas water heater does not turn on. In this case, you should remove the unit casing, check the ignition wires and clean the nozzle. To do this, use soft and thin copper wire.

If after this the water heater starts up poorly or takes a long time, the piezoelectric element will need to be replaced. The unit may also stop working due to violation of the permissible gaps between the electrodes and the wick. To correct this problem, the relevant elements must be adjusted.

Basic faults

Whatever model you have installed, sooner or later malfunctions will appear in its operation. The following malfunctions cannot be excluded:

- The device simply does not light up. There may be some clicking noises.

- The device starts, but goes out during operation.

- When the speaker is working, powerful pops are heard.

- No water heating.

- There are leaks.

- When the unit operates, a burning smell appears.

You can try to solve the problems yourself. But to do this, you must have access to gas equipment and good experience in this field.

Therefore, it is wiser to contact your local gas service and submit a repair request.

If the device is under warranty, you can contact the service department of the store where you purchased the equipment. Repairs should be carried out free of charge.

If the warranty period has expired, you will have to pay for the services. The price tags appear different. It all depends on the type of breakdown and complexity of the work.

In fatal cases, the device must be replaced.

About company

The history of Ladoga LLC begins in 2004. Already in 2005, the production of the first automatic instantaneous water heaters in Russia began here. Tula devices are bought not only by consumers in Russia, but also from neighboring countries. Products come to the market accompanied by certificates from Gosstandart, SES and the Russian fire safety service. The equipment works flawlessly in the northernmost regions. The company's priorities are taking into account the needs of the end consumer and the affordable cost of goods. Speakers from Ladoga are a budget solution available to people with average incomes. The equipment is easy to install and easy to use.

Typical problems

Most often, owners of a gas water heater have to deal with the following situations.

The heat exchanger is clogged

Due to high water hardness or too high water heating temperature, scale will form in the heat exchanger over time. This necessitates regular washing of this part with descaling agents (at home, a solution of lemon juice is most often used). If you notice that warm water flows with low pressure, while cold water pressure is high, then this is a sign of a blockage in the heat exchanger. Also, if there is excess scale, the column may not turn on at all or turn off after a short period of operation.

For another way to clean the heat exchanger, see the short video below.

Water does not heat up to the required temperature

Having discovered this problem, first of all you should make sure that the power settings of the device are correct. If everything is in order with the settings, the cause of insufficient water heating may be contamination of the heat exchanger (both internally due to scale and externally due to excess soot) or the incoming water temperature is too low (this is typical for the winter period).

The column does not light up.

The most common cause of this situation is insufficient ventilation, which can consist either in contamination of the ventilation shaft (soot accumulates in the chimney over time, and foreign objects can also get in), or in the lack of sufficient air flow into the room (for example, after replacing windows). For battery-powered devices, the situation when the device does not turn on at all is usually associated with the batteries being completely discharged. In addition, the equipment will not turn on if the water pressure is too weak (this also applies to gas pressure), the membrane is damaged or there is a gas leak. In these cases, the operation of the speaker will be prevented by the device's security system.

The following video tutorial will help you replace the membrane in the water block of the column yourself.

The burner of the device goes out during operation

Such a malfunction may be caused by a problem with the temperature sensor, worn out membrane in the water unit, poor draft, or failure of the electric valve.

Leak from heat exchanger

This problem is typical for low-quality parts in which copper is combined with various impurities. In places where there are impurities, the surface of the heat exchanger oxidizes and over time, fistulas form there. For this problem, a radical solution would be to replace the heat exchanger, but in many cases the part can be soldered using a soldering iron (if the damage is minor) or a gas torch. You will find information on how to do this yourself in our article “How to solder a gas water heater?”.

Internal breakdowns

Now let's see what undesirable phenomena can occur inside the column itself:

Water circuit

Most often you encounter the following problems:

- The “original” filters included in some speakers are clogged.

- The flow area has decreased due to scale deposits.

Solid deposits, commonly referred to as scale, are formed by magnesium and calcium salts dissolved in water. The higher the water temperature, the higher the rate of scale formation, so the heat exchanger is the first to suffer from this problem. Its thin tubes clog very easily, resulting in a drop in pressure with all the consequences described above.

Today, a number of effective products are produced to clean the pipeline from scale. If a special composition for geysers is used, the heat exchanger does not need to be dismantled. It is enough to disconnect the supply pipe from it and drain the water by opening the hot water tap on the mixer.

Gas water heater water circuits

Then a rubber hose is secured to the inlet pipe of the heat exchanger using a clamp, into which the reagent is poured through a watering can. You need to pour it slowly, otherwise the product will splash out due to a violent reaction.

Descaling products contain very aggressive components, for example, hydrochloric acid. When working with them, you must carefully follow safety rules and use protective equipment - gloves and goggles.

After a 2-hour soak, the supply pipe is again connected to the heat exchanger, the root valve is opened and a certain amount of water is driven through the column.

If you couldn’t get a special product for speakers, you can use any, but then the heat exchanger will need to be removed and washed separately. Otherwise, an important element of the column - the aluminum gearbox - may be damaged.

If for some reason you cannot purchase a factory-made reagent, use a folk remedy - a solution of 100 g of citric acid per 0.5 liter of water.

Gas-burner

In case of any damage to this element, please contact the service department.

Ignition system

In some columns, the spark to ignite the burner is generated by batteries - this is the so-called. electronic ignition.

The reason for the “strike” declared by the water heater can be very simple - the batteries are dead and need to be replaced.

The igniter may go out due to the fact that the ignition button was not held down long enough (less than 20 seconds) - the bimetallic plate did not have time to heat up.

Smoke removal system

Soot build-ups can form not only in the chimney, but also inside the column - on the heat exchanger. It needs to be cleaned periodically.

In turbocharged engines, the cause of poor draft may be a malfunctioning fan.

Modern instantaneous water heaters are very different from outdated models, so before purchasing you need to study the main characteristics of the equipment. How to choose a gas water heater for an apartment: recommendations from experts and a review of models.

We will consider the technology for pumping a well after drilling in this article. And also read useful tips on choosing equipment.

Automation

The most common type of automatic equipment that fails is the rubber membrane in contact with water. It may become deformed or crack. This element needs to be replaced.

Problem with clogs

Filters are often installed at the entrance to the gas water heater, which filter out small solid impurities contained in the water. Salts also settle here, becoming an obstacle to the normal passage of liquid. As a result, the water heater stops lighting up and providing the household with hot water. In this case, you need to turn off the water supply, unscrew the filter and clean it. If the condition of the filter is very severe, then it is easier to replace it.

To clean the heat exchanger, soak it in a solution of water and detergent, and pour citric acid into the tubes to the top and leave for half an hour.

Also, during many years of operation of the column, the tubes or heat exchanger may become clogged. In this case, you need to check the permeability of the water unit and make sure that the heat exchanger is permeable. Blockages are removed by washing with special reagents - to purchase them, you should contact your nearest hardware store. After flushing, the functionality of your geyser will be restored.

In order to prevent sediment from clogging the inside of the column, install a decent filter at the entrance to the column, which will remove small impurities and soften hard water.

Preparing for water unit repair

Often, after disassembling the frog to install a new membrane, you will find that in addition to it, it is necessary to replace one or more gaskets of different diameters. Therefore, you need to start repairs by purchasing in advance a complete repair kit for the water unit that matches the model of your gas water heater.

To carry out repairs or preventative maintenance, it is best to stock up on a repair kit, since when disassembling the water reducer, it may become clear that it is necessary to replace not only the membrane, but also several other parts

In addition to spare parts, you will need tools. For old type units: adjustable wrench, screwdrivers for straight and Phillips slotted screws. For modern Neva models and Chinese water heaters, you will need a screwdriver with a Ph2 bit, preferably magnetized. There are also devices with “tricky” fasteners. A remedy for solving the problem of soured screws, for example, WD-40, will not be superfluous.

You will also need two adjustable gas wrenches. They are necessary so that when dismantling and reinstalling while screwing on fittings (flexible hoses or fittings) they do not cause damage to the fittings of the unit.

If excessive force is applied to the fittings, microcracks or hidden cracks may form that are not visible from the outside. To prevent this from happening, hexagonal pads are made on the fittings, which are held against displacement by one of the keys. The second key is used to screw or unscrew the fittings.