The advantages of boilers with forced-air fans or smoke exhausters have been discussed in detail in many articles and reviews on the Internet. When the question arises of how to choose the right fan for a boiler , regular telephone consultations may not be enough, due to the incompetence of the consultants or vague information.

To correctly select the fan parameters for the boiler, we need to have the following data:

- Type of installed fan: injection or exhaust

- Boiler power

- What kind of automation will control the fan?

There is a rule: to obtain “X” kW of thermal energy you need “Y” m3. air, ensuring complete combustion of fuel. Based on the power of the solid fuel boiler, we will consider the practical recommendations of specialists on the selection of parameters, which are given in the table:

Fan selection table

Boiler power, kW

Maximum amount of air, m cubic.

Since different fuels can be used (wood, coal, briquettes...) and with different humidity levels, the given data will be indicative. If, for example, to burn coal, with a calorific value of 7 kW/kg, in a boiler of 30 kW, it is necessary to pump air in the amount of 180 m3/hour, then for wood, with a calorific value of 3.6 kW/kg, it will be necessary to pump 100 -130 m3/hour.

But we are tied to the actual power of the solid fuel boiler, which means it is necessary to ensure its nominal thermal performance. Unlike coal, more wood will need to be burned by weight. And since our boiler can operate on different fuels, then the same fan for the boiler should be selected, but with the ability to change the air output.

And now we come to the most basic thing. There is a huge selection of different types of fans. You need to choose the one that will be manageable in terms of performance. The control will be taken over by the controller ( by the way, their choice is also huge ), which, based on measurements of the temperature of the solid fuel boiler, will give commands to the fan to reduce or increase the speed according to the established algorithm. The best controlled fans are those with asynchronous motors, which are specifically designed and designed to be able to regulate air flow.

Depending on the type of boiler controller, the control signal from it to the boiler fan can be supplied in the range of 5-100% of its performance. This is where an important characteristic of fans comes into play: the ability to fulfill the controller’s task of changing the speed.

Why important? The fact is that not all fans are capable of fully operating at their full range. In other words, the controller can command the performance to be reduced by up to 15%, and the fan cannot operate at such a low performance due to the cheap electric motor. There are examples when the fan is regulated only in the ranges of 30-70%. Below 30% it does not respond to adjustments - it is “silent”, above 70% it immediately increases the rotation to 100%. It happens that there are “blind” fan control zones; this is when the influence of the controller’s control signal on the fan motor does not produce any results - the fan stops and hums. In this case, some controller developers release special software that bypasses these control zones, while the fan is controlled within a narrow performance range. Simply, spasmodically according to the choice of power.

If the task is to choose a fan for a boiler with truly smooth performance control, then you should pay attention to two components at once:

- to a controller with a PID algorithm, which itself will select how much power the fan should develop (5-100% in steps of 1%)

- for reviews and characteristics of the fan that will perform this task.

Buy a fan for a solid fuel boiler

There is an established, proven list of brands of solid fuel boiler fans that really offer a good product. The price tag of such fans is very reasonable, but the temptation to reduce the cost of purchasing often turns one’s attention to cheaper options. This is not always justified when the price difference is only 120-180 hryvnia.

You can call us or request a call back and we will help you with choosing a fan for a solid fuel boiler

Stable and economical operation of solid fuel boilers is ensured by good draft. With strong draft, the fuel burns out completely, and there are no unpleasant odors of combustion products in the heated room. Typically, traction is provided by natural exhaust. If it is not enough, they resort to the help of special exhaust machines and smoke exhausters. You can make a smoke exhauster with your own hands, it’s not difficult.

What are the prices for repairs from specialists?

The full list of faults that were listed above, and many other breakdowns can be easily and quickly repaired by professional technicians who specialize in repairing such equipment. A technician can be called if a breakdown has already occurred, or if there are reasons to believe that equipment failure may soon occur.

The total cost of repairs will depend on the location of the facility to which the repairman must go. The cost will also be influenced by the brand of pellet boiler, power and other factors.

Price table

Estimated cost of repair work for pellet boilers

| Name of the service provided | Price (from) in rubles |

| Visit of a specialist to carry out diagnostics of boiler equipment. | 1100 |

| Cleaning burners and removing carbon deposits | 1100 |

| Screw replacement production | 1100 |

| Cleaning the heat exchanger on the surface | 1500 |

| Replacing control units (electronic) | 2100 |

| Changing coolant temperature sensors. | 600 |

| Bearing removal and replacement work | 600 |

| Removing and replacing outlet gas temperature sensors. | 800 |

| Configuring the control unit (electronic) | 1000 |

| Repair the electronic control unit | 1000 |

| Replace fan | 1000 |

| Replace electric motor | 1650 |

| Replace the gearbox | 1650 |

| Replace the exhaust fan | 1650 |

Classification of smoke exhausters

Before installing the exhaust machine, you can try to do without it, increasing the draft with special devices that do not require forced air distillation and energy consumption. Sometimes an extended pipe or installing a deflector on the top helps. If the problem cannot be resolved, you can use:

- natural draft enhancer;

- flow exhauster;

- centrifugal exhaust fan.

The first of them consists of a fan mounted on the top of the chimney and connected to a control panel. The simplest and cheapest option, but its performance is low.

In the second design, the hood housing with the impeller is placed in the smoke duct, and the electric motor is installed outside. This configuration allows the use of engines and turbines of any power.

The highest performance of a centrifugal smoke exhauster. This design allows you to service chimneys with the most complex configuration and large cross-section.

In this video you will learn how to make a smoke exhauster:

What is better: a smoke exhauster or a blower?

When the traction turbine is integrated into the heat generator by the manufacturer, such questions do not arise. Adding an exhaust fan to a conventional direct combustion boiler is another matter. You must understand that in this case the smoke exhauster solves only one problem - creating a vacuum in the firebox and increasing draft. There are a number of negative points here:

- Without an electronic control unit, performance will have to be adjusted manually. Automatic maintenance of coolant temperature is excluded.

- When air is supplied through the open ash chamber door, the fan will force the boiler to operate at maximum. Setting up a long burn mode will not be easy.

- In the event of an emergency stop of the impeller, fuel combustion will not stop, since gases pass freely through the volute or the body of the smoke exhauster. Air enters the firebox, increasing the likelihood of overheating.

- The impeller and internal surfaces of the unit become covered with soot, which must be removed. The rate of sticking depends on the moisture content and resin content of the wood.

Blowing machines always work in conjunction with a controller, so the problems listed above do not exist:

- the blower changes performance and turns off at the command of the control unit, the coolant heats up to the set temperature;

- during the combustion process, the ash pan door is hermetically closed, air is supplied through a separate channel;

- when there is a power outage, the air channel is automatically closed by a gravity damper;

- the impeller blades do not come into contact with hot smoke and soot.

Now let’s compare the cost of a traction fan and a blower fan, not taking into account the price of the controller. A smoke exhauster for a TT boiler up to 30 kW will cost 90 USD. e., supercharger - 60-65 cu. e. The difference is due to the design features of the exhaust unit - hot gases should not overheat the electric motor, plus the impeller is made of metal (when pressurized, it is made of plastic).

The installation complexity of the units is approximately the same. Installation of the discharge volute involves cutting out an opening in the ash pan door, and the smoke exhauster involves disassembling or cutting out the pipe. It is easier to install a roof hood, but you will have to pull a long cable.

Features of use

In solid fuel boilers, such types of fuel are often used that it is impossible to do without a forced increase in air supply - sawdust or peat burn poorly without blowing. A complete heating process here is only possible with the help of a smoke exhauster.

The hood, unlike pressure units, allows fuel to be supplied to the boiler continuously, which increases its performance and prevents gaseous combustion products from penetrating into the room.

Use of hoods:

- improves the efficiency of boilers, leads to complete combustion of firewood;

- prevents the accumulation of smoke in residential premises, eliminates unpleasant odors;

- prevents the return of exhaust gases into the room when the door is open;

- reduces the amount of deposits on the walls of chimneys;

- With proper installation and regular maintenance, the service life of the smoke exhauster can be equal to the duration of use of the boiler.

Preventive measures

Maintenance of any pellet boiler is an integral part of its long-term, uninterrupted operation. Preventive maintenance should be carried out at least once a year at the end of the pellet boiler operating season. The frequency is set by the manufacturer. For service, you can call specialists, or you can do it yourself. Service consists of:

- Checking and lubricating the mechanical moving parts of the unit.

- Cleaning the pellet burner and other surfaces that are subject to the deposition of smoke and dirt.

- Replacement of all parts, parts and equipment that, for one reason or another, require replacement.

Specifications

Not only factory-made hoods can be installed in the chimney. If desired, it is not difficult to install a homemade smoke exhauster. In order not to make a mistake when purchasing or manufacturing components of a mechanism, you first need to familiarize yourself with its technical parameters.

The design of the smoke exhauster consists of:

- housing or casing for the impeller made of heat-resistant steel, the thickness of the sheets of which is not less than 1.5-2 mm;

- an AC electric motor installed outside the impeller housing, this arrangement increases its service life;

- a shaft connecting the engine to the impeller and mounted on bearings with hermetically sealed seals;

- inlet and discharge pipes and dampers;

- ash collection bunker;

- impeller (impeller), material of manufacture - alloy steel.

The metal must withstand temperature loads of up to 300° C and the aggressive effects of hot gas exhaust. Before installation, careful balancing is necessary to prevent excessive vibration, leading to premature wear of the mechanism. Impellers can be bladed or centrifugal.

Exhaust parameters for solid fuel boilers consist of:

- electric motor power;

- productivity (calculated in 1 m³/h);

- created pressure.

It will be good if the resources of all indicators of the unit are higher than those required by operating conditions. This increases the reliability of the machine.

Purpose and device

Blower fans are installed at the end points of chimneys and facilitate the removal of combustion products by creating a strong vacuum that draws smoke and other gases from the firebox system and chimney. The operating conditions of the smoke exhauster are characterized by high temperature loads; contact with combustion products contributes to rapid wear and metal fatigue. The design of the smoke exhauster must correspond to the load level and ensure efficient operation throughout its service life.

The structure includes:

- heat-resistant fan (made of stainless, alloy or, less commonly, carbon steel)

- a guide device installed on the suction side and organizing the correct flow direction

- suction funnel connecting the guide vane to the fan inlet

- electric motor

The body of the smoke exhauster, regardless of the material of manufacture, is covered with a protective polymer coating. It increases the service life of parts and helps reduce thermal corrosion of materials. The direction of inclination of the impeller blades is used both forward and reverse. The first option is most often used on small boilers with relatively mild operating conditions, the second option is used on powerful installations with high temperatures of exhaust gases.

For use as smoke exhausters, not only radial, but also axial devices can be used. There are flow-through structures that are located at the outlet of the boiler. They are not completely located in the channel, but only a part of the impeller that increases thrust. Such designs are not full-fledged smoke exhausters, but they are quite effective as draft amplifiers. The best option is to install a specialized centrifugal type device that gives maximum effect.

Homemade designs

You can make smoke exhausters for boilers with your own hands. This will save you money on buying a factory hood. To fold such a machine yourself, you only need to purchase an electric motor. The remaining components can be made from available materials.

By making such a pump yourself you will save your money

Hood from scrap materials

The set of tools required for work consists of:

- Bulgarians;

- welding machine;

- drills;

- metalworking tools;

- hammer;

- rulers;

- caliper.

Work begins with the manufacture of an exhaust fan. The impeller, matched to the size of the exhaust pipe, is secured to the motor shaft. The engine, using fasteners equipped on its body, is placed in the pipe.

To make a smoke exhauster you will need at least. Bulgarian

After connecting the motor to the wiring, during the first test run it is necessary to check the direction of the air flow and, if necessary, adjust the operation of the rotor.

The pipe for placing the turbine is selected with a diameter 2-3 cm wider. Its length should extend beyond the fan by 3-5 mm. One end of the pipe is welded with a lid, a hole is made in the center for the chimney, and another one is equipped on the side, to which the outlet pipe is attached.

During operation, the fan should not cause increased vibration of the hood body. To prevent this from happening, it is installed using bushings to center the bearings.

Preventing the condition of the chimney

To avoid the need to use means of forced exhaust of a chimney made of heat-resistant material, it is necessary to use preventive means to maintain it in working condition.

Since the main reason for reducing the intensity of flue gas extraction is the reduction in the passage of the pipe by soot accumulated on the walls, we will consider means of combating this phenomenon.

These methods could be:

- Burning about half a tablespoon of naphthalene in the furnace firebox. Naphthalene vapor decomposes soot into loose components, large ones fall inside the firebox and are subsequently removed with the ash, and small ones fly out through the pipe along with the furnace gases. This product cannot be used for smoke removal from a fireplace and for pipes of open hearths - it leaves a characteristic suffocating smell in the rooms.

- From time to time, burn potato peelings in the firebox. They are pre-dried. Starch vapors loosen the soot deposit and it will fall into the firebox. Pure starch acts similarly, which is fed into a well-lit firebox in the amount of one tablespoon.

- A good way to remove soot from pipes is walnut shells. It burns at a high temperature, burning off soot deposits on the inner walls. A single dose of shells should be no more than three liters. Frequency of application - as accumulation occurs.

- Aspen firewood has a similar effect on soot. One or two logs are burned at the end of the last stack of firewood. They burn at high temperatures.

The frequency of use of high-temperature products should be regular, at least twice a week, so that soot does not have time to accumulate.

Otherwise, you can cause a serious fire, since the soot burns and releases a very large amount of heat. In addition to those listed, there are many anti-soot agents on the market for both chemical and thermal decomposition of soot. The use of preventive measures can eliminate the need for forced measures to improve the exhaust hood on the chimney.

Maintenance and operation

To extend the service life of the unit, it is necessary to reduce the effect of moisture on it , an increased level of which leads to premature corrosion of not only the metal parts of the machine. The easiest way to protect against precipitation is to install a deflector on the top of the pipe.

To ensure reliable operation of the motor and fan, their rubbing parts are regularly lubricated and cleaned.

It will be easier to maintain the boiler if you connect it to the control of the heating and ventilation system.

In order to make a smoke exhauster for a boiler with your own hands, you just need to prepare a set of necessary tools and have a desire to save money. After all, a homemade smoke exhauster costs much less than a factory-made one.

Despite the popularity of gas heating systems, solid fuel boilers firmly hold their position in the domestic climate control equipment market. In the minds of the average person, a boiler that runs on solid fuel is an ordinary potbelly stove. In fact, modern solid fuel boiler equipment has a high level of safety and is capable of obtaining maximum thermal energy with a minimum of fuel.

Today, equipment is widely represented on the Russian market, thanks to which modern engineers have managed to significantly increase the level of comfort when using solid fuel units. This article will discuss devices that allow you to control the fuel combustion process and coolant temperature.

Calculation of a pyrolysis boiler

The calculation begins with determining the temperature difference, ºС:

Ƭ= (∆T – ∆t) / ln (∆T / ∆t)

In this formula:

- ∆Т – temperature difference of combustion products before and after the heat exchanger;

- ∆t is the difference between the temperatures in the coolant supply and return pipelines.

The resulting value Ƭ is substituted into the formula:

S = Q / k / Ƭ , where:

- Q – design power of the heating installation, W;

- k – heat transfer coefficient, equal to 30 W/m2 ºС.

An enlarged calculation of the power of a pyrolysis boiler (Q, kW) is performed based on the area of the building. Its value must be taken based on the external measurement of the house, the result divided by 10. The meaning of this action is that approximately 10 kW of thermal energy is required to heat every 100 m2 of the building. The result obtained is the calculated power of the heating system, and the heat source is taken with a safety factor. It depends on the region of residence and ranges from 1.1 to 1.5.

Traction regulator

The only problem: the owner of the boiler unit must adjust the position of the air damper manually, relying on the thermometer readings and his own experience. To automate this process, an automatic draft regulator was invented.

The device consists of a thermal element, a regulator, a metal lever and a chain. The thermoelement and regulator are assembled into a single housing made of heat-stable and corrosion-resistant steel. The thermostat is installed in the mounting socket until it comes into contact with the coolant circulating in the water jacket of the boiler unit.

The principle of operation of the regulator: when temperature affects the thermoelement, it changes its shape and, through the rod, acts on a lever, which is connected to the air damper of the boiler unit using a chain. When the coolant temperature changes, the position of the air damper automatically changes. The regulator sets the upper temperature limit.

To set up a draft regulator for solid fuel boilers with your own hands, you need to follow these steps:

- Install the regulator into the heating system. Depending on the boiler model, both horizontal and vertical installation of the device can be provided. Each installation option corresponds to a specific scale color on the regulator. At this stage the chain is not connected to the choke and hangs freely.

- Set (by selecting the color of the scale corresponding to the orientation) the desired temperature indicator of the coolant and start the boiler installation.

- When the coolant temperature reaches the value you set on the thermostat, close the air damper, leaving a gap of 2-3 mm.

- Attach the chain to the damper rod.

For the draft regulator to work correctly, the chain between the air damper and the thermostat draft must be tensioned.

Let's digress a little, because we want to inform you that we have compiled a rating of solid fuel boilers by model. You can learn more from the following materials:

Manufacturing of a pyrolysis boiler

The efficiency of this type of wood-burning installations has become the reason for their popularity among craftsmen who can make solid fuel pyrolysis boilers on their own from available materials. This process is quite labor-intensive and requires skills in plumbing and welding, a certain minimum of tools and equipment:

- electric welding machine;

- angle grinder;

- electric drill;

- set of locksmith tools.

If you have the skills, tools and a great desire, you can make a unit using the following drawing of a natural draft pyrolysis boiler:

1 – air channel; 2 – door for loading fuel; 3 – secondary chamber door; 4 – direct draft damper; 5 – primary chamber; 6 – top cover; 7 – inlet channel for air supply; 8 – air damper; 9 – pipe for the safety group; 10 – secondary afterburning chamber; 11 – chimney connection pipe; 12 – nozzle; 13 – fire tube heat exchanger.

The material for making the chambers can be heat-resistant alloy steel, but this is an expensive material, so craftsmen take simple carbon steel 5 mm thick. To protect it from high temperatures, the pyrolysis boiler is lined with refractory bricks in the lower part of the furnace. They also need to protect the bottom of the secondary chamber, where the flame is directed. To cover the water jacket, sheet metal 3 mm thick is used, it is welded to the stiffeners made of strip steel. The doors, lids and frames of the openings are made from the same metal.

The boiler device provides heat transfer from flue gases through a fire tube heat exchanger located inside the water jacket. For its manufacture, seamless steel pipes made of carbon steel with an outer diameter of 48 or 57 mm are suitable. The number of pipes should be selected according to the required heat exchange surface area, for which the pyrolysis boiler is calculated.

Considering that the fuel in pyrolysis units burns for a long time (up to 12 hours) and is productive, some owners of classic direct combustion units are wondering whether they can be modernized. Such a conversion of a solid fuel boiler into a pyrolysis boiler is possible, but provided that the furnace of the unit is made of metal and not cast iron. The grate is removed and, using electric welding, a partition is fixed in its place, separating the main firebox and the ash pan, which will serve as a secondary chamber. A nozzle is installed between them. In addition, you will need to organize an air supply to both chambers; you need to make air channels and install them, as shown in the drawing.

As a rule, converting a boiler into a pyrolysis boiler occurs not on factory units, but on home-made ones, this expands the possibilities for improving the design. You can change the nozzle flow area, the dimensions of both chambers or the surface heat exchange area, achieving the best combustion duration and increasing the efficiency of the installation.

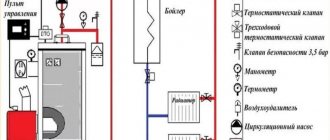

Automation for solid fuel boiler equipment

The traction control works great, but only when there are conditions for creating traction. The main problem with natural draft is weather dependence: the smaller the difference between the air temperatures outside and in the house, the worse the draft. Modern sealed houses with metal-plastic windows, into which the flow of air mixture is completely absent or limited, also add fuel to the fire. To solve the traction problem, automation was invented. By controlling the operation of the fan and circulation pump, the issue of stabilizing the temperature of the coolant is resolved.

Checking the operation of the chimney

The chimney works correctly if the gases are removed from the room to the street. Backdraft, when smoke enters the room from the chimney and stove, is an extremely undesirable phenomenon.

Signs of poor traction are easy to spot:

- when the stove operates, smoke enters the room;

- gusts of wind outside affect the movement of gases in the pipe, creating a reverse direction. Popping noises are heard in the stove and ash pan;

- fuel is difficult to ignite;

- even dry firewood burns slowly;

- opening the window or doors sharply reduces traction.

It is more difficult to find out about a bad hood of a water heater or gas boiler. Carbon monoxide can enter a room, but it is difficult to smell or see.

Breathing such gas is deadly.

To accurately determine the operating characteristics of the chimney, you can use an anemometer. It is used to measure the speed of movement of furnace gases

It is a common belief that the quality of a hood’s operation can be determined by the burning of a match or piece of paper. This method leads to an error and cannot be used. When burning, a match emits hundreds of times less smoke than wood in a fireplace, for example. The smoke from the match will go away, but this does not mean that the gases from the operating devices will be completely removed.

The exact parameters of the chimney are determined using special equipment. If you do not take into account the roughness and length of the walls, the speed of gas movement depends on the geometry of the channel and the pressure difference in the room and in the upper part of the pipe.

The gas flow must correspond to the power of the furnace equipment, gas water heater and other devices. Most often, the device readings range from 12 to 20 Pa.

Experts can determine smoke removal parameters using an anemometer. The device is compact and easy to use. They measure the speed of gas movement. But you need to know the geometry of the passages and the cross-sectional area of the pipe.

Before measurements, you need to warm up the chimney and stove. In winter, it is enough to heat a fireplace or use a gas water heater for an hour

The data obtained is checked against the requirements recorded in the passport of the gas or stove equipment. If the volume of gas removal in one hour is insufficient, operation of the equipment is prohibited.

Smoke exhauster for boiler installation

As noted above, natural draft does not always make fuel combustion and exhaust gas removal ideal. This happens for many reasons, the most common of which are: weather conditions and lack of air flow. If air flow can be created by simply opening the windows, then it is impossible for an ordinary person to change the air temperature in the summer. In order not to depend on the draft in the chimney, users install a device called a smoke exhauster into the smoke removal system. In addition, the use of a smoke exhauster allows less solid soot particles to settle on the walls of the chimney, and, accordingly, less need to resort to the services of a chimney sweep.

This is an exhaust fan mounted in a metal unit, which is mounted between the boiler and the mouth of the chimney. The picture shows the design of the exhaust fan.

Installing smoke exhausters for household solid fuel boilers with your own hands is quite simple:

- Install the unit at the installation site of the smoke exhauster. For tightness, apply heat-resistant sealant to the joints.

- Place the fan housing on the 4 studs with the impeller facing inward. Make sure that the gasket fits tightly to the exhaust fan mounting unit.

- Place washers and nuts on the studs and tighten the fan assembly evenly.

- Ground the device and connect the power plug to it.

Advice: to avoid electric shock, it is recommended to entrust all work on connecting the device to the electrical network to an electrician with the appropriate work permit.

What is a fireplace exhauster and why is it needed?

This device is a duct fan with an electric motor, which is mounted at the outlet of the chimney. The principle of operation of the device is simple - during operation of the fan, the draft in the chimney increases.

Simply put, this device is a forced exhaust system, but they are not designed for full exhaust. They are used only to improve (occasionally) the natural draft in the pipe, or during its repair.

Chimney hoods

For example, a fireplace smoke exhauster is started as needed - for a time when the natural draft drops to a certain value.

When should it be used?

There are several indications for the use of a fireplace smoke exhauster, which are in one way or another related to draft disturbances in the chimney pipe.

Indications for use:

- When there is no draft at all in the chimney pipe (for example, due to errors in the construction of the chimney pipe, or because of its weakness in terms of exhaust). This often happens when the chimney height is selected incorrectly.

- In cases where the chimney is incorrectly positioned relative to the roof ridge.

- If a taller building was built nearby and, accordingly, the draft fell because of this (due to an obstruction to wind flows).

- In cases where the chimney needs repair work (gaps, cracks, or any protruding elements have appeared).

- In cases where the diameter of the chimney chosen is not large enough, or, on the contrary, too large.

Pros and cons of use

Any device of this type has both a number of undeniable advantages and a number of disadvantages. This is also true for smoke exhausters.

Among the advantages of such a device it is worth noting:

- you don’t have to repair the chimney “right now” - the smoke exhauster allows you to postpone repair work indefinitely;

- the ability to create the necessary traction by increasing it, in any weather;

- you can significantly reduce the harm from the formation of condensation due to the fact that the draft will be increased, and as a result, less condensate will form;

- the ability to turn off the fan at any time when there is sufficient natural exhaust from the chimney.

List of disadvantages of using such a device:

- It is not always possible to install a smoke exhauster;

- additional consumption of electrical energy (however, to be fair, such fans consume relatively little electricity).

For which chimneys is it suitable?

The smoke exhauster can be used on chimney pipes for stoves, fireplaces, and various boilers (gas and solid fuel)

But there is one important condition - such a product can only be installed on chimneys in which the temperature does not exceed +600 degrees

Types of fastening of chimney hoods

This also applies to heat-resistant models. Although they are designed for high-temperature operation, they are not too high (therefore they are used for a stove or fireplace, but not for industrial purposes). Moreover, +600 degrees is a very good indicator; many heat-resistant smoke exhausters are even designed for temperatures up to +350 degrees (average value).

Chimney for solid fuel installation

Speaking about the dependence of the operation of a solid fuel boiler on draft, one cannot help but touch upon the topic of arranging a chimney, thanks to which the combustion products are released into the atmosphere in a timely manner. Modern boiler units with a closed combustion chamber are equipped with a coaxial smoke exhaust, which has many advantages and does not require it to be installed above the roof. Most models of boiler equipment with an open combustion chamber require a stationary chimney, which must be in accordance with fire safety rules and have the necessary design to ensure unhindered removal of combustion products.

https://www.youtube.com/watch?v=ZUXWDzWeXk4 The following materials are used to construct the chimney:

- Brick. Traditional brick pipes do their job quite well, but they are heavy, have a complex masonry pattern and require a solid foundation.

- Stainless steel sandwiches. An excellent design, which consists of sections of double pipes, between which there is insulation. This material allows you to do without a foundation and can be assembled by one person, like a constructor. But this design also has a disadvantage - high cost.

- A ceramic chimney is an excellent alternative to steel sandwiches. It is easy to assemble, has good fire resistance and a perfectly smooth inner surface, and can withstand temperatures up to 900°C.

It’s easy to install a ceramic chimney for a solid fuel boiler with your own hands, because it is assembled from chimney blocks, like a children’s construction set. A ceramic pipe insulated with mineral wool is inserted into the assembled chimney. Advice: when choosing a chimney for a solid fuel boiler, be guided by the installation data sheet, which gives the recommended cross-section of the smoke exhaust channel. In addition, when choosing, focus on the temperature and pressure of the exhaust gases when operating in natural draft and boost modes. Don't forget about condensate drains and collectors!

Good draft is the result of correct calculation and installation of the chimney

When asked which chimney is better for a coal boiler, and which for a diesel boiler, etc., the correct answer will always be different. Because a chimney made for a wood-burning stove may be completely unsuitable for a gas boiler, for example. And there may be several reasons for this. At the same time, few people are able to install a new capital chimney to replace an ineffective one. That is why existing chimney pipes have to be improved in one way or another. Often, an improvement involves installing a smoke exhauster for a new domestic boiler.

Everywhere the chimney for a solid fuel boiler is made of solid brick. If it has sufficient height and cross-section, then it always has excellent traction and no air movement amplifiers are required. But there are also exceptions. For example, a brick chimney for a stationary solid fuel boiler cannot be brought to the required height. As a rule, a chimney for a solid fuel boiler is simply made by hand, but it does not always cope with its function perfectly. And it often happens that additional draft needs to be provided using smoke exhausters for household solid fuel boilers, purchased or made by yourself.

What and how to lay out a chimney so that it effectively copes with smoke removal is the topic of a separate large article, and now we will not touch on it. A solid brick chimney is good for a solid fuel boiler or stove, but without additional inserts it cannot be used for modern boilers using other types of fuel. For example, a smoke exhauster for a boiler may be needed if the chimney installation was done incorrectly from the very beginning.

How to properly make a connection to the chimney for a conventional solid fuel boiler? Highly qualified specialists know about this, but they are also mistaken, not noticing some local detail in time. A good smoke exhauster for a solid fuel boiler or any other can eliminate all errors in the design and construction of boilers and chimneys. Especially if the chimney for the boiler is not brick, but metal.

This is a whole science - installing a chimney for a solid fuel boiler. What can we say about more complex options for heating devices. Therefore, errors occur quite often; even simple brick laying is rarely ideal. Compliance with all technical standards for aerodynamics is another task! How to make a chimney if a brick boiler is connected to it? Will your own chimney for a solid fuel boiler be efficient enough? Such questions often cannot be answered in advance.

Main advantages of WPA fan

It is worth noting that the modern market of heating devices and accessories offers several models of electromechanical devices. Perhaps the most popular is the WPA fan from MplusM, which has its main representative office in Poland. This organization is engaged in the production of turbines designed for solid fuel boilers.

Why should you buy a WPA fan? It's all about the quality of his execution. The Polish company MplusM uses materials with a high degree of strength in the production process, which indicates the reliability and long service life of the WPA unit. Among other things, this WPA model is perfect for all types of solid fuel boilers. The Polish WPA fan can be used both in everyday life and in industry.

Take into account the fact that it is not difficult to buy a WPA fan in Moscow, but the most important thing is not to run into a fake. offers a wide range of original units from the Polish organization MplusM. WPA fans are in stock and available for immediate order.

When is it necessary to increase the performance of a chimney?

Poor draft is not always the only reason for chimney work. It may be necessary to increase the rate of carbon monoxide removal if additional equipment is connected to the hood from the stove.

It is allowed to use a chimney to connect a column if the equipment is located on the same floor. And if the chimney has a sufficient smoke removal volume for operating the gas heater.

Another reason to increase the draft in the chimney is to install a more powerful heater. The required parameters of the chimney are indicated in the product data sheet.

It is also worth paying attention to how quickly you can light a fire in the stove. For example, if the draft is weak, damp wood will not burn

If the volumes of gases removed do not match the capabilities of the existing system, then the chimney needs to be modernized.

How to choose material for the hood?

For these purposes, brick, galvanized and stainless steel and ceramics can be used. Let's take a closer look at each of them, and also study what other options the market and engineering offer.

Brickwork hood

Although brick is used by builders when arranging ventilation, its properties do not allow them to save on other materials. Firstly, brickwork is not durable. The most comfortable conditions for her are constant contact with hot gases. Otherwise, condensation will form, which leads to its rapid destruction. Secondly, a brick chimney is labor-intensive to install, has a complex design and is unreasonably high in cost. Therefore, if you are faced with the task of arranging a chimney for a gas boiler, it is better to pay attention to other options. In this situation, a shaft is made of bricks. This same option can be chosen if for some reason heating the house with gas is currently impossible, but in the future it is planned to use it.

If brickwork is chosen as the material for the shaft, then the chimney itself is assembled from single-circuit galvanized pipes. The thickness of their walls is selected taking into account the temperature of the outlet gases.

Components of a chimney inside a brick shaft

Steel hood

In this situation, steel pipes are very convenient. They are easy to install when compared, for example, with brickwork. The wall thickness is selected depending on the heating. Gas boilers produce quite hot exhaust gas, about 400-450˚C, so the thickness of the walls should be 0.5-0.6 mm. However, there are pitfalls here too. Of course, steel is resistant to the negative effects of condensation. But on average, its wear resistance is much lower than, for example, the wear resistance of ceramic products. In addition, thin-walled pipes burn out quickly if used with solid fuel devices, so this option is not optimal when using different types of heating elements for different periods of time. Steel choose:

- during reconstruction;

- if there is no space for a ceramic hood.

Since steel ventilation ducts often spoil the exterior of a private house, they are covered with brickwork or other finishing materials.

Steel pipes are marketed in two variations - single-circuit and double-circuit. The second option is called a “sandwich” in slang. It consists of two pipes nested one inside the other, the gap between which is filled with fire-resistant basalt wool. The thickness of the inner pipe is determined by the temperature of the outlet gases (recall that this value is 0.5-0.6 mm for the devices discussed in the article).

Installation of a steel double-circuit chimney

“Sandwiches” are considered more economical among all steel hood options. This conclusion suggests itself if we take into account good thermal insulation, which increases the efficiency of the heating device.

Double-circuit steel chimneys are made of stainless and galvanized steel. Both metals are combined in “sandwiches”, since using only stainless steel is not economically feasible. The difference between galvanized and stainless steel is the latter’s higher resistance to condensation, which negatively affects its price. Otherwise, the properties of these two materials are not inferior to each other.

It is critically important that the internal part of the double-circuit structure is made of stainless steel; the material of the external part does not play a special role. This is due to the properties of zinc. Its heating above 419.5°C is dangerous. In this situation, the metal oxidizes, and further chemical reaction leads to the release of toxic fumes. Everything becomes even worse with high humidity, which cannot be avoided when commissioning a gas boiler. Therefore, when purchasing a sandwich structure, pay attention to this.

In principle, you can make a double-circuit chimney yourself without any special skills. To do this, wrap the stainless steel pipe in fire-resistant heat-insulating material. When choosing the latter, you can pay attention to basalt fiber, expanded clay or polyurethane. Then place everything together in a galvanized pipe of larger diameter.

Installation diagram of a steel hood

Features of installing a steel ventilation column:

- The segments are assembled using the “pipe to pipe” method in order, starting from the bottom;

- For the convenience of subsequent cleaning of the post, provide a sufficient number of inspection wells;

- For stability, wall brackets are attached in approximately 150 cm increments;

- When designing, pay attention to the horizontal segments - they cannot be more than 1 meter long unless forced draft is provided.

Stainless steel ventilation duct

Ceramic hood

This type of hood is the most versatile, so it is an ideal option if you plan to switch from or to gas fuel. They are easy to clean, resistant to dirt, due to their high gas density, and to aggressive chemical compounds, so you don’t have to worry about toxic substances getting into your living rooms. And, of course, ceramics are durable.

But there are also disadvantages. Ceramic pipes have high moisture absorption. If you choose them, you will have to provide good external ventilation and equip the structure with condensate drains, otherwise the invested effort and money will not be worth it.

Ceramic alone is not used in chimneys. To make the most of its positive properties, it is combined with mineral wool and stone. Simply put, the ceramic pipe is wrapped in insulating material and then placed in an expanded clay concrete shell.

Structure of a ceramic chimney

Ceramic hood design

Coaxial ventilation structure

When designing ventilation for gas boilers, pay attention to the compact “pipe-in-pipe” design, or, in other words, a coaxial chimney.

Operating principle of a coaxial ventilation system

Components of a coaxial chimney

Coaxial systems, due to their characteristics, are suitable for heat generators with a closed combustion chamber (which is a gas boiler). Oxygen necessary for combustion enters through the outer pipe, and exhaust gases are removed through the inner pipe. This design has its advantages:

- safety (exhaust gases are cooled by cold air circulating in the outer pipe);

- the incoming air heats up and increases the efficiency of the boiler;

- high efficiency means that the coaxial design is more environmentally friendly than others;

- can be used with the appliance in the kitchen (it is located outside the room and does not affect the comfort in it).

Features of installing a coaxial chimney

- You cannot use a horizontal coaxial chimney if you do not plan to install forced draft;

- try to get by with no more than two knees;

- if there are several boilers, create a separate chimney for each; combining them is undesirable.

How to make an exhaust unit

The main difficulty in assembling a smoke exhauster with your own hands is making a balanced impeller; the remaining parts are not difficult for a home craftsman who knows how to weld. If the impeller blades vary in weight, normal fan noise will turn into rumble due to vibration.

In addition to the blades, you will need the following elements:

- electric motor with a power of up to 150 W, maximum shaft speed – 1400 rpm;

- snail or homemade box shown in the drawing;

- a shaft with ventilation holes or an additional cooling impeller;

- studs with M8 nuts and other fasteners;

- power cable.