A modern geyser is a reliable device that can be used without fear for the health of people in the same room as the device. This is due to the presence of a special security system, including special sensors that monitor the operation of the equipment.

Types and their purpose

The geyser protection system includes the following elements.

Flame

This part is also called a combustion sensor. Its main function is to control the presence of flame. While the burner is operating, inside the sensor, which is a thermocouple, due to heating, pressure increases, which is transmitted to the valve responsible for supplying fuel. If the flame disappears, the temperature drops, cutting off the gas supply.

Some columns also have an ionization sensor that responds to flame ions. It is represented by an ionization electrode located directly inside the flame, and will be triggered when the flame suddenly disappears, turning off the burner.

It is located in the upper part of the device, connecting the column with the chimney. The main function of this part is to determine sufficient ventilation. If this sensor does not function, the column will not turn on and will not begin to heat the water, which will prevent combustion products from entering the room.

Overheating (thermal relay)

This part is located on the heat exchanger pipes to prevent water from heating above the permissible temperature. If it detects an excessively high water temperature, the column will automatically turn off to protect the heat exchanger pipes from damage. Most often, such a sensor is designed for temperatures up to +85ºС.

Flow

It controls the opening of the hot water tap - if the tap is closed, the flow sensor will turn off the column.

Reduced water pressure

The water pressure sensor prevents the equipment from turning on if the water pressure is too low.

Pressure relief safety valve

This part will protect the pipes from rupture if the water pressure in the pipes increases.

In the next video of the UWC Heat Service channel you can find out even more useful and interesting information about geyser sensors.

And the next video will tell you in detail about what a traction sensor is, why it is needed and how it works.

Other malfunctions of flow-through heaters

In addition to the problems listed above, speaker owners have to deal with the following problems:

- weak sparking, sometimes single discharges slip through, the gas does not flare up;

- ignition is accompanied by a strong bang;

- after closing the DHW valve, the burner continues to operate until the electromagnet shuts off the fuel supply on command due to strong heating;

- spontaneous ignition after connecting to a power source;

- insufficient heating;

- Water is leaking from the water heater.

Advice regarding weak discharges on electrodes. If the batteries and contacts are in order, try cleaning the ends of the electrodes and adjusting the gap between the needles and the plane of the burner (the value is indicated in the technical data sheet of the product). If there is no result, call a specialist - most likely the reason is in the pulse block.

Problems with sparking cause popping noises - gas has time to accumulate in the combustion chamber before a sufficiently powerful discharge is formed. If the spark remains weak, the fuel-air mixture ignites when it reaches a high concentration, which is accompanied by a micro-explosion. There have been cases where the pops damaged the heat exchanger, disrupted seals and normal contact in the electrical circuits of the sensors.

Continuing heating after turning off the water is a rather dangerous malfunction. If it coincides with a failure of the overheating sensor, a vapor phase will form in the heat exchanger that can rupture copper tubes and honeycombs. The reason is the jamming of the “frog” rod that opens the gas valve. How to repair:

- Remove the water module according to the instructions above.

- Disassemble the “frog” and remove the plastic plate.

- Unscrew the nut (or screw) in the left half of the membrane chamber and remove the pusher.

- Change the seals, thoroughly clean all parts from deposits, including the spring monostat (located on the right side of the “frog” behind the membrane).

Recommendation. Before assembly, check how freely the rod moves inside the new seals. For details on disassembling and repairing the speaker, watch the video:

Spontaneous start of heating without turning on the water is a consequence of sticking of the pusher. When the burner of the device does not turn off and the thermostat trips, the user temporarily turns off the power source. Since the rod remains pressed, after the power supply is restored, the column turns on itself, without opening the DHW tap. The “treatment” method is described above.

The reason for low heating is total contamination of the main elements of the unit - the heat exchanger and burner. The column needs to be completely disassembled and serviced - it is better to entrust such work to a specialist. In case of burnout and leakage, the heat exchange unit must be removed and properly soldered, which is not always possible to do at home.

Is it possible to install additionally?

If the required sensor is not included in the purchased column, its additional installation is possible. Usually this question concerns the traction sensor, which may not be present in some Chinese speakers. Its presence is very important for the safety of using the equipment, so it is best to make sure when purchasing that the selected column is equipped with this part.

If the absence of a sensor is discovered at home after making a purchase, it can be inserted into the device separately, although this will involve additional expenses both on the element itself and on the work to install it.

For safe and automatic operation of the gas heating boiler, a protection and automation system is provided.

It is responsible for maintaining the specified temperature conditions, as well as for the safe operation of the unit.

One of the main elements of unit protection is the gas boiler draft sensor.

Purpose of the traction sensor

A draft sensor or thermostat is a device for determining the draft intensity in the chimney of a gas boiler. Its main function is to provide a timely signal about an unacceptable amount of draft in the boiler.

Ways to eliminate backdraft

You should pay attention to any, even the most minor, changes in the operation of the gas device. If the water heater makes strange noises or turns on with a bang, you should immediately contact a specialist.

Popping noises are most common in older speaker models. In modern flow columns such defects are extremely rare. Extraneous sounds occur due to accumulated gas in the heat exchanger, which can subsequently occupy the entire chimney.

In most cases, such a violation is provoked by a clogged chimney, a broken valve, or a deviation of the ignition wick.

In new water heater models, a malfunction can be caused by:

- defective spark plug;

- spent battery installed in the control module;

- faulty microswitch located in the water unit.

Having decided to carry out independent repair work, first of all, you need to check the intensity of traction using one of the methods listed above.

Further diagnostics will differ depending on the type of device - with an ignition wick or an automatic ignition system.

Column with automatic ignition system

In this type of water heater, the ignition device is controlled by an electronic module. The system with microswitches located on the fire and liquid regulators is considered one of the most reliable. Repairing a failed part can result in significant costs.

You can determine the severity of the failure as follows:

- Research batteries . Delayed ignition of the gas may be due to a low battery charge. In this case, it is enough to replace the power source with a new one.

- Check the functionality of the liquid pressure microregulator , designed to transmit signals to the control module. Its activity is associated with the supply of water when it is necessary to ignite the gas. Like other regulators, it can fail and issue incorrect commands. The problem can be determined using an ohmmeter and a multimeter. The worn element should be replaced with a new one.

- The appearance of uncharacteristic sounds can also be caused by deformation of the location of the device that ignites the gas . The malfunction is usually caused by a temperature difference. The part is secured using a screw; you should loosen it a little and correct the position of the spark plug. The gap should be 0.4-0.5 cm.

- Gas can also accumulate due to a faulty valve, which causes fluid flow to slow down . The small metal ball should move freely under the lid. If its movement is disturbed, you can try to move the valve from its place with a cable. If there is contamination, the channel should be cleaned. But it is not recommended to carry out such a procedure unless absolutely necessary.

Upon completion of the repair work, it is necessary to check the connections for leaks. You can enhance safety using rubber gaskets and special sealants.

Ignition wick water heaters

Flow-through geysers of the previous generation often emit characteristic pops when turned on. Such structures are considered not very convenient and often even unsafe; at the same time, much less money will be needed to repair them.

The accumulation of gas in an area not intended for this purpose can be caused by improper placement of the ignition wick. Failure to do so results in a reduced flame and an inability to reach the edge of the burner with the edge. The main reason for insufficient gas supplied to the wick is a clogged nozzle.

You can fix the problem yourself, but to do this you need to completely disassemble the device.

The first step is to turn off the water and gas supply.

The main part of water heaters has the same type of circuit, so the repair instructions will practically not differ:

- First you have to dismantle the protective casing of the water heater.

- Provide free access to the tee.

- Unscrew the fastening screws, and then remove the nuts securing the supply tubes and regulator.

- The tee must be carefully pulled out of the groove.

- Examine the lower pipe. A small screw with a through hole is the jet.

- The nozzle should be cleaned using a needle or wire.

- Upon completion of all work, you need to reassemble the water heater in the reverse order.

If the problem persists, you should contact a gas company specialist for help.

There are other reasons for the appearance of reverse thrust:

- Seasonal changes , in this case it is necessary to make sure that there are no errors when installing the chimney, and insulate the channels.

- An air lock inside the smoke channel can cause reverse draft in the chimney of a household gas water heater. To fix the problem, set fire to the newspaper inside the pipe.

- Forced exhaust in a room with a column causes a compensation process , air comes from the smoke duct. Metal-plastic windows only aggravate the problem; in some houses, air from the chimney begins to actively flow into the room.

We discussed more information about the causes of backdraft in a chimney in the next article.

The situation with air compensation can also be corrected using a check valve for the chimney of a gas water heater. You should also dismantle the fan and buy supply valves for metal-plastic windows.

Mechanical shut-off devices, known as a check valve or water heater damper, ensure that liquid and gas flow in only one direction.

Designed for turbocharged geysers. Their action is based on the opening of the exhaust hole when the column is operating and its closing after shutdown, which guarantees safe use.

Device for various types of ignition of geysers

There are three types of ignition systems in geysers:

- Gas water heaters with piezo ignition. – The wick in such a system burns constantly after starting the column. When starting a gas water heater with piezo ignition, you must hold down the gas supply button while simultaneously pressing the button responsible for the spark. After the wick lights up, the gas supply button must be held for up to 20 seconds, then released and set to the working position. Now, from the burning wick, when you turn on the water, the main heating pad will light up.

- Gas water heaters with automatic ignition. – The automatic ignition of the geyser runs on a battery (in some models there are 2 of them). To put into operation a gas water heater with automatic ignition, you need to place the batteries and press the power button. Now the column is ready for use. When you turn on the water, the battery gives an electrical impulse to automatically ignite the main burner; after turning off the water, the column goes out completely.

- Gas water heaters with hydro generator. – The gas column is ignited using a turbine rotated by water flowing through the column. The turbine rotates and produces a spark to ignite the main burner. When installed, such a column is switched to the on mode, after which it operates in operating mode.

Columns with a hydrogenerator are designed for water supply systems with a minimum pressure of 0.5 atmospheres, while columns with piezo ignition and auto-ignition can operate at lower water pressure.

Design of a protection system in geysers (sensors)

- Flame sensor (combustion sensor) - is a thermocouple that heats up during the burning process of the burner, the pressure inside the sensor increases and is transferred to the gas supply valve, when the burner goes out, the sensor cools down and the gas supply valve closes. This sensor insures the gas water heater against gas leakage. Some models of geysers have a flame sensor installed, which is an ionization electrode; this sensor is installed directly in the burner flame and reacts to flame ions; if the flame disappears, the sensor will turn off the gas supply.

- Draft sensor - in the absence of draft, this sensor sends a signal to the fuel supply valve and the column goes out. If the sensor does not detect the presence of traction when turned on, the column will not turn on. The draft sensor protects the room from carbon monoxide in the event of faulty ventilation or a clogged chimney.

- Thermal relay (overheating sensor) – the sensor is installed on the heat exchanger and monitors the presence of overheating of the water; if the temperature rises above +85? C, the geyser turns off. Overheat protection is necessary to protect the heat exchanger from damage.

- Flow sensor - monitors the presence of water flow through the geyser when the water supply tap is closed, thanks to this sensor the column is turned off.

- Low water pressure sensor - this sensor prevents the geyser from turning on if there is no water pressure sufficient for its proper functioning.

- Pressure relief safety valve - in case of increased water pressure, the safety valve will protect the column pipes from rupture.

The device does not ignite initially

Before you climb inside the water heater, you should perform a number of basic steps:

- Replace the batteries and clean the contacts in the power compartment.

- Make sure there is natural chimney draft and normal pressure in the cold water supply system.

- In a turbocharged dispenser powered by mains power, check the fuse. Try switching an imported unit by turning the plug in the socket - some models are sensitive to phase location.

- Clean the filter - the dirt trap installed on the cold water supply pipe. Sometimes the mesh at the inlet is provided by the design of the water heater itself.

- After opening the DHW mixer, observe the ignition electrodes - a spark should jump from them. In a turbocharged apparatus with a closed chamber, the clicking of discharges can be clearly heard.

Heater repair begins with cleaning the electrodes and installing working batteries

Advice. If there is external access to the ignition electrodes through a window, immediately clean their working part with a long brush.

Did the above measures not produce results? Then remove the column casing and proceed to troubleshooting, following the step-by-step instructions:

- Open the hot water (ask an assistant) and watch the movement of the rod, which should move the pressure plate away from the microswitch button. If the pusher does not move, the reason is 100% inside the water block. You will have to disassemble it, clean it and change the membrane.

- The rod presses on the plate, but the button remains pressed. Probably, the stroke of the pusher has decreased due to scale inside the “frog”, which needs to be opened and cleaned.

- The pusher moves, the button turns off, but there is no sparking. Surely the microswitch is to blame, diagnosed as follows: disconnect its connector and short-circuit the 2 terminals with a screwdriver. If the element fails, then after a direct short circuit a spark will appear on the electrodes.

- The discharge skips on one needle, the second is silent. Pull the high voltage cable out of the electrode housing, trim it slightly and insert it back.

- The “frog” functions, the microswitch is triggered, the electrodes spark, but ignition does not occur. This means that gas is not supplied - the solenoid valve is turned off. The culprits of the circuit break are the traction and overheating sensors; to check they need to be closed one by one using a wire. Another option is a break or fracture of the supply wires, which is diagnosed by testing with a multimeter.

You need to short-circuit the connector connected to the pulse unit, and not the microswitch plug

An important nuance. When you discover a faulty microswitch, be sure to inspect the water block housing at the installation location. It happens that the element is flooded with water dripping from under the stem seal. It is necessary to dismantle the “frog”, pull out the leaky seal and install a new spare part.

In some models of electronically controlled gas flow columns, a special flow sensor controls the start. It operates on the principle of a limit switch - the water flows, the circuit is closed. Diagnostics is simple: open the DHW valve and test the element contacts with an ohmmeter or a light bulb - it should light up. The algorithm for a complete check of the water heater is demonstrated by the technician in the video:

How to replace the membrane

The procedure for replacing a rubber (or silicone) diaphragm differs little on speakers from different manufacturers. To independently remove and disassemble the water-gas unit, you will need standard tools - open-end wrenches, screwdrivers and pliers. The work order is as follows:

- Turn off the gas and cold water taps on the supply pipelines, remove the casing of the device.

- Disconnect the water supply and fuel supply pipes.

- Unscrew the heat exchanger tube from the “frog” (located on the right), move it to the side or disconnect the interfering wires.

- Unscrew the fastening of the block to the body and remove the assembly.

- Disassemble the membrane unit by unscrewing 4-8 mounting screws. Remove the defective diaphragm and install a spare one, having first cleaned the insides of the camera from scale and dirt.

Note. On simple Chinese devices, the “frog” can be disassembled without removing the entire water-gas unit. It is enough to disconnect the heat exchanger pipe and the screws on the flange.

Disassemble the mechanism carefully so as not to lose the sealing gaskets or rubber rings. Reassemble in the reverse order; after connecting the gas pipe, test the reliability of the joints using the soaping method.

On outdated columns with a wick and a thermocouple, the membrane is replaced using the same technology. The difference is in the orientation and location of the water unit - here the block stands vertically, as shown in the photo.

To unscrew the membrane chamber on older models, you need to disconnect 2 water tubes and loosen the locking screw

Replacing a leaking rod seal

If you notice water leaking from the frog onto the microswitch, replace the worn seal immediately. A wet end switch will quickly become unusable, the column will no longer ignite, and as a result you will have to buy 2 parts instead of one.

How to replace the oil seal yourself:

- Perform all the manipulations to dismantle the water block indicated in the previous section.

- Disassemble the “frog”, set one half with the membrane aside. Pull out the plastic plate from the second part by slightly prying it with a screwdriver.

- Using a spanner or socket, unscrew the nut from the inside of the chamber membrane and pull out the pusher.

Reference. The method of fastening the oil seal and rod depends on the brand of gas-using installation. In Neva columns, the pusher is pulled out along with the plate, and the rubber ring is hidden under the screw.

Then you can go in 2 ways: replace the entire rod (recommended) or only the rubber sealing rings. The first is located at the end of the pusher, the second is pressed inside the nut. Buy rings of identical size and replace the worn parts.

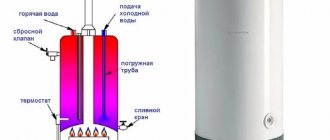

The device of the water unit (reducer) of the gas water heater

The water unit of the gas column is located in front of the heat exchanger and regulates the operation of the column depending on the water flow. The water assembly can be made of brass, plastic or polyamide. The water unit is responsible for turning on the column and its functioning when water is supplied to the hot tap. The flow of water affects the parts of the water unit - the membrane and the disk, they in turn affect the rod, which regulates the operation of the valve of the gas unit. When water flows through the water unit, the gas supply is turned on. Accordingly, when the water is turned off, the gas supply is turned off.

The water unit consists of:

- Base and cover.

- Diaphragm with a disk attached to the rod.

- Flow regulator.

- Venturi nozzles.

- Flow regulator.

- Temperature selector.

- Water purification filter.

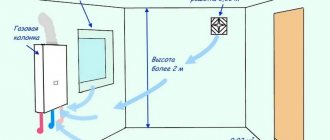

Reasons for lack of traction

The source of the malfunction can be identified by visually inspecting the column for errors made during its installation.

There are several typical violations:

- The diameter of the air duct is less than the cross-section of the water heater outlet pipe.

- Using more than three repeat angles and adapters when installing a pipe.

- The chimney length is less than 2.5 meters.

- The chimney connections are loose and there are leaks.

- The distance from the water heater to the chimney is less than 30-50 cm.

- The length of the corrugation exceeds 2 meters.

It is also important to assess the compliance of the premises with technical operating conditions. It is prohibited to install a gas water heater and a forced exhaust hood in one room. When installing metal-plastic windows, supply valves must be used.

Construction of a gas boiler gas unit

The gas unit is connected by a rod to the water unit; the rod regulates the flow of gas to the burners, only during water flow, when the column is turned on. Gas enters the gas unit through an electromagnetic valve; it also houses a rotary knob for adjusting the power and ignition of the gas water heater. From the gas unit there are gas pipes to the ignition and main burner. The rotary power regulator releases gas to the ignition burner, and the rod connected to the water unit, when the water is turned on, opens the gas access valve to the main burner.

The design of a geyser is not too complicated, but if you are not a specialist, diagnosing a malfunction will not be easy, since gas water heaters, despite a similar device, have differences, and also, each malfunction has different nuances. If you doubt that you can safely fix a geyser malfunction, contact us. We employ experienced specialists who will quickly and with a guarantee repair your speaker.

You can call a gas technician 24 hours a day by calling 8 (812) 777-0-777, and we can find out our prices in the section of the website for the repair of geysers.

How to disable

The instruction manual does not contain information on how to disable the draft sensor in a gas boiler. It does not recommend disabling this security system yourself. This can lead to negative consequences both for the device and for human health, since the activation of the sensor is a clear sign of danger.

Disabling the draft sensor is a direct violation of the safety rules established by the heating equipment manufacturer!

Carbon monoxide poisoning has the following symptoms:

- mild degree - headache, dizziness, chest pain, pounding in the temples, cough, lacrimation, nausea, vomiting, possible hallucinations, redness of the skin and mucous surface, rapid heartbeat, hypertension;

- moderate - tinnitus, drowsiness, paralysis;

- severe - loss of consciousness, convulsions, involuntary defecation or loss of urine, abnormal breathing rhythm, blue skin color, death.

The consequences of carbon monoxide poisoning can negatively affect a person’s future life activities.

At the same time, the boiler design allows for the possibility of turning off this system. To do this, it is necessary to disconnect the thermocouple breaker and the electrical wiring of the draft sensor from the solenoid valve, as well as from the electronic control unit of the boiler.

Thus, the control unit will continue to autonomously control the operation of the boiler, without taking into account the temperature of the burned gas and the force of its release into the atmosphere.