Home / Solid fuel boilers

Back

Published: 05/24/2019

Reading time: 7 min

0

2889

In the absence of the opportunity to connect to a centralized gas supply system, the owners of private houses and country houses decide to install an automatic solid fuel boiler.

The fuel used in such units is firewood, coal, peat or sawdust (pellets). But since manual loading of the listed raw materials becomes difficult, many consumers prefer devices with automation of this process.

- 1 Operating principle of automatic long-burning boilers

- 2 Difference from semi-automatic boilers

- 3 Internal structure

- 4 Types of automatic boilers

- 5 Requirements for installation of an automatic solid fuel boiler

- 6 5 best boilers with automatic fuel supply

What are coal boilers?

Coal is a solid fuel consisting of combustible substances, the main part of which is carbon. Coal is widespread in all Russian regions, much more than main gas, fuel oil and heating oil.

Coal-fired boilers have various modifications and designs

Continuously rising energy prices are increasing the role of long-burning coal-fired boilers as an alternative to gas units. Coal also has superiority over wood, since when 1 kg of coal is burned, they release 2 times more thermal energy.

A long-burning coal boiler is a variation of a solid fuel unit, the mechanism of which is most optimized for the use of coal as an energy carrier.

The use of modern technologies allows such inertial units to operate automatically. The control unit autonomously monitors combustion processes, thereby ensuring its maximum efficiency.

Types of boilers by type of fuel bunker

There are two types of loading devices: built-in fuel hopper and mechanized storage. The battery life and the area occupied by the boiler installation depend on which of them the unit is equipped with.

Built-in fuel hopper

Models with a built-in loading device are equipped with a container for solid fuel, which is located on top or on the side of the main chamber of the boiler. The advantage of this design is the relative compactness of the heating installation. However, in terms of battery life, models with a built-in bunker are inferior to units with mechanized fuel storage.

Mechanized fuel storage

Here, a separate room or part of a room with a connected flammable material supply system acts as a loading device. The volume of such storage is enough to accommodate a year's supply of fuel.

The models are distinguished by a complex electronic automatic control system, which fully regulates all work processes, as well as the presence of a remote control unit.

Application and effectiveness

Coal boilers for heating a private home have found application in regions of Russia where there is no main gas supply, and there is also a shortage of other energy resources: firewood, electricity.

The popularity of coal is higher near major transport hubs, since large quantities of coal are mainly transported by rail.

In order to increase the efficiency of a coal boiler, it is necessary to perform a number of measures. They start by choosing a brand of coal. It is mined in mines and may contain 15-20% waste rock, which cannot burn and produces a lot of ash.

Unprocessed coal has an ash content of up to 30%. Therefore, for energy purposes, coal undergoes special processing at enrichment complexes, which increases the efficiency of units, for traditional coal devices up to 70-75%, and for automatic ones - almost up to 90%.

In addition, in order to increase the economical operation of the heating system of a house equipped with a coal-fired unit, it is necessary to take into account the following points:

- Do not use raw coal, since a significant part of the energy from the thermal cycle will be used to dry it.

- Monitor the condition of the chimney system and heating surfaces of the boiler; they must be clean.

- Provide sufficient air. In the room where the unit is installed, there must be effective triple supply and exhaust ventilation.

- Use thermostats in the operating circuit of an automatic coal boiler.

- Effectively insulate your home.

- Improve the in-house thermal circuit, install a circulation pump and an indirect hot water heating boiler.

Design and principle of operation of coal-fired boilers

Traditional solid fuel coal boilers are manufactured with different configurations, but one thing remains unchanged - the organization of the combustion process. Coal boilers for heating a private home are produced with a heat exchanger made of steel or cast iron, with top or front loading of fuel.

There are boilers with natural draft and those operating with air pressurization by an axial fan. The last option provides power control. According to the principle of coolant movement through the heat exchanger, they differ, like boilers operating with natural and forced circulation.

Before putting coal into the boiler, it is heated with wood. When the hot ash from burnt firewood fills the grate, coal is poured in, which burns in the combustion chamber and forms flue gases.

They wash the combustion heating surfaces in the form of a heat exchanger and thereby heat the coolant entering the heating radiators. After this, the coolant cools down and returns to the boiler, thus the heating cycle will be completed and the next one will begin.

Varieties

Automatic coal boilers are grouped into 4 basic types: traditional, pyrolysis, pellet and long-burning. Certain models combine different design options, for example, in a traditional boiler unit I install a pellet burner.

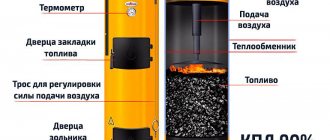

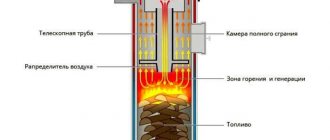

Long-burning coal boilers

Boilers operating on the principle of long combustion are otherwise called “top combustion”. They are distinguished by a long period of work on the first coal load.

In such designs there is no ash pan or grate; moreover, the bottom of the device is completely solid, and therefore combustion of fuel in the lower part is categorically unacceptable. The combustion chamber has a cylindrical shape. Air is supplied from above, strictly in the center.

Fuel combustion process

In order to organize such an air supply scheme, an air distributor is installed in the firebox, which has the ability to move down along with the fuel during the combustion process.

The air continuously approaches exactly the upper combustible layer, where hydrocarbons are partially oxidized, that is, the process of pyrolysis occurs. Products containing ash particles fly up into the combustion space. They are separated from the primary combustion zone by a thick metal disk mounted on a dynamic air-blowing tube.

In this secondary combustion chamber, atmospheric air enters the pyrolysis gas, volatile combustible substances burn, releasing heat, which is supplied to the heat exchanger, which heats the coolant for the heating system.

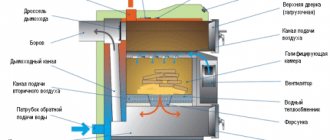

Pyrolysis coal boilers

Another very popular option for a coal unit is a pyrolysis or gas generator. The pyrolysis process has long been used in many industrial applications in the pharmaceutical and petroleum industries.

In coal-fired boilers, pyrolysis involves the slow thermal decomposition of coal under oxygen deficiency. In this case, pyrolysis flammable gases are released from the fuel, which penetrate through special passages in the loading chamber into the secondary chamber, into which the calculated volume of air is supplied by a fan.

Volatile gas substances ignite and burn completely, ensuring efficient operation of the device with the highest efficiency for coal boilers - 92%.

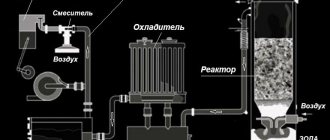

Bunker automatic boilers

Modern autonomous coal boilers, operating in automatic mode, are controlled using a controller and a screw fuel supply mechanism. The boiler system is equipped with forced air supply and smoke removal.

To keep heating surfaces and smoke channels clean, a stationary self-cleaning device is installed. Coal boiler houses equipped with such units do not require a large number of maintenance personnel due to the high level of automation of the combustion process.

Boiler with coal bunker

Operating principle of automatic coal boilers:

- When the unit starts, the screw fuel supply starts.

- The first share of coal is ignited by electroplasma.

- As combustion proceeds, a fresh portion of fuel enters the combustion chamber. The increase in unit productivity is regulated by the speed of the screw conveyor.

- Simultaneously with the screw fuel supply, a dosed air supply into the combustion chamber is turned on.

- The controller determines the rate of air intake, thereby regulating the intensity of the combustion process.

- Automatic grates dump ash residues into the ash box.

- Soot cleaning is carried out by special springs installed inside the channels.

Pellet automatic units

One of the most common types of heat generators is systems powered by wood pellets. The operating principle of pellet boilers is in many ways similar to other automatic units, but there are also characteristic features.

If you trace the similarities and differences, as well as the advantages and disadvantages of such models, it will be easier to choose the appropriate option.

Principle of operation

The basic design of pellet systems is no different from other common automatic heat generators. Combustible materials are loaded into the fuel bunker, from where they are gradually poured onto the screw conveyor. The shaft transfers the granules to the combustion chamber, where the coolants are heated.

Differences in operation can be seen at the fuel supply stage:

- After starting the auger, the mechanism directs the pellets first into a flexible hose or plastic tube, which dumps the pellets into a dispenser.

- In the metering device, the second shaft measures the required portions of fuel and moves them to the reed valve.

- The gate opens and the pellets are dumped onto a third auger, which transfers a measured amount into the firebox.

The described algorithm may vary slightly depending on the implementation of a particular model.

Advantages

The economic and operational benefits of pellet heating systems are mainly related to the merits of the type of fuel used.

Wood pellets are not inferior to traditional combustible materials in terms of calorific characteristics, but have a number of advantages:

- lower cost;

- economical consumption, which leads to longer operating time without additional loading;

- increased environmental friendliness;

- minimum amount of combustion products in the ash pan.

As for the advantages of the boilers themselves, as a rule, they are smaller in size compared to units operating on other types of fuel.

Flaws

In addition to the listed advantages, there are also disadvantages.

Since the flame in most pellet models has a horizontal direction, overheating of the boiler structural elements may occur. In addition, the efficiency and power of such equipment is lower.

How to choose

When choosing a specific model of coal boiler for a residential building, several factors should be taken into account: thermal power and size of the heated area, type of combustion, type of heat exchanger - cast iron or steel, energy independence, safety, efficiency, weight of the unit and its price.

Direct long burning or pyrolysis

In order to compare boiler units by type of combustion: long burning or pyrolysis, compare the main operating parameters of coal boilers:

- Efficiency: Long-term combustion - from 75 to 85%, pyrolysis - from 85 to 92%.

- Possibility of autonomous operation: long burning - yes, pyrolysis - yes.

- Energy independence: long burning - yes, pyrolysis - yes.

- Permissible fuel humidity: long burning - from 30%, pyrolysis - up to 15%.

- Acceptable fraction: long burning - up to 50 mm, pyrolysis - from 25 mm.

Thus, today it is possible to draw the main conclusion - it is simply not possible to burn fuel more efficiently than in an automatic pyrolysis solid fuel boiler using coal and wood.

Heat exchanger material

The type of material from which the body of a coal boiler is made is the main factor that determines the durability and maintainability of the heating system:

- Steel is a relatively light metal that can withstand changes in pressure and temperature. Its disadvantages include susceptibility to corrosion processes and burnout in the zone of maximum temperatures.

- Cast iron is the most durable material and is used in all powerful units. However, it does not withstand shock and temperature changes well. In addition, if fistulas form in the walls, it will not be possible to weld them, as in steel products.

Modern boilers, using the positive qualities of both metals, are produced in a steel body and with a cast iron combustion chamber.

Single-circuit or double-circuit

Single-circuit or double-circuit are available, either only for heating, as in the first option, or, respectively, for heating and hot water supply - in the second.

In this case, double-circuit boilers operate on the principle of switching hot flue gases to the DHW circuit when the valve on the mixer is opened. Coal units have a fairly pronounced low inertia, so it is practically possible to regulate the heating medium between the circuits only in pyrolysis devices.

Therefore, for many options for coal boilers, the preferred hot water supply scheme remains, organized through an additionally installed indirect heating boiler. In this case, the efficiency of the heat supply system is significantly increased by reducing the temperature of the exhaust gas.

Minimum required power and heated area

In order to determine the approximate thermal power, use a practical formula depending on the heated area of the room:

Mk = Pd x 0.1 where:

- Mk - design power of the boiler, kW;

- Pd - area of the house, m2.

- 0.1 - specific power indicator per 1 m2 of area (W/m2).

This calculation does not take into account many more important parameters of the house, for example, such as the level of thermal insulation, glazing area, roof structure and climatic region of residence.

These calculations are complex and can only be performed by special design organizations or using software packages.

Therefore, in everyday life, an approximate calculation is carried out, which is carried out according to the principle “from small to large” - the power is set for each room separately, and then the result is summed up. This approach also allows you to determine the number of metering devices required for each room.

Another difference for coal boilers in this calculation method, which will need to be taken into account when selecting equipment. The power according to the formula takes into account the calorific value of standard coal, which in reality is much worse, so an adjustment of 20% is made to accurately determine the coal consumption in a solid fuel boiler.

Efficiency

Efficiency - represents the ratio of the volume of fuel consumed to the volume of thermal energy generated by a coal boiler. This is the most important indicator of equipment efficiency and fuel use.

It depends on the thermal design and the use of innovative technologies in the boiler design. In EU countries, due to strict environmental protection requirements, the installation of new devices with an efficiency below 90% is not allowed. High-tech condensing domestic boilers today operate with an efficiency of 100-105%.

Recommendations for selection

Choosing the most suitable model depends on many factors. First of all, you need to decide on the type of fuel, prices for which may vary depending on the region.

After this, it is worth calculating the area that is available for installing the boiler system, and taking into account the wishes for battery life. This will help you determine the most appropriate dimensions of the boiler and the capacity of the fuel bunker, which will significantly narrow your search.

To take full advantage of the potential economic and operational benefits of automatic boilers, you need to pay attention to the following parameters when choosing:

- boiler power (must correspond to the area of the heated room);

- availability of economical modes;

- demands on the quality of fuel, its ash content;

- reliability and safety of long-term battery life;

- reproduced noise in various modes;

- availability of automatic ignition and ash collection functions;

- electricity consumed;

- possibility of operation from rechargeable batteries;

- the size of the ash bin and the ease of cleaning it;

- efficiency of working with different types of fuel pellets and in different modes;

- the presence of a remote control or the ability to additionally connect it.

You also need to pay attention to the appearance of the boiler, including the quality of the welds.

The best known manufacturers and models with prices

The Russian market for climate control equipment is saturated with coal-fired boilers, both domestic and Western-made. Moreover, Russian modifications have the best price-quality ratio.

Boiler Protherm Beaver 20 DLO

However, at present, the most functional ones with automatic operation are coal units from European companies.

For example, the following models became popular models of coal boilers with a 200 m2 area, according to buyers, in 2022:

- ZOTA “Master” 20, price as of 01/01/2020 - 31,889 rubles.

- Protherm “Beaver” 20 DLO, price as of 01/01/2020. — 38,440 rub.

- Bosch “Solid” 2000 B SFU 12, price as of 01/01/2020 - 51,430 rubles.

- Stropuva S15U, price as of 01/01/2020 - 39,789 rubles.

- Buderus “Logano” S181-15 E, price as of 01/01/2020 - 258,800 rubles.

- Teplodar "Kupper" OK 20, cost as of 01/01/2020 - 28,340 rubles.

- Thermocraft "Uragan" Prof 22, cost as of 01/01/2020 - 34,650 rubles.

Installation procedure

The boiler is a high-risk facility; it must be installed according to the design of a specialized organization that has licenses for the relevant types of work.

Algorithm for carrying out work when installing a coal boiler:

- Preparatory measures are being carried out: Selecting a room for the furnace and concreting the base for placing the unit and auxiliary equipment.

- The boiler is connected to the in-house heating circuit.

- The boiler is connected to a smoke ventilation system.

- Install auxiliary equipment: blower fan, centrifugal pump, air vents, safety valve, temperature sensors, water purification filter and expansion tank.

- Perform a test run and pressure testing of the system with water pressure of 1.5 working hours to check the tightness of the connection of pipe and structural elements.

Automatic fuel supply methods

Based on the methods of fuel supply, units with a pneumatic conveyor and a screw transmission are distinguished.

The choice of design depends on:

- noise level during operation of the heating installation;

- power consumption;

- frequency of fuel delivery to the combustion chamber and other indicators.

Pneumatic conveyor

Combustible materials are delivered to the main chamber of the boiler using air, which is pumped under pressure. The advantage of such models is that fuel is supplied less frequently. As a result, the system will be able to operate without electricity for a longer time. However, the pneumatic conveyor makes more noise during operation and consumes a lot of electricity - about 1.5–2 kW/hour.

Screw transmission

This method is used in most household units and is considered the most reliable, but it is not ideal.

Feeding is carried out via a screw conveyor, which operates almost silently and consumes less electricity - about 80 W/hour. The feed speed is adjusted automatically.

The use of an auger guarantees the flow of fuel into the boiler, but if its length is more than 2 m, flammable materials are ground into dust.

Operation: how to properly heat a boiler with coal

Ignition of coal boilers is carried out with a small amount of wood chips and paper, after which the firebox door is closed. Open the blower so that the draft ensures the combustion process. If the unit has an air supply regulator, it is set to a temperature of 70 C.

After burning wood for 20 minutes, the boiler firebox and gas ducts warm up enough that coal can be thrown in. The gate valve opens completely. During the lining process, the blower is closed. Only after this do they open the combustion door and lay a layer of coal up to 6 cm, and after it has burned out, the next layer of coal will need 20 cm.

Summarizing the above, we can draw the following conclusion that solid fuel boilers operating on coal fuel are still in demand, both in the field of individual heating of residential buildings and in production, where industrial coal boilers are still functioning in sufficient quantities.

Modern advances in the field of boiler construction make it possible to use cast iron heating surfaces in the most advanced innovative boilers.