When noises occur

The new boiler operates almost silently, no louder than a household kettle. But sometimes, over time, if the components are incorrectly installed, configured or worn out, the device beeps quietly or even makes noise like an airplane.

Loud noises in the heating boiler disturb users; the reasons may be the following:

- The water in the system is highly oxygenated. When heated, air bubbles are released which produce noise. This happens most often in open heating systems. At the same time, not only the device itself vibrates, but also the wall radiators.

- The boiler puffs if a lot of air has accumulated in the coolant system.

- Scale in the heat exchanger. If the water is hard, over time lime will build up on the walls of the radiator pipes.

This also reduces equipment durability and efficiency. A sign of scale accumulation is that the device hisses like a kettle when it warms up.

- Strong noise can be produced by an incorrectly operating fan designed to remove combustion products. This can be caused by drying out of the lubricant inside its bearings, imbalance, or accumulation of dust and dirt on and around the blades.

- Perhaps it is not configured correctly, and that is why the gas valve or bypass is howling.

Bypass installation example - When operating at high power, a faulty gas meter rattles.

- If the equipment power exceeds the required, vibration occurs from excess pressure created by the pump. The device also cracks if there is too little coolant in the system.

- Often a loose valve or a valve inside it rattles.

Reasons why gas equipment makes extraneous noise

If a gas boiler is humming, this indicates a malfunction in its normal operation. The reasons may be various, from installation errors to scale formation. The sooner the problem is identified, the faster it will be fixed. Operating problematic equipment can be dangerous. Problems can occur in any part of the unit. Therefore, it is necessary to analyze not only the nature of the sound, but also its source. This will allow you to quickly and accurately identify a possible malfunction.

Exhaust fan malfunction

Some models are equipped with fans. As a rule, these are units with a closed chamber.

While rotating, fans may begin to make noise due to:

- lack of fan lubrication. High temperatures cause the lubricant to dry out quickly. This negatively affects the condition of the bearings, which simply fail;

- dirt deposits. Dust impairs the performance of equipment. Therefore, it is necessary to periodically clean the fan.

The appearance of scale in the heat exchanger sections

The water contains a lot of salts, which cause scale to form on the surface of the equipment.

There will be a hissing sound when heated. The heating itself proceeds more slowly than usual. Therefore, the radiator needs annual cleaning. Indeed, in this part the water moves slower than in the water supply pipes, which leads to increased sedimentation of salts.

Strong water pressure is often sufficient for flushing. In difficult cases, chemical reagents are used. This is an extreme case, because chemicals can provoke the formation of cracks in the radiator that were previously clogged with scale.

Low gas pressure

The pressure in the device may decrease for the following reasons:

- There is a water leak in the appliance.

- The boiler was installed or configured incorrectly.

- Defects in the expansion tank of the device.

- The characteristics of the boiler do not correspond to the load that is placed on it.

Low pressure causes loud sounds when equipment operates. If a malfunction is detected, it is recommended to inspect the device for leaks. Particular attention is paid to the joint area. It is convenient to carry out inspection using a napkin. If any holes are found, they must be closed.

It is worth noting that when the pressure decreases, the equipment automatically stops working. Gas pressure is affected by water pressure. When one indicator decreases, the second decreases to its minimum level immediately. The boiler switches off automatically.

It is recommended to find out the optimal indicators in order to periodically check the condition of the gas apparatus.

Lack of water in the system

It was noted that water and gas levels influence each other. If one indicator decreases, the second automatically also decreases. The reason for the deterioration in water pressure levels may lie in air jams. Because of this, the amount of incoming water decreases. The air creates obstacles to the normal circulation of liquid.

A lack of liquid is dangerous because it causes overheating of the boiler. Therefore, clicks are heard when it operates. Such airing provokes a decrease in the thermal output of the device, reduces or blocks the circulation of the coolant.

The following factors can lead to such consequences:

- depressurization that occurred during repairs on risers;

- there was a violation of the integrity of the system;

- Carrying out preventive maintenance to replace devices and their elements.

If a gas boiler whistles in a private house, then this is the first sign of air pockets in the system.

To resolve the problem, it is recommended to adjust the thermostat. You should also make sure that it is installed correctly. You can add water yourself or adjust its supply in the heating system. Many boilers are equipped with a special lever in case of low water pressure.

Airing in the system

When the heating boiler clicks, the problem may be the formation of a large amount of air in the system. This problem is especially relevant if there has been a long break in the operation of the device.

When a gas boiler knocks during operation, it is necessary to bleed off excess air. Modern models are equipped with special taps. They are unscrewed and the air is released. First, be sure to install a bucket into which the water will drain. It is important to act carefully. After the air is released, the valve is screwed back on. After this, the knocking noise during operation should stop.

Boiler settings are incorrect

The boiler is making a loud noise due to incorrect equipment settings. The equipment literally howls when such a malfunction occurs. Errors in settings can cause incorrect load distribution, which will only damage the equipment.

If the gas appliance operates at high power, it may rattle. This signals that the device has exceeded its standard performance. If vibration is felt, it means the circulation pump is noisy and the problem is excess pressure.

When the boiler, when heating, makes sounds similar to metal hitting metal, this indicates that the hanging brackets located on the radiator are installed incorrectly. As a result, uncompensated expansion of the bodies occurs.

If the gas boiler is humming, it is recommended to check whether its settings are correct. Pre-study the equipment configuration. This will allow you to find out what indicators should be set for normal operation of the device. If necessary, the pump power is reduced, the location of the ignition electrodes is adjusted, and they are cleaned.

It is due to problems with ignition that the boiler makes a loud bang when hot water is turned on.

Reasons for the formation of sounds and pops

Sharp sounds and pops have the following causes:

Semi-automatic boiler wick

Why does the speaker crack and click?

Clicking and crackling noises are another common malfunction of gas instantaneous water heating equipment. Failure occurs in both automatic and semi-automatic boilers. Below is the nature of the sounds and what exactly can cause them:

- The gas heater clicks, but does not ignite - the contacts on the ignition unit have oxidized. The module cannot be disassembled and requires replacement. The catalyst for the geyser crackling but not igniting can be dead batteries.

- The gas water heater clicks after turning off the water - the “frog” water regulator has failed. Inside the block there is a rod with legs connected to the ignition block. After turning off the water, the metal rod should be returned to its original position by a spring. If the rod is rusty, it may jam. The ignition unit remains switched on and continues to produce a spark. For this reason, the speaker crackles after switching on. The malfunction can be caused by a coarsened frog membrane - it needs to be replaced.

- The piezoelectric element is constantly cracking - the contacts have oxidized, which leads to jamming and stable operation.

Noise in the column is caused by insufficient draft (the flame burns with a hum, changes color, soot is present), poor air circulation (observed after installing metal-plastic windows in the kitchen), clogging of the burner ignition wick or scale build-up on the heat exchanger. The malfunction is found by elimination during the next maintenance of the column.

Why does the gas boiler hum and/or whistle?

There are times when the boiler interferes with the noise it makes. When the burner operates, it makes a noise similar to that of a jet plane. The gas boiler is noisy and can be heard throughout the house. It naturally interferes with sleep, especially when it turns on after a pause. How to reduce the noise made by a gas boiler?

Usually, it is not the boiler or the fan installed in it that makes noise, but not the correct installation of the chimney. To make the boiler start to make a noisy sound, you just need to narrow the chimney a little, and you will get a sound like at the airport. The solution is to change or expand the chimney.

There are very frequent cases when gas equipment with pressurized burners begins to hum. The fact is that fan units are equipped with a stabilization system aimed at regulating the gas pressure supplied to the combustion chamber. When operating, such a boiler hums like a vacuum cleaner. To reduce unpleasant humming to a minimum, it is better to build the boiler room building away from a residential building and provide good sound insulation for it.

The boiler may begin to hum due to a thick layer of deposits on the inside of the heat exchanger tube. The boiler begins to boil - it makes a sound like the sound of water in a boiling kettle. The primary heat exchanger is clogged. You can check this in the following way: set the boiler to the maximum temperature and close the return or supply valve so that there is minimal water flow. When the temperature reaches about 80 degrees, the hum increases. The only way to solve the problem is to clean the heat exchanger.

Shock-absorbing lining - what is it?

The shock-absorbing lining is a rubber sheet 10-12 mm thick or rubber washers of the same thickness. To reduce noise, all connections must be sealed and rigid, the chimney must be additionally insulated with thermal insulation (basalt mineral wool, etc.)

It happens that when you press the ignition button, a whistle is heard from the pilot burner nozzle. If air appears in the gas pipeline or gas fittings, it is necessary to unscrew the nut at the junction of the gas tube to the gas fittings, press the ignition button, having first loosened the pipe, bleed out the air until the smell of gas appears. Tighten the nut.

If there is a flame separation, the pilot burner gas pressure should be adjusted using the adjusting screw. There are times when the wrong nozzle is installed, then it just needs to be replaced. This situation occurs in domestic units. The injector may also have a manufacturing defect, expressed in the absence of a chamfer along the edges of the holes. When switching to high intensity mode, the gas flow escapes and the boiler begins to whistle. The only solution in this case is to replace the nozzle.

We should not forget that gas boilers are explosive, so to fix problems it is better to contact specialists by phone.

How to avoid noise

It is important to turn off the gas before making any repairs. If you suddenly feel that you smell of gas, immediately turn off the tap at the entrance to the house, turn off electrical appliances, ventilate and call the gas service.

During installation, you can install an elastic vibration-absorbing layer under the casing in all places where the boiler comes into contact with the wall.

Boiler cleaning

First of all, it is important to carry out regular maintenance of heating equipment, which includes cleaning components, removing dust and lubricating some elements. This will increase the lifespan of your boiler and eliminate noise before it even occurs.

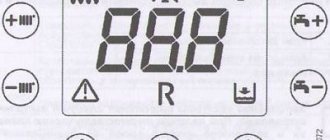

In a closed system, you need to add water from time to time, monitoring the pressure gauge. In some devices, for example, Visman Vitopend, it is displayed on the control panel at the bottom of the case.

Let's figure out what to do when the device is already making strange sounds:

- If the cause is oxygen saturation of the water, the problem can be solved by converting the open system to a closed one. To do this, air vents are installed on the water heating boiler and the expansion tank is replaced with a membrane one.

- The fan should be inspected and cleaned. It is important to note that the main blades are located inside the housing under the casing. After cleaning the dust and dirt, additionally lubricate its bearings. If this does not help, the cooler needs to be replaced.

- When the heat exchanger howls, you need to clean the scale inside it. In order to remove it, the casing is removed and the pipes connected to it are unscrewed. It is best to pour a special anti-scale chemical inside, which is sold in hardware stores, and leave it for several hours. If removing the heat exchanger is too difficult, the product is poured inside using a flexible hose.

- If the gas valve whistles, you need to check its settings. The correct configuration is written in the operating instructions.

Automatic gas valve - When the pump power exceeds the need of the system, it is necessary to reduce its speed by changing the position of the white switch under the cover on the terminal block.

- Air from the heating system is discharged through a brass air vent on the front panel of the device.

- If there is a popping noise when igniting in semi-automatic models with piezo ignition, such as Bosch W, clean the nozzle and pilot tube, which is ignited by the starter, from dust and clogging.

- When an automatic boiler, for example Ariston Genius, turns on with a loud bang, you should clean the ignition electrodes and, if necessary, adjust their location. After this, the fire will proceed quietly.

- Noise from valves can be prevented by replacing them with ball valves or installing an additional rubber gasket.

- To get rid of the fact that the gas meter is clicking, you need to call the gas service to check it. Most likely, you will have to replace the device.

- In order to eliminate metallic knocking when the temperature of the radiators changes, you should move the wall mounts to places that coincide with their support points. Putting rubber gaskets on the brackets also solves the problem.

- When heating pipes built into the wall ring, you need to lay a special insulating material called Merelon around them. It is advisable to think about this at the time of installation, so as not to spoil the repair later.

If it is difficult to localize the sound, let the boiler operate in different modes. For example, if you have a double-circuit device, for example Ferroli Atlas, and you don’t understand what and why it’s humming, turn off the hot water supply. Next, note at what time interval the extraneous sound appears, when the boiler is just starting up or at high temperatures, after it overheats.

What can cause clicking noises?

If the gas boiler clicks, you need to try to find the reason. If the equipment is used incorrectly, it becomes dangerous. Therefore, if extraneous sounds appear, it is necessary to carry out diagnostics, identify the source of the sound and eliminate the defect yourself or with the help of a specialist.

Burner installed incorrectly

If the burner is ringing, the reason may be hidden in incorrect installation.

To ensure that the part is in good condition, it is recommended to check the pressure level of the gas exiting the burner.

You can find out the required indicators in the instructions for the device. If they do not meet the standards, the burner must be adjusted.

The appliance is noisy when heating water

Noise may appear when the water is heating up. This situation can be caused by incorrect installation or configuration of equipment. Therefore, you should check whether the device’s performance meets the standards specified in the instructions for the device.

Worn parts can lead to these problems when heated. Then it is necessary to replace the failed elements. Sometimes when water is heated, noise occurs due to high oxygen content. Because of this, as the temperature rises and the liquid heats up, bubbles begin to appear. Which leads to the appearance of various unusual sounds and vibrations of the boiler.

Excess pressure in the heating pump

A pump is necessary to create high pressure in the device. Therefore, if it fails, its operation must be adjusted. Increasing system pressure can cause a dangerous situation. If the water level drops, this will cause the equipment to overheat. The thermostat needs to be adjusted. In some situations, they add water to the device themselves.

If the boiler makes sounds similar to howling, the problem may be hidden in the settings of the gas valve.

It is necessary to adjust it and check the jumpers. The increase in power is related to the gas meter. The valve may also wear out. This results in loud noises when the equipment operates. The valve needs to be changed immediately. If the noise does not decrease after this, then ball valves are installed in place of the valves. Additionally, it is recommended to equip the device with a rubber gasket. When these measures do not help, the cooler is replaced.

Causes of noise

There are actually not so many reasons for knocking in heating pipes when heating. Some noise can be ignored - it does not harm the system or heating devices. But noises such as buzzing, crackling, knocking, gurgling, and howling should give reason to think and take urgent action.

- air pockets in the system;

- clogging or overgrowing of pipes due to poor-quality coolant;

- leaks in the pipeline;

- violation of installation work when installing taps, valves and laying pipes;

- failure or wear of working equipment;

- cavitation, an increase in pressure in places where the diameter of pipes increases (decreases);

- incorrect calculation or non-compliance with design recommendations when installing the heating system.

These circumstances arise in private closed-loop systems and make us think about their urgent elimination.

The circulation pump in the heating circuit system promotes forced movement of water, which leads to uniform heating and displacement of accumulated air from the system.

If the heating in a house or apartment is connected to a central pipeline, then startup, accompanied by similar sounds, is normal. Water, filling the general system, pushes out air, and, flowing along the contour, is accompanied by gurgling, knocking and crackling sounds.

As soon as the equipment enters operating mode, the general adjustment of the system will end - the temperature of the batteries will increase, and everything will stop. This is clearly visible in the diagram of heat supply to consumers from the central boiler house.

Why there is noise in batteries and how to eliminate it

If a knocking sound is heard in the heating boiler during heating, after which it is repeated in other areas of the circulation ring, including heating radiators, the following should be done:

- On the supply and return lines, in places where removable threaded fittings are installed, filter meshes should be installed that will trap scale, limescale that has peeled off from the walls of the boiler, and other solid impurities. When suspensions and lime deposits circulate along the circuit, solid particles can hit the metal, which causes knocking. Filter pads should also be inspected and cleaned before each heating season.

- If you tap bimetallic or cast iron heating devices with a hard object, you can hear an echo in certain areas. This indicates the presence of an air lock in the system, due to which the gas boiler knocks when heating water. Excess atmospheric air accumulated in the system can be easily removed using Mayevsky taps or through automatic air vents mounted at all upper points of the system and at the bends of the circulation circuit.

- When the consumer cannot find the reason why the gas boiler is knocking, and this sound spreads to the heating radiators, attention should be paid to the circuit diagram of the network. If it is converted from open to closed, with the installation of a membrane tank, the water will no longer be saturated with oxygen. This will help avoid unpleasant sound effects when boiler equipment is operating.

When there is a crackling noise in a gas boiler, the cause may be hidden in one of the 3 cases described above. After minor modifications, this problem will disappear, which will allow you to operate the equipment in normal mode.

Types of noise in pipes

The noises that accompany the general heating start-up differ from emergency ones - they are intermittent and are accompanied by gurgling or gurgling. In bimetallic or aluminum batteries, a crackling or buzzing noise may be heard - this is also normal.

It is clear that prolonged noise is unpleasant, so it is necessary to prevent the situation in a timely manner.

The knocking and hum that occurs in the room with increasing force give reason to be wary and take drastic measures:

- Check heating devices and temperature conditions in the circuit. If a pump is installed, then its operation.

- Pay attention to the valves - if they break, a characteristic whistle appears. Sometimes a small adjustment is all it takes to get the equipment working.

- Having discovered visible problems, you need to stop the coolant and turn off the heating devices. Having assessed the breakdown, proceed to eliminate the accident yourself or invite a specialist.

These are primary measures that can prevent the development of major destruction.

Knocking in boilers and pumps

Boiler equipment used to equip heating systems can operate on various types of gaseous, liquid or solid fuel, or also on electricity. However, the operation of boilers of any type may be accompanied by certain side processes, which often affect the heating system and can cause noise in it.

In particular, wood or coal solid fuel can lead to clogging of the chimney with a decrease in draft force. The operation of boiler houses using liquid diesel fuel may be accompanied by incomplete combustion and accumulation of soot. All this often leads to noise and humming in heating communications, and requires measures to eliminate these problems.

Noise may also appear due to malfunctions of pumps, valves or other devices and mechanisms located in the boiler room or basement. The solution to the problem in such situations is to repair faulty elements or replace them.

In general, any specific situation with the occurrence of noise in the heating system requires an individual approach, and there cannot be universal methods here. In some cases, identifying and eliminating faults on your own can be very difficult, and in this situation, the only way out of the situation is to contact qualified specialists.

Sounds from heating devices

If you hear a howl in the middle of the night, then most likely the system has leaked. A cloud of steam and a characteristic whistle will immediately indicate a gust or a failed valve. In some cases, it is enough to close the tap to bring the heating system into working condition.

If no obvious causes are found, and the howling is accompanied by a crackling sound, it is necessary to check the pressure. Perhaps the flying scale blocked the free flow of the coolant, which caused increased pressure - it is urgent to stop the boiler, drain the water and look for the problem.

It happens that the batteries start to “shoot” - this is another reason to be wary. Such noise is typical for bimetallic batteries when the pressure in the system does not coincide with the calculated one.

When purchasing heating appliances, you need to take into account the operating parameters of the boiler and select the appropriate radiator. Otherwise, the problem may result in a rupture of the heating device due to water hammer, which is completely inappropriate in the winter cold.

Heated water is not able to compress; it needs to move freely along the contour. Banal deposits in pipes can provoke an increase in pressure and rupture of pipes due to water hammer.

Another reason is an air lock, which can be eliminated through the Mayevsky drain valves located at the ends of the batteries. The procedure is simple, and anyone can handle it.

Causes of humming and whistling in heating system pipes

Whistling or humming in heating pipes is quite common, and among the main factors for their occurrence are the following:

- leaks in the heating system;

- the appearance of narrowings in the lumen of the pipes, interfering with normal water circulation;

- the use in some apartments or premises of a residential building of pipes of a smaller diameter than in the rest of the heating communications.

If the reason for the humming pipes is unclear, you should first find out if there are any leaks in the heating system. For this purpose, it is necessary to inspect all apartments and rooms in the house, but if a water leak is not found in them, then also the basement, in which the main plumbing and heating structures are usually located.

Most often, leaks form in fistulas of heating pipeline structures or in valve connections. If such a leak does occur, it is usually not difficult to detect it with careful examination: as a rule, a small stream of water flows from the problem area and a small cloud of hot steam comes out. A stream of water can be detected at some distance from the leak site, and the hum of pipes can sometimes spread over quite significant distances.

If a careful audit reveals that there are no leaks in the system, then another likely cause is a decrease in the flow of pipes in a certain area. The location of this defect is determined by ear by examining the entire heating system. The identified problem area must be replaced. In any case, to repair and restore the damaged area, it would be correct to call a plumber, since this task may not be possible for a non-specialist.

Pump noise

A common cause of problems is pump operation. Typically, it has three positions to raise the water column to a certain height, which depends on the power of the device. The uniform movement of the coolant along the thermal circuit is not accompanied by noise effects.

If you hear strange sounds that sound more like mechanical sounds, you should check the operation of the pump.

In case of failure:

- water gurgles in the heating pipes of a private house;

- a hum appears;

- cracking is possible;

- The boiler begins to make noise and knock.

In this case, you need to turn off the pump, and if the sounds stop, then the cause has been found. Cracking and noise are mechanical damage: this means that the graphite sliding bearings have worn out or dirt has gotten into the housing.

Scale settles on the inner walls of the pump due to poor-quality coolant and has a destructive effect on its components.

Checking is simple:

- it is enough to remove the pump;

- lower its working part into a container of water;

- when turned on, it must pump water; if this does not happen, it must be repaired.

Important! The pump cannot be turned on without water.

Fan problems

This unit is installed in models with a closed chamber and forced removal of combustion products. If everything is in order, the noise level is minimal, the fan may hum, but does not create discomfort. In the event of any malfunction, normal operation is disrupted and extraneous noise appears - from clicks or hums to knocking or loud crackling. Most often the culprit is:

- Manufacturing defects.

When new equipment develops a problem, it is most often due to a warped housing, a rusty bearing, or poor build quality. In this case, it is best to repair the unit under warranty; you should not do this yourself.

- Bearing wear or loss of lubricant properties.

Over many years of work, wear may appear on the elements. At first, there is usually a hum, then a crackling sound, and if the problem starts, the bearing will simply jam and the automation will constantly turn off the heating boiler, since combustion products will not be removed. If the outer protection of the race is damaged, the life of the bearing will be greatly reduced, as dust and dirt will begin to get inside.

- The housing is dirty or foreign elements have entered the fan.

. Because of this, the load on the drive increases, and when rotating, the parts cling to each other, producing extraneous sounds.

- Deformation of one or more parts

. Over time, the fan housing or blades may become unstable due to changes in temperature and humidity. When rotating, the elements will cling to each other and make loud noise or crackle. Another option is cracking of the plastic due to long-term use.

Regardless of the nature of the problem, the work to fix it is approximately the same and consists of the following steps:

- Turn off the equipment

, remove the housing and inspect the fan installation location. You can read the instructions to figure out how to dismantle it.

- Remove the fan

being careful. Sometimes other components must be removed to gain access.

- Inspect for damage

, rotating and shaking the drive, wear and play will not be difficult to detect without special equipment.

- In some models, the bearing can be replaced, but most often the option with replacing the entire assembly

. Be sure to use the same node that was installed.

To more accurately determine the source of the noise, you can remove the housing and turn on the heating boiler for a short time. This is safe, but you can understand exactly where the knocking or cracking is coming from.

Extraneous sounds in the heating boiler

Sometimes the heating of the boiler is also accompanied by some sounds. When cold equipment heats up and begins to crack, the characteristic clicks should not cause panic - metal makes such sounds when it warms up.

Gurgling and gurgling are also possible - this is also a normal phenomenon: the coolant began to heat up and set the system in motion. However, the same sounds can occur if there is insufficient coolant in the pipes. In this situation, it is enough to add water to ensure uniform heating.

Cotton

You can hear such sounds if the gas outlet pipes are clogged. This happens when the boiler is ignited: the accumulated gas, without having time to escape, creates a bang. This is dangerous, as a sudden burst of flame can cause burns or fire.

If the boiler is gas, then the reasons for such noise are clogged nozzles or a malfunction of the three-way valve. In this situation, it is necessary to clean the equipment from soot.

The occurrence of a knocking sound in the boiler indicates its incorrect installation or unregulated operation of the pumping equipment. If the pump operates unevenly, moving the coolant in jerks, resonance occurs between the boiler and the pump, accompanied by a characteristic knocking sound. In this case, it is necessary to regulate the operation of the pump.

Sounds in different boiler models

Noise can occur for a trivial reason, which lies in the boiler model itself. This is typical for gas boilers equipped with ventilation burners. To avoid such trouble, you need to choose boilers with atmospheric burners and an electronic control system.

When choosing a solid fuel or electric boiler model for heating your home, you should always familiarize yourself with the technical characteristics of the equipment. Often the cause of noise can be incorrectly selected equipment, as well as the presence of a fan in the boiler.

Double-circuit boilers also suffer from noisy operation: although not obvious, water overflows and filling of the system are always accompanied by sounds.

When the boiler is turned on, a popping sound is heard

If, when you turn on the gas boiler, you hear extraneous noises: pops, clicks, knocks, you should immediately start looking for the problem.

The three-way valve is the main component of a double-circuit gas boiler. Its task is to regulate the redistribution of flows when the hot water supply is turned on. If the cause of extraneous noise lies in the valve, it is faulty and the part needs to be replaced

What to do if the gas boiler slams sharply when turned on:

- Three-way valve malfunction. This device sends water in a small circle when drawing sanitary water from taps. If it clicks, it needs to be replaced.

- Prolonged spark ignition. When ignited, the resulting excess gas flares up and a characteristic pop is heard. In this case, it is recommended to check the igniter, burner, electrode, and all contacts.

- The chimney or filter is clogged. In this case, they need to be cleaned. The chimney is checked with a lit match. If the flame deviates, everything is fine; if there is no draft, cleaning is required.

- Installation error. If the equipment is installed incorrectly, but when heated, the metal is deformed and popping sounds are heard. The same sound occurs when it cools as the metal returns to its original position. When switching to hot water supply, the boiler hums. The problem is solved by reinstalling the gas boiler.

- The injectors are clogged. A thin wire is used to clean them. You must first turn off the gas.

If the boiler vibrates during operation, it is recommended to place a gasket under the body.

How to remove an air lock with your own hands

Air in the system after a long stop is common. This problem arises not only in the private sector, but also in apartment buildings. It's quite easy to solve.

Heating radiators are equipped with Mayevsky taps located at the ends of the radiators. This could be a valve or a fitting with a notch for a screwdriver.

- armed with a small container (for draining water), you need to unscrew the tap and let out the air;

- Actions should be performed carefully so as not to get burned by the escaping steam;

- when water comes out of the hole, close the valve;

- Such manipulations are carried out on each battery.

This eliminates noise and allows the coolant to move freely through the system, evenly releasing heat.

What to do if water boils in the batteries

You can often hear sounds such as gurgling water, even intense seething. As a rule, this is due to the presence of so-called air locks. They are looking for a way out - as a result of which the water in the system can boil. Moreover, this not only leads to discomfort, but also to the fact that the efficiency of the coolant decreases, since, as is known, the thermal conductivity of air is worse than that of water. In order to eliminate air pockets, special taps are often installed at the upper levels of the heating system, through which excess air is released.

Mayevsky tap is a device for releasing air from central water heating radiators, opened using a special key or screwdriver.

Methods for cleaning radiators from dirt

During operation of the heating system, dirt accumulates in it: iron oxides, dissolved salts and possible mechanical impurities. But if water moves through the pipes at high speed, then in the radiators the process slows down and the sedimentation of suspended matter increases. Therefore, cleaning radiators is a must.

There are two methods: flushing the entire system together and disconnecting the batteries and cleaning using a compressor unit. Favorable conditions are created in the batteries for the accumulation of dirt, since the coolant slows down the movement in them. To flush, the radiator is connected to the compressor, and dirt is cleaned from it with water pressure.

If you carry out annual preventive maintenance of the entire system, then drastic measures will not be required. It is quite possible to limit yourself to a general flushing of the entire heating circuit with ordinary water. Chemical reagents are used in cases where the coolant does not meet the established parameters and significant deposits of salts and scale appear on the working elements.

After using chemicals, leaks may form in radiators and cracks may appear that were successfully covered with dirt.

To avoid an emergency, all equipment must be checked for functionality before starting the system.

Timely preventive maintenance of all components of the heating system will protect it from complex accidents and save the budget.

Why does a gas boiler whistle?

In order for the heating system to work properly and for a long time, it needs to be provided with high-quality maintenance. Problems with operation can occur for various reasons, and the symptoms of problems may also differ.

One of the most common problems is the appearance of extraneous noises and whistles in the heating system. Ignoring the problem can lead to other problems arising, which ultimately can lead to the loss of performance of the heating equipment.

Malfunctions of the working mechanism of the gas boiler

A whistling sound in a gas boiler may indicate one or a number of breakdowns. If they are not eliminated, an emergency situation will soon arise. If you are not sure that you can cope with breakdowns on your own, do not take risks, entrust the work to professionals. The first thing they must do is determine the reason why the gas boiler is whistling.

Coolant saturation

Very often, extraneous noise in the heating system appears as a result of oxygen entering the coolant. The problematic situation most often arises in open systems. The fact is that the oxygen that enters the coolant is released into small bubbles when heated. The sound is similar to that produced when a kettle boils.

In this case, we are talking not about malfunctions in the operation of heating equipment, but about discomfort for the residents of the house.

If the whistle occurs as a result of oxygen saturation of the water that circulates through the pipes, there is no danger to either the residents or the heating elements.

But noise must be eliminated, as it adversely affects the nervous system. Besides, the owner is probably worried about it.

Clogged gas boiler coolant

The only way out of this situation is to install a closed heating system, but this process is quite labor-intensive and requires financial investment. How can I do that?

- install air vents on heating equipment;

- install a membrane tank instead of an expansion tank;

- provide automatic recharge of the heating system;

- install an automatic system sensitive to weather conditions.

These measures help improve the performance of heating equipment and will also make the operation of the gas boiler more comfortable.

Gas boiler coolant problems

The water that enters the heating system is not pre-purified or filtered, so when it is heated, sediment forms. Over time, it forms scale on working parts, which reduces the performance of devices and causes extraneous noise.

The heat exchanger is one of the most important functional elements. It heats up as a result of gas combustion and transfers heat to the coolant. The whistle does not appear immediately, but only some time after the start of the equipment’s operational period. Lime deposits affect the service life of the boiler, significantly reducing it.

Important

There is only one way to solve the problem of why a single-circuit gas boiler whistles if it is caused by the formation of lime deposits. This is cleaning the heating system. This can be done using special chemicals that are sold in household chemical stores.

Gas boiler design

Fan failure

The fan performs a very important function. It is responsible for blowing through the smoke removal system and facilitating the forced removal of combustion products from the boiler. If the fan is not working properly, periodic noises and whistles appear.

In new boilers, problems of this origin rarely arise, but if the service life is already quite long, it is quite possible that malfunctions and malfunctions in the operation of functionally important parts may occur.

There are other factors that contribute to rapid fan wear:

- location above the main burner;

- no fan so the gas boiler whistles

In order not to buy a new heating boiler, you can call a technician and fix the problem by replacing the fan.

Extraneous noise in the heating system can occur due to a lack of coolant in the heating system or a decrease in pressure. The fact is that when there is little water in the heating system, the boiler itself overheats and begins to make loud noises.

To fix the problem and get rid of the whistling sound in the heating system, you must first determine why this is happening. It is quite difficult for a person without experience to do this. Only a professional technician can understand from the sound alone why the boiler produces uncharacteristic sounds. By trying to fix problems yourself, you risk making the situation even worse.

Video

By watching the video, you can find out why the circulation pump is noisy and what needs to be done.

Evgeniy Afanasyev chief editor

Author of publication 08.11.2018

Did you like the article? Save so you don't lose!

Knocking in the heating pipes of a private home is a common occurrence for owners with individual heating. Why the noise occurs and what influences it is necessary to understand.

The main indicator of trouble is poor-quality coolant containing dissolved salts and mechanical impurities.

Noise and its characteristics

The concepts of sound and noise are different. Sound is a physical phenomenon caused by the vibrational motion of particles. Sound vibrations have a certain amplitude and frequency. Noise is a disordered sound mixture measured in decibels (dB). The set hearing threshold is 0 dB.

Sanitary standards set the noise level values:

- in the apartment: 30 and 40 dBA (acoustic decibel);

- at night from 23:00 to 7:00 – 45 dBA;

- during the daytime near buildings: no more than 55 dBA.

Heating pipes make noise during system startup, when a pressure drop appears in the return and supply pipelines exceeding the normalized value. This is why water makes noise in heating pipes. As houses are connected, the clicks gradually weaken and then disappear altogether.

If, after the completion of commissioning activities, sound effects in the intra-house system continue, then it is necessary to find out why the heating pipes are noisy.

The pressure drop when starting the heating system is one of the causes of noise in the pipes, which disappears without any intervention

Causes of noise

There are actually not so many reasons for knocking in heating pipes when heating. Some noise can be ignored - it does not harm the system or heating devices. But noises such as buzzing, crackling, knocking, gurgling, and howling should give reason to think and take urgent action.

- air pockets in the system;

- clogging or overgrowing of pipes due to poor-quality coolant;

- leaks in the pipeline;

- violation of installation work when installing taps, valves and laying pipes;

- failure or wear of working equipment;

- cavitation, an increase in pressure in places where the diameter of pipes increases (decreases);

- incorrect calculation or non-compliance with design recommendations when installing the heating system.

These circumstances arise in private closed-loop systems and make us think about their urgent elimination.

The circulation pump in the heating circuit system promotes forced movement of water, which leads to uniform heating and displacement of accumulated air from the system.

If the heating in a house or apartment is connected to a central pipeline, then startup, accompanied by similar sounds, is normal. Water, filling the general system, pushes out air, and, flowing along the contour, is accompanied by gurgling, knocking and crackling sounds.

As soon as the equipment enters operating mode, the general adjustment of the system will end - the temperature of the batteries will increase, and everything will stop. This is clearly visible in the diagram of heat supply to consumers from the central boiler house.

Why does a gas boiler make noise: when turning on and heating water

Hello, dear readers. Why is a gas boiler noisy? This question is very relevant for owners of this equipment.

Noises in a gas boiler may reflect difficulties in the heating network. It is necessary to quickly identify the causes and eliminate problems, otherwise the equipment may completely fail.

Noises when heating water

When a gas boiler makes noise when heating water, the indirect reasons for this are as follows:

- Installation and connection errors.

- Incorrect setting.

- Wear of nodes.

If a gas boiler is very noisy, there are more clear reasons for this:

- The water in the pipes has a high concentration of oxygen. Therefore, when heated, bubbles form. Due to this effect, noise and vibrations of both the boiler and batteries increase.

- Air has accumulated in the system. When there is knocking and puffing in the device, you need to remove air from the pipes. Current radiators have taps. To eliminate air, you can simply unscrew them.

- If there are a lot of salts in the water, they are deposited in the heat exchanger, or rather on its walls. And when heated, the equipment hisses. At the same time, thermal output and heating dynamics also suffer. The first thing that makes noise is the heat exchanger in a gas boiler. It is necessary to clean the radiator at least once a year. For this task, a pump with a special reagent is used. Cleaning fluid flows into the device through the hoses.

- The fan began to work poorly. It is usually designed in modifications with an isolated combustion compartment and forced elimination of combustion products. It can spin very noisily and even whistle. Causes:

A) The bearings are located above the burner. And the grease dried out in them. These parts need to be disassembled and lubricated.

B). Blades are unbalanced. Contaminants have accumulated on them. They need to be cleaned and their rotation adjusted.

- There is too much pressure in the heating pump. In this situation, the gas boiler pump makes quite a noise. It needs to be configured again. Excessive pressure in the network can cause an emergency. To configure, you just need to switch the white lever on the terminal box.

The device may overheat due to a lack of water in the network. You need to study the thermostat parameters and set lower parameters. Pressure is also measured. If necessary, add coolant.

If your wall-mounted gas boiler makes a whine-like noise, the gas valve or bypass (jumper) may be set incorrectly.

When operating at significant power, rumbles also come from the gas meter.

Often a gas boiler makes a rattling noise due to a worn valve.

There is a popping sound when igniting

When a gas boiler makes noise when turned on, with knocks, clicks and pops, you need to immediately solve this dilemma. Causes of noise:

- Problems with the three-way valve. With its help, the boiler switches from DHW to heating function and vice versa. If it clicks constantly, it needs to be replaced.

- The cause of the pop is the prolonged ignition of the spark. A lot of gas is formed. And when ignited it bursts into flames. It is necessary to check the burner, igniter, electrode and all contacts.

- The filter or chimney is clogged. They need cleaning.

Checking the chimney shaft is carried out as follows:

A lit match is brought to the ventilation. If the fire is deflected, the draft is normal. If it burns directly, cleaning is required.

You can clean the shah yourself. But their total cleaning is the prerogative of public utilities.

If a gas heating boiler with automatic ignition is noisy, then the reason lies in a clogged electrode. This element is cleaned and placed 3-4 mm from the burner itself.

- The injectors are clogged. It is necessary to turn off the gas for a while and clean them using a thin wire.

- Installation errors. If the body of the device is hung incorrectly, then when the facing side is heated, the metal is deformed. When cooled, it returns to its original form. This effect is observed in pipes embedded in walls. Then, when you turn on the hot water, the gas boiler hums. When installing pipes into walls, it is necessary to maintain a small space for such deformations - expansions.

- The plates in the heat exchanger are heavily clogged. Types of blockage: dust, soot, soot. It is necessary to remove the housing and thoroughly clean these elements. A special vacuum cleaner is used.

Points 5 and 6 are the most common answers to the dilemma, why does the gas boiler make noise when you turn on the hot water?

It is worth checking the mesh under the body as well. If necessary, clean it.

- The heating pump is not functioning correctly. Resonance appears in the system. If this occurs only when the heating pump is turned on, then its settings need to be corrected.

Before any work, be sure to close the gas valve. If you smell gas, call a special service.

Check if the gas boiler is noisy. To reduce vibration, it is worth laying a gasket under its body.

Types of noise in pipes

The noises that accompany the general heating start-up differ from emergency ones - they are intermittent and are accompanied by gurgling or gurgling. In bimetallic or aluminum batteries, a crackling or buzzing noise may be heard - this is also normal.

It is clear that prolonged noise is unpleasant, so it is necessary to prevent the situation in a timely manner.

The knocking and hum that occurs in the room with increasing force give reason to be wary and take drastic measures:

- Check heating devices and temperature conditions in the circuit. If a pump is installed, then its operation.

- Pay attention to the valves - if they break, a characteristic whistle appears. Sometimes a small adjustment is all it takes to get the equipment working.

- Having discovered visible problems, you need to stop the coolant and turn off the heating devices. Having assessed the breakdown, proceed to eliminate the accident yourself or invite a specialist.

These are primary measures that can prevent the development of major destruction.

Lack of draft in the chimney

As a rule, the presence of this reason leads to the fact that the column will go out during operation. It is very easy to detect: a lit match or stick must be brought to the viewing slot located on the front panel.

When everything is in order, the flame of the match is drawn inward, this is clearly visible to the naked eye. If the flame does not move, we proceed to the second stage: we disconnect the chimney pipe from the shaft opening and repeat the test by holding a match to this hole. No traction again? There may be two reasons:

- the vertical shaft is blocked by foreign objects or clogged with soot;

- in the room where the heater is located, there is no air flow, and without it there is no hood and the column goes out.

It must be said that the first reason occurs infrequently. And it cannot happen that the craving was there for many years, and then suddenly disappeared. Unless someone deliberately threw garbage into the mine. Soot on the inner walls grows gradually and makes itself felt by a slight decrease in draft, especially in the summer. But, before calling the stove workers to inspect the exhaust shaft, you need to make sure that fresh air is entering the room.

It happens that the instantaneous heater goes out when the old wooden windows in the house are replaced with metal-plastic ones. As a result, the air flow from the street is blocked and the draft disappears.

You can determine the lack of inflow this way: repeat the operation with a match with the window open. If a draft appears, you need to organize normal air exchange in the room, and don’t sit with the windows open all the time.

It also happens that there is draft in the shaft, but there is no draft at the viewing window of the column. This means that the reason lies in the gas-air path of the device. Typically, the heat exchanger fins clogged with soot practically do not allow air to pass through and the unit does not operate normally. And the last reason related to the chimney is the failure of the draft sensor. To replace it, as well as to clean the heat exchanger, it is better to invite a specialist.

Sounds from heating devices

If you hear a howl in the middle of the night, then most likely the system has leaked. A cloud of steam and a characteristic whistle will immediately indicate a gust or a failed valve. In some cases, it is enough to close the tap to bring the heating system into working condition.

If no obvious causes are found, and the howling is accompanied by a crackling sound, it is necessary to check the pressure. Perhaps the flying scale blocked the free flow of the coolant, which caused increased pressure - it is urgent to stop the boiler, drain the water and look for the problem.

It happens that the batteries start to “shoot” - this is another reason to be wary. Such noise is typical for bimetallic batteries when the pressure in the system does not coincide with the calculated one.

When purchasing heating appliances, you need to take into account the operating parameters of the boiler and select the appropriate radiator. Otherwise, the problem may result in a rupture of the heating device due to water hammer, which is completely inappropriate in the winter cold.

Why do you hear clicking, crackling and knocking noises?

The appearance of clicking or crackling noises in the heating system pipes usually indicates that foreign solid particles have appeared inside the communications. The impact of such small particles on the pipe walls is the direct cause of such noise.

As a rule, heating pipes knock and click when the following problems occur:

- wear of some key elements of the system;

- valve valve malfunctions;

- expansion of metal heating pipes under the influence of heat.

In most cases, knocking in the heating pipes of a private house or apartment building can be eliminated by simply draining the clogged water from the heating system and replacing it with clean water. If such flushing does not eliminate noise, then the faulty parts of the system must be replaced. In particular, valve valves are subject to inspection, problems with which are often the cause of such noise.

Another reason for knocking in heating pipes may be the thermal expansion of metal pipeline structures. Usually in this case, the crackling and knocking noises are quiet and intermittent. The expansion of pipes can lead to slight movements and disruption of the fastening of some structural elements, which leads to noise of this kind. To solve this problem, it is necessary to inspect the places where various parts and elements are fixed, and, if necessary, re-fasten them.

Finally, another reason that can lead to clicking and knocking in heating pipes is the so-called water hammer. It occurs when the water circulating in the pipes is instantly shut off by closing the valve, valve or tap. Since the compressibility of water is practically zero, and stopping the water stream cannot happen immediately, for a short time, at the point where the tap is suddenly closed, the pressure can jump by tens of atmospheres. This can lead to malfunctions of valves, valves, threaded connections with clicking or crackling sounds, and even failure of some parts. Therefore, to avoid this, you should not suddenly shut off the flow of liquid circulating in the heating system.

Pump noise

A common cause of problems is pump operation. Typically, it has three positions to raise the water column to a certain height, which depends on the power of the device. The uniform movement of the coolant along the thermal circuit is not accompanied by noise effects.

If you hear strange sounds that sound more like mechanical sounds, you should check the operation of the pump.

In case of failure:

- water gurgles in the heating pipes of a private house;

- a hum appears;

- cracking is possible;

- The boiler begins to make noise and knock.

In this case, you need to turn off the pump, and if the sounds stop, then the cause has been found. Cracking and noise are mechanical damage: this means that the graphite sliding bearings have worn out or dirt has gotten into the housing.

Scale settles on the inner walls of the pump due to poor-quality coolant and has a destructive effect on its components.

Checking is simple:

- it is enough to remove the pump;

- lower its working part into a container of water;

- when turned on, it must pump water; if this does not happen, it must be repaired.

Important! The pump cannot be turned on without water.

Why does a gas heating boiler crack - scale in the heat exchanger

Over time, deposits form inside the heating unit, which disrupt the operation of the system. This is especially audible when the coolant is heating up - the boiler may click, crackle, chirp, etc. It all depends on the design of the heat exchanger.

It is best not to wait for extraneous sounds to appear, but to wash the unit once a year in the summer. To do this, it must be dismantled and filled with a special compound. If you carry out the work regularly, this problem can be completely eliminated.

Prevention should not be neglected - it is worth installing one or more filters at the water inlet for cleaning.

Extraneous sounds in the heating boiler

Sometimes the heating of the boiler is also accompanied by some sounds. When cold equipment heats up and begins to crack, the characteristic clicks should not cause panic - metal makes such sounds when it warms up.

Gurgling and gurgling are also possible - this is also a normal phenomenon: the coolant began to heat up and set the system in motion. However, the same sounds can occur if there is insufficient coolant in the pipes. In this situation, it is enough to add water to ensure uniform heating.

Cotton

You can hear such sounds if the gas outlet pipes are clogged. This happens when the boiler is ignited: the accumulated gas, without having time to escape, creates a bang. This is dangerous, as a sudden burst of flame can cause burns or fire.

If the boiler is gas, then the reasons for such noise are clogged nozzles or a malfunction of the three-way valve. In this situation, it is necessary to clean the equipment from soot.

The occurrence of a knocking sound in the boiler indicates its incorrect installation or unregulated operation of the pumping equipment. If the pump operates unevenly, moving the coolant in jerks, resonance occurs between the boiler and the pump, accompanied by a characteristic knocking sound. In this case, it is necessary to regulate the operation of the pump.

Sounds in different boiler models

Noise can occur for a trivial reason, which lies in the boiler model itself. This is typical for gas boilers equipped with ventilation burners. To avoid such trouble, you need to choose boilers with atmospheric burners and an electronic control system.

When choosing a solid fuel or electric boiler model for heating your home, you should always familiarize yourself with the technical characteristics of the equipment. Often the cause of noise can be incorrectly selected equipment, as well as the presence of a fan in the boiler.

Double-circuit boilers also suffer from noisy operation: although not obvious, water overflows and filling of the system are always accompanied by sounds.

ZOTA boilers are very sensitive to the quality of the coolant, so unpleasant effects can be caused by:

- clogged mud trap;

- oxygenated water;

- scale on working elements;

- Broken bearings on the fan.

Therefore, it is worth choosing single-circuit models and purchasing a boiler to heat hot water.

Prices for ZOTA boilers

Prevention

Timely prevention of all components of boiler equipment can minimize the likelihood of noise.

Thus, flushing the system once a year is a prerequisite for trouble-free operation. Moreover, this is becoming a mandatory requirement of many resource supply organizations in preparation for the heating season.

You can flush the system yourself or use the services of specialists.

Depending on the coolant, the type of cleaning is selected:

- Washing with water under pressure generated by the compressor. Sometimes this is enough.

- For iron oxide deposits on pipes, appropriate chemicals are used. They eliminate the problem and additionally create a protective barrier from further exposure to an aggressive environment.

- You can use the services of a specialized organization that has the equipment and tools to perform the work.

Each operating manual for heating equipment provides a recommendation for preventive inspection and cleaning of the working parts of the boiler from corrosion and all kinds of contaminants with partial disassembly - at least once a year. If maintenance is not carried out, the manufacturer withdraws its warranty obligations.

Popping and clicking noises when igniting

When starting an Ariston or another brand of boiler, do you hear knocking and popping noises? The problem requires an immediate solution.

Three-way valve

The part is used to switch the operation of the unit from heating hot water supply (DHW) to heating, and vice versa. A faulty valve will click every time it is ignited. In this case, it needs replacement.

Ignition block

A loud bang occurs when the spark ignites for a long time. Then a lot of gas accumulates, which flares up when ignited. It is necessary to carry out diagnostics of the unit: burner, igniter, electrode, contacts and connections.

Wick clogged

When ignited, the product bangs, which indicates a clogged wick or chimney. The problem is typical for semi-automatic models. Inspect the wick: if clogged, clean it.

To make sure that the chimney shaft is clogged, check for draft:

- Place a lit match near an inspection window or vent.

- If the flame deviates to the side, the draft is normal; if it burns evenly, it needs cleaning.

For your part, you can clean out the mine. But to completely remove contaminants, it is better to contact utility services.

In models with automatic ignition, the electrode may become clogged. Clean the part and install it 3-4 mm from the burner.

The injectors are clogged

When heating, a noise is heard, ignition does not occur, or the flame bursts out in jerks. Turn off the gas supply and clean the holes with a thin wire.

Incorrect installation

If the calculation and mounting of the device body is incorrect, the sounds of metal impacts appear. When the cladding heats up, the metal expands, and when it cools, it returns to its previous position, which leads to extraneous sounds.

The same thing happens with pipes that are walled into walls. When you turn on the heating and start hot water, the pipes expand slightly, which leads to knocking. When installing pipes into walls, it is necessary to leave a gap for thermal expansion.

Heat exchanger plates clogged

Then the boiler explodes when heated. And the plates can become clogged with dust, soot and soot. Remove the housing and clean the parts with a wire brush or a special vacuum cleaner.

The mesh located at the bottom of the case could become clogged with dust. In technology with an open combustion chamber, this leads to a decrease in thrust. Don't forget to clean.

Incorrect operation of the circulation pump

As a result of uneven operation, resonance occurs in the system, which leads to extraneous noise. Adjust pump settings.

Before starting any work, close the gas valve.

To reduce vibration, place a gasket under the housing. Regularly maintain the unit and clean parts from scale and dirt. This will allow you to operate the boiler safely and for a long time.

Loud noise when a gas boiler is operating may be a sign of a faulty heating system. Extraneous noise occurs as a result of some kind of malfunction, which definitely requires attention from a qualified specialist. Such a malfunction should not be ignored for a long time, as it can aggravate the problem and lead to an emergency stop. Loud noise from the boiler is a problem that can easily develop into the purchase of a new one. This is incredibly expensive and should be avoided.

If you notice that the gas boiler has become very noisy, the only and correct solution for you will be to invite our service engineer to study this problem in detail. An employee from our company is a highly qualified specialist who is needed in every home in the event of a problem in the operation of the central heating system, to carry out diagnostics to identify the malfunction.

Strong noise from the boiler is the reason for immediate contact with us and a reason to resort to the services of our engineers. There are many reasons that cause boiler noise during operation. Some problems are minor and can be eliminated during one visit of our technician, while some require financial expenses, especially where several breakdowns have occurred.

How to remove an air lock with your own hands

Air in the system after a long stop is common. This problem arises not only in the private sector, but also in apartment buildings. It's quite easy to solve.

Heating radiators are equipped with Mayevsky taps located at the ends of the radiators. This could be a valve or a fitting with a notch for a screwdriver.

- armed with a small container (for draining water), you need to unscrew the tap and let out the air;

- Actions should be performed carefully so as not to get burned by the escaping steam;

- when water comes out of the hole, close the valve;

- Such manipulations are carried out on each battery.

This eliminates noise and allows the coolant to move freely through the system, evenly releasing heat.

Seething water in heating pipes and radiators

Sometimes you have to deal with a problem such as bubbling or gurgling water inside heating lines. This noise occurs due to the appearance of air bubbles inside the water. In addition to noise effects, another undesirable consequence of this problem is a decrease in the temperature of the coolant and the efficiency of the system as a whole.

If seething or gurgling noises occur, the system should be checked for the presence of slopes and distortions, in which a layer of air can form and stagnate. In some cases, to remove air bubbles from the heating system, special air vent valves are installed in the structure on the upper floors. In other cases, it may be necessary to correct distortions and slopes, which requires shutting off and stopping the heating in the entire house.

Methods for cleaning radiators from dirt

During operation of the heating system, dirt accumulates in it: iron oxides, dissolved salts and possible mechanical impurities. But if water moves through the pipes at high speed, then in the radiators the process slows down and the sedimentation of suspended matter increases. Therefore, cleaning radiators is a must.

There are two methods: flushing the entire system together and disconnecting the batteries and cleaning using a compressor unit. Favorable conditions are created in the batteries for the accumulation of dirt, since the coolant slows down the movement in them. To flush, the radiator is connected to the compressor, and dirt is cleaned from it with water pressure.

If you carry out annual preventive maintenance of the entire system, then drastic measures will not be required. It is quite possible to limit yourself to a general flushing of the entire heating circuit with ordinary water. Chemical reagents are used in cases where the coolant does not meet the established parameters and significant deposits of salts and scale appear on the working elements.

After using chemicals, leaks may form in radiators and cracks may appear that were successfully covered with dirt.

To avoid an emergency, all equipment must be checked for functionality before starting the system.

Timely preventive maintenance of all components of the heating system will protect it from complex accidents and save the budget.

Why does the speaker whistle and hum?

If the dispenser operates quietly when the gas is turned off and only hums when turned on, it means that one of the gas control valve units has failed. In the case of automatic water heaters, a whistle from a gas water heater indicates the following:

- scale in the heat exchanger;

- The gas valve has failed.

The problem can be solved by cleaning the pipes. You can clean it yourself using improvised means and special chemicals. A boiler that whistles when hot water is turned on may also be noisy due to failures in the settings of the valve that regulates the gas supply. Usually, third-party sounds stop when a different heating mode is set.

If a semi-automatic gas boiler is noisy during operation, the breakdown may be caused by the pilot burner. A characteristic sign: the column hums if the water is not turned on. The malfunction is due to dirty jets. It's actually the igniter making noise. After cleaning, all unusual sounds will go away. The boiler will operate normally.

And the neighbors are noisy too

More often than not, it's not just you and your family who suffer this. Therefore, you first need to go around the neighbors along the riser to identify the location of the noise.

Let's find out where the pipes are making noise

Now, as for the nature of the buzz. Heating pipes, like water pipes, can emit single or rhythmic sounds, something like tap dancing, rustling, gurgling, or even generally vibrate and even hum – periodically or constantly. The reasons can be completely different, they are even classified into groups. But now we will not consider absolutely all of them, but will focus only on impact noise effects.

Note: The likelihood of noise in pipes is sharply reduced if you use metal-plastic or plastic pipes instead of metal and copper. This is explained by the high sensitivity of steel pipes to low-frequency vibrations and high rigidity. Although their material is much stronger. It is recommended to use ball valves rather than screw valves as shut-off valves, which are controlled by turning the handle. These are heavy cast copper products, not Chinese-made products made from light alloy material.