In an effort to save on heating, many home “do-it-yourselfers” make various devices. A DIY boiler, which can often be seen in a private home, is one such useful device.

There are various varieties of it. If you have the skills to work with a welding machine and metal, you can save significantly on heating installations.

Varieties

Before directly manufacturing a boiler for heating a house, you need to decide on its configuration and type. Depending on the type of coolant heating, boilers are:

- Gas;

- Wood-burning;

- Coal;

- Electrical;

- Pyrolysis;

- Oily;

- Pellet

As for the configuration, it can be anything:

- Round;

- Rectangular;

- Trapezoidal;

- Conical

Budget wood-burning autoclave

Nowadays, one of the popular and cheapest types of boilers for making at home is solid fuel. They are made for cottages or private homes.

But how to make a wood-burning boiler yourself?

You should start by preparing the necessary elements. First of all, take a thick-walled tube with the height of the heating chamber and weld the bolt.

Next, from a sheet of metal, make a circle slightly larger than the cross-section of the pipe. Then drill a slot in it for the required bolt. Connect the tube and screw and tighten the nut tightly.

At the same time, not forgetting that the air duct can be easily covered with metal, so that it is possible to change the size of the connector and adjust the combustion power of the fuel.

The second stage is the manufacture of the body. The top of the gas cylinder is removed and a cylinder of metal sheets is attached. A 15 cm pipe is attached to the side - this is a chimney.

At another stage, a disk is made that dissipates heat. Cut out a smaller circle from sheet metal and attach a handle to the body. Then you need to combine the boiler and casing. At the last stage, steel legs are welded for better air circulation.

How to make a boiler correctly

During the design process, it is necessary to take into account some design features and the principle of its operation. In particular, you need to decide on the purpose of the boiler and what type it will be. The easiest way is to make a solid fuel boiler with your own hands.

Much more difficult, almost impossible, is gas, since it is subject to increased safety requirements. You need to get permission to use it and check it. And - if all the characteristics of the device do not meet the required ones, then the relevant authorities will simply prohibit such a boiler from use.

The efficiency of the boiler is influenced by both the design (coolant capacity), the rate of fuel combustion, and the constant flow of fresh air (oxygen). It should be taken into account that the fuel burns completely and there is a possible outflow of gas, which carries a lot of heat, which must be prevented.

Open and closed chamber

It is advisable to install boiler equipment with a closed chamber or turbocharged devices in rooms that are equipped with a vertical smoke exhaust system. Such units are characterized by the presence of forced draft in the design, so combustion products are removed through a coaxial chimney using an electric fan.

The chimney double pipe allows air masses to be sucked into the combustion chamber through the outer element, and toxic components to be removed through the internal structure.

The process of creating a homemade boiler

Units with an open combustion chamber are distinguished by their operation based on natural draft. In this case, air masses are taken by the system directly from the room, and combustion products are discharged outside using a chimney.

As a rule, a lack of ventilation in open boiler equipment provokes a decrease in the oxygen level inside the room, which is important to remember when choosing the type of combustion chamber. According to experts, the open form is the best option for use in non-residential boiler rooms

It is advisable to install the most safe equipment from the point of view of operation with a closed combustion chamber in residential premises.

Gas boilers of the convection type can be represented by equipment with an open and closed combustion chamber, while condensing units have only a closed type.

Some features

The boiler configuration, its characteristics, drawings will depend on many factors:

- Material. Regular steel (sheet) will do, but heat-resistant stainless steel or cast iron is best.

- Possibility of good processing of steel, reliable connection of structural parts. Usually, a grinder, a gas cutter and electric welding are used for this.

- Type and characteristics of fuel (liquid or solid). Steel must withstand high temperatures, not deform, and not melt under their influence. Withstand internal pressure of vapors and gases without ruptures or cracks.

- Correct calculation of the coolant circulation method. Will it be natural (due to correct manipulation of pipe diameters, their slope, tank height, etc.) or forced (using a pump in the circuit).

- Taking into account vapor pressure, using valves to discharge excess gases and condensate (installation of return lines).

It is important in the process of designing a boiler and including it in the heating circuit to carefully think through everything. What and how will work after assembly.

Making a heating boiler with your own hands is not that difficult. All problems usually begin later, when something is not taken into account or done clumsily.

What you will need

When a project is selected, it is necessary to calculate how much material is required. If the instructions suggest that you need cast iron, do not buy cheaper aluminum, otherwise the device will quickly fail. It is better to purchase a thermostat and deflector ready-made than to make it yourself.

It is important to consider several points when making the device:

- It is advisable to choose a programmable thermostat, so you can set a controlled temperature.

- It is better to install the deflector above the chimney pipe, thereby ensuring exhaust. It may look like an umbrella with a cone. The material is only stainless steel.

- The device must have automation, which includes control over flame, overheating, and draft. The presence of a blast valve is also important.

Manufacturing instructions

When you have everything you need (material and tools), all that remains is to assemble the boiler in the following sequence:

- We take 2 barrels with different diameters, wall thickness of at least 4 mm;

- Use a grinder to cut out holes for the ash pan and water container;

- We install one cylinder of smaller diameter inside the other;

- We weld the lid over them, the ash pan, and the firebox;

- Close the door;

- We weld water pipes, a pipe for a check valve (pressure relief);

- We install a grate inside the oven;

- We make a hole for the chimney;

- Install the pipe;

- We check the tightness.

When there are no leaks in the boiler, it is connected to the heating system and water supply network.

If used oil or antifreeze is used as a coolant, they will be filled in manually. Connections to the water supply system and welding of pipes are not required for this.

After installing the boiler into the heating system with your own hands, you need to check that it is working correctly. A properly assembled device will heat the coolant (water or oil) during the combustion process. If he does this poorly, then you should check for air pockets in the heating network and reduce the vapor pressure by releasing them.

In any case, you need to understand the operating principle of this type of boiler so that there are no excesses or problems during its operation.

DIY fan: how to make a homemade powerful fan. Basic parameters and properties of fans (130 photos)- Why do you need a security alarm, what functions does it perform?

- How to choose winter workwear and not make a mistake - recommendations from the pros

General information

Important: The law prohibits the use and installation of gas equipment without obtaining the appropriate permission from the responsible organization, which will require a certificate of conformity for the device.

You must understand that it will be extremely difficult to obtain this type of document for a homemade device. Minor deviations from the norms will result in a complete ban on the installation of a homemade device.

Types of gas units

Boilers differ in the following parameters:

The number of circuits is single-circuit and double-circuit. Single-circuit units perform only one function, namely heating the water and pipes of the house. The second type heats the house and provides hot water;- method of removing combustion products - having natural draft and with supply draft. For the first option, air is supplied from the street, and for the second, a chimney pipe is required;

- ignition method - electric type, when work occurs, and having a piezoelectric element, in which the device is ignited with one’s own hand;

- depending on the mounting method - wall and floor;

- control method - single-stage and two-stage;

- connection method - to the central gas pipeline or to a gas cylinder;

- according to the material of manufacture - steel, cast iron and copper.

Device principle

The design of the gas unit contains the following elements: burner, heat exchange device, pumping device, expansion tank, automatic system, ventilation device, protective system, temperature measuring device, solenoid valve, air vent.

When the device is turned on, the gas burner ignites, which heats the heat exchanger with water or antifreeze. The action of the pumping device creates excess pressure, due to which there is a continuous circulation of the thermal energy transmitter in the pipes and the release of thermal energy through radiators. Then the cold coolant flows back into the boiler.

Basic operating principles

The design of a water heating system can without a doubt be called one of the most significant developments of the nineteenth century. What is the principle of its operation? When raised up through the pipes, hot water creates a continuous flow. and the vacated space is filled with cold water. The water is constantly moving and constantly heating up. This ensures that all rooms of the house maintain a comfortable temperature for a long time. After all, the water will circulate on its own through the pipes.

Types of heating systems:

- Gravity flow. Water moves through the pipeline on its own

- With forced movement. Water moves under the action of a pump

Systems using forced movement are much more effective compared to the first ones, since in gravity flow systems, passing through the radiator, the water slows down and cools, ceasing to heat the rooms. The flow of water is accelerated by a circulation pump, which is built in to ensure constant movement of water.

Such designs require an electrical connection. Perhaps this is their only drawback, but in all other respects they are the most efficient and economical compared to other types of heating systems.

Internal details

The internal parts of the heating device are cut out according to the pattern using a grinder or drill (in places where it is impossible to cut with an angle grinder). They work according to an algorithm - drilling closely spaced holes along the contour of the part, cutting jumpers with a chisel or small sledgehammer).

When cutting parts, you must strictly observe the dimensions and not deform the sheet of metal. During final assembly there will be alignment problems and gaps that are too large.

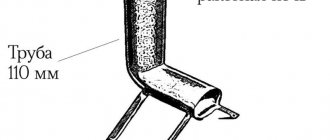

Boiler - general view without chimney

Chimney installation

For the first firebox, a temporary galvanized iron pipe 2-3 meters long is suitable. When installing the boiler at a place of permanent operation, you need to install a more reliable chimney. It is more practical to use pipes made using sandwich technology (50-70 mm of basalt wool is laid between the outer and inner pipes). Application is convenient in that the kit includes the necessary fasteners and additional elements for wiring the chimney through the ceiling, roof; two people are enough for installation.

When wiring a chimney through ceilings or a roof, you need to carefully waterproof the joints, do not forget about fire safety measures - use only non-flammable, heat-resistant materials (steel, mineral wool, silicone sealants, cement).

Assembly phase

Insulation of the house

The degree of insulation of a house or apartment is of significant importance in saving gas. If the building is not insulated, and the doors and windows are ventilated, a significant part of the heat will go outside. The material of the walls of the house also matters. For example, wood and block transmit heat faster than double brickwork.

Good insulation of the ceiling, floor and walls will save a lot of fuel. It is advisable to replace old frames with energy-efficient double-glazed windows, and wooden doors with a more airtight modern analogue. A well-insulated building will save up to 30% on gas.

Particular attention should be paid to insulating the attic and basement, since a lot of heat also escapes through them.

Note! To increase the energy efficiency of your home, you can install reflective screens made of aluminum foil between the radiator and the wall; they will allow you to return some of the heat to the room.

Safety regulations

Always follow safety precautions when using wood burning stoves

Never leave stoves burning for a long time without control, do not forget to clean the ash chamber in a timely manner and add firewood to the firebox. Pay attention to the chimney channel valves. keep them in the open position until you start to light the stove. Use only in the cold season; it is not advisable to use it in summer. Significant overheating can lead to breakdown, and then the stove will have to be repaired

and seriously. High temperatures can cause destruction of the furnace walls. That is why you should avoid excessively high temperatures and using the unit in the warm season

Significant overheating can lead to breakdown, and then the stove will have to be repaired. and seriously. High temperatures can cause destruction of the furnace walls. That is why you should avoid excessively high temperatures and using the unit in the warm season.

Assembling the heating unit

After cutting the parts, assembly and welding are carried out in two stages: the base with the combustion compartment is assembled, and the water jacket with the water pipe system is welded in parallel. At the second stage, the welded parts are combined into one whole and fixed with welding seams. You need to do it with at least two assistants, the weight of the parts is large. Details of the operations are visible in the photo.

Main joints

The assembly of parts, the water jacket, the water pipe system, and the combustion chamber must be done with a semi-automatic welding machine using high-quality wire. Allows you to create an even, high-quality seam. The semi-automatic machine is very convenient to work in narrow, cramped spaces. The seams must be done double.

When connecting parts with double seams, you need to work carefully - there is a high risk of lack of penetration.

Combustion compartment

Fuel burns in the combustion chamber, and the released thermal energy is transferred to water in the surrounding jacket. It is necessary to weld carefully using double seams. A grate is placed at the very bottom of the firebox. You can purchase a firebox ready-made to size and make it yourself. Reinforcement with a thickness of at least 20-30 mm is taken, cut into pieces with a grinder, and welded. In the firebox, the resulting grate is installed on stops made of steel corners welded around the perimeter.

The power depends on the volume of the combustion chamber. For conventional designs - 1-1.5 kW per liter of volume. For pyrolysis (they burn furnace gas released during slow combustion of fuel in an oxygen-poor atmosphere) - 1.5-2.5 kW per liter of furnace volume.

Lower body

In the lower part of the body there is a blower door, an ash pan, a bottom, and supports attached to it. The blower door is cut out with a grinder or drill, hung into the prepared opening of the housing on steel hinges, not forgetting to secure the sealing asbestos cord around the perimeter. In the closed position, the door is held by a latch, any of the designs available to the master.

An ash pan is a box made of sheet steel, which is completely removable through the ash pan, allowing you to quickly clear ash. The supports must be made from sections of thick-walled pipe with a diameter of 5-7 cm and a length of about 3-6 cm. They must be welded efficiently, at an equal distance from the edges of the bottom - the weight of the device will rest on them (including water - at least 250-300 kg).

Blower valve design

The blower valve, called a damper, can be made independently or purchased separately in finished form. When deciding to make it yourself, you need to focus on the dimensions. You will need a steel angle, a rectangular piece of steel, 5-8 mm thick. It is necessary to cut a series of vertical slits in increments of 2-3 cm. The slits are cut in the blower door. The welded corners will hold the gate plate and allow it to be moved in the horizontal plane by 3-5 cm. By changing the size of the slots, it will be possible to regulate the flow of oxygen into the firebox and the intensity of combustion of wood and coal.

Water pipe system