Date of publication: November 25, 2019

Today, more and more people are thinking about choosing and purchasing heating equipment, in particular a fireplace or stove for a summer house, a country house, and sometimes for an apartment or restaurant.

Due to the availability of this type of product these days, as well as a very wide range of prices, almost everyone can afford a fireplace or stove.

As you know, any fireplace, stove or, for example, boiler, which uses combustible fuel, necessarily requires the installation of a chimney to remove combustion products. You cannot do without a chimney in cases where the following are used for the operation of the heating device:

- Firewood

- Coal of any kind

- Diesel (diesel)

- Gas

Why do you need a chimney?

A chimney is a special channel through which smoke, consisting of burnt fuel particles, is discharged from the heating device to the street. Without a chimney, all the smoke, carbon monoxide and particles, many of which are quite harmful to health, would simply remain indoors, posing a real threat to life. At the same time, it is the chimney that is responsible for the draft, which directly contributes to the combustion of fuel in the firebox of the fireplace or stove. The function of a chimney is difficult to overestimate, just as it is difficult to overestimate the importance of the quality of execution and connection of the chimney. How well the chimney is made initially and how professionally it is connected to the heating device will subsequently affect the operation and safety of the entire heating system.

It is important to understand that heating products, due to differences in design and temperature of the exhaust smoke, require the installation of different chimneys. So which chimney is best for a home fireplace or stove? This question will be answered in this article.

Thermal insulation layer

Thermal insulation plays an equally important role in DS. She must:

- maintain the temperature in the inner pipe so that working draft is created in the chimney and flue gases are removed from the firebox;

- do not transfer high temperature to the structures enclosing the chimney to prevent fire.

Low-quality thermal insulation loses volume, settles, forming voids through which high temperatures will be transferred to the outer shell and, accordingly, to flammable materials. This is fraught with fire.

And also low quality insulation can absorb moisture, bake or coke. In these cases, it immediately loses its characteristics, forms cavities and exposes the outer shell to high temperatures.

The best option for a chimney would be a heat insulator that does not contain adhesive binders that burn out at temperatures of 500–600 °C.

Important! Ask the seller to show the insulation in the pipe. If it is printed from individual fibers, then within the first six months or a year it will lose its characteristics. High-quality insulation will be wrapped around the pipe like a blanket or consist of 2-3 segments.

Unscrupulous manufacturers use a trick - they create an illusion: they install rings consisting of high-quality segmented thermal insulation into the edges of the chimney, and fill the main space with low-grade material.

The main characteristics that a chimney should have

Regardless of what material the chimney is made of and what design it has, this product must comply with the basic parameters of fire and operational safety. So, the chimney must:

- Be made of non-flammable materials

- Be suitable for the specific type of heating equipment used

- Maintain the temperatures provided by the equipment - both operating and peak

- Withstand temperature changes and climatic influences

- Features simple installation

- Have a long service life

- Be completely sealed

- Have insulation at points of passage through walls, ceilings, and roofs

Let's take a closer look at each type of chimney pipe.

Mistake #4. Do not pay attention to the penetration of the joints of pipe parts into the ceiling

Modern chimneys are modular in design. In other words, they are assembled from several elements according to the Lego principle. So, any joint is a weak point, and in the case of pipes, it is also a thermally vulnerable point. The temperature at the joints will always be higher than at some other pipe element. Therefore, try to make sure that the joints do not fall into the ceiling and roofing.

Artemenko Vyacheslav Manager of the store on the street. Kollontai, 18

The issue with joints must be resolved at the stage of purchasing a chimney. To provide for this, we make a free drawing of a stove with a pipe in compliance with all proportions. To do this, you need to provide the correct smoke heights, after which it will not be difficult for us to accurately and quickly resolve the issue with the joints.

Moreover, our drawing will allow you to calculate the amount of insulation required on the walls. Let us repeat that this service is completely free, so contact any of our 30+ stores or call 8 (812) 605-85-05.

Fig 2. This drawing allows you to accurately calculate the height of the chimney and the required volume of insulation

Brick chimney

The most “ancient” solution for a smoke exhaust system is brick chimneys, which have been used by mankind for many centuries in a row. Today, this solution for removing combustion products is also common, but is considered outdated. Brick is a fire-resistant material, but such properties are not sufficient for high-quality removal of combustion products from heating devices. The rough surface of the brick contributes to the rapid accumulation of soot and carbon deposits, and therefore such pipes require frequent care and service. Significant disadvantages of brick pipes include their high weight and long installation time. To install a chimney of such a large weight, a special foundation is required, and the pipe will have to be built literally “brick by brick.” By the way, the brick itself is quite expensive, so a brick chimney is also an additional burden on the budget.

If a brick chimney is installed incorrectly, it can be a fire hazard, and condensation will appear inside it. At the same time, after some time, cracks may appear on the surface of the brickwork, which reduces the tightness of the chimney. Brick chimneys also have advantages. For example, the aesthetic characteristics of such chimneys are highly rated. The orange masonry of the brick chimney brings coziness to the house. They also highlight an increased level of heat transfer from bricks along with good fire resistance. A brick chimney is designed to withstand flue gas temperatures of up to about 600-700 degrees Celsius.

Summarizing the above, we will highlight the main pros and cons of a brick chimney for removing combustion products from fireplaces and stoves.

Pros:

- nice appearance of brickwork in the interior

- excellent fire-resistant qualities

- heat accumulation and release

Minuses:

- need to install a foundation

- labor-intensive and time-consuming installation

- possibility of fire hazards

- possibility of cracks

- rapid formation of condensation, soot and soot on the internal walls of the chimney due to the rough surface

- high cost of bricks

Functions of chimneys for fireplaces and stoves

Without going into details, we can say that a stove chimney is intended only to release into the atmosphere the caustic combustion products that are formed during the combustion of any fuel. But in fact, the smoke channel is a full-fledged part of the heating device. Without a chimney, it is impossible to operate either a stove or boiler, or gas equipment.

The performance of an autonomous heating device depends on how much oxygen enters its firebox. It is incorrect to say that the more oxygen supplied to the device, the better it will work: there must be a strictly defined amount of air. Both excess and lack of oxygen can lead to loss of equipment power, unstable operation or increased fuel consumption.

The principle of operation of the chimney can be described as follows:

- by and large, each chimney is part of a looped system;

- After passing through the chimney, the exhaust caustic gases are discharged into the open air. Due to this, a vacuum occurs in the receiving part of the furnace or boiler, and clean air from the atmosphere is released into the smoke hose;

- the oxygen entering the chimney burns, heats up and is again removed from the system to the outside. This happens until the fuel in the furnace is exhausted.

If you choose the wrong chimney size for a fireplace or use a chimney that is completely unsuitable for other characteristics of this type of heating device, the circulation cycle is disrupted. This leads to undesirable moments, such as:

- excessive fuel consumption;

- the release of carbon monoxide, hazardous to life, into a living space;

- high probability of fire from the emission of sparks;

- unproductive operation of the heating unit;

- inefficient fuel combustion.

The chimney provides draft, on which the fuel combustion process depends

A good chimney should ensure a condition in the furnace system in which solid fuel will burn without residue, and at the same time its overconsumption will not be allowed. Other important aspects influencing the choice will be ease of installation and the possibility of further maintenance.

Ceramic chimneys

The next type of chimney is ceramic pipes, which are common in many places these days. Such chimneys are made of durable ceramics, which are often additionally placed in a shell of brick, expanded clay concrete or other fire-resistant materials. Ceramic pipes are assembled like a brick chimney from separate blocks that are connected to each other into a single structure. Among the main advantages of ceramic pipes is their versatility - they can be used to connect any home heating appliances, and they are also compatible with various fuels.

Since ceramic chimneys are assembled from separate blocks, during their installation it is possible to create various turns of the chimney route. A ceramic chimney has a high level of fire safety and durability. Among the disadvantages of ceramic chimneys are their very high cost and heavy weight, which dictates the need to install a foundation. At the same time, the installation of such pipes is complex - ceramic blocks must be assembled in a strict order, and special solutions and materials must be used to connect and seal them. Ceramic pipes are designed to withstand fairly high flue gas temperatures - up to about 1200 degrees Celsius.

Let us summarize the above-mentioned pros and cons of ceramic chimneys for removing combustion products from fireplaces and stoves:

Pros:

- long service life

- versatility

- compatible with any home heating equipment

- high level of fire safety

- ability to create smoke exhaust routes of high complexity

Minuses

- high price

- heavy weight

- the need to build a foundation

- complex installation

- the need to use additional materials when laying

Modular chimneys made of stainless steel

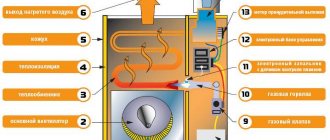

Today, the most modern, safe and affordable option for installing a smoke removal system from heating equipment is modular chimneys made of stainless steel. Such pipes are also called “sandwich” chimneys due to their characteristic design. Thus, sandwich chimneys consist of an external and internal steel contour, between which basalt heat-resistant insulating wool is laid. Such chimneys are also called double-circuit, but there are also single-circuit chimneys, consisting of one steel layer without insulating wool.

Welds

The weld seam is one of the most vulnerable places in a chimney. Welding destroys the protective layer of metal and this is where the chimney is most susceptible to corrosion.

A poor-quality seam may not be airtight and, as a result, flue gases will escape. An unacceptable option for a chimney sandwich is spot welding or an overlap connection. The best and most reliable connection is a continuous butt seam.

Important! Always look at the welds. First of all, the seams of shaped elements - tees, bends, support plates. Here, welding costs an order of magnitude more than on straight pipes, and unscrupulous manufacturers can save on it.

Material of manufacture and scope of application of modular pipes

For the production of modular chimneys, austenitic steel is used with good performance characteristics, which, accordingly, are reflected in the quality of the chimneys. Austenitic steel is characterized by wear resistance, acid resistance, and corrosion resistance. Such characteristics allow the use of steel chimneys in various, rather aggressive operating and climatic conditions.

Stainless steel chimneys are universal pipes and are suitable for connecting all known household heating appliances:

- Kaminov

- Firebox

- Furnaces

- Sauna stoves

- Kotlov

- Heating and cooking stoves

- Kitchen ovens for baking, etc.

Steel modular pipes are designed for safe and high-quality removal of combustion products from any fuel: gas, coal, diesel fuel and, of course, firewood.

The main advantages of stainless steel chimneys

The main advantages of stainless steel chimneys lie in their original characteristics. So, stainless chimneys:

- suitable for use in any climatic zones, including aggressive weather conditions;

- resistant to heavy loads, frost, wind, precipitation, pressure;

- resistant to high temperatures up to 1000 degrees Celsius;

- resistant to corrosion, rust, oxidation, condensation, and destruction;

- due to the modular design and low weight, they are very easy to install and maintain;

- suitable for the construction of chimney routes of any design, length and diameter;

- can be used both at the initial stages of building a house and installed in ready-made premises;

- have reliable fireproof insulation made of basalt wool;

- Some manufacturers of steel chimneys have a factory warranty on products that can be as long as 50 years!

- this type of chimney is manufactured using the latest generation technologies and equipment;

- affordable price

- light weight: no need to build a special foundation

- have a high level of fire safety

- nice appearance

Mistake #1. Buy a single-circuit pipe, not a sandwich pipe

Many people think something like this: “Why do I need this “sandwich”? I’ll pour more expanded clay into the ceiling and there will be good insulation.” But the key misconception here is that the sandwich pipe is not installed for thermal insulation. Although, from the point of view of fire safety, “sandwiches” have no equal, this is rather their indirect advantage than their main task.

The main purpose of the “sandwiches” is to prevent the formation of condensation inside the pipe. In short and to the point, the flue gases leaving the furnace have a certain temperature. As the gases rise through the pipe, they cool and can reach the dew point, at which point the smoke begins to turn back into water. And mixed with combustion products it is odorous and flammable creosote. Pay attention to the word “flammable”! And to prevent such a problem from happening and your construction work not going down the drain, you should use a sandwich pipe :). In this case, the sandwich pipe works like a thermos, maintaining the temperature of the flue gases and preventing the formation of condensation. Therefore, think twice before abandoning a sandwich pipe in favor of a single-circuit one.

Fig. 1. This is how a single-circuit chimney can easily become overgrown with soot

Elements of modular chimneys - complete set

Using modular chimneys, you can create smoke exhaust routes of any design, length, with various offsets, turns and detours. To create such structures, as well as for connecting pipe modules, fastening them and other actions, there is a wide range of components. Let's list them:

- Deflector. It is mounted on the chimney head to protect the pipe from the effects of wind and precipitation. It also helps to optimize the chimney draft and increase the efficiency of the chimney by about 20%.

- Clamp for stretching. It is used for reliable fixation of a chimney whose height above the roof of a building exceeds 1.2 meters. Allows you to design chimneys of any height. It is also used for fixing external chimneys, regardless of the height of the pipe.

- Skirt. It is used to seal the area where the pipe exits the roof, to protect the connection between the roofing unit and the chimney from precipitation, as well as for decorative purposes.

- Roofing element. Also called roof penetration. Used to pass a chimney pipe through the roof.

- Connecting clamp. It is used for reliable joining of modular parts of the chimney to each other.

- Flange. It is used to protect and insulate flammable materials in areas where the chimney adjoins them.

- Wall mounting bracket. Used for reliable fastening of the chimney trunk to walls and surfaces

Rules for installing a chimney for a fireplace

It is necessary to install a chimney for a fireplace, taking into account fire safety standards. There are basic recommendations that must be followed during installation:

- The junction of the pipe and the fireplace itself must be completely sealed. This determines where the smoke will go during the combustion process. The diameter of the pipe should not exceed the diameter of the fireplace inlet pipe. If this principle is not observed, there is a danger of carbon dioxide entering the room.

- The place where the fireplace pipe passes through the house must be isolated from finishing materials. Materials such as asbestos cement, basalt wool and sheet metal are used as fire protection. The distance from flammable materials must be at least 13 cm for a multi-layer pipe and at least 24 cm for a single-layer pipe. For brick pipes, it is necessary to use a thicker type of masonry and additional asbestos-cement insulation at the joints with the finishing of the house.

- It is advisable to install the chimney strictly vertically. No more than three bends in the design are allowed. If there is a need for horizontal installation of the pipe, such a section should occupy less than one meter. Otherwise, the air draft from the fireplace is disrupted.

- The size of the pipe affects the draft force in the chimney. The minimum height from the combustion source to the tip is 5 meters.

- The chimney should protrude at least 50 cm above the roof roof. If the roof is sloping, you should focus on the highest point.

- The distance between the chimney head and the ridge should be about 50 cm. If the pipe is routed through a wall, a minimum height from the ground of one meter must be maintained.

- To prevent condensation from collecting inside the pipe, and to ensure optimal draft, it is advisable to install the fireplace pipe near the inside wall of the house, rather than leading it outside. The material from which the chimney is made will also last longer, as it will not be influenced by the external environment.

Thanks to these recommendations, the installation of the pipe will be carried out as safely as possible, and will also create good air draft in the chimney.

Working conditions and operation of modular chimneys

Modular stainless steel chimneys for fireplaces and stoves are designed to work with any type of fuel - liquid or solid. Such pipes can be used to remove flue gases with temperatures up to 500°C - 650°C. The short-term maximum permissible temperature can be 750°C - 1000°C. The main circuit of the modular chimney system is resistant to aggressive acidic environments. Pressure inside the system is allowed up to 5000 Pa. Chimneys for fireplaces and stoves are designed for installation both inside and outside buildings, as well as for the rehabilitation of working smoke ducts and newly constructed chimney shafts. Suitable for use in all weather conditions and climatic zones of Russia from Kaliningrad to Vladivostok, including the regions of the Far North.

Mistake #6. Replace the “sandwich” over the roof with a “bare” pipe

Again, thinking that “sandwiches” are needed only for thermal insulation, some decide to save money and install a regular single-circuit pipe at the exit from the roof.

In this case, the following picture is obtained - moving along the “bare” pipe, the flue gases cool faster. Next, as you understand, the already familiar dew point appears, abundant condensation, rapid filling of the chimney and, voila, a fire. Therefore, there is no need to skimp on your safety, much less risk the lives of your loved ones.

Chimney maintenance

When used correctly, condensation and ash deposits form on the walls of a modular stainless chimney in minimal quantities. However, during the combustion of various types of fuel, soot, creosote, and weakly concentrated acid-containing compounds (condensate) are formed over time. Manufacturers of steel chimneys recommend inspecting and cleaning the chimney at least once a year, or at most twice a year: at the beginning and end of the heating season. Lack of timely maintenance of the chimney can lead to the ignition of ash and soot in the internal circuit.

Technical features of steel chimneys

The diameters of single-wall and double-wall chimneys, as a rule, range from 104 mm to 300 mm. In double-walled chimneys, high-quality fire-resistant basalt wool is used, a layer of which is located between the outer and inner contours. The thickness of the thermal insulation is usually 50 mm and 100 mm. For home fireplaces and stoves, it is recommended to use 50 mm insulation. The thickness of the steel chimney walls is usually 0.5 mm - 0.1 mm. For the manufacture of chimneys for fireplaces and stoves, austenitic high-alloy steel grades AISI 321 is used for the internal circuit and AISI 304 for the external circuit. High-quality steel chimneys use an internal thermal compensation system, which eliminates deformation of linear elements due to the natural temperature expansion of the metal.

It is worth noting that the standard warehouse program of most manufacturers of steel chimneys includes a product range of pipes of basic diameters and steel thickness, insulation. At the same time, today it is not difficult to find a manufacturer who makes chimneys of any diameter, insulation thickness and steel to order. Thus, in the case of using a heating device with non-standard technical connection parameters, it is possible to order a pipe with specific characteristics on an individual basis.

Mistake #3. Choose a curved design instead of a straight one, and also do not take into account the height of the chimney

There is only one rule that should be taken into account here - any bends in the chimney will always reduce draft. There is no need to try to imagine your house as in an ancient Russian hut from a fairy tale with a beautifully twisting chimney. This is not the case. The main principle in this case is “The smoother and straighter, the better.”

We add that in addition to reducing traction, turns and bends are sure to become favorite places for soot to accumulate. Simply put, the best design in all respects is a direct-flow chimney directed vertically upward.

The height of the chimney will also affect the draft.

For most stoves, the pipe must be at least 4 meters (the distance from the grate to the umbrella for a straight pipe). If you decide to save money and take a shorter chimney, then get ready to swear and be nervous because of problems with draft.

Painting of stainless steel chimneys

Since a fireplace or stove is not only a source of heat, but also a full-fledged participant in the home interior, some manufacturers of steel chimneys offer design solutions for chimneys. The external contour of the chimney for the stove and fireplace can be painted in any color according to the RAL or RR palette. This service opens up wide opportunities for consumers to create beautiful interior solutions involving not only a heating device, but also a chimney.