Insulation of basements and living spaces should be carried out correctly from the outside so that the dew point is outside the walls. This will protect them from getting wet and freezing during the cold season. The service life of load-bearing structures will increase significantly, the microclimate inside becomes optimal for storing vegetables, preparations and other things. However, it is not always possible to carry out such insulation; more precisely, if this was not done during the construction of the house, nothing can be done.

Insulated basement in a private house

In such a situation, only internal insulation will come to the rescue. It allows you to shift the dew point outside the room, which, of course, will not affect the service life of the walls, but will relieve the room from dampness. The topic of today's article is the insulation of the basement and cellar from the inside in a private house, methods of its implementation, materials for these purposes.

Insulation of basement walls from the inside

Insulating the basement with high-quality thermal insulation will allow you to create a cozy underground room for household needs (workshop, storage of garden tools, installation of a boiler room, water filtration system, etc.), or for leisure (billiards room, sauna, home gym, etc.) .

Insulating the basement with high-quality PENOPLEX boards, which have a very low thermal conductivity coefficient (0.034 W/m∙K), will not only reduce heat loss through the basement, but will also prevent the development of fungus and mold. The biostability and unchanged properties of the material are due to its zero water absorption, i.e. your basement will retain its heat-insulating properties throughout its entire service life.

External thermal insulation of the basement

Insulation of the basement of a house must be carried out at the construction stage, then you can resort to arranging external thermal insulation without unnecessary difficulties. This option is preferable to internal insulation, since external thermal insulation protects the walls from freezing, which can lead to destruction and will not in any way extend the service life of the material.

A basement is possible only in houses with a deep foundation, and the walls of the basement are vertical foundation structures, and the floor and ceiling, respectively, are the lower foundation slab and the ceiling (floor) of the first floor. Read more about the insulation of the basement ceiling here (in the section “Thermal insulation of the floors of the first floors”), about the external insulation of the basement floor (floor on the ground) - here, about the external insulation of the basement walls - here.

For external insulation of the basement, we recommend especially durable slabs of the PENOPLEX FOUNDATION brand, which perform well in thermal protection of underground structures.

Rice. 1. External insulation of the basement with finishing of the walls of the house with a layer of plaster over a metal mesh:

Rice. 2. External insulation of a basement with “heavy” finishing of the walls of the house with natural (or artificial) stone or clinker tiles:

Rice. 3. External insulation of the basement with finishing of the walls of the house with facade panels (siding, block house):

How to insulate a basement from the inside

It happens that for some reason the basement was not insulated at the construction stage, or over time the external thermal insulation lost its heat-shielding properties (which is typical for non-moisture-resistant insulation). Insulation of such a cold basement in a house is done from the inside. In this case, the floor and ceiling of the basement (floor of the first floor) are thermally insulated using the technology of floor insulation on a concrete slab.

Structural elements requiring insulation

When the basement is located not under a private house, but nearby on the site, its insulation is possible in two ways - from the outside and from the inside. The first one is simpler and more reliable, but at the same time more labor-intensive.

External insulation of the storage facility at the time of construction Source applesakhalin.ru

Indications for insulation

Deep cellars freeze due to melt or groundwater. Outdoor buildings due to exposure to low temperatures.

Indications for insulation are:

- lack of insulation in the finished cellar;

- new building;

- damage to thermal insulation;

- freezing of walls, floors, ceilings - accumulation of condensation and frost;

- the appearance of mold.

Also, an indication for insulation is product damage, even if there are no other visible signs.

Freezing of the walls is an indication for insulating the cellar

Thermal insulation of a cellar has many advantages, the main ones:

- frost protection;

- protection against condensation and mold;

- maintaining a stable temperature, optimal for storing supplies;

- protection from groundwater exposure.

Carrying out insulation work works as insulation and protection from water.

Principles and procedures for cellar insulation

Cellar insulation is divided into external and internal.

External insulation

An external insulation option is necessary for detached rooms. It has many advantages: it protects against moisture penetration and freezing, and does not affect changes in the cellar area. Procedure:

- Perform waterproofing using bitumen mastic or upholstery with roofing felt.

- Apply a special composition for gluing walls with slab material. Usually this is cold mastic. It is applied to a layer of stone wool and polystyrene foam. Pressed tightly against the wall.

- The voids are sealed with polyurethane foam, the remains of which are then cut off.

- Lay a layer of penofol, securing it to the mastic.

- The top is covered with a galvanized profile or clapboard.

Insulation slabs must be laid from below, retreating from the ground.

External insulation should be carried out during construction. If the cellar is already ready, then the work is more difficult to complete, since you will have to remove the old lining. In this case, it is advisable to entrust the work to specialists.

Internal insulation

How to insulate a cellar from the inside against freezing largely depends on its type. In general, the work procedure includes thermal insulation of the ceiling, walls, floor, ventilation and entrance area. All work includes the preliminary stage of cleaning the base, laying the frame for the ceiling and horizontal surfaces. Next comes laying out the insulation and finishing.

How and how to insulate basements

Not only the walls, floor and ceiling of a building need thermal insulation

If the building has a basement, it is important to pay attention to its insulation, which will solve a number of problems

Why and how to insulate a basement will be discussed below.

1 Why insulate the cellar?

Often, home owners prefer not to insulate the cellar to save money during construction. Because of this, the concrete base is in constant contact with the ground. In winter, the ground freezes, causing the concrete to freeze as well.

.

In addition, the soil contains moisture: after rains, it can linger in the ground for more than one or two days. In addition to precipitation, the soil itself in the area may be wet, and then the foundation of a private house will be constantly exposed to moisture.

As a consequence, this leads to the following problems:

the destruction of the concrete itself is accelerated (due to the fact that in winter moisture penetrates into the slightest cracks, cracks, recesses, and freezes and thaws there; when freezing, the liquid expands, as a result, the cracks expand);

a low temperature is established in the basement of a private house (concrete itself retains heat very poorly, even with a thickness of several tens of centimeters);

high humidity is maintained in the basement of the house, which leads to the appearance of fungus and mold;

the air in the rooms on the first floor of the house becomes cold, and if the humidity in the basement is very high, then mold can also appear in the rooms.

Condensation on the basement ceiling without thermal insulation

Due to the problems mentioned above, the usable area at the bottom of the house cannot be fully used. Dampness and mold will cause things (whether furniture or food) to quickly deteriorate. And for humans, too humid air, which contains fungal microspores, is also harmful: it can lead to allergies and respiratory diseases.

2 Where and what to insulate?

Partial thermal and waterproofing of the basement does not solve the problem: all walls and floors need to be protected from moisture and cold. Insulation of the basement ceiling (the floor between the cellar and the first floor of the house) can be done as needed to achieve the maximum heat retention effect.

Also, a home owner who does not know how to insulate a basement may have a question about how exactly to do it: from the inside or the outside?

The only correct answer will be to insulate

the outside

: only in this case will it be possible to create the correct “barrier” against the cold. Otherwise - if only the basement is insulated from the inside - moisture and cold will still have a negative effect on the concrete. In addition, mold and mildew can still appear, but this will happen inside, between the basement wall and the insulation.

Concrete temperature during external and internal insulation of basement walls

Internal insulation is necessary as needed. If the owner wants to achieve maximum heat retention inside, then work can be done inside. If you just want to avoid dampness and mold, and also protect the building itself from premature destruction, it is enough to insulate the basement from the outside.

3 About the choice of material

Since the main “threat” to the structure will be moisture, it is necessary to choose materials that are resistant to it. For this reason, mineral wool insulators, which can become saturated with moisture and crumble, are no longer needed.

In order to insulate the basement walls from the outside (this is the main type of work), it is best to use:

polystyrene foam or extruded polystyrene foam (thermal conductivity coefficient - 0.035-0.04 and 0.03 W/mK);

expanded clay (thermal conductivity coefficient - 0.12 W/mK for an average density of 400 kg/m³);

sprayed polyurethane foam (thermal conductivity - 0.03-0.035 W/mK).

Insulation of basement walls with polystyrene foam from the outside

These materials are not the only insulators, but they are the ones most often used and are best suited for the job.

In addition to insulation, the basement of the house will also require external waterproofing. To create a moisture-proof layer the following can be used:

moisture-resistant additives in concrete (if insulation of a cellar in a garage or house is planned at the stage of its construction);

Advantages and disadvantages

The work performed to improve cellars, as a rule, has a number of positive qualities, as well as some disadvantages:

- An optimal atmosphere for storing canned goods and vegetables will be constantly maintained inside the storage facility.

- You can protect the structure from freezing, which negatively affects the structural elements of the extension.

- Subsequently, it is possible to use the premises not only as storage, but also for other purposes.

- Thermal insulation will avoid periodic heating of the cellar space.

- After the insulation work is completed, there will be no increased humidity inside the storage facility.

- Thermal insulation will protect the storage from the penetration of rodents and other pests.

However, despite the positive aspects, there are also a number of disadvantages: the cost of comprehensive insulation is quite high, and a higher temperature will be regularly maintained inside the cellar. In addition, when performing cladding, the usable area inside the storage facility will be significantly reduced.

Important. Before proceeding with thermal protection of the basement, it is necessary to understand the feasibility, since if the structural elements do not freeze at excessively negative temperatures, then performing this work will be impractical.

Little subtleties when installing ventilation

You need to think about basement ventilation at the home design stage.

Ventilation holes, or vents, are made in the part of the foundation that rises above the ground. In a wooden house they are tightly closed for the winter.

Those owners who build their house themselves can equip the house with an additional ventilation hood leading to the roof. It is equipped with a damper. This hood will help ventilate the basement in the winter.

It should be noted that now there are devices that monitor the humidity in the basement and independently open the damper when the humidity levels reach a critical value. However, such devices are quite expensive. Therefore, in winter, you can simply manually open the damper for half an hour on those days when the temperature outside the house is above -15˚C. This will ensure preventative ventilation of the basement.

When installing ventilation, you need to consider the following points:

- the number of vents must be at least four;

- they should be located on opposite sides of the house, preferably on the south and north.

Usually the number of ventilation holes is even. This is due to the specifics of ventilation: one hole serves as a blower, and the other as an exhaust hood. That is, it blows into one and flies out of the other.

The main thing with ventilation is the temperature difference, which forces the air to circulate. It is for this reason that it is advisable to place vents on the southern and northern walls. For better air circulation, south-facing vents can be equipped with exhaust pipes with rain caps. Insulating the soil in the underground: it all depends on the wishes of the owners

Schemes for insulating the floor of the first floor on the ground and on the floor slab.

To properly insulate a basement, it is necessary to carry out thermal insulation and waterproofing of the soil. This is done in two ways:

- complex insulation, with the creation of a floor on the ground;

- The insulation is simple, with bulk insulation.

The first option allows you to then use the basement to store various items. If the plinth is of sufficient height, it can also serve as a utility room. It should be noted that the foundation must go deep from the floor line to a distance of at least 70-80 cm.

However, creating floors on the ground will require much more money and time than the second option. Therefore, if there is no urgent need, owners prefer to do only simple insulation of the subfloor in a wooden house.

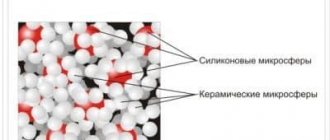

Range of thermal insulators

The range of heat-insulating materials sold on the market today is quite wide.

Let's consider only the main ones:

Foam plastic (cellular plastic)

Inexpensive material made from foamed plastic (mainly polystyrene). The excellent thermal insulation properties of polystyrene foam are explained by the presence of multiple individual granule cells, separated by partitions and filled with gas. An 8 cm thick slab is equivalent in thermal protection to 25 cm of wood or a 1.5 m brick wall.

Polystyrene foam is lightweight, easy to cut, and easy to install. Plates made from it are quite elastic and, unlike rolled materials, do not sag over time.

External foam insulation

The density and strength of polystyrene foam depend on the technology of its processing and the type of raw materials. For façade cladding, it is better to use high-density material - it crumbles less when cutting and has a longer service life.

Despite the fact that the foam itself does not rot, colonies of microorganisms can easily attach to its rough surface and can spread to other structural elements.

Due to its tendency to ignite, as well as the ability to be destroyed under the influence of sunlight, this insulation must be covered with a layer of plaster or used in ventilated facades.

Extruded polystyrene foam

Despite the fact that expanded polystyrene, like polystyrene foam, is made on the basis of polystyrene, its technical characteristics differ significantly. If foam foaming occurs under the influence of steam, then in polystyrene bulk granules are obtained by introducing a foaming reagent and then pressing it through an extruder. As a result, the material acquires a more uniform structure and strength.

All of its air granules are closed and have the same size, which is why polystyrene foam is less fragile than polystyrene foam.

Foundation insulation with polystyrene foam

The service life of this material is up to 40 years. It has minimal water absorption (up to 0.4%) and lower thermal conductivity - on average it is 0.029-0.034 W/(m K). The thermal insulation properties of polystyrene foam are very high - even a thin sheet is enough to create a reliable barrier to the cold.

But still, polystyrene foam is not able to “breathe”; it is better not to use it for wall decoration, otherwise they will get wet. The main purpose of expanded polystyrene is thermal insulation of plinths and foundation blind areas. A special high-strength, high-density material is used in construction as auxiliary or even load-bearing structures.

How to make a children's house with your own hands: from wood and other materials. Drawings with dimensions | (80 Photo Ideas & Videos)

We insulate the ceiling

The ceiling of the cellar must be insulated. If the cellar is a free-standing structure, then it is from the ceiling that cold and water will penetrate into the room

It is necessary to take into account the fact that concrete does not insulate the cellar or basement from the cold. In summer, concrete slabs overheat greatly, and in winter they freeze almost completely

In addition, water seeps through the concrete through microscopic capillaries. To keep the cellar warm and dry, it is necessary to glue a layer of thermal insulation onto the concrete slab, not forgetting about protection from moisture.

If you have a concrete slab as a ceiling in your cellar, then the work is performed in the following sequence:

- The slab is carefully covered with penetrating waterproofing. There is a wide range of similar materials on the market, so you can choose the one most suitable for your cellar. The composition will plug all cracks and capillaries in the concrete, eliminating the possibility of water penetration.

- As soon as the concrete slab has dried, we glue foam boards onto its surface, after which we must secure them with dowel nails.

- Finally, a reinforcing mesh is mounted on the foam layer and a plaster layer is applied.

If you want to insulate the cellar from the inside using traditional materials based on mineral wool, then there is a slightly different technology. Insulation of the basement in this case involves the installation of wooden blocks, inside of which mineral wool mats are mounted. Insulation is also supplemented with vapor-proof materials so that the thermal insulation does not get wet.

The technology of insulating walls and ceilings with mineral wool involves installing a wooden frame.

In any case, insulating the basement from the inside with mineral wool is relevant in cases where the room is relatively small in size and a small amount of food is stored in it. Insulation in such a situation may be the simplest.

Website editor-in-chief, civil engineer. He graduated from SibSTRIN in 1994, since then he worked for more than 14 years in construction companies, after which he started his own business. Owner of a company engaged in suburban construction.

The value of thermal insulation of the basement located under the house is very high. Thanks to the insulation procedure, it is possible to reduce heat loss, provide protection from dampness and reduce the risk of cracks as a result of swelling of the soil.

After thermal insulation measures are completed in the basement, the air temperature in it will not fall below +10°C.

The basement is a room that separates the ground from the floor of the first floor of the house. Usually its height is quite comfortable so that you can move around without problems. In this case, the height of the basement is determined by the height of the base of the house. If the basement is quite spacious, then not using it is a big mistake.

How to insulate the basement of a house with your own hands

Thermal insulation of a basement can be done in different ways. But the most successful option is when the thermal insulation materials are located outside. Thanks to the external placement of the insulation, the basement walls can be protected from freezing. There is no danger of condensation and mold development. At the same time, we must not forget that the basement walls must also be protected from moisture. It is better to use a material that is not afraid of contact with water. Well-known mineral wool and polystyrene foam can deteriorate if they get wet during use.

The most successful is considered to be such insulation, which is carried out during the construction of the building itself. At the initial stage of construction, it is possible to install waterproofing and arrange drainage without any particular difficulties. Be that as it may, it is necessary to decide on the materials used in advance. When choosing insulation, you need to take into account the practical characteristics it has, as well as the complexity of installation. Great importance is attached to the moisture resistance of the insulation and its flammability.

Preparatory work

In order to lay thermal insulation materials especially efficiently, it is necessary to first level the walls. They must also be properly waterproofed and, if necessary, coated with antiseptic substances. After insulation is carried out, the air humidity in the basement may increase. Therefore, it is also necessary to think about ventilation. Otherwise, mold cannot be avoided on the walls and ceilings.

The simplest method of arranging ventilation is considered to be one in which holes are prepared on opposite walls of the basement. It should be taken into account that as the air temperature decreases, these openings must be closed. To prevent atmospheric moisture and melt water from damaging the foundation of the house, a blind area needs to be built around the building. Thanks to it, rain moisture will be effectively removed.

Insulating the basement ceiling from the inside

In general, thermal insulation measures for the basement involve three related processes. So, the walls, floor and ceiling must be insulated. It's better to start with the last one. When insulating the ceiling in the basement, it is possible to reduce the heat loss of the room located above it.

First, the joints and all the cracks that are present in the floor are removed. Next, insulation is laid on the ceiling. As a result of such work, the floor in the house will be much warmer

But it is important that the thermal insulation material used can repel water. If such quality is not observed, the insulation should be covered with a vapor barrier

After this, finishing is carried out. For its implementation, PVC panels, plaster and other materials can be used.

Insulating the basement floor from the inside

Thermal insulation of the floor is also necessary. The fact is that moisture constantly gets into the basement from the ground, but heat, on the contrary, leaves. The most comfortable conditions in the basement will be if you install a “warm floor”

But before installing such communications, it is important to waterproof and level the base. To increase thermal insulation, penoplex is laid, which is filled with a concrete base

Roofing felt can be used as a waterproofing material. It is laid along the walls and partially extends onto them. Thanks to reliable waterproofing, you can protect yourself from high humidity. It is especially good to notice the advantages of the waterproofing layer in those periods when groundwater rises high.

Insulation of basement walls from the inside

The cheapest way to insulate basement walls is to use polystyrene foam. Its density should be about 25 g/m2. The first layer on the walls is waterproofing. The insulation can be secured using dowels in the form of mushrooms. The layer of thermal insulation coating can be sheathed with plastic panels, clapboard or covered with plaster.

The foam sheets are fastened with dowels. Each sheet requires 4-5 fasteners. When the foam is laid, all the remaining joints between the sheets are filled with polyurethane foam or mortar. Then cold bridges will not appear.

Thermal insulation of basement walls can also be done using mineral wool. But the owner must immediately take into account that such insulation cannot be left without waterproofing and protection from physical influences. To insulate walls with mineral wool, you must first lay vertical guides. They are placed in such a way that the mineral wool slabs fit tightly and are held by a similar frame.

Procedure for installing PPS

1. Seal cracks and voids in the walls with sealant or foam.

2. Plaster over any irregularities that may interfere with the fastening of the slabs.

3. Treat the walls with waterproofing material: bitumen mastic, liquid rubber, roll material.

4. PPS boards are glued to the surface from bottom to top, end to end. The next row is placed on the previous one with the seams staggered.

5. Additionally, fix the material with dowels at the rate of 5 pieces per workpiece: in the corners and in the middle.

6. The seams are foamed.

7. Treat the outside of the slabs with plaster. It is recommended to use fiberglass reinforcing mesh in the process.

8. Apply penetrating waterproofing (Penetron, etc.) to the ceiling of the cellar.

9. Glue polystyrene foam boards and secure them with dowel nails.

10. Fiberglass mesh is glued and plastered.

With reinforced concrete slab base

If there are reinforced concrete slabs at the base of the basement floor:

waterproofing is carried out with a double layer of roofing material with bitumen mastic applied between the layers;

- lay extruded polystyrene foam or polystyrene foam with high density;

- pour the screed.

If the basement floor is earthen

If the floor is earthen (for example, with strip foundations):

- remove the turf and level the surface;

- lay waterproofing material;

- pour a gravel-sand cushion and compact it. You can also use expanded clay or sawdust-clay mixture;

- put insulation;

The basement is ready for finishing. In this capacity, you can use porcelain tiles, plaster, and paint.

Floor installation

Floor insulation is most often carried out by laying expanded clay. The sequence of work is as follows:

- A layer of sand - 5-10 centimeters - is poured onto the floor that has been leveled and cleared of the old coating.

- Lay waterproofing material: polyethylene film or roofing felt. The edges of the film, 10-15 centimeters high, are placed on the walls and fixed in any available way. When laying, strips of roofing felt or film should overlap each other by 20 cm.

- A layer of expanded clay 15 centimeters high is poured onto the surface of the film and leveled along the beacons installed along the perimeter.

- A cement screed is poured over the expanded clay with preliminary laying of reinforcing elements.

Microclimate of the underground room

Room thermometer

In order for the operation of a constructed building (residential building, barn, barn, etc.) to be successful for a long time, it is necessary to ensure a certain microclimate inside the basement (subfloor) located under such a building.

The microclimate inside any room depends on the combination of a number of parameters of the air environment in this room, such as temperature and humidity, as well as the frequency of air exchange carried out by the ventilation system.

Temperature

The subfloor in a wooden house can be cold or warm, which is determined by the nature of the use of the house.

If this is a country house that is used periodically, then the subfloor is made small and cold, without laying utility networks and installing equipment in it. Insulation in this case is done only on the floor covering, so that cold air from the underground does not enter the premises of the first floor.

In houses of permanent residence, the underground floor is made warm, for which the foundation, basement, underground floor and floor of the first floor are insulated.

Humidity and air exchange

Humidity in the underground and air exchange are two interrelated parameters.

In the cold version, there is no connection between the air inside residential premises and the underground air. Ventilation of the underground space is carried out through ventilation holes provided in the foundation (basement) of the building.

When the underground is warm, air circulates between the premises of the residential building and the basement. Ventilation is carried out through openings provided in the floor of the first floor.

To reduce heat losses, the foundation and other underground elements are insulated.

How to choose the thickness of insulation?

To reduce heat loss and ensure an acceptable temperature in the premises when insulating, the thickness of the walls, their heat-insulating properties, type of foundation, climate of the area and prevailing wind loads are taken into account. If the walls are thick enough, made of materials with high heat-insulating properties (for example, made of brick or logs), insulating the facade is not necessary.

The thermal insulation of a house assembled from cinder blocks should be maximum - this material is not capable of retaining heat for a long time. When calculating the thickness of the walls, the thermal conductivity coefficient of the insulation itself is taken into account. The best characteristics are provided by materials such as polyurethane foam, polystyrene, and mineral wool.

For example, a 50 mm layer of polyurethane can retain heat in the same way as 1720 mm of brick.

Thermal conductivity of materials

Professional builders use quite complex formulas to calculate the thickness of insulation. When choosing a heat insulator for a private home, it is convenient to use online calculators. You only need to indicate your region of residence, the size of the building, the types of basement and attic floors, the thickness and material of the walls, and the type of roof.

Even with significant wall thickness, a small layer of insulation along the facade is still worth laying. After all, upon contact with cold air and temperature changes, cracks form on their surface over time, leading to premature destruction.

Veranda attached to the house - expanding the living space: projects, tips on how to create it yourself (200 original photo ideas)

Insulation in the basement

If possible, you can carry out additional insulation work on the basement side. It is produced on the ceiling surface of the basement. To do this, it is recommended to give preference to foam blocks, since this material copes well with high humidity. Foam blocks are glued to the ceiling surface using a specialized adhesive, which you can purchase at any hardware store.

After the adhesive has completely dried, the joints between the foam blocks will need to be sealed using polyurethane foam. Excess foam is removed with a knife.

It was not by chance that foam blocks were chosen as an example. Polystyrene foam is one of the cheapest materials for insulation. In addition, if it is damaged, replacement is quick and easy. However, the use of any other thermal insulation material is acceptable. This can be mineral wool, which is available in roll or slab form. The latter option is more convenient for fastening to the ceiling surface, since rolled mineral wool has a loose structure.

If you have a dry basement and floors made of reinforced concrete slabs, insulating material, presented in the form of a slab, will be the best solution. If the ceiling is made using wooden beams, it will be extremely difficult to fix the insulation in the form of sheets or slabs to the ceiling surface.

Since you will have to adjust and cut the insulation to avoid a gap at the joint. In this situation, it is recommended to give preference to roll insulation materials. Thanks to their flexible structure, they go around the beam and do not form a gap. The canvas is fixed with nails or self-tapping screws.

In order for any insulation material to efficiently cope with its functions, all joints formed between the vapor barrier film and the insulation must be sealed with construction tape. This will give a seal to the entire surface. To avoid the formation of condensation, under no circumstances should the ventilation hole be closed.

For more information on how to insulate the floor of the first floor from the basement side, see the following video.

Differences between a cellar and a basement

A cellar is a place for storing vegetables, fruits, homemade products and other food supplies. The main advantage of the cellar is the preservation of a constant temperature throughout all seasons. Usually a cellar is associated with a hole in the ground, but in some cases it must be done on the surface.

A basement is a part of a building located below the first floor, completely or partially buried in the ground. The basement may contain various utility rooms, such as a garage, laundry room, storage room, home theater or gym.

Based on the definitions, the main differences between a cellar and a basement are as follows:

- Location. The cellar is an independent structure that can be located anywhere, including in the basement. The basement is an integral part of the building.

- Purpose. The cellar is used as storage for agricultural products, and the basement is multifunctional.

- Temperature conditions. For a cellar it should be constant between 0 and 5°C. There are no strict requirements for the temperature regime of the basement; it can be cold or heated, depending on what it is used for.

Materials for basement insulation

First, the home owner must decide how to insulate the basement. There are many types of thermal insulation materials with very different characteristics on the construction market.

Let's consider the most popular insulation materials from the point of view of the feasibility of using them for thermal insulation of a basement:

Styrofoam. The cheapest and most accessible insulating material. For insulation, foam plastic with a density of 25 kg/m3 is used. Foam plastic is popular due to its properties: lightness, resistance to rotting, excellent thermal insulation characteristics, inability to absorb moisture, long service life. That is why insulating the basement with polystyrene foam is one of the most common ways to increase the thermal insulation characteristics of the basement. But we should not forget that polystyrene foam cannot be used in rooms with a high risk of fire in order to eliminate the possibility of a fire. This material is flammable and, most importantly, releases harmful toxic substances when burned;

expanded polystyrene. A more modern analogue of polystyrene foam. It has all the properties inherent in polystyrene foam, but is distinguished by a higher density (and therefore stronger), and the presence of a tongue-and-groove system. At the same time, expanded polystyrene is characterized by ease of mechanical processing (the sheet does not crumble when cut), resistance to stress and a higher price. Basement insulation with polystyrene foam is actively practiced because... this material is best suited for insulating the basement from the outside and inside;

polyurethane foam. Sprayed thermal insulation material. The peculiarity of polyurethane foam is its ability to fill the smallest cracks. Polyurethane foam does not allow moisture to pass through, does not rot, does not burn, and ensures complete tightness of the room. Insulating the basement with polyurethane foam allows you to create a durable outer layer of insulation. Disadvantages include high cost and the inability to do the work yourself;

mineral wool. Insulating the basement from the inside allows the use of soft insulation materials and only in the absence of moisture. Mineral wool is hygroscopic and, when wet, loses its thermal insulation properties;

expanded clay Despite the fact that this is a bulk insulation, it has good thermal insulation properties. However, insulating a basement with expanded clay is only justified to insulate the floor in the basement and to protect the foundation from the outside, since expanded clay gravel (crushed stone) provides good drainage.

The insulation, its type and thickness, is selected individually for each specific case. The choice of thermal insulation material can be entrusted to a professional who will calculate the required thickness taking into account many factors. Or you can do the calculation yourself. To do this, you can use the recommendations that contain:

- SNiP II-3-79 “Construction heating engineering”

- reference book on heat and sound insulation designs. Basement walls and foundations;

- SNiP 23-02-2003 “Thermal protection of buildings”

And:

Thermal requirements for basement insulation

Studying the above documents makes it possible to highlight the main thermal technical requirements:

heat transfer resistance (SNiP 23-02-2003). For Moscow – Ro = 4.15 m2•°C/W.

Dependence of the thermal conductivity coefficient of insulation and its thickness for internal basement insulation (table)

Dependence of the thermal conductivity coefficient of insulation and its thickness for external basement insulation (table)

- load perception (SNiP 2.01.07-85);

- heat resistance of the enclosing structure. Calculation of the amplitude of temperature fluctuations is based on the provisions of SNiP 23-02-2003;

- vapor permeability of the enclosing structure (SNiP 23-02-2003).

- fire safety requirements (SNiP 21-01-97, GOST 30247, GOST 30403).

The selected material leaves a significant impact on the choice of technology and determines what and how to properly insulate the basement in a private house.

Is it necessary to insulate the basement under the house?

Very often, home owners consider the basement only as a room where they can store vegetables. But the basement can also play other roles. For example, it is well suited for placing a gym, a wine cellar, or a regular recreation room. True, if you want to arrange something like this, you cannot do without insulation.

The big advantage of the basement is that the air temperature in it is stable almost all year round. But this does not mean that the conditions are simply ideal. In fact, without high-quality thermal insulation it will not be possible to successfully use this part of a country house. But insulation can reduce heat loss by about 20%. If you also insulate the basement, the basement walls will not be exposed to moisture.

Without insulating the basement, you may encounter a problem such as condensation on the first floor ceiling. The floor in the house will remain cold, which will cause serious inconvenience to the owners. To insulate the basement floor, polystyrene foam, polystyrene foam, mineral wool and other materials can be used

It is only important to fully evaluate the capabilities of the insulation so that the results of its use are of the highest quality.

Other types of insulation

Today on the construction market you can find a very large number of different insulation materials. Many of which will cope very well with the task of insulating the basement. Let's consider the most suitable materials for basement insulation.

Glass wool

The material of such insulation consists of very small fibers, which are waste from the glass industry.

Glass wool has a fairly low thermal conductivity.

This insulation is considered one of the inexpensive materials, but has several disadvantages.

Example of glass wool. Click on photo to enlarge.

It is very flammable.

When working with glass wool, be sure to protect your eyes and throat from small particles.

It is not advisable to insulate the basement from the outside with such material.

Mineral wool

This insulation is similar in appearance to glass wool, but it is made from different raw materials. It is produced during the melting of basalt rocks. In the process of a large number of operations, fibers of such cotton wool are formed.

Mineral wool has very low thermal conductivity and a relatively short service life. Like glass wool, mineral wool also needs protection from moisture. And this is the only drawback of such insulation.

Polymer insulation

This is what polystyrene looks like. Click on photo to enlarge.

Such insulation will not need to be insulated from moisture, since it is waterproof. Has low thermal conductivity.

The material is made in the form of plates, which are very simply and easily attached to any surface. It is possible to attach such material using special glue, foam or dowels.

The material is very easy to cut with a knife and you can make any desired shape out of it.

Expanded polystyrene and polystyrene are indifferent to mold and fungi.

The cost of such insulation is relatively low.

Among the materials of this type there are those that do not burn.

Polyurethane foam

This insulation is applied by spraying in the desired location. It can cover both walls and ceiling and floor. Polyurethane foam forms a fairly smooth surface without voids or seams, and hardens very quickly. The insulation does not require additional protection from moisture.

https://youtube.com/watch?v=m0KpHh4zGGs

It has a consistency that can penetrate hard-to-reach places and fill them completely. Polyurethane foam has a very long service life and does not damage the structure it covers. The disadvantage is its high cost compared to other insulation materials.

The main purpose of the cellar is to maintain a constant temperature in your room at absolutely any time of the year. Therefore, for this purpose, it is worth insulating it in a timely and correct manner. This will ensure that the temperature inside the room does not change.

How to insulate a cellar foundation

Thermal insulation of the basement base. Click to enlarge.

Before you start insulating the cellar in the garage, you should work on the foundation. Concrete walls are in constant contact with the ground. Concrete only seems monolithic.

Small channels and cracks run through the thickness of the concrete base. Moisture can easily saturate a concrete slab.

In addition, concrete has high thermal conductivity. In winter it cools down and the cold penetrates into the basement through the concrete structures. Therefore, it is necessary to build a structure that will limit the concrete foundation from moisture.

The foundation walls are insulated from the outside. First you need to remove the soil at the base of the wall. Then the wall is plastered. A layer of plaster will protect the concrete structure from frozen ground.

It is also better to lay concrete slabs with sheets of roofing material. This material does not allow moisture to pass through and will protect the concrete base from getting wet. Now you can fill the structure with soil.

How to insulate a cellar floor

When drawing up a work plan for insulating a garage cellar, do not forget about the floors. To insulate them, you can build an effective structure:

- first we deepen the floor a little, remove about 30 centimeters of soil, level the space;

- pour a layer of crushed stone up to ten centimeters onto the floor;

- the next layer is a sand cushion up to five centimeters;

- carefully compact the insulating cake;

- pour a layer of hot bitumen on top of the structure;

- Now you can make a concrete screed.

How to insulate cellar walls

It is clear that the walls of the cellar will have to be insulated from the inside. We will need wooden blocks, insulation boards and polyurethane foam. Sequence of work:

- We screw the wooden logs to the walls using a drill;

- We insert insulation boards between the bars;

- polystyrene foam can simply be glued to the wall or screwed with plastic dowels;

- carefully seal all voids and cracks with tape, you can blow them out with construction foam;

- Before plastering, a mounting mesh is glued onto the insulating structure.

Insulating the basement from the inside

Insulation of basement walls from the inside

Step-by-step instructions in the form of recommendations and rules.

It is advisable to install heat-insulating material indoors on all surfaces: walls, ceiling and floor. If the basement is intended to be left unheated (cold), it is necessary to insulate the heating pipes in the basement to avoid loss of coolant temperature as it passes through the basement.

Before insulating, it is important to ensure the basement is fully ventilated. The easiest way to arrange air exchange is to make two holes on opposite walls of the basement

Ventilation hole in basement wall

Insulation of basement walls from the inside

The work procedure is largely similar to external insulation:

- a polymer mesh is attached;

- applying waterproofing. In order for the primer to dry, it is necessary to provide ventilation in the basement;

- check the walls for deformations, irregularities (which cannot be leveled with the adhesive mixture), and protruding parts;

- a heat insulator is installed;

- plaster intended for interior work is applied.

When using another finishing material, appropriate preparatory work is carried out, for example, arranging the frame when finishing with plasterboard.

Insulation of a cold basement ceiling

Thermal insulation of the ceiling is mandatory for any method of insulating the basement. Because Insulating floors on the basement side allows you to reduce the temperature difference between the floor of the room in the house and the air in it. The order of work depends on the type of ceiling that is installed between the first floor and the basement.

For wooden floors:

- polystyrene foam (foam or penoplex) is installed;

- the ceiling is inspected;

- penofol is installed - a foil film that will reflect heat into the room;

- finishing work is being carried out.

How to insulate a basement ceiling

Reinforced concrete floors require the installation of a false ceiling, the purpose of which is to reduce heat loss through the concrete. A false ceiling is a suspended ceiling - a ceiling structure with a heat-insulating layer of considerable thickness (subject to subsequent decorative finishing).

Basement floor insulation

The main task of thermal insulation of the floor is to prevent heat from escaping from the basement into the ground. Even if we are talking about an unheated basement. When choosing how to insulate the floor in the basement, you should take a closer look at two options:

Option 1. Floor insulation with expanded clay or “floor on the ground”

Scheme of floor insulation in the basement on the ground

Expanded clay is poured onto the floor, leveled, and a metal mesh is laid on top of it and a layer of lean concrete is poured. To avoid the displacement of expanded clay during movement, a frame is made from treated timber, into the cells of which expanded clay gravel is poured or metal beacons are installed (if the layer is thin). The filled expanded clay is leveled using the rule. After this, the floor is waterproofed and the floor is screeded.

Option 2. Floor insulation with polystyrene foam

Insulation of the basement floor with polystyrene foam (at the stage of building a house) Insulation of the basement floor with polystyrene foam

In this case: the floor in the basement is leveled, rigid polystyrene foam slabs are laid on it, waterproofing (for example, roofing felt) is placed on the slabs so that the edges of the panel extend 150 mm onto the wall. After this, a concrete screed 30-50 mm thick is poured, which is recommended to be reinforced to prevent deformation of the heat-insulating cake.

Waterproofing the floor in the basement of a private house. Pouring screed on the floor in the basement.

Insulating doors in the basement

The last stage, which will prevent the flow of cold air from the unheated basement through the doors into the rooms on the first floor of the house.

Conclusion

Thus, comprehensive insulation of the basement in a private house will expand the scope of use of the basement, reduce heat loss and reduce heating costs.

Tags:

Basement Insulation

Insulation of the entrance area: doors or hatch to the cellar

If the entrance to the cellar is located in a house or garage, there are no special requirements for its insulation.

But if the entrance is located on the street, then it is necessary to insulate the entrance to the cellar.

Work order:

- Insulation of a cellar door was previously carried out using felt and other soft materials. However, now the use of rigid insulation materials that are glued to the doors is considered justified. Then the insulation is covered with a sheet of plywood, plastic or natural wood. Be sure to eliminate the gaps at the junction of the door and the frame. The door seal is installed at this location;

- Insulation of the cellar hatch is carried out in a similar way. Only more attention is paid to reliable fixation of the insulation on the surface of the lid. Otherwise, it may fall off.

An important point that you should pay attention to when insulating a door or hatch is to exclude the possibility of them opening arbitrarily. Otherwise, all work on thermal insulation of the cellar will be useless.

Material selection

Without a doubt, it is best to insulate the cellar from the outside. But for many, this work seems impossible: you will have to dig up walls, dig huge pits to get to the walls, make sure that the dug holes do not damage the foundation of the building, etc. This work is labor-intensive, costly and not always doable with your own hands.

Polystyrene foam is an inexpensive and practical thermal insulation material.

You can insulate a cellar from the inside with almost any modern thermal insulation material. Builders recommend using the most common insulation - polystyrene foam. This material is durable, has a lot of positive properties and is well suited for insulating basement or cellar walls from the inside.

- does not collapse under the influence of water;

- not subject to biological effects;

- ease of installation in any quantities, ease of processing.

Among the disadvantages is the possibility of damage by rodents (mice easily chew through the foam layer). In addition, the material burns and supports combustion, but this disadvantage is not relevant for most cellars.

Polystyrene foam slabs do not collapse when exposed to moisture, but are resistant to rodents.

Materials for thermal insulation of cellars and their characteristics

A variety of insulation materials can be used as heat-insulating materials:

- Expanded polystyrene can be in the form of regular polystyrene foam or penoplex. The material is durable, insulates any surface well, and is safe – it does not emit harmful substances. The disadvantages of polystyrene foam are that it is flammable and does not allow air to pass through. Penoplex retains moisture well and is easy to install. The thickness of the foam varies from 20 to 150 mm, it does not wrinkle.

- Penofol. High-quality thin insulation with a foil layer. The environmentally friendly material is resistant to temperature fluctuations, does not allow moisture to pass through and is easy to install. Thanks to its reflective properties, it retains heat perfectly. Its thickness is from 2 to 10 mm.

- Liquid PPU insulation. A two-component mixture of isocyanate and polyol. Pros: adheres well to any surface, applied in a layer of any thickness, moisture resistant. Disadvantages - Requires a pressurized installation.

- Mineral wool. Available in the form of roll material, slabs of different thicknesses. The density of mineral felt is 100-150 kg/m3, slabs - from 100 to 400 kg/m3. Depending on the manufacturer, there are different thermal conductivity options. From Isover - from 0.032 to 0.044 W/mK, URSA - from 0.032-0.044 W/mK, Knauf - from 0.032 to 0.047 W/mK, Rockwool - from 0.035 to 0.045 W/mK.

Mineral wool adheres well to any surface, repeating design features, wear-resistant and non-flammable.

- Basalt wool. It has high resistance to heat and moisture retention, and is fireproof. Shelf-life Unlimited. It is stronger than mineral insulation.

Sand and expanded clay are traditionally used to insulate floors.

Main types of heat-insulating materials

The main types of heat-insulating materials are:

- polymer materials;

- fibrous materials.

Polymer materials

Polymer materials include polystyrene foam, polystyrene foam, penoplex and polyurethane foam.

The most suitable insulation is certainly sprayed polyurethane foam. It will perfectly fill all the cracks, in addition, it will not require additional hydro and vapor barrier. All that remains is to make a false wall on top of it and the work is completed.

When using polystyrene foam, penoplex or expanded polystyrene, you must first apply a waterproofing layer to the wall. This can be liquid rubber, tar, or waterproofing films.

On top of it, using special glue and dowels with fungi, sheets of insulation are tightly attached to each other. The gaps between the sheets are sealed with foam or sealant, in the case of expanded polystyrene. The thickness of the insulation layer is usually 10 cm, but it all depends on the specific situation.

After this, the outer side of the insulation is covered with an adhesive composition, onto which a reinforcing mesh is applied. Another layer of glue is applied to the mesh. After all layers have dried, you can begin finishing - grouting, priming and plastering.

Important: when insulating basement walls, it is not recommended to use polystyrene foam. But if you still choose it, you need to choose the most moisture-resistant and durable, for example, PSB-S-15 brand

Mineral wool and other types of fibrous materials

These types of insulation are categorically not recommended for insulating any premises from the inside. Due to the fact that the dew point when insulating from the inside is located on the inner surface of the wall, it will constantly condense moisture.

When moisture gets on any materials that have fibers in their structure, they lose their heat-insulating properties, and the entire insulation procedure becomes meaningless.

If you still have to insulate the basement with such materials, you must carefully protect them from the wall. This can be a double layer of waterproofing, or an air gap.

After installing the mineral wool, be sure to use a layer of vapor barrier so that the wool “breathes.” Then again there is an air gap and only then finishing with plasterboard or wooden panels.

Foam insulation

Insulation of the basement in a private house is often carried out with ordinary polystyrene foam. A more modern alternative is polystyrene foam. It has all the characteristics of foam, but is more durable. This material is often used in outdoor work. It is also used to insulate non-residential premises from the inside.

The popularity of foam thermal protection is due to the following advantages of the material:

- excellent thermal insulation properties;

- relatively light weight, due to which there is no additional load on the foundation and walls;

- affordable price;

- resistance to mold and rot;

- low hygroscopicity.

But this insulation also has certain disadvantages:

- when heated, it may emit an unpleasant odor, so it should not be used for interior decoration of residential premises;

- upon contact with fire, combustion occurs quite quickly;

- insufficient environmental friendliness.

To insulate a cellar with polystyrene foam, experts recommend using PSB-25 sheets 5 centimeters thick. Their installation does not involve the construction of sheathing, but is done by gluing insulation to brick or concrete walls using frost-resistant glue. Dowels with a wide head can be used to additionally secure the sheets at the joints.

To prevent the appearance of condensation when insulating the basement from the inside, a vapor barrier film is attached on top of the insulation. Its joints should be taped with reinforced masking tape.

Regular polystyrene foam

Foamed polystyrene

This material, at a certain density, has sufficient heat-saving properties to serve as an effective insulation for the external walls of the basement. (For example, slabs with a density of 35 kg/m³, produced by one of the Russian brands, have a thermal conductivity coefficient of 0.037 W/m·°C.) But in terms of other characteristics, foamed polystyrene is inferior to EPS.

Firstly, although it is minimally permeable to moisture (at the level of 3% of the volume), and therefore, it should not be allowed to come into direct contact with water; and secondly, the strength of the material is about 0.15 MPa at 10% deformation, that is, it is more than two times lower than that of extruded polystyrene foam. Thus, it will be necessary to take measures to reduce the soil pressure on the insulation. For these purposes, expanded polystyrene slabs are protected with a layer of, for example, bitumen-polymer insulation, and are also cut off from the ground by half-brick masonry or a profiled HDPE membrane.

Creating ventilation in an insulated cellar

Home storage of harvest and winter preparations certainly requires a reliable ventilation system. It is especially necessary for an insulated cellar, since due to the constant above-zero temperature, air humidity increases in it, as a result of which mold appears.

To prevent this, it is necessary to create ventilation openings during the construction stage of the storage facility.

They are closed in winter and kept open at other times of the year. For example, supply and exhaust ventilation ensures the inflow and outflow of fresh air masses, and normal temperature is ensured in other ways. You can insulate the ventilation duct with mineral wool and cover it with waterproofing material. As a result, the ventilation system will function smoothly and efficiently, and the temperature in the cellar will always be comfortable.