The proper functioning of the fireplace depends not only on the installation of the firebox, but also on the competent design and installation of the chimney. Everything is important: from calculations of the pipe cross-section to the nuances of thermal insulation. Only a high-quality chimney will best suit its purpose.

Do you want to build a chimney duct, but don’t know which pipe to choose and how to install it? We will help you deal with this problem - in the article we looked in detail at how to make a chimney for a fireplace, paying attention to the pros and cons of pipes made of various materials.

They also provided important requirements for arranging fireplaces and drawing up a project. The article material was supplemented with detailed instructions for installing a chimney, providing it with step-by-step photos.

How to install the most fire-hazardous section of the chimney

When installing an amber stove through a wall, sandwich systems are installed with your own hands. The first segment of the chimney is made from a fragment of a smaller pipe. It is fixed in such a way as to prevent overheating of the fasteners; for this it is necessary to retreat a sufficient distance. Basalt insulation is laid from the 2nd bend.

The first segment of the chimney is made from a fragment of a smaller pipe.

Safety regulations

Do not forget that the chimney is a source of danger. Place the flue away from the cable and gas pipe. Contact with other utilities is undesirable. The maximum length of individual fragments is 1 meter

It is important to follow building codes and regulations

Place the flue away from the cable and gas pipe.

Choosing the material and design of the chimney pipe

The design of the chimney pipe is directly related to the type of stove for heating the room. So, for a stone Russian stove, a brick structure is most organically suitable, which rests on the stove itself, or is built on its own foundation. In multi-storey buildings of the last century, chimney ducts were installed in the thickness of the walls.

Similar chimneys are usually equipped with all types of stone stoves and fireplaces. Installation of brick chimneys should ensure the smoothest possible surface of the internal channel and ideal verticality of the masonry.

As a compromise, in recent years old brick chimneys have been "sleeved" - a steel pipe inserted into the brick chimney. This was necessary to reduce the cost and, accordingly, the amount of materials for a stone chimney, the installation of which could be more expensive than the rest of the stove structure.

In more modern and technologically advanced metal furnaces, steel or ceramic-composite pipes are usually used. A metal chimney is much cheaper than a brick pipe and much easier to install. However, under the influence of the condensate that appears, the metal actively corrodes and collapses. In addition, at the junctions of individual sections it is difficult to ensure perfect tightness and smoke can leak into the room.

Ceramic chimney pipes are more reliable. But, unlike steel ones, they have significant weight, require reinforced fastening, and are comparable in cost to brick ones. The new design systems, called sandwich chimneys, do not have all these disadvantages.

Varieties and materials

Pipes for fireplaces come in the following types:

made of brick;

metal;

monolithic or multilayer;

decorative or the most simple ones.

But in fact, it doesn’t matter: what shape, what material, whether they are prefabricated systems or not - nothing really matters

One thing is important - adequate ventilation of the firebox. And based on these considerations, only that pipe is good for a chimney, which ensures that the room with the fireplace does not smell of smoke and that the wood ignites from the very first match

If you are planning to install a fireplace with a chimney, then at a minimum you should know something about the materials from which chimneys are installed.

Ceramic

These are chimneys that are resistant to relatively high temperatures. They have great heat capacity and durability, but they cost a lot. A ceramic chimney is usually a three-layer structure with a ceramic inner pipe (fireproof), a heat insulator and a concrete shell. Thermal insulators are non-flammable mineral wool, and the concrete shell contains channels that reduce the temperature of the outer surface and provide additional heat removal.

Steel

A steel chimney is a round pipe, made of stainless steel or galvanized, with insulation and an insulated contour on the outside. The steel kit is quite easy to install and weighs very little. Metal pipes are increasingly becoming fashionable today, and to connect a stove or fireplace to a chimney, they very often use products made of black steel, because with them there will be no condensation at the fire source and the pipe will not corrode.

Ordinary metal cannot act as the main chimney riser. Inserts and open connection components are most often enameled steel sectional pipes, the metal thickness of which is at least 0.5 mm. This is due to their corrosion and acid resistance and are designed for temperatures of 450C, and for a short time - at 750C. As a rule, this is enough.

Stainless steel

The cost of a metal chimney made of stainless steel will be higher, but its service life will be longer. In addition, this design can withstand much higher temperatures (up to 1200C).

If these are domestic heating sources, then the thickness of the steel is used in the range of 0.5-0.8 mm, sometimes 1 mm. At the same time, easy installation of the entire structure, its low weight and immunity to acids are of great importance.

The highest chemical aggressiveness of the emission occurs when liquid fuel is burned. Here it is worth mentioning modular chimneys for metal fireplaces, which can be single or double, insulated. They can be laid openly, without fear that the structure may catch fire or, even worse, burn.

It must be said that visually such pipes look quite aesthetically pleasing, do not require brickwork, and do not require a foundation. The double chimney with insulation is suitable for installation both indoors and outdoors.

Combined

A variant of combined insulated chimneys made of metal is also possible, when the inner part is acid-resistant stainless steel from 0.8 to 1 mm, and the outer part is thinner and enameled.

Sandwich

Stainless steel sandwich pipes require special attention.

This is, first of all, durability, excellent traction due to the smoothness of the inner surface and minimal soot deposition.

At first glance, it is expensive, but it is unlikely that a brick structure, and even taking into account the foundation, mortar for masonry and payment for all the work, will be cheaper.

Coaxial

This is a chimney of a double-circuit design, having pipes of different diameters and the narrower of them is located inside the wider one. To prevent the pipes from touching, jumpers are provided.

Attached chimney

The safest solution may be to install a fireplace with an attached chimney. In this case, there will be no combustion products in the living space even if the masonry becomes leaky. And such a smoke removal system is installed not necessarily simultaneously with the construction of the house itself, but at any convenient time.

In this case, a device in the form of a tee with an inspection channel and a condensate collector is connected to the chimney.

External placement

A pipe with external placement increases the area of a small room. The chimney for the fireplace here is led through the wall near the heating device directly to the street.

Oval chimney

The draft force in it will depend on the cross-sectional shape of the chimney. The most aerodynamic are round tubes. Square pipes are better than rectangular ones, and an oval chimney is completely rare; it is used only when lining a rectangular brick channel.

Options

Made of brick

This chimney is made of brickwork. In terms of costs, this option is considered the most budgetary, but it is not particularly effective.

Of steel

A steel chimney is a round pipe, stainless or galvanized, insulated and with an external contour. The steel pipe is quite easy to install and weighs relatively little.

Made of ceramics

It is better to entrust the installation of such a structure to a professional with experience in such work. As complex as the construction of such a chimney is, the thermal insulation is also excellent. Such chimneys can last 30 years without failure, or even longer.

From glass

This chimney option is considered the most expensive and difficult to install, but visually the interior with this design looks very impressive. Glass chimneys are not afraid of corrosion, heat, or moisture, and this is their undoubted advantage.

Construction of a ceramic smoke channel

The most reliable and safe option for installing a chimney in a wooden house is a construction made of ceramic blocks. Its outer side practically does not heat up, which means there will be no problems with passage through the ceilings.

Let's consider the sequence of assembling a smoke channel from components of the German brand Schiedel Rondo Plus:

Let’s immediately make a reservation that the main one is constructed from ceramic modules, i.e. a separate pipe for which a separate foundation is arranged.

All technological holes are cut out along the construction site. Cutting is done with a regular grinder with a diamond blade.

To make geometrically accurate holes, the ceramic chimney kit includes a template. Further:

The ceramic chimney is assembled in a standard manner: modules are built up one after another

However, it is worth paying attention to the specifics of passages through the attic floor and through the roof

In our example, the chimney and ventilation riser are located next to each other, which is why we had to slightly trim the rafters:

We also have another article on our website containing step-by-step instructions on how to build a ceramic chimney, attach it and decorate the outside.

Installation

Installation of structures is always considered on an individual basis. This is the most critical stage; to install a chimney for a fireplace with your own hands, you need to calculate its diameter and location.

A suitable place to place a fireplace chimney is near the ridge of the roof. This will make the protruding part of the pipe smaller.

The height must be at least 4 meters. Calculation of maximum values depends on your building.

Calculation of the diameter of the pipe will also be required to ensure that the structure passes all the floors without difficulty.

Particular attention is always paid to the installation of equipment in wooden buildings. Such buildings are most susceptible to fires

In order to avoid this, it is necessary to use a transition pipe, which will not only protect against fires, but will also provide high-quality insulation between the roof and the fireplace chimney.

In order to make a hole in the roof, you must remember that its size should be slightly larger than the diameter of the pipe.

In addition, you need to pay attention to possible joints. They can not only reduce the efficiency of the heating device, but also worsen safety parameters

In addition, the service life will be noticeably reduced.

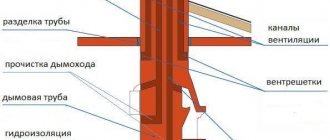

Sectional view of a chimney pipe on the roof

The most difficult part of the installation is considered to be the point where it passes through the roof.

The main parameters that you need to pay attention to are quality and safety.

For each design there is a basic set of requirements that need to be addressed

Diagram of the relationship between the type of heating device, the temperature in the chimney and the material of its manufacture

For example, for a brick building, the work scheme looks like this:

- Foundation.

- Solution.

- Masonry.

- Mopping.

- Header.

- Dymnik.

For a ceramic device, the work flow is as follows:

- foundation,

- Fastening modular elements.

The construction and installation of chimneys for fireplaces is carried out taking into account the expansion of the material under the influence of heat. In addition, it is necessary to take care of the tightness of the equipment during operation.

A properly equipped chimney will last a long time.

Make it yourself or order it

At first glance, there is nothing complicated about installing a chimney with your own hands, however, this is not entirely true. First of all, it should be remembered that the structure must be absolutely safe, which means it must be durable, airtight and with good traction force. And this will require from the “stove-maker”, at a minimum, relevant knowledge and thoroughness, and, at a maximum, certain experience and skills.

On the other hand, entrusting such a responsible job to a builder whose professionalism and integrity you doubt is not the most reasonable decision. After all, poorly done work can subsequently result in a fire or carbon monoxide poisoning.

Therefore, preference should be given only to trusted construction companies or take on the work yourself.

But to independently implement the project, you will need to make every effort:

- study a number of building rules and technical information about the heating device;

- make the necessary calculations;

- carry out construction and installation systematically, often at length and with special care.

Tips for cleaning chimneys

Unlike chimneys of heating solid fuel stoves, which are cleaned at the beginning of each heating season, sauna pipes are serviced as needed. Practice shows that if you regularly use a steam room, this procedure must be carried out at least 2 times a year.

To remove soot from the inner surface of the flue, it is convenient to use metal or plastic brushes with a metal weight. A rope tied to them allows you to lower the device from top to bottom, cleaning the channel along its entire length.

A brush with a weight for cleaning smoke ducts allows you to clean chimneys of any length

If it is not possible to get to the upper end of the pipe, then a hatch is installed in its lower part. Through it, cleaning is carried out from the bottom up, using the same brush attached to a long steel cable. Condensate from a system with metal pipes is drained using a ball valve, which is mounted at the lowest point of the moisture trap.

The mechanical method, although the most effective, is associated with quite serious labor costs. The process of removing soot can be made easier by using chemicals that are burned in the stove along with firewood.

Video: how to clean a chimney in a bathhouse

https://youtube.com/watch?v=WT3FqN4DLa0

The chimney is a mandatory attribute of a sauna stove, on which the efficiency of its operation depends. Choosing exactly what its design should be is only half the battle.

It is equally important not to forget about SNiP and fire safety standards during the design and installation process. Only in this case will the wish “enjoy your steam” sound like a call for a safe and pleasant pastime

Advantages and disadvantages of sandwich chimneys

In industrial conditions, stainless steel products are used for the inner layer of the sandwich, and zinc-coated steel pipes are used for the outer layer. In this case, the inner contour is covered with thermal insulation and placed inside the outer cylinder. As a result, such a structure functions quite efficiently and efficiently.

Installing a chimney made from sandwich products does not take much time and effort - all the work can be completed in a day. Below we present a number of advantages and disadvantages of such pipes.

Among the advantages of such structures are:

- multitasking - such pipes can be used in buildings made of any materials;

- occupy a minimum of space;

- ease of transportation;

- Even a beginner in construction can install sandwich pipes, as it is very simple and quick;

- laconic and pleasant appearance;

- fire safety - this is one of the best options for chimneys in this regard;

- the existing roof truss system does not create any obstacles to the installation of a sandwich pipe;

- due to the presence of several layers, much less soot accumulates in such a pipe and almost no condensation forms, so cleaning it is required much less frequently;

- The sandwich pipe is capable of fully protecting residents from the influence of toxic combustion products.

But such designs have very few disadvantages, although they still exist:

- the price of a sandwich pipe is quite significant;

- The optimal service life of such products is only about 15 years.

If you want to make a sandwich pipe with your own hands, then such a chimney will cost you much less than, say, one made of brick. This will result in a completely reliable chimney, and there should be no difficulties with installation and assembly.

Firebox dimensions

The fireplace in the house plan and its drawing and diagram must be ready long before installation work begins. The project must be based on both the room and the financial capabilities of the home owner. Every 10 centimeters in one of the dimensions gives a significant increase in price, but this absolutely does not mean that the more the better. Everything should be correlated and made in suitable proportions. The outside must match the inside

It is important to understand whether a fireplace was planned when designing the house or not. If such preparation has been carried out, then there will be no difficulties.

However, if the repairs have already been made and you need to assemble the classic brick version, then the following should be taken into account:

- Get advice from professionals who will point out all sorts of pitfalls.

- Assess the level of readiness of floors for additional load

- Choose the correct location.

- Check the possibility of removing the chimney pipe.

- Take into account the external dimensions (including firewood boxes).

We recommend taking a closer look at the design based on a convection box. This alternative to the classical method is the most popular at the moment.

Advantages:

- fast heating;

- efficient fuel consumption;

- takes up less space;

- has a reasonable price.

Criteria for choosing natural draft flues

When selecting the material for a future chimney, most homeowners focus on the price of the product and the cost of installation. For reliable and safe operation of heating equipment, other factors will have to be taken into account:

- Compatibility of the chimney with the type of boiler. Units with high efficiency (gas, diesel) emit smoke at a temperature of 70...120 °C, brick stoves and solid fuel heat generators - 150...200 °C, steel and cast iron stoves - up to 400 degrees.

- The method of installing a gas duct is internal installation with a passage through the ceilings and roof, or external installation along the wall.

- Combustibility of the material from which the building is constructed.

- The ability to repeatedly withstand an increase in the temperature of exhaust combustion products up to 1000 degrees. Such emergency situations occur when soot accumulated inside the pipe ignites.

- Corrosion resistance, durability.

Wooden structures located next to the hot pipe of a wood-burning stove must be protected with non-combustible materials.

Before choosing a chimney material, decide on the option for laying it and sketch out a diagram. Let us remind you about the requirements for smoke exhaust pipes:

- the diameter (sectional area) of the channel is no less than the outlet of the boiler, stove or fireplace;

- the minimum pipe height is 5 m, calculated from the grate (burner) to the top cut;

- the chimney head should not fall into the wind pressure zone formed behind the ridge of a gable roof or a tall building standing close to it;

- the maximum number of channel turns by 90° is no more than three;

- the indentation of the pipe surface unprotected by insulation from combustible (wooden) building structures is 50 cm, protected – 38 cm;

- the length of the horizontal section connected to the boiler pipe is a maximum of 1 m;

- According to fire safety requirements, all metal gas ducts laid through the rooms and attic of a residential building must be insulated with non-flammable material - basalt or kaolin wool.

The chimney for a stove or boiler must provide stable natural draft and removal of harmful gases to the outside of the room - this is the main requirement

It is equally important to comply with other fire safety standards, for example, not to use corrugated aluminum hoses on heating boilers

Regulatory requirements for head height and fire clearances

Disadvantages of brick chimney pipes

Like most materials, a brick chimney for a fireplace also has some disadvantages. One of them is a short service life (7 – 10 years). In addition, temperature changes in winter will inevitably lead to the formation of condensation on such pipes, which, after numerous freezing and thawing, will cause destruction of the brick chimney masonry.

However, the impact of this negative factor can be significantly reduced by using one of the following actions:

- increase the cross-section of the chimney for the fireplace, or rather, its external walls to 25 centimeters in those areas that are above the roof;

- insulate this sector of the pipe with mineral wool.

Another disadvantage of a brick chimney is a large number of irregularities on its inside. In this case, the draft efficiency is significantly reduced, which cannot be said about chimneys with a smooth inner surface. To avoid such a problem, even at the design stage, the chimney should be provided with a certain cross-sectional reserve.

When installing fireplaces and chimneys, the use of galvanized steel chimney pipes mounted inside will also increase the service life.

Conclusion

In any case, the best chimney is the one that will allow your fireplace to function safely, efficiently and economically. And if a brick chimney is quite suitable for your unit, then you definitely don’t need that ultra-modern and super-fashionable chimney about which you read such rave reviews on the Internet. It is clear that everyone will decide this issue at their own discretion, but you should always remember about the safe operation of your fireplace both for you and for everyone around you.

Stainless steel chimneys for fireplaces

These pipes are assembled elements made of stainless steel, and their thermal insulation is carried out using flammable materials.

Chimneys of this type can have different diameters and lengths. The kit often includes ceramic pipes that are mounted inside steel pipes.

A galvanized steel chimney has a number of advantages:

- due to their light weight, sandwich chimneys for fireplaces can be installed without a foundation (read: “Sandwich pipes for a chimney - installation”);

- such a chimney can be installed even after the entire construction process is completed;

- a stainless steel chimney pipe is cheaper than block and ceramic chimneys;

- Individual parts of the chimney can be easily replaced if desired.

Information with photos on installing chimney pipes made of stainless steel can be found on our website if desired.

Location

Chimney structures can be mounted (installed on top of the fireplace and extending it vertically), radical, that is, standing separately, when the vertical chimney duct with an offset location from the fireplace stands on a separate base, and wall-mounted, with the chimney duct running inside the wall of the building.

Cases when a chimney may be more expensive than the fireplace itself:

- if the firebox is simple, and the chimney system is one of the most modern and reliable. For example, a ceramic chimney and an economy class fireplace insert;

- if the fireplace is a potbelly stove or fireplace fan, and the chimney is made of stainless steel, and even insulated more than 10 meters in height;

- if the old chimney duct is converted into a modern heating system (lining or a completely new chimney);

- if they are trying to install a fireplace in a house where there was no plan for a chimney at all;

- if you decide to build a free-standing modern chimney on the outside of the house;

- if it is decided to build a fireplace in a penthouse or on the top floor of a high-rise building.

Block ceramic chimneys

Thus, the installation of fireplaces and chimneys is sometimes carried out using special block ceramic pipes. Technical characteristics of block ceramic chimneys. The ventilation channels of these chimneys are represented by blocks made of light weight concrete. Today there is a wide selection of samples, and everyone can choose the one they need in terms of height and size.

These blocks are connected using vertical reinforcement, and a ceramic pipe and thermal insulation made of non-combustible materials are placed inside. There may be several options for making a ceramic pipe; it all depends on the manufacturer, who recommends applying one or another technology to a specific sample. Therefore, there is no single device system.

About the mount

Proper mounting for the chimney is very important. To fix the pipe, the outer contour must be crimped using a special clamp and secured with rivets. After this, the clamp must be secured to the ceiling with a special angle and fastening bolts. In this case, the main weight of the chimney will fall not on the fireplace insert, but on the clamps and corners attached to the ceilings.

Even when the chimney for a fireplace is constructed in compliance with all the rules, some amount of water can still get into the pipe. Everything will depend on the cross-section of the chimney and the size of the “skirt”, which has an umbrella or deflector installed above the chimney.

Advantages and disadvantages of ceramic chimneys for fireplaces

The advantages of a ceramic pipe include the following characteristics:

- the material is very quick to install and assemble;

- is a guarantee of high efficiency;

- long service life;

- the range of blocks is large, which makes it possible to mount a chimney opening with any configuration;

- the presence of a special hole that makes it possible to clean the chimney;

- the condensate that appears drains away thanks to the hole located at the bottom of the chimney.

Among the disadvantages of block ceramic pipe systems, it is customary to highlight the following:

- relatively high price;

- Due to the fact that most of these chimneys are manufactured abroad, the delivery time is sometimes very long.

Design features of the chimney

The purpose of the fireplace chimney, as well as the main function of the chimneys of stoves or boilers, is to discharge fuel combustion products out into the atmosphere. Gases along with soot flow from the furnace into the chimney under the influence of draft.

The correct formation of a chimney consists in choosing and constructing a structure in which a minimum of soot remains on the walls of the pipe, and the draft prevents the flow of gases into the room.

Chimneys made of different materials have their own characteristics and may differ in design. For example, a traditional brick chimney consists of the following parts.

Modern chimneys made of steel or ceramics do not have such fragments as otter or fluff, but for the normal removal of smoke in brick pipes and to protect the ceilings from heating, they are simply necessary

When choosing a material, it is necessary to take into account the temperature of the gases: in the furnace it is higher, at the outlet it is lower, but even at the highest point it can reach +100 ° C. The creation of draft is based on the temperature difference - hot air is replaced by cold air.

Also important are indicators such as the height and internal diameter of the chimney - they are calculated when drawing up the project.

A variant of a fireplace design with a chimney made of a steel pipe. Features: floor and wall cladding with non-combustible materials, finishing of floors, possibility of creating non-vertical sections using half-bends

No matter how hard you try, it is impossible to build a chimney that does not need cleaning. Even in a properly assembled ceramic chimney, soot accumulates over time, making it difficult for gases to escape. Therefore, chimney cleaning must be carried out regularly. This is usually done during the period when the fireplace is idle.

In addition, it is necessary to monitor the integrity of the connections and the internal surface: cracks, potholes or protrusions that may appear over time prevent the normal circulation of hot air.

Calculation example

For example, there is a house of 60 sq. meters. On average, heat loss is 100 W/sq.m., the required heat flow is 6000 W. We apply a safety factor of 1.2 - 6000 * 1.2 = 7200 W In the table, the maximum approximate value will be 7185 W at a flow speed of 0.5 m/s. In the leftmost column, the internal diameter of the pipe will be 15 mm. Using the manufacturer's table, we find the required outer diameter of the pipe. For example, for the closest value in the direction of increase - 18 mm. This is a universal multilayer pipe (PE-Xc\Al\PE) 25 mm. We look the same way. A 25 mm Stabi polypropylene pipe is suitable for us.

Possible problems with the operation of the fireplace pipe

The operation of a fireplace largely depends on the correct installation of the chimney. If insufficient draft occurs, you should check the calculations according to which the chimney was built.

The fireplace pipe is installed incorrectly if:

- smoke enters the room;

- lighting a fireplace takes a long time;

- the fire in the fireplace burns too low;

- The burning intensity of solid fuels varies constantly and depends on weather conditions.

The first step when these problems occur is to ensure proper ventilation in the room. It is necessary to check the tightness of the windows and the intensity of the ventilation, if any. Since the fireplace flame burns most of the oxygen, there must be a constant flow of fresh air into the house.

The reasons for the chimney not working properly are as follows:

- Insufficient pipe height. The larger the fireplace, the higher the duct must be to provide sufficiently strong draft.

- The pipe design contains bends of more than 45 degrees. It is advisable to make the chimney as straight as possible. If there are still horizontal elements, you should choose the minimum angle of inclination. The vertical part must be at least 5 meters.

- Incorrect calculations. The draft largely depends on the correct cross-section of the chimney.

- External influence. Weather conditions can affect the intensity of draft in the pipe. To prevent this from happening, it is necessary to install a weather vane on the chimney.

The chimney pipe for the fireplace must be installed in accordance with all standards. This will make the fireplace fireproof and also ensure its proper operation.

Special cases

To build a chimney on the second floor means to mount it using sealant either through a hole in a load-bearing wall or through a balcony, if there is one. Here, a coaxial pipe is best suited for use as a chimney. It is double-circuit, that is, the internal circuit serves to remove waste substances, and the external circuit serves to intake air, as in the diagram:

In the case of designing a chimney for a fireplace and simultaneously connecting it to a kitchen stove, adhere to the optimal height and design of the chimney, increasing the cross-section and installing several dampers so that access to smoke can be closed. However, according to experts, a fireplace chimney should not be connected to another heating device, including a stove.

Diameter

In order to calculate all the parameters, it is now necessary to decide on the material that will be used in the construction process. It is most convenient to carry out the calculation on paper, creating a sketch of the future structure; it is necessary to take into account some nuances:

- The diameter of the chimney for a fireplace must have a certain relationship with the firebox. Calculating this value has its own subtleties. For example, when calculating the diameter of a pipe that connects to an open firebox structure, a proportion of 1:10 is used. This method is only correct for a cylindrical type of chimney.

- The calculation of the cross-section for a square type device contains proportions of 1:15. But the diameter should be smaller than the size of the blower. If the resulting heat transfer is less than 300 cal/hour, the cross-section should not be less than 140 x 140.

- In order to determine the optimal diameter of the fireplace chimney, you can take as a basis state standards, which stipulate the permissible cross-section under certain conditions.

- In addition, the height and diameter are calculated in accordance with the area of the room.

Standard dimensions of internal diameters and cross-sectional areas of brick chimneys

It would be a good idea to show your calculation to specialists and analyze it together. In addition, a suitable calculation scheme can be posted on the Internet.

It must be remembered that the calculation of these parameters must be done correctly; the efficiency of the heating device depends on this.

A short video tutorial on installing a chimney in a private house

It must be remembered that the choice of a chimney does not depend on its external data, but on the stove on which it will be installed, as well as on the fuel used and other heating parameters. Therefore, before purchasing or constructing a chimney, you must consult a specialist.

And one more warning - for some inexperienced builders, the abundance of requirements for arranging stove heating and chimneys, in particular, may seem like unnecessary “nit-picking”, which can, if desired, be ignored. Believe me, these rules were developed by life itself, based on centuries of experience and careful engineering calculations. It’s sad, but more than once their neglect has been paid for with human lives.

Rules for installing a chimney through a wall with your own hands

Smoke removal will be effective if you follow the basic rules:

- For good traction, you need to raise the pipe above the ridge.

- With a long part of the chimney (more than 10 m), the fuel will quickly burn out; with a short part (less than 5 m), there will be no intense combustion.

What is the best way to route the pipe from the stove through the wall, experts say. The main stages of installing a smoke exhaust system are indicated in the step-by-step instructions.

For good traction, you need to raise the pipe above the ridge.

Sandwich chimney installation diagram

Installation of a chimney made of sandwich pipes through a wall is carried out in accordance with the following standards:

- Indoors without condensate drainage;

- From the outside - “through condensation”, the resulting moisture flows into the drainage cup.

The scheme is selected for a specific room, taking into account the interior design. You can install a sandwich chimney with a passage through the wall yourself.

The scheme is selected for a specific room, taking into account the interior design.

Preparatory stage

Before installing the heat generator, insulate the base with cement or heat-resistant metal. All components are assembled; the sandwich system consists of many elements; it is necessary to prepare a complete sandwich set. Swivel fittings will be required to form the elbows. They buy insulation with a reserve. It is recommended to lay a foil layer to the inner contour. You will need hardware to install fasteners. The joints are fixed with clamps.

It is recommended to lay a foil layer to the inner contour.

Basic installation steps

After determining the location of the pipe, heating equipment is installed. Then a hole is made in the wall slightly larger than the outer diameter of the sandwich. A connecting pipe is mounted, the chimney is connected to the heating equipment through a tee. At the last stage, the outer part of the flue is attached to the outer wall of the building in increments of at least 50 cm.

At the last stage, the outer part of the flue is attached to the outer wall of the building in increments of at least 50 cm.

Video description

How to pass a pipe through a wooden base is shown in this video:

- Making a hole for the box. At this stage, the diameter of the product is taken into account, as well as the space for the insulating material (basalt wool inserts).

- Pipe installation. An asbestos sheet is laid between its walls and the box. The element is displayed strictly at a right angle. Any deviation will impair the operation of the boiler.

- Attaching a protective screen outdoors. This is a steel plate fixed to the outside of the wall. It protects the wood from overheating and reduces the risk of fire.

Pipe protection with insulating material Source petropech.ru

- Tee installation. A vessel for collecting condensate is attached to its lower part.

- Installation of support. It is screwed to the wall or rests on the ground. Its task is to maintain the vertical part of the structure.

- Chimney connection. Condensation should not get into internal joints. Every meter the structure is fixed to the wall with brackets. During fastening, a building level is used to maintain the strictly vertical position of the pipe. The last clamp is installed under the roof.

Lastly, a protective fungus is put on the pipe.

How to remove soot

It will be safe and comfortable to have a fireplace in the house only if there is good draft in the chimney. And this largely depends on his condition.

There are several cleaning methods for chimneys: there are traditional ones, which people have used for centuries, and modern ones, based on scientific developments. These methods include:

People's

In the old days, chimneys were cleaned with aspen wood, which could generate heat in the firebox up to 1200C. Under such influence, the soot becomes loose and burns, and everything that remains of it flies out along with the smoke into the chimney.

Before cleaning using this method, you must be sure that such high temperatures will not harm your chimney, since it will be difficult to avoid destruction or fire if the chimney, for example, cracks.

Even in the old days, they used another method of cleaning the chimney: they burned dried potato peelings, the combustion of which released substances that could loosen the soot, and then it was easily removed from the cleaning holes. But traditional methods will not always help, and in case of severe blockage it is better to turn to chemistry.

Chemical

Today, you can find a variety of cleaning products for cleaning chimneys in the stove store. It can be powder, tablets, liquid or special pellets, logs and briquettes, which are simply placed in the firebox (with or without firewood) and burned. More details about the use of each chemical are described in the instructions supplied with them.

Cleaning briquettes are considered the most convenient of all chimney cleaning chemicals. They heat the fireplace for about two hours, due to which the substances that bind the soot in the chimney are destroyed, and the remaining fines are carried out, like the smoke, into the chimney.

If there was a large blockage in the pipe, it will fall down, and therefore, after servicing the chimney, an inspection of the entire chimney space is necessary, for which there are special doors.