A long-burning boiler is a boiler unit capable of maintaining fuel combustion and heat generation for a longer period: a day or more. Most models are designed specifically for 24-30 hours of activity. However, there are long-burning solid fuel boilers that require loading once a week, which greatly simplifies the combustion process.

To achieve such a duration of heat generation on one stack, it is important to choose not only the appropriate model, but also the type of fuel, its characteristics and fraction size.

Purpose of boilers

Solid fuel boilers are the best option for heating rooms of varying sizes.

Gas heating equipment, even with access to the central main line, requires significant costs and effort to connect an individual line.

Electric boilers are more convenient to use. But to service large facilities, models with significant power are required, the installation of which requires a three-phase power supply. This is accompanied by additional costs and the need to coordinate the wiring design. Also, in the event of an emergency power outage, the house will be left without a heating source.

Expert opinion

Torsunov Pavel Maksimovich

Solid fuel boilers are often the best choice for heating a room. And the long-burning function allows you to create heating systems for houses with large areas and provide objects with heat from a single source.

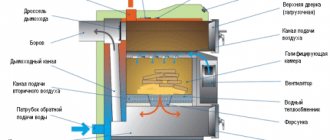

Internal structure

A solid fuel boiler for heating a private house with automatic fuel loading differs from semi-automatic boilers in having a more complex internal structure. Thus, the fuel combustion process is carried out in a special burner, and waste in the form of ash is gradually poured into the ash pan. With the help of grates you can heat the boiler in semi-automatic mode.

In order for the equipment to work efficiently and without failures, you need to prepare coal with the correct fraction. The heating fluid heating procedure is carried out in a heat exchanger.

To extend the service life of the boiler installation, it is important to correctly adjust the return temperature. If the return is cold, the heat exchanger will undergo cracking or severe deformation.

In large-sized systems with long circuits, 3-way thermostatic valves are placed, which will automatically mix hot coolant with cold.

Features of devices

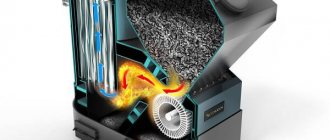

Long-lasting combustion is ensured by a large reservoir for storing firewood, as well as by the method of two-stage combustion of fuel.

Operating principle of the device:

- Firewood or other solid fuel is loaded into the firebox. The tank is filled completely, leaving a small space with small wood chips and branches just next to the window to facilitate ignition.

- Using paper or a torch, set fire to the bookmark. At this stage, enough air enters the chamber to begin intense combustion.

- When the fuel is occupied, the air flow into the tank is reduced to a minimum. This technique leads to a transition from combustion to smoldering of the material.

- During thermal decomposition, wood releases large amounts of gases with increased energy potential (pyrolysis process).

- In standard furnaces, pyrolysis gases rush into the chimney, and in long-burning devices they pass into the afterburning compartment. There, under the influence of oxygen and high heat, they ignite, completely burning out. This process is accompanied by the release of a large amount of heat.

During the operation of the boiler, solid fuel is processed into fine ash, and the gas burns out in the afterburning tank, which makes it possible to minimize harmful emissions and waste.

Selection options

When choosing a solid fuel boiler, a number of important criteria should be taken into account:

- The power of the unit is selected depending on the heated area and the required coolant temperature.

- Availability of fuel.

- The type of traction in the pushing compartment is natural or forced. This characteristic affects the performance of the device and the possibility of its installation in a certain room.

- Heat exchanger construction material. The most common products are made of steel and cast iron. The reliability of the boiler and its heat-saving qualities depend on their quality.

- Efficiency factor (efficiency) is determined by the type of fuel used, the specifics of the design and the presence of additional elements, such as exhaust, automatic fuel supply, etc.

- The “water jacket” placement option allows you to optimally select the unit for installation in compliance with fire safety requirements.

- The method of loading fuel and the size of the combustion chamber allows you to calculate the operating cycle of the boiler and the possibility of automating its operation.

- The weight of the device is taken into account when determining the basis for installing the equipment. The surface must be durable and resistant to deformation.

- The location of the ash pan and its design determine the ease of maintenance of this element during operation of the equipment.

- Price depends on the characteristics of the device and the popularity of the brand.

Device classification

Boilers are divided into several types according to the type of fuel combustion:

- Pyrolysis - equipped with a pair of combustion chambers. In the first, smoldering occurs and gas is formed, which is mixed with oxygen in the second compartment and burned. Such equipment emits a small amount of pollutants into the atmosphere and is considered environmentally friendly. Also, after fuel combustion, little soot remains. Automatic models are additionally equipped with a power regulator.

- With an overhead combustion compartment . Easy to maintain devices, with a minimum of automatic functions required for operation. They can operate autonomously, without access to the power grid. But as a result of work, a large amount of ash accumulates, and not all types of fuel are suitable for them. For example, sawdust and fine chains cannot be used.

- Pellet boilers are boilers for which special compressed briquettes are used for lighting. Such equipment is economical, durable, environmentally friendly and efficient in operation. The disadvantages of the devices are high cost, demanding fuel storage conditions. Pellets are stored only in a dry room.

What long-burning solid fuel boiler is installed in your home?

Pyrolysis Pellet

Popular models

The most famous suppliers of solid fuel units are the following brands:

- Lithuanian Stopuva;

- German Buderus;

- Czech Wattek;

- Belgian ACV;

- Austrian Wirbel;

- Russian NMK, Zota and TeploGarant LLC.

Among the models on the market from various companies, there are several popular devices.

Stropuva Mini S8

A power-independent unit serving an area of up to 80 square meters. m. Works with three types of fuel and is distinguished by its small size. Equipped with a convenient vertical firebox door.

The special design of the ash pan allows you to reduce the need to clean it to twice a month. One bookmark is enough for daily heating; the pellets burn out in 48 hours.

Advantages:

- high efficiency;

- quality of construction;

- safety;

- presence of a thermometer.

Flaws:

- heavy weight;

- The rough surface of the door makes it difficult to clean.

Reviews

| Roman Oborin: | Igor Falaev: |

| “Economical and compact unit, burns for a long time. It consumes little fuel, heats the house well, and does not produce soot. The only negative is that it’s a bit heavy.” | “A small, convenient barrel, the device is immediately ready for use, you don’t need to assemble or screw anything in. The door handles are of high quality and reliable, they do not open spontaneously. It takes a long time to heat, it can burn for up to 20 hours.” |

Teplodar Cooper Expert-15

Russian model with the ability to install a burner.

In the upper half of the housing there is a fitting for air outlet. Compatible with firewood, coal and briquettes. Three air entry zones and top combustion ensure long-term heat maintenance. At the bottom there is a water reservoir that prevents excessive heating of the floor. A steel plate protects the door from heat. You can additionally attach a draft regulator.

Advantages:

- possibility of installing a pellet or gas burner;

- convenient door placed at an angle;

- continuous burning for 24 hours.

Flaws:

- complexity of installation;

- small firebox.

Reviews

| Oleg Egorin: | Semyon Ivin: |

| “It’s a convenient boiler, you can buy an additional burner, it works for a long time and even after switching off the house remains warm.” | “It’s not a bad unit, it’s enough for almost a day of heating, but it consumes a lot of fuel. Convenient door design for stowage." |

ZOTA Topol-16VK

A device with a water circuit at an affordable price. The triangular shape of the pipe avoids blockages and increases the service life of the device. To refuel the boiler, you can use firewood, coal and pellets.

The model is distinguished by a spacious firebox and the possibility of top and side fuel storage.

Advantages:

- low price;

- ease of use and cleaning;

- efficiency.

Flaws:

- low efficiency.

Reviews

| Vladimir Kharitonov: | Alexey Zaitsev: |

| “A high-quality device at an affordable price for its segment. Works flawlessly." | “The device is pleasant to use, cleans without problems, you can load different types of fuel, both briquette and regular.” |

Teplodar Cooper Expert-22

The device is small in size, capable of operating in 4 modes: fast heating, classic, medium and maximum. Combustion from top to bottom ensures uniform and longer combustion of the material and good heat transfer.

The upper cleaning hatch is protected by a steel screen that prevents burning.

Advantages:

- two hatches for cleaning;

- inclined door for top loading;

- top burning function.

Reviews

| Evgeny Zherdev: | Ivan Alaev: |

| “Sophisticated heating adjustment, you can adjust the burning duration from 30 minutes to a day. Easy to clean, special cleaning accessories included.” | “A high-quality model, the design allows you to connect heating pipes from either side. The device comes with a heating element and a thermomanometer.” |

Stropuva S30

Solid fuel boiler for placement in commercial and residential premises. Equally effective for year-round and seasonal use. It is characterized by high efficiency, is independent of power supply and is compatible with a variety of fuel materials.

The device has compact dimensions and is environmentally friendly. The duration of firewood burning is up to 30 hours, briquettes can smolder for up to 2 days.

Advantages:

- safety of use;

- high efficiency;

- durability;

- build quality.

Flaws:

- high price.

Reviews

| Kirill Malin: | Maxim Kansky: |

| “It burns for quite a long time, it is demanding on the quality of fuel. Soot forms on the outer skin.” | “It uses fuel economically and can be cleaned without any problems with a special powder. The downside is the high price.” |

Model characteristics:

| Model | Stropuva Mini S8 | Teplodar Cooper Expert-15 | ZOTA Topol-16VK | Teplodar Cooper Expert-22 | Stropuva S30 |

| Number of circuits | 1 | 1 | 1 | 1 | 1 |

| power, kWt | 8 | 15 | 16 | 22 | 30 |

| Combustion compartment | Open | Open | Open | Open | Open |

| Non-volatile | Yes | No | No | Yes | |

| Heated area, sq. m | 80 | 150 | 160 | 220 | 300 |

| Control type | Mechanical | Without control panel | Without control panel | Without control panel | Mechanical |

| Fuel | Firewood, wood briquettes | Firewood, coal | Coal and wood briquettes, firewood, coal | Firewood, coal | Firewood, wood briquettes |

| Efficiency, % | 85 | 75 | 75 | 85 | |

| Installation | Floor | Floor | Floor | Floor | Floor |

| Coolant heating, °C | 60-95 | 50-95 | 95 | 50-95 | 60-95 |

| Maximum water pressure in the circuit, bar | 1,5 | 3 | 3 | 3 | 1,5 |

| Weight, kg | 145 | 148 | 108 | 165 | 257 |

| Price, r | 52000 | 34500 | 29500 | 42400 | 85000 |

Prices: summary comparison table

| Model | power, kWt | Efficiency, % | Firebox dimensions, weight | Cost, rub. |

| Metal-Fach SMART EKO-20, Poland-Russia | 20 | 90 | 1250x1345x610 mm, 360 kg | 152 000-280 000 |

| Galmet Duo 17, Poland | 17 | 81-86 | 1130x1475x840 mm, 355 kg | 220 000-250 000 |

| ZOTA "Optima" 20, Russia | 20 | 82 | 1290x1590x890 mm, 376 kg | 151 000-211 000 |

| Pereko KSP Duo 18, Poland | 18 | 92 | 1160x1385x845 mm, 370 kg | 283 000-327 000 |

| Heiztechnik Q Eko Lux 15, Poland | 15 | 88 | 350x270x380 mm, 363 kg | 154 000-179 000 |

Tips for choosing

Before choosing a boiler, you need to calculate the required power, based on the area of the room, the presence of insulation, the height and thickness of the walls. The selection of the burning time for one bookmark also depends on these parameters.

Most devices use the following types of fuel:

- briquettes;

- coal;

- pellets;

- peat;

- wood;

- oil shale.

You should also decide on the type of fuel in advance, giving preference to a more affordable option.

The material from which the heat exchanger is made is also important. Cast iron products have a sectional structure and are of high quality, but are poorly protected from thermal shock. Steel models are produced in the form of monoblocks. They withstand thermal shock better, but are difficult to transport and repair.

The cost-effectiveness of operating a unit is determined by the totality of service costs, suitability for repair and efficiency indicator.

When choosing a heating device, you should correctly compare its functionality and the size of the room so as not to overpay for excess power. It is better to give preference to models from trusted manufacturers that use affordable fuel.

Calculation of the minimum required power

Correct calculation of power will allow you to survive any frost without worries and always have warm water in sufficient quantities. The minimum required power is calculated at the rate of 1 kW per 10 m2 of heated area for a standard house with 2 bricks and a ceiling height of no more than 2.7 meters.

According to the technology, calculations are carried out separately for each room, but in practice the total area is often divided by 10 and multiplied by 1 kW. Then losses and calculation inaccuracies are added to increase the received power by 20%; if a DHW circuit is also planned, it is necessary to add another 20% reserve.

For example, the standard boiler power for heating and hot water when operating on an area of 150 m2 can be: (150x1)/10 = 15 kW for heating. But a power reserve is needed. 15 kW x 0.2 = 3 kW reserve for unexpected frosts, losses and inaccuracies. 15 kW x 0.2 = 3 kW for DHW. The minimum required boiler power in this case should be at least 15 + 3 + 3 = 21 kW.

Excessive power results in underutilization of the boiler, but retains the opportunity to expand its use in the future. An error in lack of power promises a loss of comfort and an inevitable rework of the heating system.

This is largely an approximate calculation; for an accurate calculation, you can involve a heating engineer or, based on SNiP 2.04.01-85, you can recalculate the hot water consumption in accordance with the standards, but you will still have to take into account the safety margin, and such an estimate will have little effect on the choice of a specific model. For a private house up to 400 m2, in more than 90% of cases the simple calculation given above is sufficient.

How to calculate the required boiler power Individual calculation, formula and correction factors