A correctly selected and installed chimney for a geyser not only ensures its reliable operation, but also does not allow combustion products to enter the interior of the house. Therefore, special attention should be paid to this issue, because cases of waste from improper operation of instantaneous water heaters are not so uncommon.

The following material will help you figure out how to choose a gas chimney for different types of water heaters and install it yourself in accordance with the rules.

Requirements for chimneys for geysers (SNIP)

Requirements for chimneys are set out in the following documents:

- SNiP 41-01-2003 in a new edition (SP 60.13330.2012);

- NPB 252-98 (fire safety standards);

- SP 42-101-2003;

- VDPO (rules for the production of pipe and furnace works).

The main provisions regarding the direct removal of smoke from household water heaters are collected in the following paragraphs:

- The cross-sectional area of the chimney pipe must be greater than or equal to the cross-section of the outlet pipe of the column;

- Laying gas pipes through living rooms is prohibited;

- The chimney system must be completely sealed, resistant to corrosion and temperatures up to 200°C;

- The vertical section of the chimney at the outlet of the column should not be shorter than 500mm. Only in some cases this figure is reduced to 250mm;

- The length of connecting pipes should not be more than 3 m in designed houses and no more than 6 m in existing ones;

- The design allows for no more than 3 turns with a radius of at least the pipe diameter;

- If the wall of the building is made of non-combustible materials, the distance from it to the exhaust pipe must be at least 5 cm, if the wall material is flammable - at least 25 cm. If the fire protection requirements of SP 42-101-2003 are met, the distance can be reduced to 10 cm;

- If the connecting pipe passes through an unheated room, it must be protected with thermal insulation;

- The slope of the exhaust pipe towards the column must be more than 0.01;

- You cannot use one hood for a gas water heater and a gas stove;

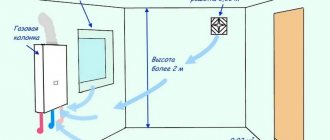

- The ceiling height in the room with a water heater and chimney should not be less than 2 m. Area – at least 7.5 m for one device, at least 13.5 for 2 devices.

Fire safety rules

The distance from the brick wall to the chimney is 130 mm. If the structure is wooden, then this parameter increases to 260 mm. When pipes pass in close proximity to rafters or through flammable materials, these places must be insulated.

Fire protection of a chimney Source petropech.ru

When using solid fuel equipment, the chimney is equipped with a mesh metal spark arrester, regardless of the material from which the building is constructed. The cell size does not exceed 5*5 mm. In addition, there are other rules:

- the chimney head must be positioned correctly relative to the roof;

- to reduce moisture condensation, the temperature at the outlet of the structure should be 15°C higher than the dew point temperature (60°C);

- if the chimney height is less than 5 m, then the installation of an electrically driven smoke exhaust is required.

The outer wall is separated from the structure by an asbestos-cement sheet or basalt overlay.

Corrugated aluminum chimney

More details Aluminum corrugation for geyser. To remove burnt gas from a geyser into the ventilation shaft. Easy installation | Size | Wholesale | Retail price |

| Aluminum corrugation Ø110 | 320 | 340 rub. | |

| Aluminum corrugation Ø130 | 350 | 370 rub. |

Exhaust pipes are installed on the gas water heater in an apartment or house, and are designed to exhaust burnt gas into the ventilation shaft. The air duct pipes for the geyser are made of steel and covered with a high-quality protective coating of white heat-resistant enamel.

Enameled white air ducts of a geyser are highly safe, aesthetically pleasing and resistant to the destructive effects of hot gas and the resulting carbonic acid. White enamel applied to the chimneys of a geyser easily withstands elevated temperatures and protects the outside of the pipe from corrosion. White air ducts "Whitesteel" have the following advantages:

- Special sealed Z-shaped seam

- Easily cut to size with a hacksaw or grinder

- Chemical resistant - resistant to condensate and carbonic acid

- Covered with white heat-resistant enamel to match the color of the geyser

- Recommended for installation by the gas service of St. Petersburg

High strength steel 0.6mm, which reduces to zero the possibility of damaging the chimney of a geyser and ensures durability

High quality workmanship. Bends and other elements are made as compact as possible to look aesthetically pleasing in your kitchen or bathroom and take up as little space as possible. Elements are decoratively thought out and measured according to air resistance indicators

VentDom is a manufacturer of chimneys for geysers "Whitesteel" in St. Petersburg, carrying out retail and wholesale sales. In most apartments, modern enameled exhaust pipes are installed; they look beautiful and do not spoil the appearance of the room; they are much more reliable and safer than corrugated pipes. Modular chimney pipes for geysers are used to remove hot air from geysers.

White chimneys are recommended for installation on geysers of all manufacturers: Neva, Neva Lux, Electrolux, Bosch, Zanussi, Roda, Gorenje, Ariston, Termet, Baxi, EDISSON, Mora Top, Ladogaz, Elsotherm (tested for compatibility with each brand).

Structurally, chimneys are modular elements that are connected to each other in series, similar to a constructor. Due to the modular assembly principle, you can independently install the chimney of a gas water heater with your own hands while meeting the necessary safety requirements. During installation, the pipes are laid from the outlet of the column to the wall flange fixed to the opening of the common house ventilation shaft. Additional sealing of chimney seams is not required. To pass through or close to a suspended ceiling (film), a heat-insulating mineral wool cylinder is used, which is placed over the pipes.

Corrugated flexible chimneys are prohibited for installation on a gas water heater according to SNiP and are allowed for installation only on an exhaust hood. It is also prohibited to combine the hood from the stove and the gas water heater into one hole in the common shaft. According to the design, such houses have 2 separate shafts; the building manager or neighbors living on the same riser as you can help you find it. If the second shaft could not be found, the gas water heater is connected to the ventilation duct, and the hood starts in recirculation mode.

What are the concerns?

For some, installing suspended ceilings in a kitchen with a gas heater seems completely impossible. This opinion exists among many people and is caused by a misconception about the film that is used as a base for the ceiling. Let's look at the most common concerns.

Hot? No problem!

In the kitchen, as you know, conditions are different than in other rooms. These are high humidity, temperature changes due to cooking and, finally, the presence of heating devices themselves - a gas water heater and a stove. Therefore, materials must be safe and non-flammable. So, film coverings are absolutely suitable for the kitchen.

PVC film, on the contrary, is initially designed for installation at high temperatures - plus 70 degrees. The heat gun gives so much, as a result of which the film heats up, becomes softer, more elastic, and stretchable. When the fixed canvas cools down to normal values, it stretches, becomes even and strongly stretched.

But perhaps when the gas heater heats up in the kitchen, the film may sag? This is also excluded. Heating of 70 degrees is almost impossible to achieve without special equipment, and the hottest masses of air can only accumulate directly near the burning burners.

Smoke, dust

No matter how high-quality the hood is, gas combustion products still accumulate in the kitchen, greasy stains are deposited on the upper surfaces of kitchen cabinets in an unpleasant and difficult-to-remove residue. Therefore, many housewives fear that the suspended ceiling in the kitchen will soon cease to be perfectly white and shiny and will become covered with a layer of soot and grease. Plus, the ubiquitous dust will do its job - it will settle on a wet and greasy stream, and it will not be possible to paint over it or whitewash it, as is the case with an ordinary painted ceiling. In fact, caring for film coatings is simple. A ceiling made of PVC film can be easily wiped with a damp cloth, you can add a non-aggressive detergent to the water, and for a glossy finish on the ceiling, add 10% ammonia.

Fungus, humidity, condensation

People are often afraid that the film will become covered with condensation, since it does not breathe and does not absorb moisture. In addition, fungus and mold may grow under it. As for fabric canvases, the fears here are completely unfounded: the fabric ceiling can breathe, so condensation does not collect under it, and mold does not form.

As for the film, the situation with it can become more complicated if:

- initially the rough ceiling was affected by fungus;

- There are leaks on the ceiling, walls, or in the space above the ceiling there is a cold water supply pipe on which condensation accumulates.

- humidity is often high.

If the room is damp and there has already been mold, then before installing the stretch ceiling you need to thoroughly clean and treat the surface of the affected base with anti-mold preparations. Ventilation will help avoid problems in the future. In all wet rooms (bathroom, kitchen, etc.) it is recommended to install a vinyl ceiling with ventilation holes. As a preventive measure, experts recommend regular ventilation of the room.

How to install a geyser

Self-installation is prohibited by Russian law, but since representatives of the gas service often remain elusive, we recommend installing the device yourself. Specialists should only be invited to connect the hose to the gas pipe and check all connections for leaks.

What you need to have with you

First of all, prepare all the necessary materials and tools. You will need:

- new gas water heater;

- PVC pipes for water supply and metal-plastic for gas;

- fitting;

- taps - gas and water (it is better to use ball taps);

- salt and magnetic filters;

- corrugated or galvanized pipe (if included with the column);

- Mayevsky crane;

- a ring to make an entrance to the chimney;

- gas hose (its length depends on the distance between the pipe and the column);

- water hoses (also select the length depending on the distance);

- dowels and screws;

- gas key;

- pipe cutter;

- set of wrenches;

- drill;

- level;

- sealant, FUM tape and tow;

- soldering station for pipes.

In the case of a private house, you may also need a metal (asbestos) pipe to remove smoke. Its diameter should not be less than 120 mm, and its height should be two or more meters.

We remove the old

This is an old gas water heater and is not safe to use. It is best to replace it with a modern analogue.

If you already had a water heater, then the first thing you need to do is dismantle it. For this:

- Close all gas valves.

- Using a gas wrench, unscrew the fixing nut on the hose.

- Then remove the hose from the column. If the hose is new and undamaged, it can be used further. Otherwise, buy a new one.

- Now you can proceed to disconnecting the device from the water supply. Turn off the water (if there is a tap near the water pump, then just turn it off, otherwise you will have to block access to water for the entire apartment).

- Remove the connecting pipe located at the outlet of the column and pull it out of the chimney.

- Dismantle the water heater by removing it from its mountings.

Direct installation

Installation of a gas water heater occurs in several stages. After choosing a location, you need to prepare all communications: water supply, chimney and gas pipeline. All this should be in close proximity to the future column, so that after installing the latter, all you have to do is connect the hoses to the pipes.

To connect gas to a gas water heater, be sure to call specialists from a special service.

- So, the first thing you need to do is mark the location for the water heater. I hang it on a special bar that is included with the device. That's why you will need a drill, dowels and screws. It is better to mark using a level.

- We drill holes, drive in dowels, attach the plank and screw it to the wall with self-tapping screws.

- The next thing you need to do is connect the water heater to the chimney. This is done using corrugation or a metal pipe. Installing the latter is easy. The pipe needs to be put on the pipe (and the sleeve must also be tightened with a clamp) of the column. The other end is inserted into the chimney and covered with cement (asbestos can also be used). But do not forget that the horizontal section of the pipe cannot exceed 6 m and you cannot make more than 3 corrugation bends.

- Now you can proceed to connecting the column to the water supply. As mentioned earlier, it is better to do the installation of pipes and branches in advance. At the same time, cutting into the nearest line is not always a good option (if the pressure in it is weak, cut directly into the main pipe going to the apartment). Be sure to install a tap on the new branch going to the water heater so that you can repair the water heater or replace it without turning off the water in the entire apartment or house. To install the pipeline, you will need metal-plastic pipes and a soldering iron, as well as a tap and couplings.

- After finishing work with the hot and cold line pipelines, all you have to do is connect the hoses to the corresponding outlet and inlet of the dispenser and to the pipes.

This is what a chimney made of corrugation looks like. The ring has a purely aesthetic value.

Your work is now complete. Connection to the gas pipe is carried out by specialists from the relevant service. A ball valve is also placed at the entrance to the column, all connections are sealed and then checked for leaks.

Make it yourself or order it

You should only take on making chimneys yourself if you have good knowledge of the theory in this industry, a set of professional tools and the ability to use them. The slightest miscalculation can lead to fatal consequences.

It is much easier and faster to order a finished product and entrust its installation to specialists. But, this service will cost much more than doing it yourself. It is worth carefully weighing your options before making a decision. Studying the regulatory documentation on this topic will help with this.

Rules for arranging a hood

It is allowed to be placed in niches built in external walls made of fire-resistant material. To prevent the appearance of condensation formed during the removal of combustion products, it is necessary to thermally insulate the wall from the outside.

In the absence of walls or partitions made of suitable material, the use of a casing or root pipe is allowed.

Building regulations require an individual exhaust pipe for each stove or apparatus. It is possible to connect no more than two devices or stoves to one pipe, provided they are located in the same room or on the same level. When connecting two pipes to a channel, a cut must be provided.

According to the standards, fireplaces, small boilers, devices and heaters for removing combustion products must be equipped with a separate chimney.

In functioning buildings, two gas appliances can be connected to one channel if they are located on the same level. If the equipment is not located on the same floor, then the removal of burnt gases into the chimney should be at different levels. In this case, the distance between them should not be less than 75 cm. If this condition cannot be met, the chimney is equipped with a cut of the same height. The diameter of the chimney duct is determined in accordance with the simultaneous operation of all connected devices.

If there is no ventilation duct in the building, the installation of chimney ducts of an attached type is permitted.

Chimney device

The operation of the gas water heater is accompanied by the process of gas combustion, so it is connected to the chimney. When installing the device in a private house, it is equipped with one of the following exhaust systems:

- coaxial chimney;

- corrugated pipes;

- steel channels.

It is better to use a ready-made coaxial chimney or steel pipe. A significant disadvantage of a corrugated channel is its rapid burnout.

If there is a classic chimney, the pipe is often routed into it. If there is no ordinary pipe, then the chimney is extended to the street.

Note! The installation of a chimney should be approached with all responsibility. Errors during installation of the system are unacceptable, otherwise it poses a danger to the health of residents.

Installation

The hood must be installed with extreme care. It is very important to correctly perform all calculations to avoid harmful substances entering the room.

Basic installation rules:

- correct determination of the diameter of the hood and the length of the pipes: very long ones can cause weak draft;

- taking into account the power of the unit: the greater it is, the stronger the traction required;

- compliance with safety precautions during installation: the structure must be intact so that gas does not leak through it.

Any violations of the rules for installing the hood will appear immediately or after some time. It must be remembered that gas appliances, if used rashly, can cause serious harm to both the owner of a private home and his neighbors.

Chimney installation

To ensure long-term and safe operation of the hot water column, it is necessary to meet all the requirements for the chimney set by regulatory documents. The result of compliance with these requirements will be the presence of stable good draft, which is so important for the normal functioning of atmospheric heaters. In addition, the standards take into account measures to protect against fire and carbon monoxide poisoning, and minimize the impact of emissions on the environment or people living nearby.

When laying a coaxial chimney outside, the following rules must be observed:

- the total length of the horizontal section of the pipe should not exceed 3 m;

- the number of channel turns by 90º is no more than three, with a radius of curvature equal to the pipe diameter or greater;

- It is not recommended to install the double-walled gas duct of an instantaneous heater vertically and pass it through the ceilings and roof. The length of the channel will increase, and then the aerodynamic resistance will increase; the unit’s fan may not be able to cope with it;

- The passage of the coaxial pipe through the wall is carried out in a steel sleeve and with a slope of about 2º towards the street to drain condensate.

The hole in the wall where the chimney of the gas water heater will pass must be at a certain distance from various elements of the building and ventilation devices. The table below shows the minimum distances that should be maintained:

The requirements for installing smoke ducts for units with an open combustion chamber are somewhat more complicated. The number of turns of the pipe here is the same as in the previous case, only the deviation of the vertical part is still allowed by no more than 30º with a displacement of no more than 1 m. If it is planned to jointly connect the boiler and the column to one shaft, then its cross-section should be designed for simultaneous operation two units. In this case, the connection of the gas water heater to the chimney must be made above or below the insertion from the boiler at a distance of at least 75 cm.

The diameter of the connecting pipe cannot be less than the outlet pipe of the heater, and immediately behind it there should be a vertical section of the channel 25 cm long for rooms up to 2.7 m high and 50 cm in rooms with ceilings higher than 2.7 m. A steel or corrugated chimney inside the room must be fixed with clearance 5 cm from walls and ceilings made of non-combustible materials, and sagging of the horizontal section of the corrugation is not allowed. If the wall is made of combustible material, then the gap between it and the pipe increases to 25 cm.

To avoid the zone of wind pressure and deterioration of draft, the height of the chimney must be observed in accordance with the diagram:

Types of chimney pipes

Installation of an internal chimney requires compliance with fire safety rules.

Chimneys are divided according to location and materials of manufacture. According to location - internal and external.

Mounted indoors - internal. Its walls are not exposed to the negative influence of external factors - rain, negative temperatures, ultraviolet radiation, temperature changes. This design is more durable. The increased heat transfer is used for additional heating of the premises.

The disadvantage of internal pipes is:

- danger of leakage of harmful gases during depressurization;

- possibility of fire due to improper thermal insulation;

- the need for additional thermal insulation when passing through the floors;

- The chimney pipe occupies a certain place in the room and its presence sharply limits the usable area.

The construction of an internal chimney is associated with additional costs for interfacing structures and thermal protection.

External chimneys exit through the wall of the house and go outside the room. They have many advantages:

- simplicity of construction and the possibility of integration without affecting the finishing of the house;

- price;

- ease of repair and preventive maintenance;

- safety in case of leakage of harmful gases.

To prevent condensation from forming, the pipe must be insulated.

Along with the advantages, there are a number of disadvantages:

- need to be insulated to reduce the formation of condensation inside the pipe;

- negative environmental influences;

- cannot be used for additional heating of the room.

Kinds

A coaxial chimney for a gas water heater is structurally composed of two pipes of different diameters, with a smaller diameter pipe (designed to remove combustion products) located inside a larger diameter pipe (designed to provide additional ventilation).

The enameled chimney for a geyser is made of high quality steel with a thickness of 0.6 mm and is coated with heat-resistant enamel to increase its strength characteristics. Additional insulation of the chimney system is required during winter use. Review of technical characteristics and elements of stainless steel chimneys here: https://mykaminz.ru/dymoxod/vidy/nerzhavejka/obzor-texnicheskixe-xarakteristik-i-elementov-dymoxodov-iz-nerzhaveyushhej-stali.html.

The corrugated chimney for a geyser is made of laminated multilayer aluminum foil, and between the layers of aluminum there is an additional reinforcing frame made of steel wire.

Chimneys for geysers made of stainless steel, as a rule, are double-circuit pipes, and mineral wool is used as an intermediate thermal insulation layer.

In the case of a chimney for a gas water heater through a wall, a special hole is prepared and a passage pipe is installed to isolate the chimney pipe from the wall of the house.

When installing a chimney for a gas water heater in an apartment, keep in mind that you cannot connect one chimney to both a gas stove and a gas water heater, since the chimney system may not be able to cope with the removal of a significant volume of flue gases.

When installing a chimney for a gas water heater in a private house, keep in mind that the vertical section of the pipe, from the smoke outlet of the gas water heater to the horizontal section of the pipe, must be at least half a meter. When installing a chimney system, no more than three turns are allowed, and the radius of curvature must be no less than the cross-section of the pipe. Read an overview of types of chimney dampers.

Checking traction

The reason for the lack of draft in the chimney, as a rule, is blockage and large accumulations of soot in the chimney.

The cause of backdraft may be improper design of the chimney system (the diameter or height of the chimney pipe is incorrectly selected). Also, incorrectly selected thermal insulation material and installation of the thermal insulation layer can lead to a large difference in the temperature of the outside air and the temperature of the exhaust gases, which will accordingly lead to the formation of a large amount of condensate and possible icing of the chimney.

Photo

An enameled chimney is installed using straight sections of pipes and ninety-degree bends. The technical characteristics of enameled chimneys allow their use at operating temperatures up to 300ºС.

The photo shows an enameled chimney.

The advantage of a corrugated chimney is that, if necessary, the length of the chimney can increase from one to three meters. Corrugated chimneys are very mobile and also affordable.

The corrugated chimney is shown in the picture.

Almost all modern geysers (especially if they are from a European manufacturer) are equipped with a closed combustion chamber and a coaxial chimney. The advantage of using a coaxial chimney is that there is no need to provide additional ventilation to the room. Since the coaxial chimney is designed in such a way that it not only performs the function of removing flue gases, but also provides the gas burner located inside the gas water heater with the necessary air (and the air is taken from the street, and not from the room).

The picture shows a view of the coaxial chimney from the outside.

Connection

The process of installing a geyser with a chimney can be divided into several stages. Let's consider the simplest option for installing a chimney, using a corrugated pipe:

- Installation of a geyser begins with choosing the location of the equipment, so that it is convenient to install the hood;

- Then a hole is made in the ceiling and roof;

- A piece of asbestos pipe one and a half or two meters long is inserted into the prepared hole;

- A pipe sticking out of the ceiling can be disguised with a special decorative rosette;

- Next, using dowels and self-tapping screws, a gas water heater is installed;

- When the column is fixed to the wall, take a piece of corrugated pipe, one end is put on the outlet pipe of the column, and the other end is inserted into the chimney socket (if an enameled steel pipe is used to install the chimney, then a tee is used to connect the chimney to the gas column);

- To supply gas to the equipment, a tee is cut into the gas pipe, a gas tap is installed, and a flexible line is connected to the column with a fitting with a union nut;

- In the same way, a tee is cut into the water supply system, a water tap is installed and the water supply pipe is connected to the column (salt and magnetic filters must be installed);

- All that remains is to connect the column to the hot water supply system. Read the instructions on how to make an insulated chimney on this page.

Options for installing a gas chimney in the figure.

When installing a chimney for a gas water heater, you should adhere to some rules:

- do not use more than three taps;

- the constituent elements of the chimney must be rigidly fixed and not bend;

- cross sections should not have narrowings;

- an inspection grille and a condensate collector are installed at the bottom of the chimney;

- the chimney should not have joints in the ceiling;

- the internal surface of the chimney should have as little roughness as possible.

Video

Watch the video for recommendations on installing a geyser:

Using a geyser in everyday life is very convenient; modern water heating equipment can provide, in a fairly short period of time, the required amount of hot water, without significant expenditure of energy resources. The main thing is for more efficient operation of water heating equipment (ensuring high draft), choose the right chimney, connect it to the gas water heater, and periodically carry out preventive inspections and cleaning of the chimney system.

Tips for installing a chimney

Before installing a gas water heater in a private house, you need to decide where and how to remove flue gases. Exhaust pipes - chimneys - are used for this purpose; they are made from the following materials:

- Galvanized or stainless steel.

- Asbestos pipes.

- Brickwork.

When the house has an exhaust duct made of the listed materials and with sufficient draft, the problem is solved; you can select and install a gas water heater of any type. You just need to correctly connect the outlet pipe of the device to the entrance to the smoke duct. It would seem that the task is not difficult, but many people make mistakes when performing it. So, when cutting into a finished vertical shaft or installing a chimney for a gas water heater, you must adhere to simple rules:

- The number of turns of the smoke channel from the outlet of the heater to the insertion into the vertical channel should not exceed 3.

- Connections between fittings and straight sections should be made hermetically.

- The vertical pipe for the gas water heater must have a condensate sump at the bottom and an inspection hatch or drainage.

- The section of the chimney pipe located outdoors should be insulated.

- It is prohibited to use various weather vanes or umbrellas. It is recommended to install a special nozzle on the exhaust.

- Do not combine the exhaust duct from the boiler with the chimney from the boiler.

Installation of connecting sections made of aluminum foil is not allowed. You can use a corrugated chimney made of stainless steel.

The rules for using gas installations prohibit the connection of ventilation ducts to them as a chimney; the shaft for the emission of combustion products must be made separately from the ventilation shaft. An exhaust hood can be used in a country house or apartment if the cross-section of the shaft meets the requirements in the product data sheet and when there is an additional exhaust duct in the same room.

In order to comply with the rules, it is best to place the column in the furnace room, where natural air exchange is organized. When this is not possible, you will have to mount an additional chimney pipe on the street, securing it to the outer wall and raising it to the height shown in the diagram:

Exactly the same rules must be followed when installing a geyser in an apartment. Only here you don’t have to install external chimneys, but only hang the unit from the wall and make all the connections correctly.

It is somewhat easier to install a gas water heater without a chimney. That is, there is a chimney in it, but it is short and in some models of heaters is almost invisible, since it comes out directly from the back wall of the device and immediately horizontally penetrates the outer wall.

Installation of a gas water heater without a chimney

Such a pipe is called coaxial and consists of two channels; combustion products move through the inner one to the street, and air, driven by a fan, passes through the outer one. All heaters without a chimney are equipped with a closed combustion chamber and an electronic control unit; they can take combustion air both from the street and from inside the house. When installing a coaxial kit, a simple rule is followed: to prevent condensate from flowing through the pipe into the column, it must be laid with a slight slope towards the street.

Advantages of chimneyless water heaters

As we have already found out above, there is no gas water heater without a chimney, and in the case of turbocharged units it is structurally simplified. This is the main advantage of forced-air water heaters, thanks to which they can be installed in any private house or apartment. It is enough just to lay the chimney horizontally along the shortest path from the apparatus to the outer wall and take it outside by making a hole.

This is what a coaxial chimney looks like when laid through an external wall

Now we list other advantages of “flueless” gas heaters:

- Increased efficiency and cost-effectiveness compared to traditional household appliances for heating hot water;

- Thanks to the closed chamber, the penetration of harmful gases and unpleasant odors into the premises is excluded;

- To install a water heater, it is enough to organize regular supply and exhaust ventilation, since it is impossible to do without a hood completely. But you don’t have to worry about how to arrange a supply of fresh air for combustion in the room.

- The high degree of automation of the turbocharged column makes it very convenient to use.

- The ability to use not only natural but also liquefied gas as an energy carrier. True, for this it is necessary to install it in the lower zone of the room (propane is heavier than air and spreads along the floor).

The water heater is closed on all sides, with a pipe for connecting a coaxial pipe coming out from above, and fittings for water and gas from below

. In addition to several sensors responsible for the safety and maintenance of water temperature for domestic hot water needs, the forced-air dispensers are equipped with a heat exchanger antifreeze system. The principle is simple: when the temperature in the room drops below zero, the electric heating element will automatically turn on, heating the heat exchanger and preventing the water from freezing.

The anti-freeze function in a turbocharged column may be useful in case of emergency shutdown of the heating system in winter. It will keep expensive equipment from defrosting until the owners take measures to heat the house. True, it is unknown what will happen to cold water pipelines if they are made of steel or polypropylene.

Construction of a condensation column with a cylindrical burner

Requirements for ventilation and chimney

To create air circulation in the room, a ventilation hole is necessary. It should not be clogged, air should pass through it calmly. If you neglect this rule, then in the event of a gas leak, the residents of the apartment will receive poisoning with serious consequences.

The risk of household gas detonation will increase significantly if it is not removed naturally, since a leak can occur at night, when a person is not able to detect it.

For the normal functioning of the gas water heater, an additional chimney must be installed. It can be brought into the common house system or directly onto the street. When constructing a chimney, it must be taken into account that it cannot have more than two bends at an angle of 90 degrees.

The total length of the chimney should not exceed three meters. Three options for the location of the chimney pipe are allowed.

The pipe must have a vertical section at the point of connection to the water heater. The length of the vertical section must be greater than or equal to 50 cm. The length of the horizontal section of the pipe should not exceed two meters.

It is possible to make a chimney from a flexible corrugated pipe, but it is necessary to prevent its sagging, which can block the removal of combustion products.

If the installation of the column does not involve a chimney, then you cannot limit yourself to a ventilation hole in the wall. It is necessary to install a full-fledged hood, but even in this case, the gas service will have questions about such a carbon monoxide removal system.

Image galleryPhoto from The channel intended for removing combustion products from the gas water heater must be discharged into the general house ventilation shaft. It should have a minimum of turns and areas that impede the outflow of gas. The smoke exhaust device for a gas instantaneous water heater uses rigid and corrugated pipes made of plastic or metal. Increasingly, owners of gas equipment prefer easy-to-install corrugated pipe options. The installation of smoke exhaust channels is still used to this day. pipes and turning elements made of galvanized sheet metal, plastic, stainless steel, painted steel Smoke exhaust from a gas water heater Corrugated pipe for smoke exhaust Construction of a gas outlet made of polymer corrugation Smoke exhaust from rigid pipes and bends

Installation work

Benefits of proper installation:

- High-quality and safe smoke removal;

- Increasing the efficiency of equipment operation;

- Protection against accident and leakage.

- The pipe is being installed into the wall. After this, the structure is connected to the column and connected to the pipe for output to the street. All cracks and connections are sealed with sealant;

- A chimney is mounted on the external wall. All connections are secured with clamps;

- To ensure that the device is level and stable, it is additionally secured with brackets while maintaining a distance of 2 meters. It is important that there are no deflections in the system;

Place for installing a gas boiler

If we talk specifically about apartments, then gas boilers are installed in them, mostly in the kitchens. There are all the necessary communications: running water, gas, a window and an exhaust hood. All that remains is to determine a suitable location for the boiler. For this installation, wall-mounted (mounted) boilers are used. They are installed on several hooks fixed to the walls (usually included in the kit).

As for installation in other areas of the apartment or house, as a rule, none of them meet the requirements. For example, in the bathroom there is no window with natural light, the corridor is usually not suitable in size - there is not enough tolerance from the corners or to the opposite wall, there is usually no ventilation at all or it is insufficient. The problem with storage rooms is the same - there is no ventilation and windows, there is not enough volume.

The exact distance from walls and other objects is indicated in the boiler operating instructions

If there is a staircase in the house to the second floor, the owners often want to place the boiler under the stairs or in this room. In terms of volume, it usually passes, but in terms of ventilation it will have to be very powerful - the volume is considered to be at two levels and it is necessary to ensure its threefold exchange. This will require several pipes (three or more) of a very large cross-section (at least 200 mm).

Once you have decided on the location for installing the gas boiler, all that remains is to find a place for it. It is selected based on the type of boiler (wall-mounted or floor-standing) and the manufacturer’s requirements. The technical data sheet usually specifies in detail the distances from the wall on the right/left, the installation height relative to the floor and ceiling, as well as the distance from the front surface to the opposite wall. These may vary from manufacturer to manufacturer, so it is worth reading the manual carefully.

Installation standards according to SNiP

In the absence of such recommendations in the equipment passport, the installation of a gas boiler can be carried out according to the recommendations of SNiP 42-101-2003 p 6.23. It says:

- Gas boilers can be installed on fireproof walls at a distance of at least 2 cm from it.

- If the wall is fire-resistant or combustible (wooden, frame, etc.), it must be protected with fireproof material. This can be a three-millimeter sheet of asbestos, on top of which a sheet of metal is fixed. Plastering with a layer of at least 3 cm is also considered as protection. In this case, the boiler must be hung at a distance of 3 cm. The dimensions of the fireproof material must exceed the dimensions of the boiler by 10 cm from the sides and bottom, and from the top must be 70 cm larger.

Questions may arise regarding asbestos sheet: today it is recognized as a material hazardous to health. It can be replaced with a layer of mineral wool cardboard. And also keep in mind that ceramic tiles are also considered a fireproof base, even if they are laid on wooden walls: a layer of glue and ceramics provide the required fire resistance.

A gas boiler can be hung on wooden walls only if there is a fireproof substrate

The installation of a gas boiler relative to the side walls is also regulated. If the wall is non-flammable, the distance cannot be less than 10 cm. For flammable and non-combustible walls, this distance is 25 cm (without additional protection).

If a floor-standing gas boiler is installed, the base must be non-flammable. A non-flammable stand is made on the wooden floor. It must provide a fire resistance rating of 0.75 hours (45 minutes). These are either bricks laid on spoons (1/4 brick size) or thick ceramic floor tiles laid on top of an asbestos sheet fixed to a metal sheet. The dimensions of the non-combustible base are 10 cm larger than the dimensions of the installed boiler.

Installation of a chimney in an apartment with wooden walls

In wooden houses, the use of a blue fuel water heater is allowed, but fire safety standards for installing a gas water heater must be observed. The chimney cannot come into contact with wood; non-combustible material must be placed between them.

Basalt or mineral wool can be used as thermal insulation. It is allowed to use heat-resistant polyurethane foam.

This is necessary to prevent fire in the event of strong heating of the chimney. As a rule, old wooden houses do not have chimneys, or they are intended for stove heating. It is prohibited to install gas equipment in unsafe houses.

Selection of insulating materials

So , how to properly install a stove in a house with a chimney through the wall is already clear, so you need to consider the issue of insulating the outer part of the structure. If a sandwich system is used, then this procedure need not be carried out (except for the place where the element passes through the wall). The insulation must be fireproof. It is allowed to use the following materials:

- Stone wool. This is the best option for a wooden house. The material is easy to use, does not contain harmful substances, does not burn or smolder. Cotton wool not only does not burn, but also prevents the spread of open flames.

Insulation of structures on the street Source teplo.guru

- Asbestos. Many masters refuse to use it. The material contains toxic carcinogens. However, it has high insulating qualities and does not come into contact with humans in any way.

- Superpower. Modern insulation, which does not burn, provides good insulation. The disadvantage of the material is its high cost.

- Basalt cardboard. It is characterized by a long service life. The insulator is relatively cheap and resistant to high temperatures. The material contains no toxic substances, and its quality is better than mineral wool.

The insulated structure may not look very presentable, but this stage cannot be avoided. Without insulation, condensation will collect inside the structure. It will not only deteriorate moisture, but will also have a negative effect on the metal.

Rules for safe installation of a geyser

When a large-scale redevelopment is planned, a radical relocation or installation of a gas heater in an apartment for the first time, it is impossible to do without obtaining the appropriate permits from the gas services. The complexity of the coordination is determined by the distance of “moving” and the location chosen for mounting the speaker.

A transfer project is drawn up if the device is moved more than 1.5 meters from the previous installation area. On average, it takes up to several months to obtain official permission

We also recommend that you pay attention to the rules for moving a gas pipe

Since a geyser is a potentially dangerous device and requires extremely careful handling in everyday life, let’s talk in more detail about the general rules and requirements regarding installation. Almost any manipulation with the device requires approval from regulatory authorities

There is no need to coordinate your actions only in two cases: if the unit has already been installed, remains in the same place, or is replaced by a similar one

Almost any manipulation with the device requires approval from regulatory authorities. There is no need to coordinate your actions only in two cases: if the unit has already been installed, remains in the same place, or is replaced by a similar one

Requirements for the installation site

The placement of the appliance in the kitchen is limited by rigid boundaries. It is strictly forbidden to install the unit above a sink, refrigerator, or gas stove. The minimum distance between them is 1 meter.

Access to the gas water heater should be as free as possible. This will ensure quality service and the ability to inspect the device if necessary.

In addition, the device should not be mounted too low or high. It is advisable that the burner be at eye level or at least within sight.

For residents of small apartments, where the kitchen area does not exceed 6 m², an exception is provided: they can hang the column above the sink

Recommended height:

- from the floor to the bottom surface of the device – 0.8-1.2 m;

- from the top surface to the ceiling - from 0.3 m;

- from the side panel to the wall - at least 0.15 m;

- from the front panel to the opposite wall – from 1 m.

It is better not to decorate the walls near the speaker with wallpaper and plastic panels. The surface on which installation is to be carried out must be covered with non-flammable materials. The same rule applies to all panels used to disguise the device.