A geyser is a flow-through water heater that runs on natural gas. If you do not have hot water supply, but gas is supplied, this equipment will increase the comfort of your life. You simply open the tap, hot water flows out of it, and its temperature is regulated by you yourself. Even if you have a centralized supply of hot water in your house or apartment, but you are not satisfied with the price you have to pay for heating, or perhaps you are not satisfied with the temperature, installing a gas water heater will also solve these problems. Heating water costs much less than it is provided centrally - this results in significant savings on utility bills. To understand which geyser is better, you will have to study the structure of the equipment and its types. Then the choice for you will be simple and conscious.

Which geyser is better depends on your requirements

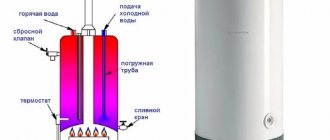

The structure of the geyser

Instantaneous gas water heaters consist of three main components:

- gas burner device and gas removal system;

- heat exchanger;

- ignition and control module.

Structure of a water heating column with piezo ignition

All these units have several modifications and their layout gives different models with different characteristics. All this allows you to choose a unit to suit your own requirements, because you can only say which geyser is better by being tied to a specific situation.

Reasons for heat exchanger failure

The period of operation is determined primarily by how the water in the city water supply is disinfected. In Russia, either pure chlorine or chlorine dioxide is used. When the water flowing through the copper tube heats up, it causes a violent chemical reaction. Copper chloride is inferior to pure metal in strength, and therefore fistulas appear quite quickly. The luckiest people are residents of cities where tap water is ozonated.

But there are still very few such settlements. The high cost of the modern solution does not allow us to count on the rapid spread of ozonation. Moreover, now manufacturers have begun to save in every possible way. And if previously troubles happened quite rarely with thick tubes of heat exchangers, now thin, low-quality copper is used everywhere. The service life of products has significantly decreased.

Type of ignition

For the dispenser to start working, you need to light the gas. Older models were lit manually by holding a burning match to the igniter. Today such units are no longer on sale; they are a thing of the past. They have been replaced by others that operate in automatic or semi-automatic mode.

Piezo ignition

In geysers with a piezoelectric element, ignition occurs in a semi-automatic mode. There are two burners - main and pilot. The pilot burner is a small wick that burns continuously, whether there is hot water flow or not. The main burner turns on only when the tap opens. The rest of the time it is turned off.

The procedure for starting a gas water heater with piezo ignition is simple: press the button located on the front panel, a spark appears on the candles, which ignites the pilot burner. When the hot water tap opens, gas is supplied to the main burner and ignition occurs from the pilot burner. While water is being consumed, both burners are lit. The valve was closed, the gas supply to the main one stopped, only the pilot one was on again.

Piezo ignition device for geysers - a simple and inexpensive device

What are the advantages of geysers with piezoelectric elements? These are the cheapest models and usually have a mechanical control - a regulator that allows you to change the height of the flame, thereby regulating the temperature of the hot water. These models are non-volatile, which can be important for a summer residence.

There are more shortcomings and they are more serious. The wick burns (should burn) constantly while you are using the column, and this is gas consumption. Even if it is small, but constant, as a result, quite a decent amount accumulates in a month. So this is far from the most economical way to heat water. The second disadvantage is also associated with the burning of the wick. If it goes out, you will not be able to light the column. The wick goes out because it does not have enough oxygen to burn, or because backdraft periodically occurs in the chimney, which blows out the flame. Since there is a flame controller, this is not a big deal - the gas shuts off automatically, but having to light the pilot burner again is unpleasant.

Electric ignition

Automatic geysers have electric ignition. This is an electric spark generator that is activated when the tap is opened. The rest of the time the gas is not lit, which significantly saves fuel. There is an electric ignition powered by batteries, and there is one from a 220 V network. Which gas water heater is better for this parameter must be chosen depending on the circumstances.

If your lights go out frequently, it makes sense to choose a battery-powered model. As you understand, in this case you have to make sure that they don’t “sit down.” If there are no problems with electricity or there is a backup power source, it is better to choose a gas water heater operating from a 220 V network. Plug the cord into the outlet once and forget about it. Electricity consumption is negligible, so they have almost no impact on bills.

The electric ignition is controlled by a microprocessor

Gas water heaters are electronically controlled. A board with a microprocessor is installed in the case; the desired temperature is set from a small control panel (push-button or touch). A small liquid crystal screen is often installed here, which displays the current state of the equipment, the temperature of the water, if it is being heated. This type of geyser is the best if you value ease of use.

Disadvantages - higher price and power requirements. Electronics need a stable voltage of 220 V with small deviations of the order of 2 * 3 V. We cannot maintain such parameters, so in order for an automatic gas water heater to work for a long time, a stabilizer is required, and it is better not a relay, but an electronic one. It not only stabilizes the voltage, but also evens out the shape of the pulses, which is also very important for imported water heaters.

Gas ignition methods

Columns have several types of ignition, but they all have one thing in common - the main burner of the device is ignited using a water unit, which sends a signal to supply gas.

Otherwise, all speakers can have the following types of ignition.

- Ignition from a piezoelectric element. A manual control option in which the power button is located on the external panel of the device. When it is pressed, the piezoelectric element ignites the igniter, which ignites the main column. This ignition method has one drawback - the igniter must be turned off manually. If this is not done, it will continue to burn, which will lead to excessive gas consumption and the formation of scale on the walls of the tubes.

- Battery powered. In such models, a signal is first sent from the rod, and then an electric spark ignites. In such designs, the role of the igniter is played by special electrodes - the main burner is ignited directly from them. One of the disadvantages of such models is the need to regularly change batteries. At a minimum, this should be done once every 10 months, and with regular use - every 2 months.

- From a hydraulic turbine. In some cases, gas ignition can be achieved using a rotating turbine, which is driven by water pressure. In such columns, the main burner is also ignited by an electric spark, but there is no need to monitor the batteries. This is due to the fact that the turbine itself generates the necessary electricity when rotating. Dispensers with a hydraulic turbine are not very common in Russia. This is due to the need to ensure sufficient pressure in the pipes. The column will operate at a pressure of at least 0.3 bar. But this condition is not guaranteed everywhere.

Burner, combustion chamber, chimney

Heating of water in a gas water heater occurs due to the heat released during gas combustion. The combustion itself occurs in the burner, and it is “packed” into the combustion chamber. Unburnt gases that remain in the chamber are discharged through the chimney. Let's take a closer look at all these devices.

Burner - main unit

Burner

The heat source in the gas water heater is a gas burner. There are three types: single-stage, two-stage, modulated. The first two types are almost never seen lately - they do not allow maintaining a given temperature, so there is no point in considering them - all columns have a modulating burner.

This is what a gas burner for a water heater looks like when installed

Modulating burners can be controlled manually - with a special handle mounted on the body - or through a microprocessor that maintains a given water temperature. Burners are made mainly of galvanized steel, since this material is optimal for performing the assigned tasks. It is inexpensive, durable, has a high melting point, and can withstand frequent heating.

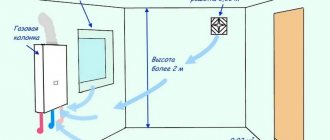

Types of combustion chamber and chimney

Combustion chambers in geysers are of two types - open and closed. Their name reflects the essence:

- closed (turbocharged, fan) is a metal box into which a burner is inserted with a socket at the top for installing a chimney;

- open (atmospheric) - this is actually the entire body of the column, since there is no isolated space, just a burner is installed in a certain place, on top there is a lid with a socket to which the chimney is connected.

Different types of combustion chambers require different chimneys. In an open chamber, air is taken from the room, therefore an effective ventilation system, normal air flow and an atmospheric chimney exiting into the ventilation duct are necessary. The closed chamber is equipped with a coaxial chimney (two pipes of different diameters inserted into one another), which is led through the wall to the street. In this case, combustion products are removed forcibly, using a fan, through the inner pipe, and oxygen flows directly to the burner through the outer pipe.

Open and closed combustion chambers at gas water heaters require the installation of a different type of chimney

A gas water heater with a closed combustion chamber operates more stably under normal conditions, but it has disadvantages. In winter, the chimney can become overgrown with frost, causing the heater to go out (it is extinguished by an automatic system that controls the removal of combustion products). The second point is that with a strong side wind, the air flow can blow out the flame. The gas supply is turned off by the same automatic system, but the situation is unpleasant. The third circumstance is that not all city authorities allow holes in the walls of houses and the insertion of pipes.

So in this case, it is difficult to say exactly which geyser is better - it depends on many factors.

Unit design

Gas water heaters, regardless of the manufacturer, have similar components, the presence of which may differ slightly between different models. For example, we can consider the construction of the Neva gas water heater.

Device structure from the outside

The diagram of the gas water heater is shown in the figure below.

Gas water heater diagram

The front part and sides of the water heater are covered with a metal casing (1). There is an observation window (2) on the facade of the device for visual monitoring of the operation of the unit. Under the window there are regulators: a knob that regulates gas flow (3) and a water flow regulator (4). Between the handles there is an LCD display (5), which displays the temperature of the water supplied to the consumer.

At the very bottom of the device there are pipes for water supply and outlet, as well as for gas supply. On the right side of the water heater there is a pipe (6), to which cold water from the water supply is connected, and on the left, a pipe (7) is connected to drain the heated liquid. Next to it, but a little closer to the center, there is a pipe (8). A hose is connected to it, connecting the dispenser to the gas main, and in some situations, to a gas cylinder. At the very top of the water heater, there is a flange (9) for connecting the gas outlet pipe (chimney).

All elements of the unit are fixed to a metal base (10), which serves as the rear wall of the device. It has 2 holes for hanging the unit on the wall using brackets.

The new Astra gas water heater model has a similar design.

Internal structure of the unit

Now let's look at how the geyser works from the inside, with the outer casing removed. As mentioned above, pipes numbered 6, 7 and 8 are intended for connecting cold water, discharging heated water and connecting gas.

The water block of the unit (12) is connected to the water supply pipe (6). A rod (13) comes out of the water block, on which a handle is attached to adjust the water pressure. Below is a cylindrical part (14), which has a notch on the walls. It functions as a plug that can be removed to drain liquid from the device if repairs are required. The plug also has a safety valve that opens when there is excess pressure in the water supply.

In the center of the unit there is an electronic control unit (16). Wires are routed from it in different directions, going to various elements of the unit and sensors.

Column structure from the inside

On the left, symmetrically to the water block, there is a gas block (17). Both modules are assembled in such a way that they represent a single structure. From it, like from the water one, comes a rod (18) to adjust the gas supply. In the middle between the gas pipe and the control valve there is a valve (19) (electromagnetic).

There is also a microswitch (15) on the gas block, which is pressed by a special pusher when it is turned off. Above you can see the manifold (20), connected to the gas block using a pipe fitted with flanges. The manifold is attached to the body using 2 screws (21). The nozzles are located at the rear of the manifold. Through them, gas is supplied to the burner (22), which has 10 rows. A pair of elements are attached to the front of the collector, similar in appearance, but performing different roles. On the right is the spark plug (23), which ignites the burners, and on the left is the flame sensor (24).

Above the collector there is a copper heat exchanger (25). It just gives off the heat obtained from the combustion of gas to the water passing through it. A water unit (26) is connected to the heat exchanger on the right, and a pipe for discharging heated water (27) is connected to the left side. The heat exchange module is attached to the unit body using 2 screws (28). There are 2 sensors installed on the pipe for discharging heated water. The top one (29) protects the water heater from overheating, and the one below (30) serves as a thermometer. Wires go from it to the LCD display mounted on the casing of the unit.

At the top of the apparatus there is a device for removing waste combustion products (31). Thanks to a system of jumpers of different shapes, the flow of hot exhaust gases is directed towards the chimney channel. A draft sensor (32) is installed on the left, which is connected to the overheating sensor (29) via an electrical circuit. At the bottom of the water heater body there is a block (34) for 2 power elements (batteries). To fasten the outer casing of the device, there are places for screwing in screws (33) on both sides of the housing.

The diagram of the internal structure of the Oasis geyser is no different from the one shown above, except for the presence of a “winter-summer” switch on the front panel. It is designed to turn off half of the operating burners in the summer to save gas.

You may be interested in: how to repair a gas water heater.

Heat exchanger

Water is heated while it flows through the heat exchanger. It is a metal pipe installed above the burner. The shape of the heat exchanger in a gas water heater is special - a pipe with fins is laid in a snake at the bottom, then a sheet of metal is installed around it, on top of which the pipe is wound in a spiral. Water flowing through this long path is heated by the heated metal.

This is what a heat exchanger for a gas water heater looks like

Heat exchangers are made from galvanized steel (the most budget option), stainless steel and copper. The best in terms of efficient heat transfer are copper. They are the most economical, but also expensive. The most durable ones are stainless steel, but they are much worse at heat transfer. Which gas water heater is better in this case is up to you to decide. Choose the quality that is more important to you.

If you decide to buy a gas water heater with a copper heat exchanger, do not try to find a cheap model. In order to reduce the price, manufacturers use low-quality copper, and the tubes are also made with thin walls. Such a heat exchanger will serve the warranty period, and then problems will begin - a leak will appear.

If you remove the casing, you will see fistulas in the tubes through which water drips. They are located mostly on the outside of the pipe, exactly in the place where condensation forms. If the pipe is of normal thickness, this is not a problem, but it quickly corrodes thin walls. Such a heat exchanger with a leak does not need to be replaced (it costs about 1/3 of the total price), it can be soldered. You will need refractory solder with a melting point of about 200°C, a powerful soldering iron and soldering flux. The technology of work is usual - clean the damaged area to bare metal, degrease, tin, and solder.

Recommendations for maintenance and repair

All elements of the column structure are subject to destruction due to various factors. Any gas equipment requires regular maintenance. If defects are identified during maintenance work, they must be eliminated as quickly as possible. Of course, some repair work should be entrusted to a professional, but some can be done independently.

Dismantling and adjusting the gearbox

You must first turn off the fuel and water supplies. Only after this can you begin to carry out preventive or repair work. To remove the gearbox, you need to perform several steps:

- Water is drained from the heat exchanger;

- using an adjustable wrench, the gas and water pipelines are disconnected from the column;

- If no mistakes were made at the previous stages, the gearbox can be easily dismantled.

Depending on the model of the unit, changes may be made to its design. To avoid problems when dismantling the water reducer, you must first disconnect all pipes and parts that make the work difficult. The housing should be easy to remove; no physical effort is required.

To adjust the gearbox, you must use special bolts located on the back side of the unit. Most often, the unit is already prepared for operation at the factory and does not require additional configuration. It is not advisable to adjust the unit unless absolutely necessary.

Cleaning the water unit

This event must be held at least once every 12 calendar months. When unscrewing the fastening bolts located on the unit cover, you must be careful not to damage the folds. When the cover is removed, it is necessary not only to clean the internal space of the gearbox, but also to perform the following procedures:

- All solid residues from the bottom of the part must be removed, and the coarse water filter must also be rinsed.

- It is advisable to lubricate the rod with grease or castor oil.

- If you suspect that the gasket has lost its former elasticity, it also needs to be lubricated.

With regular maintenance of the unit, its service life can be significantly extended. Most often, the rod seal and membrane fail. The first element must be replaced once every 3 years, and the second - after the appearance of ruptures or microcracks. In addition, during intensive work the spring for returning the rod to its original position may break.

Having carefully studied the design and principle of operation of the gas water heater, you can carry out all preventive measures yourself. If you don’t have confidence in your own abilities, then you should turn to professionals for help. When working with the unit, you must strictly follow the instructions.

How to determine power

First of all, you need to decide on the power or performance of the gas water heater. These are two interrelated characteristics that simply reflect different characteristics of the unit. Performance is how many liters of water a column can heat per minute, and power is how much heat it can release. Some manufacturers indicate power, others indicate performance, so you need to understand exactly what you need.

Let's first figure out what kind of performance you need from your geyser. This depends on the number of consumers who need to be provided with warm water. There are consumption standards for different types of equipment:

- kitchen sink, washbasin - 4 l/min;

- shower - 7-10 l/min.

The higher the power, the larger the size

If you have a kitchen sink, shower and washbasin connected to hot water, so that all three points work simultaneously and the water temperature does not drop, you need a capacity of 4 + 4 + 10 = 18 l/min. This is a lot, the price tag will be substantial. If you think about it, you will realize that all three devices are almost never turned on at the same time. There are situations when the shower and one of the taps work together. To provide them with hot water, the capacity must be 14 l/min. This is a little more modest, but quite enough for a comfortable stay. Look for the found value in the technical specifications; it should not be less.

Now let's look at power. Gas water heaters can allocate from 6 kW to 40 kW of heat for heating water. Here the division is:

- a gas water heater with a capacity of up to 19 kW is suitable for heating water for one water collection point;

- for two points the power should be from 20 kW to 28 kW;

- three require more than 29 kW.

Now, you can definitely say which geyser is better in terms of power in relation to your needs.

Main characteristics of the speakers

Now let's talk about the practical aspects of using the speaker. One of the main characteristics is performance. It directly correlates with power, which is indicated in kW and shows the volume of water heated per minute by 25 °C.

The characteristics are usually indicated in the device passport. A regular water heater heats 10-20 liters of water per minute at 25 °C, although this value can vary significantly.

Another characteristic of modern speakers is power modulation. It shows how the power of the column can change depending on the flow of water and is measured as a percentage of the initial power.

For modulation, the columns are equipped with special fittings with a membrane, which changes the gas supply to the burner depending on the flow. Modulation in the range of 40-100% of the device power is considered normal.

The diagram shows the modulating valve and the principle of its operation, which is similar to the operation of a water unit and its membrane

What else to look for when choosing

There are a few more lines in the technical characteristics of geysers that are worth paying attention to. First, look at the minimum water and gas pressure that this model can work with. Imported gas water heaters from European manufacturers are more capricious in this regard - they are designed for stable pressure and do not tolerate changes well. But under normal conditions they work stably and without breakdowns.

Some manufacturers, in order to adapt their equipment to our conditions, install gearboxes that compensate for surges. If the model you like does not have such a device, and your water and/or gas pressure fluctuates, you can install the reducer in front of the entrance to the dispenser. This device is simply placed into a pipe break; installation is standard. At the same time, your other consumers will be protected.

Operating parameters must be monitored

It is also useful to review the list of utility programs and protection levels. The safety and comfort of equipment operation depends on them. It is highly desirable to have the following functionality:

- Gas control. Monitors the presence of a flame on the burner; if it goes out, it shuts off the gas supply.

- Traction control. The presence of draft in the chimney is controlled. If combustion products are not removed, the gas supply is shut off.

- Flow control or hydraulic valve. Turns off the column if the water pressure is too weak or there is none at all.

- Overheat protection. The temperature sensor monitors the temperature of the water in the heat exchanger; when it approaches a critical point (boiling), it turns off the column. This extends the service life of the equipment (if it boils, the heat exchanger can rupture, as can the pipes).

These functions are necessary for the safe operation of the geyser. This is almost a standard set that is found in all good gas water heaters. All others are optional. They, as a rule, are no longer so critical (for example, the remote control).

Checking the correct assembly

Place the faucet handle in the closed position. We open the gas supply. Press the automatic button. We bring the match to the igniter. The igniter must not light up!

Turn the tap handle to the igniter position. Press the automatic button. We bring a match. The igniter should light up (this may take up to a minute, since air may have entered the system during disassembly and reassembly). Release the automatic button. The pilot light should be lit; when the hot water tap is opened, the main burner should not flare up!

Turn the tap to full open mode. Open the hot water tap. The main burner should light up.

Place the faucet handle in the closed position. The igniter should go out completely.

After making sure that the gas tap is working correctly, we light the column and check the tightness of all gas connections with a soap solution. If the column is not ignited, the tightness can only be checked up to the automatic button.

Geyser sizes and prices

The overall dimensions of gas water heaters are small - they are comparable to a small wall kitchen cabinet. The average height is 550-650 mm, width 300-400 mm, depth 200-300 mm. But if you wish, you can find models that are wide and flat, or vice versa, narrow and deep. Which geyser is better based on this parameter can only be determined by reference to the installation site, so there is no definite answer here either.

Colors may vary

Prices for geysers vary widely. Simple models with piezo ignition and a galvanized burner cost from $110. Equipment with electric ignition and a bunch of service functions - up to $450. So there is somewhere to roam.

| Name | Manufacturer country | Power | Performance | Max water temperature | Min water pressure | The combustion chamber | Burner | Body exchanger | Ignition | Dimensions (H*W*D) | Price |

| Neva 4511 (Neva) | Russia | 21 kW | 11 l/mm | 90°C | 0.3 bar | closed | electronic/batteries | 565*290*220 mm | 175$ | ||

| Electrolux GWH 265 ERN NanoPlus | Sweden/China | 20 kW | 10 l/min | open | copper | electronic/batteries | 665*390*245 mm | 110$ | |||

| Bosch W 10 KB | Germany/Portugal | 17.4 kW | 10 l/min | 0.15 bar | open | stainless steel | copper | electronic/batteries | 638*341*242 mm | 145$ | |

| Bosch WR 10 - 2P (GWH 10-2 CO P) | Germany/Portugal | 17.4 kW | 10 l/min | 60°C | 0.1 bar | open | stainless steel | piezo | 638*341*242 mm | 167$ | |

| WERT 10EG RED GLASS | Russia/China | 20 kW | 10 l/min | 0.2 bar | open | copper alloy | electronic/batteries | 550*330*188 mm | 92$ | ||

| Ariston FAST EVO 11 B | Italy/China | 19 k/W | 11 l/min | 65°C | open | copper | electronic/batteries | 640*370*240 mm | 164$ | ||

| Vaillant MAG OE 11-0/0XZ C | Germany | 19.2 kW | 11 l/min | 55°C | open | piezo | 177$ | ||||

| Bosch WR 13 - 2P (GWH 13-2 CO P) | Germany/Hungary | 22.6 kW | 13 l/min | 60°C | 0.1 atm | open | stainless steel | copper | piezo | 720*385*242 mm | 210$ |

| Neva Lux 6014 | Russia | 28 kW | 14 l/min | 0.1 bar | open | electronic | 650*350*240 mm | 210$ | |||

| Ariston FAST 14 CF E G20 | Italy/China | 24.3 kW | 13-14 l/min | 60°C | 0.2 bar | open | copper | piezo | 580*374*223 mm | 115$ |

Principle of operation

To correctly understand the principle of operation of a gas water heater, you must first understand how its security system works.

If the device is turned off, the control unit of the geyser stops receiving power, because The electrical circuit in the switch is broken. This occurs due to the fact that the pushing mechanism presses the switch plate and keeps it off.

The electromagnetic valve on the gas column is also in a closed state and blocks the gas flow from the inlet pipe, because No power is supplied to it either. However, not only does it prevent the passage of gas: the spring valve located in the gas module is also turned off, and the outflow of gas into the manifold is completely closed.

The main element of the water reducer of a gas water heater is a two-chamber module with a bending membrane, popularly called a “frog”. These modules communicate with each other using the appropriate channel. If the water supply is turned off, the pressure in the chambers is equalized.

What heating equipment can be handed over to collection points?

Gas water heaters of any type and purpose are accepted for scrap metal. Modern models are classified according to parameters such as type of ignition and type of burner. Industrial-scale equipment is quite heavy, so we can make a logical conclusion that renting out such structures is significantly more profitable than boilers used for home heating. However, to make the sale of a large batch of scrap more profitable, it is recommended to use the collection service from the collection point. This way, you can save on transportation yourself.

Parts Compatibility

When purchasing spare parts for Neva geysers, you can count on their compatibility. In any case, the heat exchangers here are almost identical. As for other manufacturers, they use their own parts, so you can’t really count on compatibility. It is best to buy spare parts that are 100% suitable for a particular gas water heater.

Knowing the structure of such a simple geyser as the Neva, you can figure out other water heaters, including imported ones. All of them are built according to the same principle, differing only in some details. Having coped with the repair of the simplest device, you can cope with the repair of a more complex and expensive geyser.

Installing a new speaker

It is quite acceptable to install a new gas water heater yourself, but with the exception of connecting the device to gas (this should be done by a licensed specialist).

The independent actions of the column owner will be as follows:

- If necessary, prepare the wall for installation of new equipment, and also replace the fasteners.

- Having hung the device on the prepared place, they begin to connect the communication systems one by one - first the chimney, and then the water supply hose.

- They invite a specialist to connect the gas hose, install the shut-off valve and register the column.

- After making sure that there is sufficient draft and that there is no smell of gas or leaks, the equipment is started.

- They regulate the water supply and the power of the device.

Safety sensors and their meaning

A geyser can be dangerous, because it is connected simultaneously to water and gas mains, each of which individually can pose a threat.

If there are problems with the gas or water supply, safety sensors turn off the operation of the column, and special valves will shut off the water or gas supply.

Typically, geysers can withstand voltages of up to 10-12 bar, which is 20-50 times higher than normal pressure in pipes. Such sharp jumps are possible with so-called hydraulic shocks.

But if the pressure is lower than 0.1-0.2 bar, then the column will not be able to work. You need to carefully study the instructions and specifications before purchasing to understand whether the dispenser is optimized for low water pressure in pipes in the CIS countries and whether it will work properly. And vice versa - will it withstand sudden changes in pressure, which, alas, is also not uncommon in our conditions.

Ignition circuit for a burner powered by an electric spark. Locations of the main safety sensors for a household geyser

In general, a modern geyser contains many safety sensors. All of them, in case of breakdown, can be replaced.

More details about the purpose and location of the sensors are in the table below.

| Sensor name | Location and purpose of the sensor |

| Chimney draft sensor | Located in the upper part of the device, connecting the column with the chimney. Turns off the column when there is no draft in the chimney |

| Gas valve | Located in the gas supply pipe. Turns off the column when gas pressure drops |

| Ionization sensor | Located in the device camera. Turns off the device if the flame goes out while the gas is on. |

| Flame sensor | Located in the device camera. Shuts off the gas if the flame does not appear after ignition |

| Relief valve | Located on the water supply pipe. Turns off the water when the pressure in the pipeline is high |

| Flow sensor | Will turn off the column if water stops flowing from the tap or if the water supply is turned off |

| temperature sensor | Located on the heat exchanger pipes. It will block the burner operation if the water is significantly overheated to avoid damage and burns (mainly triggered at +85ºС and above) |

| Low pressure sensor | Will not allow the column to turn on when the water pressure in the pipes is low. |