We're sure you're not a fan of unexpected expenses. And you probably don’t want to replace a completely new boiler because of a problem that was not resolved in time. Meanwhile, problems appear even in devices that work for the first day. In the article we wrote about errors in Kiturami gas boilers and their codes. Read it. Even if you do not have heating equipment of this brand, it is better to learn more about it - you will understand whether it is worth buying it in the future.

You will learn to recognize errors in Kiturami boilers. Find out what causes them, in addition to the main reasons. For convenience, we have presented their codes in ascending order. Immediately after them, other failures and problems that do not have codes were indicated. Read the article and you will know what to do if a malfunction occurs.

Boiler errors are determined through codes. They differ among manufacturers. On Kiturami devices, combinations of numbers from 01 to 98 pop up. The decodings are the same for all boilers of this brand that run on gas. They can differ only because of the names of individual modules.

The coolant level is below the established norm

- Low coolant pressure in the system: if the boiler pressure gauge needle leaves the green sector and turns to red), it is necessary to increase the pressure to the minimum threshold of 1 Bar

The make-up valve is located at the bottom of the heating installation, next to the connection pipe for the cold water pipe.

It opens counterclockwise until the characteristic noise of the incoming liquid appears; do not forget to close the tap in the reverse order, otherwise the pressure will creep into the reverse red zone and the relief valve will begin to operate (water will flow).

Air in the system: an accumulation of bubbles moving through the pipes along with the coolant reduces the flow rate, causing the pump to malfunction.

It is necessary to bleed the air from the system, you should not rely entirely on the air vent in the boiler pump, over time it wears out and is no longer as effective at venting air, in such a case it is good to have an additional air vent at the highest point of the system (2nd floor) which is additionally mounted on the battery instead of the Mayevsky tap, if there is no such thing, then you can manually bleed the air through the Mayevsky taps (until water appears).

- Inspect pipes, connections, and components for leaks . If damage is found, seal it;

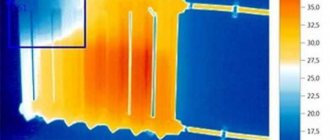

A leak in the heating system is often not noticeable to the eye, but it steadily lowers the pressure; we look for the location of the leak.

- The coolant filter is dirty - clean the coolant filter: it’s as simple as disassembling it and cleaning it.

Checking the expansion tank: the working cavity of the tank is divided into 2 compartments, one is filled with nitrogen or air under pressure within 0.8–1.2 bar. Non-compliance with this value affects the correct operation of the system, resulting in an error being displayed. If the air pressure in the tank compartment is low, bring it to normal using a car pump. If, when pumping, you realize that air is escaping into the system (the pressure does not increase, the batteries begin to crack), then the tank needs to be replaced.

Recommended replacement parts

- Filters

- Tube/Nipple

- Bucky

- Heat exchangers

Gas boilers Kiturami

Kiturami has been making boilers since 1962 and produces up to 9,000 units daily. Kiturami produces devices that run on gas, diesel fuel, and solid pellets. Gas boilers are manufactured for fuel in accordance with GOST 5542-2014.

Most products from the South Korean manufacturer have a dual-circuit structure, a closed combustion chamber and are fully automated. The efficiency of the devices reaches 94%.

The Kiturami company uses low-carbon technologies, equips its boilers with a large number of fuses and sensors, and makes compact and advanced internal structures

Popular models of Kiturami gas boilers:

- World Plus;

- Eco Condensing;

- TGB;

- KSG;

- World Alpha;

- Twin Alpha;

- World 3000;

- World 5000.

The power of Kiturami boilers reaches 465 kW, and for wall-mounted models it ranges from 13-35 kW. Their turbocyclone burners operate at low pressure - about 30 mm of air column. Each type of fuel has its own burner models that can operate on the same boiler.

Kiturami appliances have protection against freezing and blowing out the chimney. Heat exchangers in World Plus devices maintain their quality even after long-term use of “hard” water.

Kiturami gas boilers last up to 15 years or more, much depends on the conditions of use. Devices display errors with simple numbering - from 01 or from Er 01. Read about them to quickly fix problems and keep the device in working order.

Error codes 01 – 08

Errors 01 to 03 indicate that the control system does not see the flame or has blocked ignition - before or after starting.

Errors 01, 02 and 03 often appear due to a closed valve - open it and restart the device, at the same time check the air supply to the boiler

Code 01 - no flame. Perform the actions from the list, and if nothing changes, move on to the following points:

- Open the gas supply valve to maximum.

- Bleed air from the heating system.

- Inspect the grounding. The wire may have lost its integrity, or it may have been routed incorrectly. Re-ground to a depth of 30 cm or more.

- Compare the gas pressure in the boiler with the indicator in the instructions. If there is a discrepancy, call the gas workers.

- Check the integrity of the ignition wire and its power source.

- Remove soot and dirt from the boiler burner.

- Also clean the ignition and control electrodes. Soot and deposits collect on them. Reposition the electrodes according to the instructions if the inclination has changed. Check if they work at all.

- Check that the gas valve and photocell of the flame detection system are working properly. Replace elements with new ones if necessary.

- Check the circuit board, connections and wires that go to it. Replace if necessary.

Code 02 - false flame or its defect. Check and, if necessary, replace the photocell of the flame control system. Replace the board if it is broken beyond repair.

Check it for oxidation, open circuit, short circuit. The burner nozzles could cause the electrodes to become dirty. Clean them and put them in the correct position.

Code 03 - the flame appears and disappears for a short time. Check the flame sensor and replace the faulty device. Check the pressure on the pressure gauge. Contact your gas service if the reading is outside the normal range.

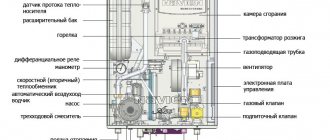

The structure of the Kiturami boiler along with the flame sensor (photocell) of the flame control system, pressure gauge in the lower left corner and gas valve

The problem may be ventilation. Open windows and doors, inspect the built-in ventilation ducts of the room. The error remains - check the external condition of the boiler fan and determine the resistance with a multimeter. The device could break. Also look into the chimney and remove any dirt.

Code 04 - the temperature sensor of the heating element is not working correctly. Inspect the wires that go to the sensor. Connect the broken wires and clean the oxidized contacts. Check the sensor for an open or short circuit. Inspect the control board. If something happens, contact a service that professionally repairs Kiturami brand gas boilers - they are repaired in many service centers in Russian cities. Replace these components if necessary.

Code 05 - overheating sensor failure. Ring the seismic sensor if your boiler has one. Replace if necessary, but do not remove. Also inspect the overheat indicator itself. Determine the pressure in the system and add water if the reading drops. Take a look at the heat exchanger. If there is excess scale, clean the unit.

Code 06 - fan failure - fan speed cannot be determined.

Fan for Kiturami gas boiler: the device supplies air to the combustion chamber, removes flue gases and other combustion products

To fix the error you will need to take seven steps:

- Inspect the wires that go to the fan. Clean if oxidized. Restore broken contacts.

- Assess the condition of the fan blades. If there is noticeable wear and tear, purchase a new device.

- If the differential relay connections are stuck (including after they have come loose), replace the unit.

- Make sure that the mains voltage matches the required value. If not, install a transformer and an uninterruptible power supply.

- Clear the chimney of anything foreign.

- Inspect the fan rotating mechanism.

- Check the Hall sensor.

Replace any unusable parts.

Code 07 - problems with the chimney. The likely cause is the fan/blower speed being higher or lower than normal. Inspect the unit, remove foreign objects. At the same time, clean the chimney of dirt and condensation.

The error appears due to gusts of wind. If the problem occurs frequently, you will have to change the pipe pattern. You need to design taking into account the wind rose.

Many Kiturami boiler models come with CTR remote thermostats, which make it easier to regulate the room temperature and allow you to set the operating time

Code 08 - problem with the room temperature controller. The error appears when communication with the boiler control unit is disrupted. Code 08 will also appear if the length of the regulator wire exceeds 10 meters. Thermostat cables are sometimes exposed to telephone and high-voltage wires.

First of all, turn off the regulator and check the operation of the boiler. If everything is fine, first try to find a different location for the thermostat and turn it on again. Re-route the temperature sensor cable correctly if nothing has changed. Avoid placement in pipes under the floor.

Error codes 14 – 98

Let's start with similar errors - 14 and 34.

Code 14 - malfunction of the hot water outlet temperature meter. Look for a problem in the sensor itself and its wire.

Code 34 is an error of the same type regarding the hot water supply inlet temperature sensor.

After the DHW (hot water supply) sensor fails, the boiler will continue to heat the home, and regulating and maintaining the temperature of running water becomes impossible

Code 95 - indicates low pressure in the boiler/heating system, i.e. due to a lack of coolant (usually water).

Proceed like this:

- Check to see if there is water in the boiler and what pressure is in the heating circuit.

- Check and clean filters if necessary.

- Look for leaks in heating pipes and radiators. Then, eliminate leaks in the expansion tank and heat exchanger.

- Take a look at the expansion tank membrane. Replace if stretched or becomes too dirty.

- Add water to normal pressure.

- Inspect and repair the air valve on the pipe through which coolant enters the heating system.

Code 96 - the temperature indicator has activated. The temperature rose above the permissible 92...97 °C. The boiler will operate in emergency mode until the temperature drops. When the error disappears, restart your device.

Eliminate the cause of the temperature jump:

- Clean the heat exchanger from scale.

- Check and replace the circulation pump if necessary.

- Ring the thermostat. Buy a new one if repair is not possible.

- Do the same with the board.

Code 97 - possible gas leak. There could be a leak of natural gas near the burner. Stop the gas supply to the boiler and turn it off. Call the gas emergency service. Error 97 may also appear because air has accumulated in the system.

Technologies used in Kiturami boilers to ensure tightness: protection against water hammer and flue gas penetration in the upper part of the heat exchanger

Code 98 appears on liquid fuel appliances. Indicates insufficient energy level in the fuel tank.

Basic error codes for pellet boilers

03

Error 03 in a pellet boiler means that the engine through which pellets enter the boiler has turned off.

What should you do in this case:

- check for a wire break;

- measure the sensor for open and short circuit;

- Check the serviceability of the engine itself; if it is not working, replace it.

07

Error 07 appears when the fan operates at too high or too low speed.

To determine, check:

- It is possible that foreign objects have gotten into the fan housing, remove them;

Kiturami boiler fan - there is a strong wind outside;

- The fan is faulty, check the rotor for short circuits and open circuits; if a discrepancy is found, replace the fan.

97

Error 97 appears when the pellet filling level is low. It is necessary to fill the pellets to the level of the bottom of the holes in the burner plate.

Probable errors and causes of occurrence

This article contains all possible malfunctions and options for eliminating them, as well as error codes for Kiturami boilers. All information is read in the following order: code - name - possible malfunction. If you have any additional questions, please leave them in the comments to this article.

Error code 01, 02, 03 - No ignition

- It is possible that gas is not entering the burner due to the shut-off valve being closed. It is necessary to open it, then restart the unit. The gas filter needs to be checked. If it is so contaminated that gas does not pass through, you must call a specialist from the nearest service center.

- The device lights up, but after that it stops due to an accident. It is necessary to make sure that the blinds and other openings that provide air access to it are not blocked.

- It is important to ensure that combustion products are successfully discharged into the chimney. Remove all detected obstacles. After this, you need to restart the unit. If the problem cannot be resolved on your own, it is recommended to contact your nearest service center.

Error code 04 - Temperature sensor signal error

The device does not receive a signal from the water temperature sensor, or the sensor is broken, or there is no connection. You need to turn off the unit and contact the nearest service center.

Error code 05 - Error in the sensor signal that controls water overheating

The Kiturami boiler does not receive signals from the sensor that controls water overheating. The sensor may be broken or the connection may be interrupted. You need to stop the device and contact the nearest service center.

Error code 07 - Fan error

There may be some foreign object in the fan, the rotation speed of the blades is either too high or too low. Strong wind entering the chimney affects the rotation speed of the fan. If this code appears, the smoke exhaust pipe must be adjusted and reinstalled. There may be condensation in one of the elbows. It should be removed. If you could not solve the problem on your own, you need to contact the nearest service center.

Error code 08 - Communication between the boiler control unit and the room regulator CTR-5700 is broken

The length of the wires through which this connection is carried out should be no more than 10 m. Also, the operation of this sensor is affected by devices or wires operating nearby. To verify the cause of the problem, you need to turn off the sensor and check how the device works. If the problem goes away, then you need to install the room regulator in another location. If the problem cannot be solved on your own, you must contact your nearest service center.

Error code 10 - Room remote control dirty

Press the “Restart” button on the room remote control - restart the boiler.

Error code 11 - Air pollution in the room (increased carbon monoxide)

It is necessary to ventilate the room.

Error code 14 - Problems with the DHW outlet temperature sensor

There is no contact with the sensor, or it is broken. You need to stop the boiler and contact the service center.

Error code 34 - Problems with the DHW inlet temperature sensor

There is no contact with the sensor, or it is broken. You need to turn off the unit and call a service technician.

Error code 95 - The coolant level is below the established norm

Make sure there is water in the boiler. Check the system for tightness. Check the pressure in the system. Make sure the automatic air valve is working. If the problems cannot be solved on your own, contact a specialist.

Error code 96 - The coolant water temperature exceeds the maximum permissible values

It is above 97 degrees. In this case, the circulation pump is forcibly turned on to ensure cooling of the water. You need to make sure that the coolant has cooled down and then restart the device. If the above malfunctions cannot be resolved, you need to contact your nearest service center.

Error code 97 - Gas leak

Urgently close the gas valve located in front of the unit. Call a gas service specialist.

Error code 98 - Fuel availability error

Check whether there is enough fuel and whether it is entering the boiler.

Error code 00 - Malfunction of the room remote control or the wire to it

Press the “Restart” button on the room remote control - restart the boiler.

If you are not 100% sure what exactly the problem is and that you can solve it, immediately contact the service center to diagnose and fix the problem.

Possible breakdowns

The LED on the control unit does not light up indicating the network

- No power supply. You need to make sure that it is present in the outlet.

- Check the fuse located on the ignition transformer. Replace if necessary.

The light indicates low water level.

- There is no water in the unit, or its level is significantly below the minimum required value.

- The sensor is not receiving power. Check the power on the black wire in the device body.

LED lights up indicating overheating

- The coolant in the heating system is not heated correctly.

- The system of valves installed on the heating system pipeline is not adjusted or configured incorrectly.

- The mesh filter is heavily contaminated and the coolant circulation is disrupted.

- The circulation pump is broken or turned off.

Security light is on

- There is no gas supply, or the gas supply is at too low a pressure.

- Check the valve.

Pump running time is significantly longer than usual

At the same time, the LED on the control unit lights up, which is responsible for the temperature of the water in the boiler.

- The coolant is not heating correctly.

- Air has formed in the heating system.

The boiler takes longer than usual to reach the required temperature

When the burner is running, the unit reaches the required temperature in a significantly longer period of time than usual

- The gas pressure in the system is too low.

- The gas filter is too dirty.

When the burner is turned on, a vibrating sound is heard. When the boiler goes into constant operation, the sound stops. The chimney is incorrectly designed, combustion products are not discharged correctly. After some time of using the device, its performance changed for the worse. This is observed both in heating mode and in DHW mode. It is necessary to clean the heat exchanger, as it is coated inside with plaque.

Design and principle of operation of Kiturami boilers

The Korean brand "Kiturami" produces powerful heating equipment. The devices can compete with other famous brands. The model range is represented by mounted and floor-mounted units.

Wall-mounted boilers are attractive due to their compact size. They can be placed in any non-residential premises: kitchen, corridor. Floor-standing options require a separate room (boiler room). But you can count on high performance.

High power - from 13 to 470 kW - allows Kiturami equipment to heat residential and industrial premises.

Models differ in the type of combustion chamber. The closed type is connected to a coaxial pipe, which is led outside through a hole in the wall. The turbocharged burner takes air from the street, and the built-in fan forcibly removes the smoke outside.

The open chamber is connected to a stationary chimney. The flame in the burner is maintained by drawing air from the room.

Based on the number of circuits, Kiturami offers single- and double-circuit models. Devices with one circuit work exclusively to heat the coolant for heating. Double-circuit ones provide hot water supply (DHW) and heating.

Read more about this on the page: “Review of Kiturami gas boilers.”

Conclusions and useful video on the topic

Details about repairing the control unit after error 06:

Maintenance of the Kiturami boiler by gas workers:

You have read about malfunctions in the operation of Kiturami gas boilers and their symbols. Most of the errors indicate a temporary failure without risk to the entire device, but be prepared for the fact that the device may not work for several hours or days.

Fix any problem step by step. Monitor the pressure in the device and heating system, network voltage, and external conditions. Avoid gas or water leaks. Eliminate them as quickly as possible. Do not touch the gas communications inside the boiler and those leading to it.

Write comments on the topic. Tell us about the most common errors on your boiler and its brand. Write down whether it had to be repaired and how many times. Are you satisfied with your technology? The contact form is located below the article.

Features of Kiturami boilers

Kiturami is a South Korean company with more than half a century of experience in the development and production of heating boilers and related equipment.

During this time, the company became one of the leaders in the domestic Korean market, and also found a large sales market in North America and nearby Asian countries. In our country, Kiturami boilers have been officially distributed for at least ten years and have already managed to show their good side.

The main emphasis in promoting boilers is on the introduction of innovative technologies and, in particular, our own developments, which have no analogues from other manufacturers or determine the narrow specificity of the equipment’s operation.

Diesel boilers, by definition, are not considered as the main model range for a wide range of applications. In terms of economic feasibility, they are inferior to gas, electric and even solid-state boilers. However, they are still in demand among consumers due to a number of reasons why liquid fuel is becoming preferable.

In remote areas of residence, where there is no stable connection to power grids and no gas supply, the issue of fuel availability becomes acute. At the same time, the heating of the house must, by definition, work uninterruptedly throughout the entire season. If for many countries such situations are rather the exception to the rule, then for us, on the contrary, they are commonplace, the reason for which is the vast expanses that separate populated areas.

Diesel fuel, unlike gas, is easier to transport and easier to store with minimal risks to life and the environment. Unlike solid fuel boilers, diesel fuel, when burned, provides uniform heating and a greater degree of control over resource consumption. And finally, the design of a diesel boiler and, in particular, the burner does not limit the use of other heat sources.

With minimal changes, a diesel burner can be replaced to use blue fuel, and boilers equipped with an extensive combustion chamber and grate can quickly switch to using coal, wood or pellets.

Kiturami diesel boilers are highly technologically advanced and are ideally balanced equipment for using diesel fuel as a heat source, and at the same time they are excellent for the listed types of conversion to operate on gas or solid fuel. So constructive and functional flexibility is the first significant advantage.

Kiturami boilers often use their own developments and a unique layout. On the one hand, this reduces the maintainability of heating equipment, but on the other hand, it ensures the highest boiler efficiency and balanced operation while observing simple and transparent operating rules. This is the second good reason to turn our attention to diesel boilers from South Korea.

The last advantage is the cost of boiler equipment. Even taking into account the high performance and proven quality of the boilers, their cost does not exceed the market average among similar offers.

So it turns out that Kiturami boilers have three features: a balanced design, high efficiency and an affordable price.

Kiturami boiler design

Specifications

The operational characteristics, dimensions and parameters of Turbo series boilers are presented in the table below. It is clearly seen that the series of floor-standing diesel boilers covers a power range from 10 to 35 kW, which is quite enough to heat houses up to 250-275 square meters. Part of the heat will be used to prepare hot water, which must be taken into account in the calculations.

All Kuturami double-circuit boilers and heat exchangers, by the way, are ideally designed specifically for these tasks.

| Boiler model | Unit change | TURBO-9R | TURBO-13R | TURBO-17R | TURBO-21R | TURBO-30R |

| Power | kcal/hour | 9000 | 13000 | 17000 | 21000 | 30000 |

| Power | kW | 10,5 | 15,1 | 19,8 | 24,4 | 34,9 |

| Fuel consumption | liter/hour | 1,13÷1,5 | 1,6÷1,97 | 1,87÷2,15 | 2,28÷2,80 | 3,75÷4,30 |

| Efficiency | % | 92 | 92 | 92.2 | 92.4 | 91.8 |

| DHW consumption | Δt=25ºC | 6,0 | 9,7 | 11,3 | 14,0 | 23,3 |

| Δt=40ºC | 3,8 | 6,1 | 7,1 | 8,7 | 14,6 | |

| Heating supply and return | mm | 25 | 25 | 25 | 25 | 25 |

| Hot water inlet/outlet | mm | 15 | 15 | 15 | 15 | 15 |

| Chimney diameter | mm | 80 | ||||

| Power supply | V/Hz | 220/50(60) | ||||

| Energy consumption | W | 80 | 160 | |||

| External size | w×d×h | 325×600×835 | 365×650×930 | |||

| Weight | kg | 60 | 79 | 85 | 85 | 85 |

Fuel consumption

Fuel consumption is indicated in the table with technical requirements. However, please remember that actual consumption depends on individual settings. Based on the actual power required to heat the house, an appropriate nozzle is selected from the set offered by the manufacturer.

Thermal power, fuel consumption and fuel combustion mode are set. The parameter indicated in the table displays factory presets sufficient to ensure proper performance provided that only high-quality fuel is used, more often this means diesel fuel with winter additives that do not allow it to thicken or separate paraffin in excess of the norm.

In a real situation, for a boiler model with a power of up to 15 kW, you can expect fuel consumption at the level of 8 liters per day , taking into account the frequency of burner operation and the optimal temperature regime in the house. However, this is not the limit.

The right approach to choosing a heating mode, as well as installing a controller with variable temperature conditions, for example, depending on the time of day and day of the week, can reduce consumption even more.

Chimney

Cuturami boilers, gas, diesel, floor-mounted or wall-mounted, are mostly equipped with a closed combustion chamber and, accordingly, a forced exhaust gas removal system. The Turbo series we are currently reviewing is no exception.

Chimney installation diagram

The chimney for boilers is coaxial to simultaneously supply fresh air from the street and remove exhaust gases. Since the exhaust temperature after passing through the heat exchangers is no longer high, the requirements for the heat resistance of the chimney are reduced, and the list of acceptable materials is expanded.

In the best case, a steel coaxial chimney is still used, but a ceramic vertical chimney with a group of internal separate channels for supplying air, removing gases from the combustion chamber and ventilating the boiler room can be effectively used in the same capacity.

The size of the chimney is strictly indicated in the boiler specification and operating instructions. For the entire Turbo series it is 80 mm.

If desired, you can make a chimney with a slightly larger diameter, but no more than 50% above the specified value, that is, up to 120 mm.

Under no circumstances should the size and cross-section be reduced. Even though the removal of combustion products is forced, the resistance of the chimney will greatly affect the combustion mode and the quality of fuel combustion.

Error 07

Consultations and discussion of questions on Kiturami wall-mounted boilers

Moderator: KituramiRussia

collector Applicant Messages: 12 Registered: 06 Oct 2014, 10:11 Reputation: 0 From: Murom

Error 07

Message from collector » 06 Oct 2014, 10:49

Good day Dear specialists!!! Help me solve the problem with the Kiturami 5000-20 boiler... It worked fine for a year, but in the spring it started giving error 07... while the boiler continued to operate... I turned off the boiler in the summer, but a week ago I tried to turn it on, but it again gives error 07... I tried it I disassembled it myself as a plumber by profession... I removed the fan, but everything is fine... I checked the chimney, it is also clean... the pipes barely heat up during operation and the boiler switches off spontaneously after working for 20-30 minutes... I just don’t understand what could be the reason??? With uv.

wetleo Master Messages: 1210 Registered: 01 Sep 2014, 18:23 Reputation: 49 From: Yekaterinburg

Post by wetleo » 06 Oct 2014, 19:27

what does this error mean?

I don't care what you think about me, I don't think about you at all

collector Applicant Messages: 12 Registered: 06 Oct 2014, 10:11 Reputation: 0 From: Murom

Re: Error 07

Message by collector » 06 Oct 2014, 19:47

this error indicates either a foreign object getting into the fan or something with the chimney...for example, a counter flow of air or condensation...

collector Applicant Messages: 12 Registered: 06 Oct 2014, 10:11 Reputation: 0 From: Murom

Re: Error 07

Message by collector » 06 Oct 2014, 20:12

All my friends have different brands of boilers... but they also have headaches... so by buying another boiler I will get rid of my problem, but I will buy another one... and that’s a fact....

oleg.dmitrievic Guru Messages: 9139 Registered: 26 Feb 2012, 22:45 Reputation: 258 From: Chekhov Moscow Region Contact information: Message by oleg.dmitrievic » 06 Oct 2014, 21:40

Well, it depends who else will install...

The disappointment from low-quality products lasts much longer than the short joy from a low price. ch-tehnik.ru We are on YouTube