The accumulation of carbon monoxide is harmful to humans and can be fatal. To avoid poisoning, the air pressure must be constant. The draft sensor of a gas boiler helps determine the intensity of suction and turns off the device if it is absent.

The draft sensor monitors the air vacuum level

Description and purpose of the traction sensor

The safety element ensures safe operation of the equipment. The draft sensor of a suspended and floor-standing gas boiler is responsible for turning off the device when carbon monoxide accumulates. The presence of sufficient draft in the device ensures the replacement of combustion products with fresh air, which ensures safety.

The function of the draft sensor is to send a message to the system valve that the air vacuum is insufficient and an intense accumulation of carbon monoxide may occur. As soon as a draft violation message is received, the valve turns off the device.

Insufficient exhaust air suction leads to the phenomenon of “backdraft”. The release of combustion products does not occur through the chimney channels, but into the room in which the equipment is installed.

What causes blood pressure to drop?

A drop in pressure (the boiler goes out) indicates the appearance of leaks. It is necessary to check the condition of pipelines, threaded connections, gaskets and other external elements of the heating system . If there is no visible damage, you should look for problems with the boiler.

The main problem element may be the heat exchanger. Welded joints sometimes crack or break due to frequent temperature changes. Sectional cast iron heat exchangers used on powerful floor-standing models are risk factors at section connections.

In addition, the pressure relief valve may be triggered or jammed open..

Threaded connections of pipes can also lose their tightness due to drying out or destruction of gaskets, non-threaded connections, etc. All detected problems are eliminated in accordance with their specifics.

The principle of operation of the draft sensor in a gas water heater

Combustion products from the firebox flow through the chimney to the street. If the level of air suction in the duct is reduced, smoke occurs in the room. The room is filled with carbon monoxide, which has a detrimental effect on humans. Poisoning from its vapors can lead to suffocation.

Attention! If carbon monoxide has accumulated in the room, it is necessary to intensively ventilate the apartment (open all windows), close the doors to adjacent rooms and call gas specialists.

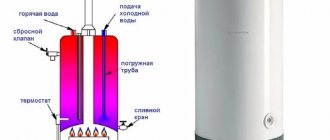

The draft sensor consists of:

- bimetallic plate;

- plugs;

- nuts;

- fitting.

The bimetallic relay signals the shutter valve to turn the boiler system on or off.

The thermal relay consists of a bimetallic plate with movable contacts

The temperature of the exhaust gas located in the chimney depends on the intensity of fresh air suction. The better the traction, the lower it is. When heated, the bimetallic plate expands, which leads to disconnection of the contact when the temperature reaches a critical value.

Gas boilers operate on natural and liquefied gas. In the first case, the normal range is considered to be 75-950 0C. In the second case, adequate operation of the boiler occurs when the gas is heated within the range of 75-1500 0C.

The calorie content of liquefied propane butane gas is higher than natural gas. Therefore, the combustion temperature also increases. The thermal relay is set to turn off at 950 0C for natural gas and at 1500 0C for propane-butane devices.

The draft sensor of the AOGV gas boiler is located in the area of action of the wick and is connected to the electromagnetic element of the circuit, which opens the gas supply.

The gas supply control circuit of the AOGV boiler requires the presence of a temperature sensor

The thermocouple electrode is located near the igniter. While it is heating up, the gas supply does not stop. As soon as the electrode has cooled, the supply is closed.

What it is?

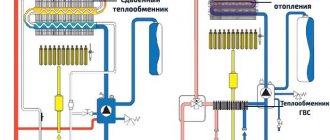

Pressostat, monostat, smoke sensor, differential smoke pressure switch, pneumatic relay - all these are different names for the same device. An important part controls the activity of the boiler fan, as well as the process of removing smoke, protects the heating apparatus from overheating during a sharp drop in gas pressure or when the amount of water supplied is reduced. In addition, the smoke sensor allows the burner to function or, conversely, causes it to turn off.

Visually, the pressure switch is a small flat plastic box , inside of which there is a sensitive membrane and a three-pin microswitch connected to it. It is these parts that control the operation of a complex heating apparatus.

Types of traction sensors

The relay device is distinguished according to the principle of operation of the combustion chamber. There are 2 types of construction: open and closed. A draft sensor operates in a gas boiler with an open view of the combustion chamber. Install it in the smoke eliminator. The gas supply stops if the bimetal exceeds the expansion rate, breaking the contact in the circuit. The valve reacts to the signal and blocks movement to the igniter.

Boilers with an open combustion chamber pose a danger in the form of reverse draft. It occurs if:

- the chimney is clogged with debris and rubbish;

- A strong gusty wind is blowing, which blows the system.

In this case, carbon monoxide smoke is drawn from the chimney into the room. The traction sensor is not designed for such cases, so experts additionally advise installing a gas sensor. This will prevent accidents from occurring.

In gas boilers with a closed type of combustion chamber, a pneumatic relay is installed. Its job is to control the fan, which creates forced draft and helps draw combustion products into the chimney and discharge them outside.

There are wired and wireless sensors. The first alarms require additional installation to the wire connections. Wireless relays operate from a radio signal. Such sensors are installed in cases where the operation of the device is monitored from another room.

The wireless alarm system consists of 2 blocks. The first is installed near the boiler and connected to its terminals, and the second - in the room from which the equipment is controlled. These blocks are connected by a radio signal. The controller is equipped with a keyboard and display for easy operation.

Based on the functions they perform, thermostats are divided into simple and programmable. The first relays perform only one task: monitor the set temperature. Programmable alarms can perform the functions necessary to analyze the operation of the boiler remotely:

- setting the temperature regime for daytime and nighttime operation;

- programming the device by day of the week;

- monitoring indoor humidity (in this case, the device is additionally equipped with a hydrostat);

- maintaining a given humidity parameter.

The type of draft sensor depends on the operating principle of the gas boiler

Incorrect placement of the chimney contributes to the wind blowing in and extinguishing the burner. To prevent such cases from occurring, experts advise additionally installing a stabilizer.

Prices

Each brand produces boilers of a special design, so there is no need to talk about the universality of protective elements. If it is necessary to replace this controller, then you should look for a replacement from the same company as the gas unit itself. Moreover, it must fully comply with the performance characteristics.

Approximate cost of draft sensors for popular boiler models:

| Boiler series | Code/article | Suitable Models | price, rub. |

| Vaillant atmoTEC | 0020039083 | Pro VU200/3-5, 240/3-5, 280/3-5 and Plus VUW 200/3-3, 200/3-5, 240/3-3, 240/3-5, 280/3-3 , 200/3-5 | 1 900–3 200 |

| BAXI atmoMAIN | 600870 | DIGIT 240i, 24I BSE and 24I BSB | 1 200–1 800 |

| Vaillant turboTEC | 0020041905 | Pro VUW INT 202, 242, 282/3-3 and Plus VUW INT 202, 242, 282, 322, 362/3-5 | 2 400–3 100 |

| BAXI turboSLIM | 721890400 | 1.230 Fi, 1.300 Fi and 2.300 Fi | 2 800–3 400 |

As can be seen from the table, purchasing original parts will require quite a significant investment. However, it is not worth saving and buying a Chinese analogue: despite the fact that they are 5–10 times cheaper, they are of appropriate quality, which in the future may negatively affect the safe operation of the boiler.

How to install a gas boiler draft sensor

Experts recommend installing heating equipment in a separate room. To do this, choose the coldest room without radiators. The draft sensor is installed on the gas boiler. The heater is located in a place protected from sunlight. Also, the room should be away from drafts. The building cannot be located in a windy area to avoid the possibility of burner extinguishing.

Using a terminal, a thermostat is attached to the gas boiler. If it is necessary to install additional equipment, study the instructions from the manufacturer. Different boiler models have their own installation nuances, so it is important to follow these recommendations.

The thermal relay is installed using clamps that extend from the thermostat or heat exchanger

If the device needs to be placed outside the speaker housing, it is released from the front panel. At the installation site, prepare a recess according to the dimensions of the relay, and provide the box with a lid so that it is possible to replace the element if it breaks.

Attention! Experts recommend removing the thermostat when installing heated floors in order to monitor the performance of the system.

The heating cable is connected to the contacts, and the sensor to the terminals. Attach the power cord and perform packaging. The front panel is placed on top and closed with a lid.

What does it look like and where is it located?

This is what the traction sensor of a turbocharged BAXI ECO Four looks like.

The exact location is always indicated in the instructions for the boiler. According to the gas safety rules PB 12-368-00, domestic heating boilers must be equipped with a draft sensor. The installation site, as a rule, is the smoke hood (located in the smoke extractor) or the free space between the ventilation duct and the unit body.

In atmospheric boilers, the draft sensor has a slightly different appearance.

It is worth paying attention that it cannot be attached closely to the surface of the flue. Paronite gaskets are used as a “separator”: this measure reduces the likelihood of contact heating, as well as creates a gap that will provide technical access to the flue opening and to the draft sensor.

Checking the gas boiler draft sensor

The thermal relay is replaced if the normal functioning of the device is disrupted. If no problems are found in the chimney, and nothing prevents the exit of combustion products, and the boiler constantly turns off, specialists check the working condition of the alarm.

You can check the draft sensor of a gas boiler with a multimeter and other methods:

- Install a mirror near the relay. If the boiler becomes wet during operation, the sensor is faulty.

- The chimney is not tightly covered with a damper. If the thermostat is working properly, the heater turns off.

- When checking the pneumatic relay of a double-circuit device, turn off the heating system, leaving the workers only heating hot water, and open the tap. If the system turns off, then the problem is with the thermostat.

Check the serviceability of the thermostat with a multimeter

All types of alarms are used for various modifications of wall-mounted and floor-mounted heating devices.

Symptoms of a problem

Evidence that the pressure switch for a gas boiler has become unusable are the following factors.

- The fan in the monostat turns on silently. The absence of a beep indicates that the device has malfunctioned and requires immediate repair or complete replacement. Important! When the fan starts, you should definitely hear a clicking sound.

- The boiler does not turn on, and when you try to turn it on, the device gives an error signal (most often the red indicator lights up).

If the pressure switch does not work for any reason, it is better to suspend further operation of the gas boiler in order to avoid serious problems.

Reasons for triggering the traction sensor

Problems with the actuation system or wind may cause the system to shut down. The most common reasons for the thermostat to trip:

- gusty wind;

- chimney blockage;

- incorrect installation of the boiler or chimney, incorrect calculations;

- fan shutdown.

Gusty wind

To prevent a gust of wind from extinguishing the burner, experts recommend installing a stabilizer. It is mounted at the outlet pipe.

Chimney blockage

Debris in the chimney serves as an obstacle to the removal of combustion products. The draft is reduced, and carbon monoxide is not released into the street. The system overheats and the device shuts down. In this case, the problem is eliminated by cleaning the chimney.

Incorrect installation

If errors were made in calculations or installation during installation. Carry out control measurements and check the correct installation of the boiler and chimney. The height of the outlet is calculated depending on the location of the pipe from the ridge. Experts recommend placing it in the center of the roof. The head is placed 50 cm above the ridge.

Disabling the fan

Turning off the fan stops the supply ventilation, and carbon monoxide is not discharged to the street. In this case, the reason for stopping the operation of the ventilation system is identified.

Experts recommend performing a seasonal preventive inspection of the heating device in the fall and spring. Operating the boiler without a thermostat is not recommended.

Removing air pockets in the system

It's better to start with batteries. To remove air pockets, a Mayevsky tap is usually installed on them. We open it and wait for the water to run. Did you run? Let's close. Such manipulations must be done with each heating device separately.

How to start a boiler with your own hands photo

After the air is removed from the batteries, the pressure in the system will decrease and the pressure gauge needle will drop. At this stage of work, the solution to the question of how to start the boiler involves re-filling the system with liquid.

Now, the most difficult thing is that starting gas boilers requires bleeding air from the circulation pump. To do this, the boiler needs to be disassembled a little. We remove the front cover and look for a cylindrical object with a shiny lid in the middle, which has a slot for a screwdriver. After we have found it, we put the boiler into operation - we supply it with electrical power and set the water heating controls to the operating position.

Relieving air from the circulation pump when starting the boiler photo

The circulation pump will immediately turn on - you will hear a faint hum and loud gurgling and many incomprehensible sounds. This is fine. As long as the pump is aired, it will be so. Take a screwdriver and slowly unscrew the cap in the middle of the pump - as soon as water starts seeping out from under it, screw it back. After two or three such manipulations, the air will come out completely, the strange sounds will subside, the electric ignition will work and start working. Check the pressure again and add water to the system if necessary.

Basically, that's it. While the system is warming up, you can begin to study the instructions in detail (if, of course, you have not already done so) and start debugging the system that involves starting the boiler. Everything is simple here - the batteries closest to the boiler need to be screwed on, and the ones farther away need to be turned on to their full potential. This debugging is carried out using control valves installed on the supply connection pipe to the heating radiator.

How to disable the draft sensor in a gas boiler

The draft sensor of a floor-mounted and wall-mounted gas boiler is replaced in stages. Stop the heating system, remove the housing, dismantle the relay. The operation of the thermostat is analyzed and, in case of malfunction, a new one is installed.

A faulty draft sensor can lead to an air lock and reverse draft.

Disabling the thermal relay poses a great danger to human life. In the event of an emergency, it is impossible to turn on the boiler’s protective function. Therefore, experts recommend that if a thermal relay is found to be damaged, replace it immediately.

Repair the board or replace it with a new one?

The electronic board of any boiler is an expensive device and replacing it with a new one in case of any malfunction is not advisable, especially since Beretta boards do not have the most complex circuit diagram.

We offer our clients board repair because it is, first of all, profitable, since the cost in most cases does not exceed 30% of the price of a new board. To carry out repairs, we have professional equipment, diagrams, original spare parts and experience.

To carry out diagnostics, special stands have been organized that simulate a real unit, on which the boards are checked after repair.

We don’t just repair boards, but we provide a significant warranty period for the work, because we have already repaired more than one such board and are confident in the result.