A powerful gas boiler installed in a cottage can easily solve the problem of heating and supplying the house with hot water. But the amount of heated liquid for hygienic and household needs is limited and does not always suit the owners. To compensate for its deficiency, they install a BKN - an indirect heating boiler for a gas boiler.

Let's look at the features and functional capabilities of the storage unit, and also find out how best to use it in tandem with a gas boiler so that the result is as efficient as possible.

What is a single-circuit boiler

Single-circuit gas boilers are used to heat the coolant that fills the heating system. A single-circuit boiler does not prepare water for hot water supply. In rooms where the heated area sometimes exceeds three hundred square meters, floor-standing boilers are used. These heating devices are much more powerful than wall-mounted ones.

Wall-mounted single-circuit heating devices are most often used in high-rise apartments and can heat an area of up to three hundred square meters. These boilers are much more compact than floor-standing ones, and weigh just over 40 kilograms. The wall-mounted single-circuit boiler fits organically into the interior. Also, these wall-mounted devices are more functional than their floor-standing counterparts. The power of the most advanced models of wall-mounted single-circuit boilers is no more than 35 kilowatts.

A single-circuit gas boiler does not have any complex elements or mechanisms in its design. This boiler consists of:

- burners;

- heat exchanger;

- control unit;

- water pump;

- turbine electric motor (if the boiler has a closed combustion chamber);

- pressure gauge;

- sensors;

- shut-off valves.

Wall-mounted single-circuit boilers can be equipped with an expansion tank, which is hidden under the boiler casing. Also, the expansion tank can be part of a floor heating device, which has low power.

Calculation of the required boiler power

When calculating power, the area of the house, the number of windows, the degree of wall insulation, and climate are taken into account

. Before purchasing, it is important to calculate the optimal thermal performance indicator. The roughest method is based on the area of the home: it is assumed that 1 kW of power is needed to service every 10 m2 (if the height of the room does not exceed 3 m) and 20-30% of the reserve is added to the resulting result. However, the situation is influenced by a number of factors that are not taken into account in this method: climate, sources of heat loss, the amount of heated water consumed, installations of forced circulation of air masses.

A more accurate calculation will be obtained if you enter into the formula a specific coefficient determined by climatic conditions: for the south of the CIS it will be equal to 0.7-0.9, for the central region of the European part of Russia - 1-1.1, for the northern regions 1.3- 1.4. Then the formula will take the form: N=S*k/10, where N is power in kW, S is area in m2, k is coefficient. If a boiler is purchased for heating and water supply at the same time, the resulting result is multiplied by 1.25.

What is a double-circuit boiler

This heating device not only heats the coolant, but is also intended for preparing hot water. A double-circuit boiler has a more complex structure than its single-circuit counterpart. The most complex device has a dual-circuit heating device, which is equipped with a three-way valve.

There are dual-circuit heating devices that are equipped with a pair of heat exchangers. One heat exchanger is responsible for heating water in the heating system, and the second heats water for water supply. The most rational design has dual-circuit heating devices that are equipped with a bithermal heat exchanger. Such a heat exchanger is two in one. Inside the bithermic heat exchanger there is another heat exchanger, which is designed to heat water for domestic purposes. But boilers with separate heat exchangers are considered more popular models.

Double-circuit gas boilers are good because they solve all the problems associated with preparing hot water for heating a room. Such heating devices are quite compact and fit organically into any interior. The design of a double-circuit heating device resembles the design of its single-circuit counterpart, which is also supplemented:

- a second heat exchanger (if the boiler design provides for this);

- 3-way valve (if the heat exchanger is not bithermic);

- inlet and outlet for the DHW pipeline.

Other options

We talked above about storage-type structures. That is, the water in the tank has a certain volume, which heats up. But there are also flow-type models on the market. In them, water is heated to a certain temperature as it moves through a special heat exchanger.

Typically, the heat exchanger is made of a material with high thermal conductivity and good corrosion resistance. Therefore, this unit is most often made of copper, aluminum or stainless steel. But their shape is coiled, because you have to install a heat exchanger of quite a long length in a small volume. And the longer it is, the more efficiently it heats the water. By the way, water heating gas boilers, which were already mentioned above, operate using this system.

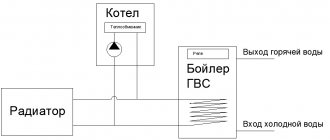

Simple connection diagram

Pros and cons of a double-circuit boiler

A dual-circuit heating device has many advantages. The main advantage of this device is that thanks to such a boiler you can simultaneously heat the room and use hot water. Using a double-circuit boiler will save you from additional costs that may be associated with the purchase of a boiler. Also among the undeniable advantages is the external attractiveness of dual-circuit heating devices. These boilers look aesthetically pleasing not only in the boiler room, but also in any other room.

Modern double-circuit heating devices have high efficiency, which can significantly reduce utility costs. Double-circuit boilers allow you to ideally adjust the temperature inside the room, as well as regulate the temperature of the water in the DHW pipeline.

These heating devices are not without several disadvantages, the list of which includes:

- turning off the heating at the time of dispensing hot water;

- relatively low productivity in preparing hot water.

Boiler location in the house

Floor-mounted models are installed in a specially equipped room. You can use the utility room for this. Floors must be non-flammable. If the device is equipped with a built-in burner, it cannot be replaced in case of breakdown. Blowing configurations are more profitable - you need to purchase them yourself, but they can be easily replaced at home.

A hanging boiler does not require a special room and can be installed, for example, in the kitchen. Compact dimensions allow you to place it in a niche in the wall or in a small closet.

What is an indirect heating boiler

Today, more and more people are resorting to using indirect heating boilers. This useful device allows you to use the heat of a gas boiler more efficiently. In winter, when the heating system is turned on, the indirect heating boiler operates from this system, and in summer, when the boiler does not operate for heating, such a boiler operates from an electric heating element or the boiler is switched to summer mode (if settings allow).

Heating of water in an indirect heating boiler does not occur in a direct way, but in a kind of incidental way. Inside such a boiler there is a fairly large coil, inside which coolant from the heating system circulates. Thus, the gas boiler heats the water in the indirect coil, which circulates in the heating system with the help of a pump, and the heat exchanger heats the water that is in the boiler. This type of water heating for the DHW main is recognized as the most cost-effective.

The casing of this boiler is mainly made of steel sheet, and its inner part is made of stainless steel. Between the outer and inner parts of an indirect heating boiler there is a special material that almost does not conduct heat. The design of such a boiler is very similar to the design of a thermos.

As a rule, an indirect heating boiler is installed near the heating boiler. The heated coolant must pass through the boiler first. The water in such a boiler will always be hot, and several hot water sampling points can be connected to this boiler at once. Hot water is heated in an indirect heating boiler without damaging the operation of the heating system.

In most cases, such a boiler is equipped with a highly efficient heat exchanger, which is made of special steel. More expensive indirect heating boilers are equipped with heat exchangers made of brass. The boiler heat exchanger has the shape of a long spiral, which allows you to very quickly heat the water to the temperature that the water in the heating system currently has.

Types of gas boilers

Gas devices with an indirect heating boiler may differ in the type of placement and shape of the tank.

According to the principle of placement: wall and floor

Can be:

- wall;

- floor

Units of the first category are devices of small volume - up to two hundred liters.

A floor-standing gas boiler in a package, with an indirect heating boiler, is installed in a special room.

They are installed using special brackets on a stable wall that can support the weight of the water tank without loss. It is clear that flimsy plasterboard partitions are not suitable for this purpose. Typically, such devices are purchased by one small family for their private home.

The second ones are capacious water heaters designed for a large number of people. Such devices will require the installation of a special boiler room.

They are usually purchased by enterprises and owners of large cottages and estates.

According to the shape of the tank

- Horizontal: very bulky, but they do not require pumps; they themselves maintain the water in the required volume.

- Vertical: have a small capacity.

When choosing, you should take into account the number of people in the family, as well as the layout features and the availability of free space in the country house or in the house.

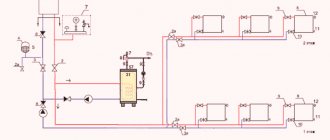

Gas floor-standing boiler installed in the boiler room and a small vertical expansion tank.

Pros and cons of a single-circuit boiler and BKN

A boiler that produces hot water by indirect heating is often used in conjunction with a single-circuit heating device. This tandem has both advantages and disadvantages. The main advantage of such a boiler is that this device practically does not require any maintenance and financial costs throughout its entire service life. An indirect heating boiler does not overload the electrical network with excess load, which is very important for those regions where voltage sags are observed.

An indirect heating boiler, which works together with a single-circuit gas boiler, is very convenient to use. Such a boiler uses water efficiently, since it does not require draining a large amount of water until hot water flows. Such a boiler heats water very quickly, and several mixers can be connected to this device, which can be located in different places in the house or apartment.

The heat exchanger of an indirect heating boiler operates under conditions that completely eliminate the formation of scale. The design also prevents the formation of harmful microorganisms inside the device. An indirect heating boiler does not require periodic cleaning and can operate for more than ten years without any maintenance.

The heat exchanger of the indirect heating boiler has special protection against corrosion. This protection very effectively protects these boiler elements from stray currents that occur in water mains.

Indirect heating boilers have several minor disadvantages, the list of which includes:

- higher cost than their electric counterparts;

- indirect heating boilers are larger than conventional boilers;

Solution with a remote storage tank

14 liters or one and a half buckets of hot water for one minute is a good indicator, but it is not always enough. The dimensions of suspended heat generators are limited, so they cannot accommodate large volume vessels. But it is the amount of heated water in reserve that determines the long-term performance of the hot water supply system. And the weight of the structure along with the water will eventually become such that not a single wall can support it.

Many manufacturers offer heating units with a built-in tank in a floor-standing design, but significantly increasing their size in order to place a large container inside also does not make sense. When you need greater productivity, you should pay attention to remote vessels for hot water.

- A – thermal insulation made of polyurethane foam;

- B – connection to the water supply;

- C – hot water output;

- D – heating coil located in the lower part of the vessel;

- E – stainless steel vessel;

- F – technological opening for maintenance.

Such remote boilers with a capacity of up to 500 liters can be connected to heat generators that provide this capability. That is, to connect a separate vessel, the unit must have outlet pipes, and inside there must be a circulation pump servicing the DHW circuit. In this case, the power of the gas boiler needs to correspond to the capacity of the vessel, otherwise the water in it will never reach normal temperature for use.

The fact is that the controller that controls the entire circuit gives priority to the heating system. If the temperature of the coolant in the system circuits drops to the lower limit, the control unit will direct all the power of the installation to increase this temperature, and then to the DHW circuit. In this situation, you can use the functions of the controller by programming the preparation of water at the required temperature for a certain time of day.

Using a single-circuit boiler and a conventional boiler

Along with indirect heating boilers with single-circuit gas boilers, conventional boilers are also used. Conventional electric boilers are slightly cheaper than indirect heating boilers, but are significantly inferior to them in many parameters. A conventional electric boiler takes much longer to heat water and this device requires regular maintenance.

It is advisable to clean the electric boiler from scale once a year, and also periodically change the anode, which serves as protection for the electric heater. An electric boiler also needs reliable power supply, and an independent electrical line must be laid to this device. Also, this water heating device seriously loads the electrical network - in general. Therefore, it is better to use an electric boiler in rooms where the electrical wiring has a safety margin.

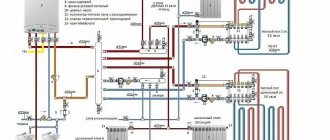

Subtleties of installing system components

Having decided on the method of connecting a gas boiler and an electric boiler, you need to carefully think through and draw up a wiring diagram, and then proceed with installation.

Stage #1 - connecting a gas boiler

This stage should be entrusted to professionals: like any other gas equipment, only professionals certified by the gas service have the right to connect a gas boiler. This is due to the fact that even minor errors in installation and configuration are fraught with serious consequences.

It is quite possible to get confused in the variety of outputs of a double-circuit boiler, and if you start an incorrectly connected boiler, expensive equipment may fail

If a water supply or sewer leak threatens you with a puddle, a maximum of a couple of centimeters of water on the floor, then an error in connecting a gas boiler threatens a fire, explosion or poisoning by combustion products.

We reviewed installation diagrams for a double-circuit gas boiler in this material.

Stage #2 - boiler installation

An electric boiler operating in conjunction with a gas boiler is connected in the same way as for standard use. The only difference is that not cold water is supplied from the water supply, but hot water from the boiler.

When planning a hot water supply scheme with a boiler and boiler, be sure to set the latter’s thermostat to a lower temperature than in the boiler

Step-by-step instructions for installing a boiler are discussed below:

- You need to punch two holes in the wall for dowels at the same distance as the boiler mount.

- Then hammer the dowels into the holes, screw the hook-brackets into them almost all the way, and turn them with the hooks straight up. Fasteners are usually included with the boiler and are designed to support its weight when filled with water.

- Hang the tank on the hooks, check that they fit exactly into the grooves.

- Make water connections to the boiler and taps using plastic, metal-plastic pipes or flexible hoses. Install a ball valve at each connection for easy maintenance of the boiler.

- Make a branch from the safety valve into the sewer using a thin tube. You can neglect it, but then you will need to tighten the locking screw, provide a container into which a small amount of water can drain, and check the operation of the valve manually every 2 weeks.

- Connect to the electrical network - this procedure is performed through a dedicated grounded line - a separate cable stretched from the meter. Regardless of whether the boiler will be plugged into an outlet or connected directly to a cable, you will need to install a circuit breaker for additional protection.

- It is also important to take care of high-quality insulation, because the room may be damp.

Installing the boiler and boiler is the main, simplest and most important part of the work, but this is only the beginning. For their effective interaction, it is necessary to perform the piping according to a pre-selected pattern. We will talk about the elements of such schemes further.

Stage #3 - connections and additional equipment

The first thing any water-related system should begin with is installing a filter to clean it.

Installing a mechanical water purification filter will prevent small solid particles from entering the heating and water supply system and extend the life of the equipment

When choosing a filter, remember that the better it purifies water, the longer the boiler, boiler, and all other equipment will last. Otherwise, small particles from the water settle on the walls of the coil and tank, form scale on the heating element of the boiler, contribute to the destruction of the tank and lead to rapid failure of all parts of the system - from the boiler to the faucet in the kitchen.

However, it is also not worth choosing the most expensive filter that purifies tap water to drinking state - it is too expensive and irrational. A filtration system with 2 – 3 levels of mechanical purification of varying degrees, from coarse to fine, will be quite sufficient.

The filter is installed at the very beginning of the chain, before connecting the water supply to the boiler. Be careful with the direction of flow - it is usually indicated by arrows on the body.

During operation, do not forget to regularly change the filter cartridges, otherwise they cease to perform their function and may negatively affect the water pressure.

The second obvious and necessary equipment is ball valves. You need a lot of them, they are placed at each connection: in front of the filter, at the boiler inlet and outlet, on both boiler connection pipes, at each outlet from the hydraulic needle, in front of each water tap.

This number of cranes ensures safety and comfort of operation. At some point, every part of the system will require preventive maintenance, and possibly replacement, and the ability to turn off just that will be very important.

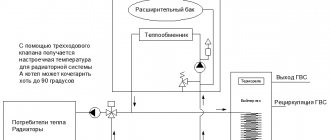

Expansion tanks are installed to compensate for pressure drops in the water supply or heating circuit caused by changes in water temperature - for safety

When organizing DHW through a boiler, an expansion tank is usually not required: in the event of a critical increase in pressure, the boiler safety valve will operate. But if the heating circuit is installed separately, such protection will not be superfluous.

In addition to the listed devices, as well as the hydraulic comb discussed above, check valves are installed on the pipelines, which do not allow the flow to reverse even when the pump is turned off, safety and three-way valves, and, if necessary, a pressure reducing valve to reduce pressure.

Principle of operation

The unit operates in two stages:

- the return flow of coolant enters the condensation chamber . It is a heat exchanger in which the energy from the settling water vapor from the flue gases is transferred to the heating water (heating water). This causes the temperature of the coolant to rise slightly, which makes the heating mode of the gas burner more economical and gentle;

- From the condensation chamber, the OM enters the primary heat exchanger and then the whole process occurs according to the usual traditional method . Having received full heating, the liquid enters the secondary heat exchanger, giving up part of the energy for the preparation of hot water. It then enters the heating circuit or underfloor heating system.

For efficient operation of a radiator-type thermal circuit, it is necessary that the return temperature is not higher than the degree of heating of the condensation chamber heat exchanger, otherwise the operation of the first stage will become impossible.

IMPORTANT!

In Russian conditions, it is physically impossible to provide such conditions, so all that remains is to use condensing models to power the heated floor circuits. Such a limitation calls into question the feasibility of using these units in unsuitable conditions, since the difference in cost destroys all the benefits of fuel economy.

Manufacturers

Today, the leading manufacturers of gas boilers with a built-in boiler are: Electrolux, Ariston, Viessmann, Baxi, De Dietrich, Vaillant, Wolf, Chaffoteaux, Biasi.

| Manufacturer | Model | Characteristic |

| Electrolux | Electrolux GCB Magnum 28 Fi | Gas wall-mounted boiler with a 60-liter boiler . Power: 28.70 kW. Efficiency: 92.4%. Voltage: 220 V. Combustion chamber: closed. Number of circuits: dual circuit. Heat exchanger: separate. Dimensions (HxWxD): 900x600x460. |

| Ariston | Ariston Clas B Evo 24 FF | Wall-mounted gas boiler with built-in boiler. Power: 24.00 kW. Efficiency: 92.0%. Voltage: 220 V. Combustion chamber: closed. Number of circuits: dual-circuit (heating and hot water supply). Heat exchanger: separate. Dimensions (HxWxD): 943x600x460 |

| Ariston | Ariston Clas B Evo 30 FF | Storage capacity: 8 liters. Power: 30.00 kW. Efficiency: 92.0%. Voltage: 220 V. Combustion chamber: closed. Number of circuits: dual circuit. Heat exchanger: separate. Dimensions (HxWxD): 943x600x460 |

| Viessmann | Viessmann Vitopend 100-W WHKB025 | Storage capacity: 4 liters. Power: 25.10 kW. Efficiency: 90.0%. Voltage: 220 V. Combustion chamber: open. Number of circuits: dual-circuit (heating and hot water supply). Heat exchanger: separate. Dimensions (HxWxD): 725x450x360 |

| Viessmann | Viessmann Vitopend 100-W WHKB026 | Storage capacity: 4 liters. Power: 30.00 kW, efficiency: 90.0%. Voltage: 220 V. Combustion chamber: open. Number of circuits: dual-circuit (heating and hot water supply). Heat exchanger: separate. Overall dimensions (HxWxD): 725x450x360 |

| Baxi | Baxi Nuvola-3 B40 280i | Designed for heating private houses, cottages, country houses, cottages with an area of up to 280 m², as well as for organizing hot water supply. Features: 40 liter boiler; separate heat exchangers; weather-compensated automation; LCD display; push-button control; hydraulic group made of brass; expanded functionality; programming. |

| De Dietrich | De Dietrich MS 24 | Wall-mounted gas boiler with a storage tank of 6 liters. Power: 24.00 kW. Efficiency: 91.0%. Voltage: 220 V. Combustion chamber: open. Number of circuits: single-circuit. Heat exchanger: separate. Overall dimensions (HxWxD): 730x400x299 |

You can read about Biasi gas boiler models with a built-in boiler here.

Thus, by purchasing a gas boiler with a built-in boiler, you can achieve significant cost savings without losing functionality and ease of use.

Solid fuel water heating boilers

Solid fuel water heating boilers are another worthy alternative to gas boilers. The fuel can be wood, coal, coke or wood pellets. You can find boiler models that operate on any of the listed types of fuel.

Many solid fuel boilers are automatically capable of maintaining the desired outlet water temperature. It happens this way. The boiler has a sensor that monitors the water temperature at the outlet. The sensor is connected to the damper. When the temperature starts to go off scale, the damper begins to close. Due to this, the combustion process slows down. When the temperature drops, the damper begins to react and open slightly. It should be noted that such a device does not require a network connection. Let's look at the main types of solid fuel boilers: (See also: Water supply for a bathhouse)

Features of the electric boiler

The main design elements of an electric heating boiler are a tank and a heating element. The devices are equipped with monitoring and automatic control systems.

Various models may also include expansion tanks and circulation pumps.

When purchasing a boiler, you should pay attention to the type of electric heating element. Over time, lime particles settle on the heating elements, which affects the power of the device

Electric boilers have several advantages:

- Fire safety . Thanks to automatic control systems and the absence of open flames, the devices are safe. They do not emit toxic substances or combustion products and are not capable of exploding.

- Ease of installation. Electrical equipment requires no flue or ventilation, making installation easy.

- High efficiency . Regardless of the type of heating device, all electric boilers are highly efficient.

- Compactness . Electrical appliances, especially wall-mounted ones, take up little space.

- Nice design . Most modern models are stylistically versatile and look good in the interior.

Electric boilers are almost ideal - easy to use and safe. Their only serious drawback is the high cost of electricity. One more nuance: for residents of regions where there are frequent interruptions in the power grid, it is better to choose boilers that operate from other energy sources, or take care of purchasing additional heating devices.