There is a lot of talk about the dangers of various insulation materials on human health. Such a popular material as polystyrene foam has not been spared. Let's figure out whether polystyrene foam is harmful to others. And if there is a danger, then how to avoid damage to the body if you use polystyrene as an insulator.

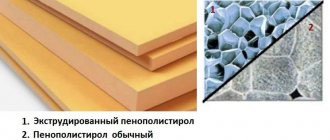

Expanded polystyrene sheets for building insulation Source stroyportal.ru

How to obtain polystyrene insulation

The first polystyrene foam was produced by polymerization more than a century and a half ago. The starting materials were polymers. And over the years of production of the material, it was obtained from literally any plastic. But polystyrene and its derivatives have become the most common.

In fact, expanded polystyrene is a popular type of foam. They continue to call him that in everyday life. And today, many technologies have been developed to obtain such a sought-after material. The simplest method involves filling styrene granules with natural gas.

At the same time, they increase in size many times over. And in the final product of the original polymer, no more than 2% is obtained. The rest is just air (gas). After this, the mass is treated with steam. And if its freedom is not limited, then crumbly balls are obtained.

Foamed polystyrene in granules Source pulscen.ua

They are most often used in construction, as well as in the production of frameless furniture. But such granules have found particular popularity for packaging. They sprinkle even very fragile things and transport them over any distance without fear.

But if the raw materials are first placed in a special block mold, then during the process of saturation with gas and heating with steam, the polystyrene expands and sinteres together. This is how materials can be obtained in almost any shape. And thanks to their excellent properties, they are used in a wide range of industries.

Expanded polystyrene has a number of excellent advantages:

- Almost does not absorb moisture at all.

- Has very low thermal conductivity.

- Biologically resistant to decay.

- Does not attract parasites and is not palatable to rodents.

The material is durable and resistant to various aggressions of nature. And most importantly, its production cannot be called expensive. In addition, there are many technologies for its production. For example, vacuum, which does not use gases at all.

But the most widespread method is foaming. To obtain granules, suspension polymerization is used. The produced polystyrene is treated with steam from low-boiling liquids, and it is evenly distributed into the raw material. And due to heating, it begins to increase, exceeding its original dimensions by 30 times.

Mold for producing polystyrene foam Source 2gis.ru

The result is fine-cellular granules that are sintered together. There are micropores inside them, and between them there is emptiness. And after leaving the mold, the products have sufficient density to prevent air, moisture and steam from passing through.

The material has been successfully used:

- In the production of isothermal packaging and disposable containers.

- On construction sites, for insulation of building facades.

- For military purposes, in the form of personal protection.

- As an insulator for domestic refrigerators.

- In art, as well as for creating interior items and even children's toys.

- When transporting valuable and fragile goods.

- In the furniture industry, as a filler for frameless chairs and poufs.

Some countries (Finland, Japan, Norway and the USA) successfully use the material in road construction. In particular, for protection against freezing. Also widely used in landscape design. Artificial reliefs are created using polystyrene foam.

Characteristics, properties and scope of application

To determine the harm of polystyrene foam as insulation, it is necessary to consider its properties, composition and manufacturing method

Special attention should be paid to the area of application, since it is the decisive factor in identifying the impact on humans.

Insulation

Foam plastic is almost irreplaceable as a material for protection against cold.

- Its porous structure can significantly reduce thermal conductivity.

- The polystyrene foam holds its shape perfectly, something that not one of the insulation materials in this price category can boast of.

- It is more than 90% air, so it does not burn and does not support this process.

- In its production, a minimum amount of styrene-containing substances is used, which is considered a decisive factor in determining environmental cleanliness.

- The maximum service life of foam plastic exceeds 50 years. This is evidenced by the installation instructions and the quality certificate included with most products made from this material.

Release of toxic substances

It is believed that polystyrene foam, when burned or subjected to strong heating, releases styrene, which is very harmful to the body and in its pure form can become a real poison. However, the harmfulness of basalt insulation is sometimes much higher, especially if violations were made during its manufacturing process, which leads to the decision to use a less dangerous material, although it emits unnecessary substances.

Thus, it becomes clear that it is quite safe to insulate a loggia or other premises using polystyrene foam. In the same cases where it will emit harmful substances, there are many other materials, in the form of vinyl wallpaper and plastic interior items, that can cause more harm.

Rodents really like this material. What may indicate lack of toxicity

Application area

When determining the degree of harmfulness of a given material, it is necessary to consider the places where it is used.

First of all, it is worth understanding that polystyrene foam is used indoors only when insulating plastic windows or entrance doors. In all other cases, cheaper materials are used. Therefore, its impact on humans is minimal. Separately, it is worth noting the insulation of walls in contact with the street. The fact is that it must be done only from the outside (see also article)

Otherwise, condensation will appear between the insulation and the wall, mold and mildew will form. When plasterboard partitions are erected, it does not matter at all whether the basalt insulation is harmful or whether styrene foam releases. In this case, both of these materials are placed in such conditions that their use is not only the most optimal solution, but also environmentally friendly. The only unsafe place to use this insulation is considered to be a metal roof

However, taking into account the fact that foam plastic is separated from the immediate area of incandescence by a layer of waterproofing, and from the living space by a vapor barrier film, then using it for these purposes is quite acceptable.

Research and practice

Many novice craftsmen, doing installation work with their own hands, turn to specialists or the Internet for advice. However, there is no clear opinion from experts or reliable research from specialists on the issue of the dangers of this material.

At the same time, practice has shown that the location of the insulation and external influences on it cannot completely eliminate the release of harmful substances. True, the probability of such cases is so small and requires certain conditions that it is not worth taking it seriously.

It is also necessary to remember that the price of other environmentally friendly insulation materials is very high, and their natural components also emit harmful substances when burned or overheated.

For example, polystyrene foam is used as insulation. How safe is it for humans and can it be used for insulation?

Many users, in particular owners of apartments on the upper floors, prefer to carry out thermal insulation work from the inside of the room. What does this mean? Which insulation material should you prefer and what is the difference between polystyrene foam and polystyrene? Is polystyrene foam harmful to human health? If it is dangerous, then why and what are the harmful properties of polystyrene foam?

Combustion of foam plastic

The big disadvantage of an excellent thermal insulator is its ability to ignite. But this is the problem with most building materials. And there is a widespread struggle with this property. For example, wood is impregnated with a fire retardant, and it becomes fireproof.

So a way was found for foam plastic to make it more resistant to fire. A technology has been developed in which natural gas is replaced with carbon dioxide when processing styrene granules. The result is a material with fire-resistant properties. If you remove the source of fire from it, the burning of the foam itself will quickly stop.

Ignition of polystyrene foam Source YouTube

Self-extinguishing polystyrene foam began to be positioned as a safe building material. Until there was a serious disaster in the fire. And people suffered not from the fire, but from the toxic emissions of the foam while it was being processed by fire.

After all, when a material containing polystyrenes burns, strong smoke formation occurs. Not only does such a cloud quickly displace all the air from the room, it contains the strongest toxins - hydrogen cyanide and hydrogen bromide. And they are lethal when inhaled by humans.

The use of foam plastic, even after treatment with fire retardants, does not solve the problem. Expanded polystyrene causes more damage by secretions than by fire. But otherwise the material has proven itself only on the positive side. Therefore, it was decided to use its excellent properties in places where it could least cause harm to human health. Even in a fire.

Toxic smoke from burning polystyrene foam Source Twitter

Durability

The use of this material as insulation in construction practice has a relatively short period of time. And therefore, scientists are studying polystyrene foam very closely for durability.

One of the parameters that expanded polystyrene must comply with is the thickness of the insulation. And this is an important parameter, since it affects the thermal conductivity of the material and naturally entails additional costs for heating the premises.

The most remarkable incident in construction practice occurred during the major renovation of an underground shopping center in Moscow, which was built just a few years ago. After dismantling the covering, significant destruction of the polystyrene foam boards was discovered. As a result, after only two years of operation, the thickness of individual slabs decreased from the design value by more than 8 times.

A study of insulation in external walls showed that the heat transfer value decreased by 49–59%.

After a series of investigations, the reason for this condition of the insulation boards was identified. It was caused primarily by non-compliance with construction technology and design errors. The physical and chemical characteristics of expanded polystyrene were not taken into account.

Styrene release

But the danger of material fire is not the only problem. After all, the main component of polystyrene foam is styrene. And it turned out to be very toxic. And although manufacturers claim that it is almost completely exhausted through technology, what remains is quite enough for polystyrene foam to cause irreparable harm.

Crafts made from polystyrene foam Source solitrade.by

After all, styrene can appear already at room temperature. And with its increase, the release only intensifies. Therefore, the biggest danger may lie in a foam-insulated kitchen. The room can warm up to high temperatures, and it is not without reason that in some cases it is compared to a bathhouse.

High concentrations of styrene can lead to:

- to dizziness;

- irritation of the mucous membrane of the eyes;

- to pulmonary poisoning;

- disruption of the liver and kidneys;

- failure of the hematopoietic system;

- to the occurrence of cancer.

But officially styrene is classified as a third group of hazardous substances. And they are considered moderate. This means that the toxin is on a par with copper, aluminum and alcohol. And only high concentrations of these substances are truly dangerous.

Defenders of expanded polystyrene compare the toxin to nuts and berries. After all, he is present in them. And if a person consumes a moderate amount of them in food, then they even bring benefits. Besides the pleasure of their taste. When the norm of use is violated, then too much always leads to negative consequences.

Packaging corners made of polystyrene foam Source tiu.ru

But in addition to high temperatures, the release of styrene is no less affected by light. And especially infrared radiation. And also the sun's rays. And also oxygen and ozone. Yes, and moisture. And if you simply bring polystyrene foam into the house and leave it near an uncurtained window, then after a very short period of time the concentration of styrene in the room will be 10 times higher than the permissible limit. And if you raise the temperature in the room to 75 °C, then by 150 times.

Release of other toxins

But styrene isn't the only toxin released from foam. Scientists have proven the presence of phenol and formaldehyde in vapors.

The latter can cause very serious damage to a person:

- Inhalation causes bronchitis and asthma.

- Ingestion of the substance can lead to stomach bleeding and kidney and liver failure.

- When it comes into contact with the skin, the toxin provokes dermatitis, rashes and eczema.

Phenol is more dangerous because it is a strong poison. And poisoning can even lead to death if you do not seek medical help in time. And in order to save a person’s life, it is often necessary to administer an antidote.

Saving a person from poisoning Source toksikolog.com

FAQ

Let's look at a number of questions about polystyrene foam and give answers to them.

Are foam ceiling tiles harmful?

To answer this question, you need to understand where the tiles will be installed. It cannot be installed in the kitchen, as sudden temperature changes are possible, and the surface is difficult to clean from a layer of dirt. You can install tiles in other rooms, but you just need to remember that the lighting should not heat up the foam tiles so that styrene does not release.

At what temperature do harmful substances release from polystyrene foam?

As already written above, the temperature should be above 40°C or below -40°C.

Why are polystyrene foam or polystyrene foam harmful?

The material itself is not harmful to human health, but if it is heated, styrene will be released, which is very dangerous.

Steam barrier

Polystyrene foam does not breathe. And if he does it, it’s very bad. Therefore, its vapor permeability is practically zero. This may not lead to very dire consequences, but they do exist. There are also serious dangers.

Accumulation of water between the wall and the insulation Source nauka-i-religia.ru

First of all, the inability of the walls to remove fumes leads to a deterioration of the microclimate in the room. This usually leads to a decrease in general condition. The mood deteriorates, and health drops below normal.

Since the foam will delay the release of vapors to the outside, moisture will begin to accumulate inside the walls. And if the fungus does not take root on polystyrene foam, then it feels great on another surface. In such a situation, black mold may occur.

It develops excellently on most surfaces when they are characterized by high humidity. And since the fungus spreads by spores, it quickly spreads through the air and soon occupies all rooms. And in this case the danger is much more serious.

Mold spores cause in the body:

- internal bleeding;

- respiratory tract lesions;

- migraine attacks;

- digestive system failure.

Is penoplex harmful inside the house? Insulation of walls from the inside with penoplex and plasterboard

If you want to insulate the walls of your apartment or house with penoplex and plasterboard from the inside, then see the comments on this page about this insulation method. Insulating walls inside a house with penoplex and plasterboard is possible, but some nuances should be taken into account and not violate the work technology.

So, let's see what the pros and cons of this method are, and also take into account the specialists they leave under this publication.

Advantages of insulation from the inside

The biggest advantage when we insulate walls with penoplex and plasterboard from the inside of a room is the ability to carry out work in winter at negative outside temperatures.

Indeed, it’s winter outside, but it’s cold inside the house. And there is no way to wait for warmer weather to do any work outside.

In such conditions, it is quite possible to increase the level of thermal resistance of the walls by insulating them on the inside with extruded polystyrene foam.

The second big advantage of this method is that it is the only method that allows you to insulate individual apartments in an apartment building at any time.

Moreover, you can insulate the walls from the inside with penoplex and plasterboard yourself. And such work outside on the facade of a multi-apartment high-rise building would require complex lifting equipment and skills in high-rise installation work.

Disadvantages of internal wall insulation

The biggest disadvantage of insulating walls from the inside with penoplex and plasterboard is that we trap moisture inside the room. Extruded polystyrene foam has minimal vapor permeability. This means that all the moisture that should escape through the walls in the form of water vapor will remain in the premises.

However, there are two points that mitigate this disadvantage:

- This minus is valid only for vapor-permeable walls. These include wooden, aerated concrete, foam concrete, and brick walls.

If your house walls are made of concrete panels or expanded clay concrete blocks, then this minus does not matter to you - even before EPS insulation, your walls did not allow water vapor to pass through and did not “breathe.”

- Even in a house with “breathable” walls, you can avoid the appearance of moisture on the inner surface of the insulation sheets, under the gypsum board, if you reconfigure the ventilation system so that it removes a larger volume of air from the premises.

In this case, the volume of air that was previously removed through the walls of the house will be removed through exhaust ventilation.

Practical lesson on wall insulation and plasterboard covering

Next, we will look at how to insulate a wall with penoplex and cover it with plasterboard.

If you don’t understand something or have any questions, leave yours in the answer form at the bottom of the page. We hope that this material was useful to you.

Other damage from polystyrene foam

When considering whether polystyrene foam is harmful, you need to pay attention to its disposal. Most discarded plates simply end up in landfills. But it needs to be buried, and at best, recycled. But there is no need to talk about the latter.

Discarded polystyrene foam in a landfill Source antiris.tilda.ws

The only component that can be obtained through recycling is the polystyrene itself. And it is cheaper to obtain it from original raw materials. Therefore, pieces of foam plastic lying under rain and sun rays continue to release toxic substances into the atmosphere.

But even the polystyrene foam that was buried has not yet decomposed. And without exposure to oxygen and ultraviolet radiation, and even at low temperatures, it can last for quite a long time. Therefore, it remains to be seen what harm it may cause in the future.

It should also be said about the deception of manufacturers regarding rodents. It's more of an understatement, but that doesn't make it any easier. Manufacturers don't lie when they say mice don't eat foam. They simply do not spread that due to the excellent thermal insulation, rodents in these places equip their burrows.

Arrangement of burrows by rodents in polystyrene foam Source munroviapictures.com

General characteristics of the material

Polystyrene foam is a white porous substance that consists of many individual grains. It is obtained by foaming plastic mass, and the main volume of this material is supplied by gas, due to which its density is lower than the density of the original polymer. This explains the high thermal insulation properties and good sound insulation.

Depending on the composition of the feedstock and the method of its processing, materials with different densities, resistance to mechanical stress and different purposes are obtained. Depending on these factors, building materials are selected for a particular purpose.

Elimination of harmful effects

Simple rules to help avoid bad influence:

- Avoid indoor use. But if the situation requires the use of polystyrene foam in a room, then it is necessary to reduce all risks by contacting only trusted manufacturers.

- Avoid purchasing material from the market and small retail outlets. It is necessary to look for specialized companies that produce foam plastic.

- Insulate the house only from the outside. In this case, it is necessary to establish ventilation indoors. Up to the installation of a forced system.

- Insulate the ceiling only from the attic side. If it is not used for residential purposes.

- Avoid using polystyrene foam items in your household. This is especially true for the construction of children's houses. As well as dummies that are used in residential premises. For example, decorative fireplaces made of polystyrene foam.

Rules for safe use

How to minimize harm from polystyrene foam, you need to take into account a number of rules:

- You cannot insulate rooms with high temperature changes;

- do not insulate the ceiling of a balcony or loggia, and those places where direct sunlight may fall;

- look at the certificate when purchasing, try to buy material in large retail chains;

- systematically ventilate the room;

- Humidifiers and ionizers cannot be used if there is foam insulation;

- The kitchen should have a good hood with air venting.

It must be remembered that styrene can be released when heated, so it is better to insulate areas that will not get very hot with foam boards.