Stable and economical operation of solid fuel boilers is ensured by good draft. With strong draft, the fuel burns out completely, and there are no unpleasant odors of combustion products in the heated room. Typically, traction is provided by natural exhaust. If it is not enough, they resort to the help of special exhaust machines and smoke exhausters. You can make a smoke exhauster with your own hands, it’s not difficult.

You can make such a smoke exhauster yourself

Classification of smoke exhausters

Before installing the exhaust machine, you can try to do without it, increasing the draft with special devices that do not require forced air distillation and energy consumption. Sometimes an extended pipe or installing a deflector on the top helps. If the problem cannot be resolved, you can use:

The first of them consists of a fan mounted on the top of the chimney and connected to a control panel. The simplest and cheapest option, but its performance is low.

In the second design, the hood housing with the impeller is placed in the smoke duct, and the electric motor is installed outside. This configuration allows the use of engines and turbines of any power.

The highest performance of a centrifugal smoke exhauster. This design allows you to service chimneys with the most complex configuration and large cross-section.

In this video you will learn how to make a smoke exhauster:

Popular models on our market

Most often you can find domestic devices on sale from the companies ASK, Rus and Kraft . They produce the entire range of sizes and components for them. Such compact and inexpensive models of the D and DN series are popular; their prices start at 5,250 rubles.

Foreign-made companies are well recommended by Bosh, Rowen, Zota, WPA . For example, the popular and inexpensive model RR 152-3030, made in Poland. It has a stainless steel blade and a 0.16 kW motor located outside the working area. Maximum temperature 350 degrees. The cost of the assembled unit is 6,000 rubles.

Features of use

In solid fuel boilers, such types of fuel are often used that it is impossible to do without a forced increase in air supply - sawdust or peat burn poorly without blowing. A complete heating process here is only possible with the help of a smoke exhauster.

The hood, unlike pressure units, allows fuel to be supplied to the boiler continuously, which increases its performance and prevents gaseous combustion products from penetrating into the room.

Use of hoods:

Purpose of the smoke exhaust device

The main task of the smoke exhauster is to remove carbon monoxides that are formed during the combustion of fuel inside the combustion chamber of the boiler. The equipment is installed after the last one, cutting into the chimney. Installation location - indoors or outdoors.

The model line of equipment includes smoke exhausters used in fire protection systems. Their task is to remove smoke from premises, toxic substances, fire extinguishing powders, gases, aerosols, and lower the temperature.

Specifications

Not only factory-made hoods can be installed in the chimney. If desired, it is not difficult to install a homemade smoke exhauster. In order not to make a mistake when purchasing or manufacturing components of a mechanism, you first need to familiarize yourself with its technical parameters.

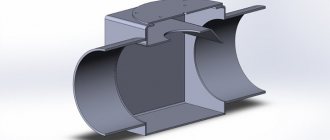

The design of the smoke exhauster consists of:

The metal must withstand temperature loads of up to 300° C and the aggressive effects of hot gas exhaust. Before installation, careful balancing is necessary to prevent excessive vibration, leading to premature wear of the mechanism. Impellers can be bladed or centrifugal.

Exhaust parameters for solid fuel boilers consist of:

It will be good if the resources of all indicators of the unit are higher than those required by operating conditions. This increases the reliability of the machine.

Device

The smoke exhauster is a simple device in terms of design. It consists of several nodes, each of which has its own purpose.

- Frame.

- Suction pipe or suction pocket of the smoke exhauster.

- Guide apparatus. There is right and left rotation, which is determined by the direction of the fan blades.

- Working wheel.

- Frame.

- Electric motor.

The body is made in the form of a “snail”, which provides the required swirl of air entering the unit. Made of heat-resistant steel, covered with thermal insulation.

The guide apparatus of the smoke exhauster is located on the suction pipe and allows air pressure to be regulated using a rotating mechanism that combines the fan blades. Each blade is curved, which allows the air flow to rotate in the same direction in which the rotor rotates. Using a rotating mechanism, you can block the lumen of the pipe to one degree or another.

The smoke exhauster impeller is the unit on which the fan blades are located. They are attached to it by welding or rivets. A rarefied atmosphere is created in the central part of the wheel as it rotates. For this reason, incoming air is drawn in here. Small-sized devices such as smoke exhausters for fireplaces work in a similar way.

The wheel docking unit can be located on the motor shaft or intermediate shaft, depending on the design of the unit. If this is dust collection equipment, the device includes special filters with absorbents. All fire-fighting units are equipped in this way. Ash collectors can be included in the design of boiler room equipment. The design of the smoke exhauster determines its purpose.

The impeller may have holes necessary to fix the blades in a given position. Balancing can be done manually or by an electrical actuator. You can distinguish the direction of rotation of the fan blades if you look at the unit from the side of its electric motor. The axial guide apparatus of the smoke exhauster ensures rotation of the blades, regardless of their number and direction of slope, at an angle from 0 to 90°.

A blower fan and a smoke exhauster have a similar design, but differ in purpose. Devices of the first type provide air injection into the boiler furnace. The latter are designed to remove fuel combustion products and release them into the atmosphere outside the boiler room.

Fans and smoke exhausters of boiler installations have the same operating principle; they can be left- or right-handed, with forward and reverse draft. These machines are designed for long-term trouble-free operation in a temperature range from 0 °C to +250 °C. Smoke exhausters are marked as “D” and “DN”, fans - as “VDN”. The latter are produced with the impeller mounted on the electric motor shaft.

Repair of smoke exhausters and fans is carried out by persons who have undergone appropriate certification and instruction in the safety precautions for operating electrical appliances.

Homemade designs

You can make smoke exhausters for boilers with your own hands. This will save you money on buying a factory hood. To fold such a machine yourself, you only need to purchase an electric motor. The remaining components can be made from available materials.

By making such a pump yourself you will save your money

Hood from scrap materials

The set of tools required for work consists of:

Work begins with the manufacture of an exhaust fan. The impeller, matched to the size of the exhaust pipe, is secured to the motor shaft. The engine, using fasteners equipped on its body, is placed in the pipe.

To make a smoke exhauster you will need at least. Bulgarian

After connecting the motor to the wiring, during the first test run it is necessary to check the direction of the air flow and, if necessary, adjust the operation of the rotor.

The pipe for placing the turbine is selected with a diameter 2-3 cm wider. Its length should extend beyond the fan by 3-5 mm. One end of the pipe is welded with a lid, a hole is made in the center for the chimney, and another one is equipped on the side, to which the outlet pipe is attached.

During operation, the fan should not cause increased vibration of the hood body. To prevent this from happening, it is installed using bushings to center the bearings.

The hood assembly is completed by welding the back cover to the pipe and attaching the motor to the stand. After connecting the air ducts and electrical wiring to the unit, it is ready for use.

Intermediate option

If the option with a factory product seems too expensive, but you want to reduce the time it takes to create it yourself, you can use an intermediate option . To do this, you need to purchase the main components of the structure in the store - an electric motor and a cooling impeller. Then make the hood body from the pipes yourself. This is done in the same sequence and with the same tools as when performing the economy option.

This option for assembling a drawing machine does not require special alignment of the impeller, which is a rather delicate and complex job for a non-professional. A factory-assembled mechanism is usually already centered and only requires checking during trial operation.

Types of chimneys

The two main subspecies are internal and external. With the exception of brick ones, which are installed only inside, all the rest are universal; more about them below. The installation of chimneys for solid fuel stoves and boilers must meet certain requirements. For example, each type has its own requirements for height, temperature

Pay special attention to height calculations. Modern systems can provide a wide selection of varieties from a variety of materials. Differences may include cost, temperature resistance, durability, mounting process and installation.

So, the types:

Differences may relate to cost, temperature resistance, durability, installation process and installation. So, the types:

- Brick

- Steel

- Ceramic

- Sandwich panels

Brick chimney

Brick, often much cheaper than more modern systems. But, despite the relative cheapness, the associated waste may be slightly higher. For example, a brick requires a heavy foundation and laying skills (it is difficult to lay a brick chimney for a boiler or solid fuel stove on your own). Refractory bricks should be used, marked no less than M125; the most common mortar can be used; there are no special requirements for it. Take into account the peculiarity of how to lay bricks correctly; the walls should not be less than 120 mm.

The outlet channel must be built based on the size of the brick and its masonry, for example, a section of 140 * 140 mm corresponds to 1⁄2 * 1⁄2 brick. Please note that those areas that pass through unheated rooms must be insulated and carefully sealed. Brick chimneys are excellent only for solid fuel boilers; for them it is necessary to maintain a high temperature of the exhaust gases

Steel chimney

It can be made from either black steel or stainless steel. Despite the higher cost of the second type, it is recommended to be installed by stove manufacturers. All chimneys of this level have the following advantages:

- smoothness of the walls;

- versatility;

- possibility of installation even after the final finishing of the house;

- durability, even with high efficiency;

- no blockages.

Chimney made of sandwich panels

It is possible to build a chimney for a solid fuel boiler with your own hands using relatively new sandwich structures. This system involves the presence of two steel pipes, which are inserted into each other, and a thermal insulation layer is installed between them. During operation, it is the thermal insulation that takes on all the loads and temperature changes, avoiding the formation of condensation. The most optimal use of these types of chimneys is considered to be in wooden houses, where fire safety is given a high priority.

Ceramic chimney

A solid fuel boiler can operate in tandem with a ceramic outlet. It consists of pipes for which a special fire-resistant material was used, with additional thermal insulation. The material is incredibly resistant to temperature changes, as well as to aggressive environments. In addition, such structures turned out to be the most durable in terms of use without cleaning or repair. When selecting pipes, you need to focus on certain requirements, such as the temperature of the exhaust gases. For solid fuel sources, pipes with a tolerance of 650 degrees must be used.

An important condition for the operation of such systems, due to external thermal insulation, ventilation and airing play a special role. They absorb moisture quite strongly, so take care of this in advance and think about a reliable system so that the air does not stagnate. Otherwise, the service life may be significantly reduced

Otherwise, the service life may be significantly reduced.

Maintenance and operation

To extend the service life of the unit, it is necessary to reduce the effect of moisture on it , an increased level of which leads to premature corrosion of not only the metal parts of the machine. The easiest way to protect against precipitation is to install a deflector on the top of the pipe.

To ensure reliable operation of the motor and fan, their rubbing parts are regularly lubricated and cleaned.

It will be easier to maintain the boiler if you connect it to the control of the heating and ventilation system.

Installing the deflector

Once installed, the deflector is bolted to the roof to prevent it from being blown away by the wind.

Homemade and purchased models are assembled into a finished product at the bottom, before installation on the pipe. The aerodynamic structure is bolted to a round metal asbestos pipe; usually, 3 holes are made in the pipe for this purpose. If there is slight play, a clamp is used.

An adapter is used to mount the deflector in a brick pipe of rectangular or square cross-section. The device is tested after installation. The spark arrestor is made independently from a thin metal mesh or stainless steel sheet.

How to make a smoke exhauster for a solid fuel boiler with your own hands

In order for the operation of a solid fuel boiler to be stable, it must have a good smoke exhaust and draft.

Thus, the firewood will burn completely, and there will be no smoke smell in the room. For these purposes, a smoke exhauster is additionally installed for the solid fuel boiler. It can be purchased at the store, but to save money you can easily make it yourself. Sometimes you can do without mechanical components to increase traction. It can be made larger using natural methods, for example, installing a reflectron at the end of the ventilation shaft. But if such methods do not help, then there are several other options related to the installation of mechanical components.

You can use the following options:

For powerful heating systems, other options may be used. For example, the use of two high-power fans synchronized with the boiler.

The main reason for installing a fan to increase draft is the increased resistance of the heat exchanger.

In it, gases can change the direction of movement along the flame tubes several times in an instant. The purpose of installing the unit is to increase efficiency by taking in the maximum amount of heat and changing its direction in the desired direction. It is important to synchronize the operation of the boiler and fan during operation. Installing a smoke exhauster on a boiler without a control and automation unit is impossible, so you will have to buy and install all the electronics entirely from scratch.

Such fans are indispensable when the following situations arise:

No matter how powerful the fan is, it will not produce results without the necessary influx from the street. First, the smoke exhauster creates a slight vacuum, and then only mixes the air in place. Natural draft is the basis for the good operation of any heating system.

Increasing draft using a smoke exhauster also has a downside. If, after operating the fan for a certain time, the natural pressure does not increase, then you cannot turn off the smoke exhauster, since a possible consequence may be carbon monoxide suffocation. If the electricity goes out at night, smoke will enter the room, and this cannot be avoided. While the chain thermostat closes the damper, the entire boiler room will be in smoke. Due to this, it is very important to do good natural lifting to avoid such cases from occurring.

Smoke exhausters, unlike air blowers, have higher performance. They allow you to add firewood during work without negative consequences in the form of smoke in the room, since they manage to draw out all the smoke. When installing them, it is necessary to correctly match the power and cross-section of the ventilation pipe so that the structure works efficiently.

A high draft hood will protect residents from carbon monoxide poisoning. This is only possible when installing smoke exhausters. With natural cravings, such indicators cannot be achieved.

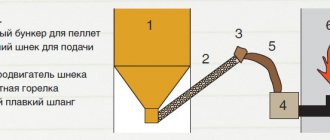

Pellet burners or boilers running on sawdust or peat do not burn well without well-organized draft. Only with the additional installation of a smoke exhauster can truly effective operation of such units be achieved.

The use of smoke exhausters in solid fuel boilers has a number of significant advantages :

There are practically no downsides to such devices. Unless it needs regular maintenance. At the same time, the service life of the smoke exhaust unit is comparable to the operation of the boiler itself.

To install, as well as make a smoke exhauster for a boiler with your own hands, you need to know and understand its design and all the structural features.

The diagram of any smoke exhausters for solid fuel boilers includes the following elements:

When choosing a smoke exhauster, you need to pay attention to parameters such as performance, pressure created, and engine power. All this data is indicated in the instructions from the manufacturer.

To calculate the power of a smoke exhauster, you need to know several details, such as the cross-section of the pipe, how much fuel is burned per hour of operation, and the amount of oxygen for complete combustion of a certain volume of firewood.

Subsequently, using the formulas you need to calculate the indicators:

Exact indicators are declared in SNiP standards.

It is not difficult to make a smoke exhauster for boilers with your own hands. All components can be assembled from scrap materials. The electric motor can be removed from old equipment or purchased at a specialized store. It is possible to make the main element - the impeller - on your own, but since this is a very important component that requires good balancing, it is better to buy a factory model (or a non-new one).

Tools you may need for manufacturing:

It is better to make an exhaust type smoke exhauster with your own hands. To do this, it is necessary to place the blades on the electric motor shaft. Its power can be small - up to 1 kW. The motor is also equipped with special brackets and fasteners for fixing it in the housing - pipe, where the blades and all other elements will be located. After connecting, you should see in which direction the air flow will move.

The centrifugal type design is much more complex than the previous one.

It is made as follows:

After this, you only need to connect the electrical wiring to the air ducts.

To make or buy a smoke exhauster correctly, you need to follow some recommendations. For example, if the house has a special technical room for a boiler room, then the hood is installed in it, since in this case it will be more convenient to service it.

If you need to install a powerful smoke exhauster for a large ventilation system, then it is better to install it outside. The fact is that such devices are very noisy, and this noise will not be heard from outside.

The principle of operation of the stabilizer

If the draft force in the system begins to exceed its optimal values, then a valve opens in the regulator, which reduces the pressure and thermal lift force due to the air coming from the room and mixing with the flue gases. The valve will remain open until the temperature drops and reaches the optimal level. Next, the valve will automatically close and the chimney system will continue to function properly.

This method of maintaining normal traction is simple and effective. Fuel in a stove or boiler will be burned evenly and consumed economically.

Installing a chimney draft stabilizer provides the following advantages:

- increasing the operational safety of the chimney system;

- reducing the amount of harmful substances released into the atmosphere;

- better air circulation when the valve is kept slightly open;

- the ability to operate on both forced and natural draft;

- uniform combustion of fuel in the boiler, which makes it impossible for the chimney to overheat;

- protection from strong gusts of wind;

- no burning smell in the room;

- increasing the service life of the smoke exhaust channel;

- preventing heat loss;

- possibility of installation in modern low-temperature boilers;

- ensuring fuel savings of 15-20%.

How to choose and install a smoke exhauster for a solid fuel boiler or fireplace

Previously, draft and blower fans were used only in industrial boiler installations. The first ones are placed inside the chimney channel and create a vacuum, the second ones pump air into the firebox. Gradually, the units migrated to the domestic sphere - manufacturers began to equip heaters with a closed combustion chamber with turbines. The idea was picked up by home craftsmen, because a smoke exhauster for a boiler helps solve the problem of poor draft in the chimney pipe. Let's figure out whether forced exhaust of combustion products is always necessary.

Measurement methods

If you doubt that the chimney draft of a stove, fireplace or heating boiler is sufficient, you need to check it. The easiest way to dispel doubts is to check it yourself using an anemometer. If the device shows a draft of 10-20 Pa, then it is considered normal. The problem with this method is the low measurement accuracy of inexpensive anemometers; if the draft is less than 1 Pa, then they will show that there is no draft. More accurate professional instruments are expensive; they are used by stove makers.

If you don’t have an anemometer, use one of the popular methods for determining the draft force of a chimney:

- By the smoke. The most obvious sign that there is no draft is the presence of even slight smoke inside the room; a large amount of smoke indicates a high risk of fire and carbon monoxide poisoning.

- By the color of the flame. By looking at the color of the flame, you can check the level of draft force. If the flame inside the firebox has a white tint and crackles during combustion, the draft is excessively strong. Orange-red color indicates insufficient traction. If the chimney is designed correctly, the flame has an even golden-yellow hue.

- Using a match. If you light a match, candle or other source of fire and bring it to the heating device, the flame should deflect towards the firebox. If it remains level, you can be sure that there is no draft. When the flame deviates in the direction opposite to the firebox, there is a reverse draft in the chimney.

- Using a mirror. Another method to check the draft force inside the chimney is to hold a pocket mirror near the firebox. The appearance of condensation on its mirror surface means that smoke removal is difficult.

Ways to check traction

Checking traction with a spark plug

Design and principle of operation

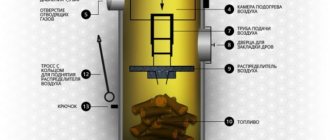

An exhaust fan for a factory-made boiler includes the following elements (the device is shown in the diagram, the positions coincide with the points):

Note. The boiler smoke exhauster DM-01 from Kalvis is taken as an example. The design of other types of fans differs in the shape of the housing - volute, box, hemispherical landing pad. The set of parts is similar.

The unit is attached to a special box located on the rear panel of a domestic TT boiler next to the chimney pipe. The temperature sensor bulb is inserted into the immersion sleeve of the water jacket, the remote control is placed separately.

The principle of operation of the smoke exhauster is the forced removal of high-temperature gases from the fire-tube heat exchanger of the boiler into the chimney. The algorithm looks like this:

Reference. On TT boilers equipped with an automatic draft regulator, there is no need to open the ash pan door. The thermostat, through a chain, will open the air supply damper to the required angle.

High or low performance of the draft fan is set individually depending on the quality of solid fuel, combustion mode and degree of heating of the chimney. The main thing is to avoid the accumulation and leakage of smoke into the room.

You also can’t go overboard with the speed - the lion’s share of the heat will go down the drain. Before opening the door and reloading, it is better to increase the rotation speed to maximum.

A ready-made fan unit from the famous Russian brand Zota is mounted on wood-burning heaters with rear gas outlet

Checking the operation of the chimney

The chimney works correctly if the gases are removed from the room to the street. Backdraft, when smoke enters the room from the chimney and stove, is an extremely undesirable phenomenon.

Signs of poor traction are easy to spot:

- when the stove operates, smoke enters the room;

- gusts of wind outside affect the movement of gases in the pipe, creating a reverse direction. Popping noises are heard in the stove and ash pan;

- fuel is difficult to ignite;

- even dry firewood burns slowly;

- opening the window or doors sharply reduces traction.

It is more difficult to find out about a bad hood of a water heater or gas boiler. Carbon monoxide can enter a room, but it is difficult to smell or see.

Breathing such gas is deadly.

To accurately determine the operating characteristics of the chimney, you can use an anemometer. It is used to measure the speed of movement of furnace gases

It is a common belief that the quality of a hood’s operation can be determined by the burning of a match or piece of paper. This method leads to an error and cannot be used. When burning, a match emits hundreds of times less smoke than wood in a fireplace, for example. The smoke from the match will go away, but this does not mean that the gases from the operating devices will be completely removed.

The exact parameters of the chimney are determined using special equipment. If you do not take into account the roughness and length of the walls, the speed of gas movement depends on the geometry of the channel and the pressure difference in the room and in the upper part of the pipe.

The gas flow must correspond to the power of the furnace equipment, gas water heater and other devices. Most often, the device readings range from 12 to 20 Pa.

Experts can determine smoke removal parameters using an anemometer. The device is compact and easy to use. They measure the speed of gas movement. But you need to know the geometry of the passages and the cross-sectional area of the pipe.

Before measurements, you need to warm up the chimney and stove. In winter, it is enough to heat a fireplace or use a gas water heater for an hour

The data obtained is checked against the requirements recorded in the passport of the gas or stove equipment. If the volume of gas removal in one hour is insufficient, operation of the equipment is prohibited.

Types of traction fans

Several types of smoke exhausters are sold for solid fuel boilers and wood-burning fireplaces:

Various attachments that improve natural draft, such as deflectors, round rotating elements and rotating weather vanes, should not be classified as smoke exhausters. The effectiveness of these hoods depends on the wind speed, which changes with the weather.

The duct fan is distinguished by its own housing with two connecting flanges or pipes. The unit is installed vertically or horizontally into the gap in the chimney duct. The device and principle of operation are similar to the operation of a boiler smoke exhauster.

The overhead smoke exhauster for a domestic boiler is equipped with a semicircular platform and clamps-ties. Installation is carried out on a vertical section of the chimney (uninsulated):

Note. The overhead element is selected according to the diameter of the flue pipe. The installation process is demonstrated in the video.

Electric fireplace hoods are mounted on the head of a brick chimney and secured with spacer bolts. The power cable is laid through a pipe and introduced into the room next to the home stove.

Causes of poor traction

A difficult situation arises if the chimney is designed and laid incorrectly. An inexperienced person selects the wrong pipe diameter or makes a mistake with the length. The smoke removal system must be rebuilt to provide traction force.

There is no traction if the tightness of pipe connections, elbows, or bends is broken. You can increase smoke extraction by sealing all the holes through which hot air leaks. Clogging of the outlet channel with soot also causes a decrease in draft or reverse movement of combustion products. Sometimes heat exchangers of various designs are installed in the smoke exhaust duct to collect heat and reuse it. But built-in installations affect traction and worsen fuel combustion.

Traction force weakens under conditions:

- rain, fog;

- high air humidity;

- high temperature outside;

- high wind speed.

When do you need a smoke exhauster?

Manufacturers of heating equipment equip their products with traction fans due to the increased resistance of the heat exchanger, where gases change direction of movement several times through the flame tubes. The goal is to remove maximum heat from combustion products and increase the efficiency of the boiler installation.

A nuance: the operation of the smoke exhauster in a factory-installed boiler is coordinated with the combustion process and is controlled by an electronic unit. When installing a fan unit on a “brainless” heater, such consistency is excluded; you need to buy an automation unit or adjust the speed manually.

Organize fresh ventilation in the boiler room, and only then think about installing a smoke exhauster

We list the situations when a smoke exhauster will help improve the operation and maintenance of a solid fuel heat generator:

Important point. No fan will save the situation if there is no influx from the street in the boiler room. At first, the working impeller will create a slight vacuum, but then the blades will begin to mix the air in place. Supply ventilation is a prerequisite for the normal operation of any heater.

Some wood boiler designs (for example, shaft type) tend to emit smoke through an open loading hatch. A similar picture is observed in heat generators with a three-pass fire-tube heat exchanger of high resistance. The solution to the problem is to install a traction or blowing machine controlled by a controller.

Strengthening natural draft with the help of a smoke exhauster also has a downside. If, after warming up the pipe, natural exhaust has not been restored, the unit cannot be turned off - you may get burned. Now imagine that in the middle of the night the power supply goes out and the fan stops. While the chain thermostat closes the damper, smoke will fill the boiler room.

Recommendation. The smoke exhauster should not become a panacea. Be sure to take measures to restore draft - repair or alter the flue in accordance with the requirements specified in the boiler instructions.

Fan in the chimney for forced exhaust of gases from the stove

Draft is the natural movement of air masses from any heat generator into the external atmosphere along with the removal of hazardous combustion products. If it is weak, the fuel will burn very slowly. It can also have a detrimental effect on the human body - indoor gas pollution in some cases leads to death. To create forced air circulation, install a chimney fan.

If there is any doubt that the draft in the chimney from the heating device is weak, then you should definitely check it. The simplest method is to use an anemometer. The normal indicator is a traction force of 10−20 Pa. The big disadvantage of such devices is that inexpensive devices have poor measurement accuracy. If the indicator is below 1 Pa, then they will show that the system does not remove combustion products at all. Professional devices are quite expensive. They are often used only by stove makers.

To check the chimney, you can use traditional methods:

- 1. By the smoke. Even slight smoke in a room is an obvious sign of a lack of normal draft. If there is a lot of smoke, there is a high risk of fire. Residents can also suffer from carbon monoxide poisoning.

- 2. By the color of the fire. If there is a white tint in the flame, then the draft is too strong. An orange color with a red tint may indicate that the ventilation is not working properly. When the channels are functioning normally, the fire is golden yellow.

- 3. Using a match or candle. It is necessary to bring them to the firebox of the heating device. The flame should deviate towards the exhaust hood. A tilt in the opposite direction indicates reverse thrust.

- 4. Using a mirror. It must be brought to the firebox. If condensation forms on the surface, this means that removal of combustion products is difficult.

Natural circulation of air masses occurs due to the difference between street and internal atmospheric pressure. The indoor temperature is much higher. Cold air presses on warm air from below, thereby removing it to an area with lower pressure, that is, to the street. Measurements in summer will be less accurate.

Before we talk about using forced exhaust for a chimney, you should understand the process of removing combustion products. You also need to understand the reasons for the deterioration of draft in the chimney. All factors influencing this can be divided into three main groups:

- 1. Indoor conditions.

- 2. External factors.

- 3. Chimney design.

Internal also includes the temperature and volume of air in the house, the number of oxygen consumers, and the conditions for the movement of air masses. The design of the house also affects draft. For example, installing plastic windows often impairs air circulation. This is due to the higher tightness of double-glazed windows, which reduces the volume of incoming oxygen.

External factors include outdoor air humidity, temperature, atmospheric pressure, wind currents, and air mass flow speed. Because of all this, constant changes in draft in the chimney appear. The process of removing carbon monoxide from furnaces and other heat generators should be constantly monitored.

Factors associated with chimney design include:

- 1. Location of the structure. The chimney can be located outside near the wall or inside the room.

- 2. Pipe length and number of turns.

- 3. The quality of the surfaces of the inner walls of the channel. A large amount of soot narrows the chimney, which is the main reason for poor draft. It accumulates more actively on rough chimneys.

- 4. How high is the smoke chimney relative to the top point of the roof?

- 5. Heat transfer from the materials from which the chimney is made. Insulated structures promote good traction.

Which is better - a smoke exhauster or a blower?

When the traction turbine is integrated into the heat generator by the manufacturer, such questions do not arise. Adding an exhaust fan to a conventional direct combustion boiler is another matter. You need to understand that in this case, the smoke exhauster solves only 1 problem - creating a vacuum in the firebox and increasing draft. There are a number of negative points here:

Comment. We don't mention the fan's power consumption. The consumption is relatively small and will not have a significant impact on the overall cost of heating.

The disadvantages described in paragraphs 1 and 2 are eliminated by connecting the smoke exhauster with a controller that controls the impeller speed and water jacket temperature. Electronic units can be purchased at a price of 50-100 USD. e.

Blowing machines always work in conjunction with a controller, so the problems listed above do not exist:

Reference. In pyrolysis boilers, pressurization is always used, since the operation of this type of heater is based on forced air injection.

Now let’s compare the cost of a traction fan and a blower fan, not taking into account the price of the controller. A smoke exhauster for a TT boiler up to 30 kW will cost 90 USD. e., supercharger - 60-65 cu. e. The difference is due to the design features of the exhaust unit - hot gases should not overheat the electric motor, plus the impeller is made of metal (when pressurized, it is made of plastic).

Behind the mounting flange of the unit there is a small impeller designed to cool the electric motor

The installation complexity of the units is approximately the same. Installation of the discharge volute involves cutting out an opening in the ash pan door, and the smoke exhauster involves disassembling or cutting out the pipe. It is easier to install a roof hood, but you will have to pull a long cable.

Brief conclusion: install a smoke exhauster only if necessary, or better yet, correct mistakes made during the construction of the flue. Add electronically controlled turbocharging as desired - the system will automate and secure the combustion process.

How to make an exhaust unit

The main difficulty in assembling a smoke exhauster with your own hands is making a balanced impeller; the remaining parts are not difficult for a home craftsman who knows how to weld. If the impeller blades vary in weight, normal fan noise will turn into rumble due to vibration.

In addition to the blades, you will need the following elements:

We offer ordinary homeowners the least thorny path - buy a factory electric motor with an impeller and a cooling impeller, weld the box and assemble a fully functional duct smoke exhauster for a TT boiler. How to do this correctly, watch the video.