The boiler is a key component of the heating system. The creation of a comfortable temperature in a country cottage or apartment and the efficiency of energy consumption directly depend on the quality of the device’s operation. However, even the most powerful boilers may not cope with their main task - maintaining the required temperature and heating the coolant at a certain speed. The reasons for the decrease in temperature in the boiler room can be very different. This review describes the most common problems of why the boiler may not reach temperature.

Poor quality connection to the gas pipeline

If, during gas flow, the installation was performed poorly, the needle on the pressure gauge may not reach the desired mark.

To conduct gas, a thread is usually welded (especially in cases where workers do not want to connect a large section of the gas pipeline) and a tap is screwed in, resulting in a welded thread with a tap. The tap is opened and a hole is made with a drill. If the drill is of small diameter, and as a rule, the drill is much smaller than the pipe, the hole is obtained with a small throughput.

A sign of poor-quality tapping into the gas pipeline may be a sharp decrease in the flame immediately after the boiler is ignited. The flame may go out completely, or the boiler simply will not begin to gain temperature.

Insufficient pipe diameter or narrowing area

When choosing a pipe diameter, several parameters must be taken into account:

- pressure in the system (with low pressure, larger diameter pipes are needed);

- area of the heated room and boiler power;

- pipe length (a longer system requires pipes with a larger cross-section);

- the number of turns in the system (a large number of turns affects the flow rate of the coolant; in this case, pipes with a reserve diameter are also selected);

- number of consumption points;

- required level of water heating;

- pump parameters.

The diameter of the pipe is determined primarily taking into account special calculations. For this, a special table is used to calculate the pipe capacity. If the boiler is powerful, a large diameter pipe needs to be inserted.

Only a specialist can accurately and accurately determine the cross-sectional diameter of pipes so that the system works properly and as efficiently as possible. However, you can determine the approximate range of the permissible cross-section yourself using simple calculations.

So, based on the average coolant speed of 0.02 km/s, it can be calculated that to ensure a throughput of 30 l/s, a pipe with a diameter of 25 mm will be required, and to provide a throughput of 50 l/s - 32 mm. When calculating depending on the length of the system, for a length of less than 10 meters, pipes with a cross-section of 20 mm are used, for a length of 30 meters - with a cross-section of 25 mm, for a length of 35 or more meters - 32 mm, etc.

Even if the main pipe through which the coolant passes has a suitable diameter, but in some area there is a narrowing, the throughput will decrease throughout the system and this will serve as an obstacle to reaching the desired temperature.

Repair of wall-mounted and turbocharged units

Modern products have a complex design, they are equipped with electronics and a security system. Even in such instances, you can eliminate minor problems yourself.

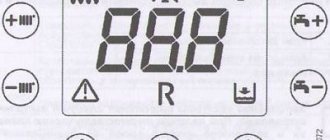

To detect malfunctions, you need to study the instructions for using the device. The technical documentation specifies the error codes that appear on the unit display. The heat generator does not work due to the following symptoms:

- The indicator lights do not light up, the heater does not turn on;

- Automatic ignition does not occur when the device is turned on, in which the display and network notifier are lit;

- Extinguishing occurs after the main burner starts.

In such situations, the voltage supply is immediately checked; if it is supplied to the device, it is necessary to proceed to subsequent repair points. Initially, the front panel of the device is unscrewed and the front cover is removed. The remaining manipulations are performed step by step:

- the fuse box is checked, if a faulty element is present, it is replaced with a new part;

- when the equipment starts, the work process begins;

- if the product turns on and stops working again, then you need to seek help from a technician, since this problem cannot be fixed without professional knowledge.

It is possible to eliminate other signs of device failure by describing the error code. You can deal with such breakdowns yourself:

- A clogged sump can be easily cleaned after disconnecting the generator from the electrical network and turning off the taps;

- Jamming of the rotor or the appearance of airiness affects the operation of the circulation pump. These causes are eliminated by unscrewing the large screw to bleed air and turning the rotor with a screwdriver. When completely dry, the parts are mounted in place;

- Low pressure on the pressure gauge without leaks in the system itself is eliminated by pumping air into the expansion tank;

- If the pressure is low due to a leak, the faulty area should be repaired and water added to the heating system.

Minor breakdowns can be quickly repaired using your own efforts, without the need to call a specialist whose work requires additional financial costs.

When designing your home, you need to take care of the future heating system. After all, the comfort and health of all residents of the house depend on high-quality heating. In order for the heating system to work effectively, you need to select a suitable heating boiler and install it in the system in compliance with all rules and technologies. If the boiler is installed incorrectly, various types of problems may occur in the future. The most common problem is the heating boiler turning on and off frequently. But not everyone knows the possible causes of this problem. Therefore, in our article we will consider the reasons for frequent turning on and off of a gas boiler, as well as ways to eliminate them.

Incorrect boiler gas valve setting

Settings can be made on any gas valve. Errors in the settings include setting the output pressure below the permissible norm for your system according to the regulations. If the valve is set incorrectly, the boiler will not operate at full capacity. Accordingly, it will not be able to reach the desired temperature. The valve adjustment is usually done by the boiler installer.

Problems with closed-type turbocharged equipment

Sometimes when installing a new chimneyless apparatus, the flame periodically goes out. In this case, you need to check the components and parts. The problem is detected by the following factors:

ignition of the igniter is accompanied by periodic attenuation - this indicates a failure of the thermocouple, which affects the operation of the valve. It is produced in the form of a copper tube with a bimetallic piece at the end. When different metals come into contact, the voltage increases to 20-45 W. This problem keeps the gas valve open. The thermocouple must be replaced with a new one; it cannot be repaired;

- breakdown or clogging of the traction sensor - the flat part is combined with the fuel valve. When the leading contacts are closed and the burner is ignited, a fire occurs - this indicates the need to replace the sensor. Oxidized areas of contacts can be cleaned with sandpaper with fine abrasives;

- if the circulation pump malfunctions, it is necessary to carry out a complete diagnosis of the unit and replace it;

- A yellow flame is due to the fact that the jet is clogged. You can clean it if you have experience working with gas appliances.

Most of the reasons can be eliminated with your own hands, however, this will require some knowledge and a lot of time.

Heat exchanger fouled by soot

During long-term operation of the boiler, combustion products are deposited on the surface of a plate, bithermal or fire-tube heat exchanger. Due to the layer of soot, the fire ceases to be in direct contact with the walls of the combustion chamber, heat transfer from the source decreases, the boiler does not heat up as efficiently and does not reach the desired temperature.

To solve this problem, you need to clean the heat exchanger. Considering that soot settles on the walls along with resin, tar and ash, cleaning the combustion chamber after it has completely cooled is not so easy. For quick and effective cleaning, you can contact specialists. Professionals use special equipment to remove soot:

- the “Streamer” complex (electric discharge method) is an effective procedure that allows you to remove a fairly thick layer of combustion products without damaging the heat exchanger;

- use of a high-pressure pump (hydrodynamic method) - quick removal of small deposits, the combustion chamber does not even need to be removed;

- booster for chemical washing. This method is effective if the heat exchanger is very dirty, and the deposit of soot and tar is old and cannot be removed in any other way. The disadvantage of this option is the risk of reducing the service life of the combustion chamber.

All these methods involve additional expenses. To remove combustion products yourself, you can use one of the common methods offered by experienced professionals. For example, heat the surface of the chamber using a hair dryer and use a regular spatula to remove soot.

How to avoid the problem and fix it quickly?

Reliable operation of the boiler begins with its selection and installation. It is important to determine which boiler is right for you, what fuel you will be comfortable using, and what power is required. And only after that order it, deliver it to the site, install it and do the strapping.

offers customers installation, repair and maintenance of heating boilers in Kaluga and the region. If you see that the equipment does not reach or maintain the set temperature, contact Profteplo. We will arrive on site, diagnose and fix the problem as quickly as possible. We work with all types and models of boiler equipment. If you have questions and need preliminary consultation, call +7 (4842) 75 02 04.

Scale deposits inside the heat exchanger

The heat exchanger can be clogged not only with combustion products, but also with scale and limescale that forms with each portion of water entering the boiler. Scale is formed as a result of heating hard water.

Inside the heat exchanger, solid deposits of salts turn into a kind of insulator, reducing heat transfer from heating. The larger the scale layer in the heat exchanger, the worse the heat transfer from fire to water will be, because heat will not be able to penetrate a thick layer of solid deposits. This significantly reduces the energy efficiency of the entire system and the boiler stops reaching the desired temperature.

To remove scale, the heat exchanger must be removed and descaled using a special acid. As a preventative measure, it is recommended to maintain the operating temperature in the boiler.

Traditional methods for descaling include the use of ordinary table vinegar (3-10% acetic acid solution). Table vinegar is poured in equal parts with water, the solution is left to interact with the scale overnight. Cationation and reverse osmosis methods are also used.

Mismatch between the volume of water and the power of the boiler used

The volume of coolant must correspond to the speed at which the boiler heats the water. Otherwise, by the time the water passed through the pipes returns in a cooled state, the boiler will not have time to warm up the entire volume that is in the system.

For example, a volume of water of 300 liters for a heating system does not correspond to the power capabilities of an 8-kilowatt boiler. Such a boiler will not turn off, it will work continuously, but will not be able to reach the required temperature.

Incorrectly selected boiler power

The next reason for insufficient temperature rise is the opposite of the previous one. This is the case when the volume of water is calculated correctly, but the boiler power does not match.

The volume of water generally depends on the number and volume of all heating devices and pipe circuits installed in the system, additional buffer tanks, separators, etc. If, based on the volume of coolant, the boiler has insufficient power, as in the previous described situation, the boiler will not have time to warm up this entire volume.

Too much draft in the chimney

Increased draft occurs in tall, insulated chimneys with good supply ventilation. The optimal air exchange rate in the boiler room is three, i.e. The air is changed three times within an hour. With increased draft, the air in the boiler room changes up to 10-15 times. In this case, the flame does not burn, but is literally blown away with a gust of air. Thus, the boiler does not heat the coolant to the required temperature.

You can adjust the draft by using a damper, but not all old models of floor-standing boilers have dampers in the chimney to regulate draft, which cannot be said about modern devices. Manufacturers are constantly modernizing boilers, and new models have built-in draft regulators. Despite the fact that this reason is less common, experts still recommend that when choosing equipment, pay attention to the presence of an option for adjusting traction.

Operating rules

In order for a solid fuel boiler to operate safely and efficiently, you should follow some simple rules when operating it:

- Install only on fireproof materials. A metal sheet with a thickness of 0.6-1 mm with a backing of asbestos or basalt cardboard with a thickness of at least 3 mm should be laid under the base of the device. Moreover, the metal sheet should be located not only under the device itself, but also protrude from the front side by 0.5 m.

- Do not use flammable liquids for kindling.

- Before ignition, ventilate the firebox for 10-15 minutes.

- Keep the firebox doors tightly closed during operation.

- Do not leave unattended for a long time.

- Carry out periodic cleaning of chimneys.

- At the end of the heating season, lubricate the moving parts of the device mechanisms with graphite lubricant.

The occurrence of leaks in systems with automatic make-up

This reason applies to powerful industrial boiler houses or private systems with automatic make-up. Automatic replenishment is a kind of fuse that comes into action when the pressure in the system drops. When there is a water leak (for example, when a pipe breaks underground), the automatic system begins to constantly add more and more water. If there is an intense leak, the volume of water will increase significantly, and the boiler will not be able to reach the desired temperature. At the same time, due to the constant flow of cold water into the boiler, the device will not turn off.

Siberia model range

Household heating equipment produced under the Siberia brand has a wide range of models. Today the company offers its consumers the following boilers:

- Floor standing boilers with steel heat exchanger. Reliable dual-circuit device with an atmospheric burner.

- Single-circuit units with a cast iron heat exchanger of increased power. Ideal for heating a large country house. Some models can be equipped with an indirect heating boiler.

- Wall-mounted models are compact and high-performance.

Let's look at the technical characteristics and design features of Siberia boilers in more detail.

Floor equipment

Siberia floor-standing boilers are available in two types:

- With steel heat exchanger.

- With cast iron heat exchanger.

Models with a steel heat exchanger have an additional copper circuit for connection to the hot water supply system. The automatic control unit (SIT) includes:

- magnetic valve;

- modulation thermostat;

- pressure stabilizer and gas filter;

- thermoelectric device with piezo ignition and flame control sensor.

The advantageous characteristics and design features of these Siberia units are the following:

- Optimal dimensions and modern design.

- Ease of automation control.

- Wide range of powers from 11 to 35 kW.

- High efficiency – 90%.

For uninterrupted heating of a private home, the Siberia single-circuit boiler with a cast iron heat exchanger is ideal. If there is a heating system with natural circulation, this gas appliance is able to provide heat even when the electricity is turned off.

Increased reliability, simplicity of design and control make such boilers the best option for the Russian outback, where there are problems with electricity and pressure in the gas main. Here are some technical characteristics and advantageous features of units in this series:

- Increased power (from 16 to 50 kW) is suitable for heating areas up to 500 m2.

- The modern stylish design allows the massive device to look organically in any room.

- Quiet operation.

- High efficiency.

- Durability of the heat exchanger, as well as other parts and components of the boiler S

Wall-mounted devices

The Siberia wall-mounted double-circuit boiler is in high demand among consumers due to its functionality, practicality and reliability. Thanks to its compact dimensions, closed combustion chamber and coaxial chimney, installation of this heating device is possible even in small rooms.

Let's look at the main technical characteristics and advantages of Siberia wall-mounted boilers:

- Copper bithermic heat exchanger Gianoni.

- Polidoro gas burner made of alloy steel.

- Automation based on a Honeywell electronic board produces smooth modulation of the flame on the burner, which allows for rational consumption of energy.

- This boiler is equipped with a modern anti-freeze function for the heating system.

- Liquid crystal display, which displays current information about the state of the unit and error codes in the event of a malfunction or malfunction of the system.

As you can see, the Rostovgazoapparat company produces modern, reliable Siberia gas appliances, suitable for heating small apartments and country cottages. A dual-circuit unit will allow you not to worry about the availability of hot water for domestic needs. The high quality, simplicity and reliability of equipment from this brand are deservedly appreciated by consumers.