Experts are quite ambivalent about the option of insulating a house from the inside of the walls. Most often, this method is considered as an alternative if for some reason it is not possible to insulate the house from the outside. In any case, it is not recommended to insulate a house from the inside without the necessary qualifications. If there is no clear understanding of how to insulate the walls of a house from the inside, then mistakes in choosing insulation and vapor barrier materials are guaranteed to lead to the constant formation of condensation, which will cause the spread of fungus and mold in the walls.

The general principle of work is unchanged - the sheathing and insulation is attached between its joists

Basic principles of internal thermal insulation

The correct choice of thermal conductivity of insulation makes work on internal insulation as effective as creating an external thermal layer, provided that the heat barrier is correctly placed.

Not every heat-insulating material is suitable for insulating a house from the inside. It must meet certain properties to achieve the assigned tasks:

- Low permeability.

- No secretions harmful to human health.

- Waterproof.

- Ability to maintain configuration under mechanical loads.

It is important to know! The vapor permeability of insulating materials should decrease, that is, the insulation must provide more reliable protection for vapor than a wall. This purpose guarantees the free exit of moist air through the thickness of the wall to the outside.

To avoid problems with insulation from the inside, first of all, you need to determine the location of the dew point. Its correct position should be in the wall or insulation, but not at the junction between them.

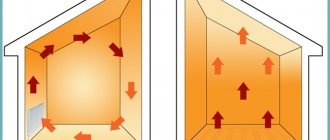

Changing the location of the dew point

If this happens, then the accumulation of moisture and, as a result, rot, mold and mildew on the surface is inevitable. This situation is possible due to the large thickness of the insulation, since the wall is completely insulated from internal heat.

This also happens as a result of low vapor permeability. Walls made of brick and concrete are especially susceptible to this phenomenon. In this regard, internal thermal insulation in such houses is justified only in non-alternative options.

But in buildings made of timber or logs, such a layer of insulation is quite acceptable; you just need to maintain a gap between the wall and the insulation. Therefore, in order to meet all the requirements for internal insulation, you must first make a frame on the wall from a vertically located beam along the width of the insulation size.

Then a waterproofing film is spread and secured along the wall and insulation material is placed between the slats. It, in turn, is fixed with transverse strips and then a vapor barrier film is stretched on top.

With internal wall insulation, such a “pie” is created

Why do you need to insulate your apartment?

Very often, complaints about poor heating come from owners of apartments on the lower floors of panel buildings. The small thickness of the walls does not allow heat to be retained at the proper level. Drafts arise and the walls begin to become damp. As a result, fungus appears on wet surfaces, which is already dangerous to health. Mold not only deteriorates the appearance, it is also impossible to even hang wallpaper over it.

On a note!

Taking into account the fact that utility prices are regularly rising, additional heating sources that consume a lot of electricity are impractical because they are prohibitively expensive.

Insulation of walls inside and outside the house - differences

Wall insulation is carried out both inside and outside .

If it is necessary to insulate walls, then, as a rule, one insulation option is chosen: either from the inside of the load-bearing wall or from the outside.

It is also possible to insulate a wall on both sides, but this is not always necessary : insulation options are chosen based on climatic conditions, construction features, and individual preferences.

Indoor insulation is installed on the inside of the building.

The disadvantages of this option are the following:

- the free space of the room decreases;

- the likelihood of dew point formation inside the wall or between the insulation and the wall.

Internal insulation of the walls of a house is good because:

- weather conditions will not affect the work schedule;

- If the building has cladding, it is possible to preserve it unchanged.

IMPORTANT!

When installing internal insulation, it is necessary to install a reliable vapor barrier inside the building.

Insulation of external walls is carried out from the outside of the building. With this type of thermal insulation, the usable area of the structure is preserved; there is no need to install a vapor barrier layer . However, if the cladding of the building has already been completed, it must be dismantled.

Which insulation for home is better?

The choice of material depends on what kind of coating you are going to insulate. Since one thing is suitable for walls, another for a field, and a third for pipes. It is also important to take into account the location factor: where the insulation will be used - indoors or outdoors.

Types of insulation

The next step, when determining which insulation for your home is best, is to choose which types have the properties you need:

- mineral ones are environmentally friendly and non-flammable;

- extruded polystyrene retains its properties in conditions of high humidity;

- liquid insulation is an innovative material that increases fire safety and allows you to experiment with design;

- Foamed polyethylene can withstand high compressive loads, is chemically resistant, and has good sound insulation qualities.

Choosing insulation for your home is a crucial step and depends on many factors.

Ways to insulate a cold attic: 10 popular and effective materials

Technical characteristics of insulation (1-10)

In addition, the technical characteristics of the material are taken into account:

- soundproofing properties;

- lowest thermal conductivity coefficient;

- fastening method;

- vapor permeability. Insulation materials are divided into vapor-permeable and impermeable. The value of the former ranges from 0.1 to 0.7 mg/(m.h.Pa)

- shrinkage. Over time, a number of insulation materials lose volume or shape under the influence of their own weight. This requires more frequent fixation points during installation (partitions, clamping strips) or use them only in a horizontal position.

- mass and density. Density indicates insulating properties. The value varies from 11 to 220 kg/m3. The higher it is, the better. But there is one proportion: the greater the density of the insulation, the correspondingly greater its weight, which must be taken into account when loading building structures.

- water absorption (hygroscopicity). If the insulation is exposed to direct water (accidental spillage on the floor, roof leakage), it can either withstand this without harm, or become deformed and deteriorate. There are materials that absorb water from 0.095 to 1.7% by weight in 24 hours, and those that do not.

- Operating temperature range. The insulation placed next to the fireplace or roof or directly behind the heating boiler must be resistant to withstanding elevated temperatures while maintaining the properties of the material. The value of some varies from -60 to +400 degrees, while others reach -180...+1000 degrees.

- flammability. Insulation materials for the home are: non-flammable, low-flammable and highly flammable. What affects the protection of a building in the event of an accidental fire or intentional arson.

- thickness. The cross-section of the layer or roll insulation can be from 10 to 200 mm. This affects how much space will need to be allocated in the structure for its placement.

Technical characteristics of insulation (11-14)

- durability. Some insulation materials last up to 50 years, others only up to 20.

- ease of installation. For soft materials, the cut of the insulation can be cut with a small margin and they will tightly fill the niche in the wall or floor. While for solid insulation the pattern must be exactly the same size so as not to leave “cold bridges”.

- environmental friendliness. Implies the ability to release vapors into the living space during operation. Often these are binder resins (of natural origin), that is, most of the materials are environmentally friendly. But during installation, some types can create an abundant dust cloud, harmful to the respiratory system, and prick your hands if you do not wear protective gloves.

- chemical resistance. Using it you can determine whether it is worth laying plaster over the insulation and painting the surface. Some species are completely stable, others lose from 6 to 24% of their weight when in contact with alkalis or an acidic environment.

When determining which insulation is best for your home, it is a good idea to consult with specialists. Because a competent choice of thermal insulation material requires a certain skill and knowledge. Therefore, the easiest way is to find suitable insulation on specialized forums on the Internet (in sections where everything for insulating a house is discussed). There are also consultants in construction companies and stores.

In the tables below you can compare the types of thermal insulation materials:

Table N1. Comparison of types of thermal insulation materials

Table N2. Comparison of types of thermal insulation materials

Types of insulation - which is better?

For proper internal insulation of a wooden house, insulation materials are used that, while maintaining thermal insulation properties, do not cause an unpleasant odor over time, are fireproof and environmentally friendly.

The most common options for internal insulation are:

- mineral basalt wool . It is the most popular material for wall insulation. The features of this material are: good thermal insulation properties, high level of sound insulation, fire resistance, strength, high hygroscopicity, due to which it is necessary to install piping from vapor barrier films;

- foam boards . Because the material can release styrene, extruded polystyrene foam is used, which requires a containment system. The material has good thermal insulation, has soundproofing properties, however, it is quite fragile;

- glass wool It has greater thermal conductivity than mineral wool, but the price of the material is significantly lower than basalt slabs. The material crumbles a lot, so it should be laid in protective equipment: crumbs of material are harmful to health. In addition, it is necessary to install enclosing structures;

- isoplat . Insulation, which consists of compressed flax fibers and wood board. An ideal thermal insulation material from the point of view of environmental friendliness, and also durable enough that it does not require the installation of fencing systems;

- polyurethane foam , which is installed by spraying it onto the surface, is installed using special equipment. Modern and quite expensive material.

Comparative characteristics of thermal insulation

The type of insulation should be chosen based on the characteristics of the building, climatic conditions, and the purpose of the building.

Insulation materials for thermal insulation of a cottage from the inside

To insulate a dacha, you can use various types of thermal insulation materials, differing in the composition of the raw materials used for their manufacture, technical characteristics, sizes and shapes.

Based on the type of raw materials used for production, thermal insulation materials are divided into products from:

- mineral wool;

- glass wool;

- ecowool, the raw material for which is cellulose;

- expanded polystyrene;

- polyurethane and penoizol.

At the same time, materials based on mineral wool, glass wool can be made in the form of slabs or rolls, ecowool is represented by slabs, as well as a scattering of compressed fibers, although this option is used less often for walls, as it requires special technology.

Expanded polystyrene insulation is presented in the form of foam boards and extruded polystyrene foam, and polyurethane-based insulation is a sprayed material, for the application of which special equipment is used.

How to attach penoplex to the wall? Video:

Criterias of choice

In order to choose the most successful insulation option intended for internal wall insulation, you must first pay attention to the following characteristics:

- Resistance to high temperatures and exposure to open fire (fire safety).

- Low thermal conductivity, preventing the outflow of heat from the room.

- Safety (absence of toxic substances and toxic impurities).

- Durability and the ability to retain its original shape for a long time.

- Resistant to moisture and aggressive substances.

The material from which the walls are made and its characteristics also play an important role.

For a panel house, it is recommended to choose the material depending on the future decoration of the walls of the room.

If the walls are planned to be plastered, then it is best to insulate them with extruded polystyrene foam. Feature - the flammability group of EPPS should not exceed G1 .

The choice in favor of expanded polystyrene is also justified by the minimal capture of usable space.

If the walls are sheathed with plasterboard, then they can be insulated with mineral wool and other soft insulation materials, with the obligatory installation of a vapor barrier layer.

It is not recommended to insulate walls in panel houses with polystyrene foam, due to its high flammability and ability to accumulate moisture .

The main task of internal insulation of a house made of foam blocks is to ensure vapor barrier of the thermal insulation material on both sides. (second wall) also required For this purpose, plasterboard or lining is used.

Accordingly, soft cotton insulation or polystyrene foam will not work. It is best to use polyurethane foam, penoplex and polystyrene foam.

A wooden house is made of environmentally friendly material , and the choice of insulation is guided precisely by this characteristic. The best option for insulating wooden walls of a private house is laying ecowool. It is also possible to use polystyrene foam and penoplex, which cannot be said about polystyrene foam.

Expanded polystyrene during operation begins to release carcinogenic substances harmful to humans and animals.

Mineral wool is well suited for insulating an apartment, if the footage allows . You can also use polystyrene foam, provided you first apply a layer of liquid waterproofing to the prepared wall surface.

However, polystyrene foam, like penoplex or foil penofol, is a waterproof material that increases the risk of mold and mildew .

Cork material, warm plaster or fiberboard are excellent for insulating apartment walls. This is only a small part of the commercially available insulation materials, so the choice must be made based on the characteristics of the apartment’s external wall , as well as room finishing options.

Foam plastic and penoplex

Both types of material are made from polystyrene foam, but there are some differences between them.

Polystyrene foam is 98% air, lightweight and environmentally friendly . Its main disadvantages are rapid flammability and fragility.

Penoplex is more dense, elastic and durable. It is not subject to rotting and is less flammable.

Foam plastic and penoplex

Preparing the room for internal insulation

Like any other construction project, internal insulation begins with preparation. At this stage you need to do the following:

- Eliminate weak and defective areas;

- Perform antiseptic surface treatment.

First of all, you need to assess the general condition of the walls, the presence of cracks, chips in the plaster, and weak spots.

It is recommended to eliminate all defects found. And the point here is not so much the quality of insulation, but rather the improvement of the performance characteristics of the walls. Correcting defects in a timely manner will prevent them from aggravating the situation in the future. After all, if the crack spreads further and the plaster falls off, then to fix this problem you will need to dismantle a large section of the insulation and redo everything again. This is not only unpleasant, but also expensive, time-consuming, and labor-intensive. It is imperative to check the walls for existing mold and fungi before insulating them from the inside. Under no circumstances should you carry out further work until the problem has been completely eliminated. If fungal infections are found, we recommend removing the plaster in this area completely - to the base of the wall. Next, you need to treat the area with a special antifungal chemical 2-3 times. There should be no visible marks on the surface after treatment.

For pre-treatment of surfaces in order to destroy existing lesions, we recommend using the following compositions:

- Antiseptic Anti-mold Propitex 1l. A composition that contains active substances to destroy mold on wood, stone, cement and other substrates. Can be used to effectively remove spores, yeast and other types of fungi.

- Dufa mold removal solution. Instant action composition. Due to the inclusion of chlorine, it is characterized by the instant destruction of fungi and mold. Penetrates well into porous wall materials, due to which it is able to remove damage in the structure. When using, it is recommended to thoroughly ventilate the room and use personal protective equipment for hands and respiratory organs.

The next stage is priming the wall with a composition with antiseptic additives. This must be done regardless of whether fungal infections were found or not. In the future, such a composition will effectively prevent the formation of mold under the insulation. You should choose a primer only with special antiseptic properties and a long-lasting effect. For example, suitable:

. Composition for porous surfaces of plasters and concrete. Penetrates deeply into the structure, strengthens, removes dust from the surface and binds small particles. Reduces water absorption and improves strength. Has a long-lasting antiseptic effect with protection against fungi and mold.- Antiseptic Anti-mold Propitex 5 l. This composition has a long-term biocidal effect, due to which it can be used for subsequent insulation.

After the primer composition has completely dried, you can begin subsequent work. The technology for installing insulation will depend directly on the material used for wall insulation. In particular, this can be thermal insulation using polystyrene foam or mineral wool.

Thermal insulation wallpaper

Wallpaper with thermal insulation properties is an excellent solution that will not only insulate walls from the inside, but also hide small defects on the surface.

This type of wallpaper is made from polystyrene foam and is produced in rolls, the length of which reaches 10 meters, and the width ranges from 0.5 to 1 meter. Thanks to its insignificant thickness - 3.6 and 10 millimeters - thermal insulating wallpaper practically does not reduce the area of the room .

They have many advantages:

- pronounced thermal insulation properties (6 mm of such wallpaper is equivalent to 12 cm of a brick wall);

- providing reliable protection from extraneous noise;

- excellent moisture-resistant properties that prevent the formation of mold and fungi.

Wallpaper with thermal insulation properties is glued end-to-end using special glue onto a pre-made substrate.

The backing is applied to the cleaned walls after filling existing potholes and cracks with plaster. You can glue it with a special glue designed for heavy wallpaper or regular PVA. It is necessary to coat both the substrate itself and the wall with adhesive.

The backing for warm wallpaper to insulate the walls should be glued end-to-end. After this, you can start gluing the wallpaper in such a way that its sheets overlap the joints of the backing.

Insulation under wallpaper

How to insulate walls with your own hands?

The algorithm for insulating walls in an apartment from the inside depends on the type of house and the selected insulation. However, the main stages of work remain unchanged in any option:

- Completely prepare a well-dried wall by removing old wallpaper, paint, and remnants of decor or cladding.

- Treat the wall surface with an antiseptic. Let the wall dry.

- Prime. The primer must have deep penetration.

- Plaster the wall if polystyrene foam will be installed.

- Prime the plaster that has dried for several days.

- Instead of plaster, if the walls are insulated with concrete, seal the joints using a special mastic or sealant.

- Install the sheathing if mineral wool is selected.

- Lay insulation or apply it according to individual technology.

- Allow the structure to dry.

- Install a false wall.

Insulating walls from the inside with polystyrene foam: video instructions.

Plaster on insulation

A protective leveling layer on the surface of polystyrene insulation is created using a reinforcing mesh and a special mass designed for this type of material.

Experts recommend purchasing a universal mixture used for gluing reinforcing mesh to insulation boards and subsequent leveling of surfaces from the manufacturers Stolit, Ekomix, Ceresit.

The mesh, which prevents the decorative coating from deforming in the future, is glued with a thin layer of plaster. Then a thin leveling layer of universal mass is applied. The treated surface is left to dry for at least a day.

After drying, the surface can be rubbed. After rubbing, the treated surface is primed . The last stage of work is decorative design.

Thermal insulating paint

Paint for insulating walls inside is a relatively new insulating material.

It is a special coating consisting of miniature ceramic and silicone balls filled with vacuum, as well as a latex-acrylic mixture that acts as a binder.

Thanks to the vacuum present inside the balls, heat-insulating paint applied to the inside of the walls acts like a thermos, retaining heat for a long time.

Thermal insulation paint has many undeniable advantages compared to other materials:

- possibility of use in the most difficult to reach places;

- Convenience and ease of application (using a spray gun, brush or roller);

- resistance to rotting and ignition;

- absence of harmful fumes;

- excellent adhesion to various types of surfaces - concrete, metal, plastic, etc.;

- Apply in a thin layer without weighing it down.

CAREFULLY!

Before using this coating thermal insulation, it is necessary to thoroughly degrease and dry the surface.

Thermal insulation paint

Insulating a house from the inside with mineral wool

Mineral wool is not an optimal thermal insulation material for internal insulation. There is only one reason for this - cotton wool allows steam to pass through perfectly. Because of this, described at the beginning of the article, the dew point shifts from the inner surface of the wall into the insulation itself. Condensation can accumulate in it, thermal performance deteriorate, and mold and mildew can form. However, it is possible to use mineral wool for internal insulation if all technological nuances are observed.

Choosing mineral wool for internal insulation

Mineral wool should be selected based on criteria such as thickness and environmental friendliness. It is possible to use rolled wool, which is cut to the required length directly during installation. Also, such products are produced in slabs. For internal insulation, 50 mm is the optimal thickness at which good insulation is achieved without significant loss of the usable volume of the room.

Example of suitable types of mineral wool:

- Ecoroll Plate 40. It has a relatively small thickness of 50 mm and does not contain phenol resins. Recommended by the manufacturer for internal insulation, including walls.

- TeploKNAUF For COTTAGE Thermo Plate is a modern insulation material from a well-known manufacturer, the features of which are: low thermal conductivity (0.37 W/m*K) and excellent water-repellent properties due to impregnation of the fibers with a special composition. In addition, this board has a special fiber arrangement structure, due to which sound absorption significantly increases. Thus, this insulating material is recommended for insulating the inside of walls, floors, and attics in houses located in noisy areas.

Basalt wool for internal insulation

Separately, attention should be paid to a type of mineral insulation such as basalt wool. The peculiarity of this heat insulator is not only its excellent thermal insulation properties and environmental friendliness, but also its high fire safety. Basalt fiber is obtained from natural stone. Accordingly, such a material has excellent resistance to open flames.

The fire resistance of basalt wool is an important nuance that must be taken into account when insulating the walls of wooden houses, country houses, and baths. In this case, we especially recommend choosing certified products.

These could be slabs:

- Rockwool Light Butts SCANDIC. Products that are designed specifically for insulating residential buildings, apartments and cottages. It is characterized by compliance with environmental standards (has low resin emissions, safe in residential areas). Flexi technology ensures simple installation with filling of gaps in the frame due to the spring properties of the insulation. The material is biostable - bacteria and mold do not form in it, and it is not a good habitat for insects or rodents.

- Rocklight insulation. Manufacturer TechnoNIKOL recommends using this insulation for internal thermal insulation from inside walls, floors, and attics. The material has low thermal conductivity (0.39-0.41 W/m*K). It is non-flammable, bioresistant, and due to special impregnations, it repels water well without accumulating it inside the structure. At the same time, the compressibility of the slab is 30%, which makes it possible to simplify the process of laying it between the joists and efficiently seal all the cracks and gaps.

Installation of mineral wool indoors

A vapor barrier film must be installed around the perimeter of the wall.- A frame made of wooden blocks is mounted on top of the vapor barrier. It is not recommended to use metal profiles. Metal perfectly transmits heat and will become an artificial bridge of cold

- !!! The metal frame should be used when arranging thermal insulation from the inside of objects with increased fire safety requirements together with basalt wool. These include wooden buildings: baths, saunas, etc. !!!

- The joints between the frame and the vapor barrier are taped with tape, since when fastened to the vapor barrier, a hole from the dowel is formed.

- Cotton wool is installed in the frame and carefully compacted to avoid the formation of any cracks.

- A second layer of vapor barrier is installed on top of the frame. This creates a double vapor barrier between the insulated wall and the room.

- The fastening points and joints of the vapor barrier are taped with aluminum tape.

- The frame is covered with preferred slabs - gypsum plasterboard, chipboard, etc.

If the technology is followed and only if a vapor barrier is installed in the insulation, a good result of internal thermal insulation can be achieved. On our own behalf, we would only like to add that insulating a house or apartment from the inside is, rather, an extreme and necessary measure. It is recommended to use it only if it is impossible to install thermal insulation from the outside. If such an opportunity exists, then we definitely recommend considering its implementation as a priority. We hope that the prepared publication will allow us to avoid mistakes and carry out internal insulation as efficiently as possible.

We insulate the walls from the inside using polystyrene foam

When choosing between mineral wool material and expanded polystyrene, you need to keep one nuance in mind. This insulation has low vapor permeability, so it is not recommended to use it on walls with high vapor permeability (timber, logs, porous concrete).

It will be more effective to use for thermal insulation of brick walls and blocks with low moisture permeability. An adhesive mixture is used to glue this material.

When fixing the insulation, in addition to glue, special nails with heads are used.

Special fasteners with wide caps for insulation

Installation of slabs is carried out sequentially in several stages:

- The surface is being prepared. Cleaned, primed and marked with beacons.

- A rail is fixed at the bottom to support the PPS sheets so that there is no displacement during connection.

- Apply glue to the surface of the wall and the plane of polystyrene foam.

- Apply, align and glue the insulation sheets. It is recommended to do this some time after applying the glue.

- The slabs are additionally secured with nails. They are driven in so that the caps are slightly recessed into the polystyrene foam.

- Then a mesh is applied to the slabs, and the surface is treated with plaster mortar with finishing rubbing. After drying, the panels are ready for further finishing: painting or wallpapering.

On a note! Despite the fact that internal thermal insulation is positioned as an alternative to external insulation in bad weather conditions, insulation of walls inside the house is recommended in the summer when the partitions are heated and in the absence of precipitation.

Warm plaster

Insulating plaster, characterized by excellent thermal insulation properties and ease of use, is increasingly in demand. It is made from perlite and foam glass . The second option is more preferable for interior work.

It is based on unsorted foam glass granules, due to which this plaster has a number of positive features:

- excellent heat and steam conductivity;

- environmental friendliness;

- durability and strength;

- fire resistance;

- sanitizing properties.

Plaster

PIR insulation is a modern analogue of extruded polystyrene foam

PIR insulation appeared on the market relatively recently. Therefore, they need to be considered separately. This heat insulator is a three-layer material consisting of an inner layer of polyisocyanurate foam, covered on both sides with aluminum reflective foil.

In fact, PIR (or polyisocyanurate foam) is a special type of polyurethane with a rigid structure, ultra-low thermal conductivity and increased strength parameters. Due to this, it has successfully proven itself as a heater for internal thermal insulation of any premises, from bedrooms to balconies and loggias.

A special property of this insulation is the additional reflection of heat back into the room due to the foil. Thus, the thermal conductivity coefficient decreases to an unprecedented 0.022 W/m*K, water absorption is only 1% (this is when immersed in water for a day). But the main thing is that the vapor permeability of PIR insulation is reduced to zero due to the same foil coating.

For internal insulation, an excellent solution would be to choose materials such as:

- LOGICPIR universal insulation L 1190x590x50 mm. It has the optimal thickness for medium and large rooms, equipped with an L-edge to prevent the formation of cold bridges.

- Insulation LOGICPIR Balcony L 1185x585x30 mm. It is used on the bottom of small unheated balconies. L-edge present.

- Insulation LOGICPIR Balcony L 1190x590x50 mm. Recommended for insulating a heated balcony, as well as a balcony that is part of a living space.

How PIR boards are installed for internal insulation

The aluminum surface of Pir-plates does not allow high-quality fixation of the insulation using the traditional adhesive method. In this case, the technology with plastic mushroom dowels with plastic nails is used.

The very essence of the technology does not differ from the fastening of polystyrene foam described above. After completing the installation of the last slab, the joints are glued. The gaps between the floor and the slab can be filled with polyurethane foam. Next comes finishing. Instead of dowels, you can use wood sheathing. The beam presses the insulation against the wall, after which the cladding is carried out with panels, lining, gypsum board and other materials. An example of installation can be seen in the photo instructions:

Penoplex is an environmentally friendly material for insulation

This heat insulator is a popular modern insulation material that exceeds foam in its qualities. This granular polystyrene mixture has many advantages:

- moisture resistant;

- fireproof;

- environmentally friendly material;

- neutral to chemical influence;

- ideal sound insulator;

- a light weight.

It showed excellent performance under mechanical loads and at low temperatures.

Production of penoplex - solid slabs before further processing

When should you use foil wall insulation?

To insulate a dacha from the inside, in some cases it becomes especially important to use thin materials, but with a high thermal insulation ability. One of these can be considered penofol, one side of which has a foil surface.

With equal thickness to other insulation, its efficiency is 50-80% higher, which makes it possible to use materials with a minimum thickness for thermal insulation, thus maintaining the size of the usable area in the room.

Such insulation with foil is made of foamed polyethylene with a reflective layer applied to it, which should “look” towards the room during installation.

Installation is not difficult and is carried out using glue and/or dowels, but it requires obligatory maintenance of the gap between the insulation and the layer of external finishing, as well as effective ventilation in the room.

The main obstacle to its use in dachas is the rather high price of the material and the need to perform additional work. But this material has undeniable advantages, among which we should highlight:

- moisture resistance;

- possibility of use in a wide temperature range, therefore, more often than for finishing residential premises, foil penofol is used in baths and saunas;

- high efficiency, including due to reflectivity;

- excellent heat, steam and waterproofing characteristics, thanks to which it is possible to create a stable microclimate in the room for which it is used as insulation, which, in turn, can significantly reduce heating costs.

Stages of work

First of all, before insulating the walls of a house internally, it is important to know that the dew point will change - the place where moist air turns into condensation.

Consequently, if you choose the wrong material or its thickness, then such insulation can worsen the condition of the walls: mold, mildew, or destruction of the partition will appear.

It is important! In order to avoid irreparable mistakes, it is better to entrust all calculations for choosing insulation, as well as installation work, to specialists from a trusted construction company.

Before starting work on wall insulation, certain rules must be followed:

- Remove old coatings to the base of the surface, clean, remove possible formations of mold or mildew.

- Treat the wall with an antiseptic and primer solution. At the same time, give each coating a chance to dry.

- When using polystyrene foam, plaster the surfaces with the placement of beacons, which will allow for a more even plane. Allow to dry for at least two days.

- Laying the material.

- Finishing the wall.

Selecting a material based on the type of construction

It is not advisable to insulate frame, wooden, adobe, adobe structures with vapor-tight materials. Otherwise, moisture will begin to accumulate under the insulation, which will lead to damage to wooden structures susceptible to water. Fungus and mold will begin to develop on the frame.

Suitable options for wooden and frame buildings: mineral wool, ecowool, cork. It is better to insulate stone, gas block, concrete, brick and shell rock with vapor-proof insulation materials: penofol, polyurethane foam, extruded polystyrene foam.

Choosing the correct thickness of insulating material will allow you to shift the dew point deeper into the wall without causing condensation to form.

Expanded polystyrene

Extruded polystyrene foam is characterized by increased density and high heat transfer resistance. This insulation is characterized by high moisture resistance and low vapor permeability. There is no need to install an additional vapor barrier layer. When arranging an insulating pie, it is recommended to lay a layer of this material at least 5 cm thick. Installation is extremely simple. Expanded polystyrene is highly durable. It does not release toxic substances when used under normal conditions.

What processes occur in a wall that is insulated from the inside?

All negative processes occurring inside an insulated wall occur not only in winter, but also in autumn and spring, when there is a slight plus outside the window. And this is not surprising, because the main problems arise precisely when there is a large temperature difference between the outside and inside of the room. It is the outer walls, based on the “buffer” principle, that take on all the blows of the elements.

Temperature affects multi-layer protective structures depending on their moisture state. Their main enemy is water. After all, when it freezes, it tends to expand and destroy building structures and their connections. When it gets inside the insulation, it disrupts its thermal insulation properties and becomes the source and cause of the emergence and spread of harmful fungi and other microorganisms.

How does temperature affect the humidity level of a wall? Here a phenomenon occurs in which, under certain conditions, water vapor from the air becomes supersaturated and settles in the form of condensate. The temperature at which this occurs is called the “construction dew point,” which directly depends on the relative humidity in the room. When the humidity increases to 100%, the dew point is compared with the actual temperature. To calculate the exact dew point, a complex formula is used. The set of rules SP 23-101-2004 “Design of thermal protection of buildings” contains a table that shows the ratios of various indicators of air humidity and room temperature.

According to the manual on sanitary standards for the operation of residential premises (GOST 30494 and SanPiN 2.1.2.1002), the normalized air temperature in residential buildings should be within 20-22 degrees Celsius, and air humidity should not exceed 55%. Following the indicators in the table, we determine that the dew point at these indicators is +10.7 degrees Celsius. This means that if the temperature in the wall corresponds to this indicator, then the moisture in the air will turn into water and settle as condensation in that part of the wall where this temperature will be.

Naturally, when the temperature of the outside air changes, the dew point will also move inside the wall, sometimes approaching and sometimes moving away from the interior of the house. This happens because indoors we warm up the wall using various heating devices, and on the street side it is exposed to the cold influence of the environment. A phenomenon occurs that can be compared to a tug of war.

The specific location in the wall where condensation may occur is determined by the thermal characteristics of the wall, its thickness and the materials used in each layer, as well as their relative position.

In a non-insulated structure, the dew point is in the wall and heat evaporates even with the most powerful heating operation. The room will be cold.

If the heat insulator is located outside the building, then the load-bearing wall is completely heated, as a result of which the dew point moves towards the insulation. There is a need to release the moisture formed in it. For this purpose, there is a technology for installing ventilated facades.

A wall insulated from the inside freezes completely, because it is completely fenced off from internal heating by a heat insulator. This leads to premature destruction of the load-bearing walls of the structure. The dew point, which is located in most cases on the inner surface of the load-bearing wall, can move into the wall mass when the outside air rises. As a result, moisture appears between the insulation and the wall, which negates the thermal insulation characteristics of the insulation. When freezing, the adhesive connection of the heat insulator layers is destroyed. The wall gets wet, fungus and mold appear on it.

Expanded clay

Expanded clay is a relatively cheap and yet effective insulation material that can be used to increase the thermal insulation of floors. Expanded clay is not flammable and does not emit harmful substances when used. Burnt expanded clay is a relatively moisture-resistant material. It has excellent soundproofing qualities. The recommended laying layer when forming an insulating cake is 25 cm. This is its only obvious drawback.