SHARE ON SOCIAL NETWORKS

FacebookTwitterOkGoogle+PinterestVk

The quality of life largely depends on the comfort of the indoor microclimate, especially in the cold season. One of the most important indicators of comfort is temperature. Its increase in residential buildings and industrial buildings is carried out through the use of thermal energy. There are several heating methods. And among them is the increasingly popular air heating system.

Air heating system is one of the most popular today

Air heating of premises: an excursion into history

If we look at the history of human development, we can confidently state that the first methods of heating a home were carried out using air: an open fire was lit in the cave. Then, with the advent of real housing, man began to create air heating systems.

The stove is one of the first methods of air heating of premises

The first written description of such a system (hypocaust) appeared in the 1st century BC. e. Its author was the Roman architect Vitruvius. Heating was carried out in two stages. A stove was laid out outside the room, hot smoke flowed through exhaust channels under the floor and into the walls. After the furnace went out, the smoke channels were closed. However, others opened, through which air came from outside, passed through the stove, was heated, and entered the home fresh and warm.

So it would be wrong to talk about creating modern, completely new air heating systems. The existence of such heating, and even with the use of ventilation, dates back many centuries. The hypocaust was a fairly expensive system, so it was available only to the rich.

The next significant era for the development of engineering dates back to the 15th century; it gave humanity the Russian stove. The air was in direct contact with the heated surface, reducing heat loss and increasing efficiency. The price of air heating has dropped significantly, and efficiency has increased.

Further, air heating systems were gradually modernized and improved. Furnaces began to be made not only from stone, but also from various types of metal. Pumps and fans began to be introduced into the systems, air purification and humidification were carried out. They began to use automation and electronic control.

In the twentieth century, fans, air conditioners, pumps and electronic controls began to be introduced into heating systems

Classification of air heating and ventilation systems

There are several modern home air heating systems. Their classification is based on the method of air circulation and depends on the characteristics of the devices used, air exchange and location of the structure. According to the method of air circulation, they are distinguished:

- Mechanical systems. The movement of air flow through the air ducts is provided by fans.

- Systems based on a natural circulation method. Temperature differences and the presence of heated and cold flows ensure the movement of air masses (according to the laws of physics).

Classification by device type:

- Central systems. Designed for heating large areas.

- Local. Provide the required temperature in individual rooms or zones.

Depending on the method of air exchange used, systems are divided into the following types:

- Recirculation. Only the air of the heated room is used.

- Partially recirculating designs.

- Inlet. Air intake is carried out from the street.

Project of an air heating and ventilation system for a private house

Depending on the location they are distinguished:

- floor devices;

- suspended structures.

Each system differs in the number of components, installation method and operational characteristics. The floor-mounted mechanical recirculation option is the most affordable type of system. Providing external air flow requires auxiliary devices, thereby complicating installation and attracting additional financial investments.

Helpful advice! Before choosing an air heating system for a room, you need to consult with a specialist who knows the specifics of house construction where you plan to install heating.

Features of carrying out competent calculations

Despite the assurances of would-be experts, it is very difficult to independently calculate air heating. Only specialists can do this task.

The customer can only check the availability of all project items, which include:

- Determination of heat losses for each heated room.

- Type of heating equipment indicating the required power, which should be calculated based on actual heat loss.

- The required amount of heated air, taking into account the power of the selected heating device.

- Required cross-section of air ducts, their length, etc.

These are the main points for calculating the heating system. It would be right to order a project from specialists. As a result, the customer will receive several calculation options from which he can choose and implement the solution he likes best.

An air heating system is a complex structure consisting of many elements. To calculate it, it is better to involve professionals; to familiarize yourself with the components, it is worth studying the diagram in detail (+)

Equipment for air heating of a private house

The installed air heating device is a central air conditioning system that provides round-the-clock heating and air circulation that maintains the set temperature in the room. Traditionally, an air heating system consists of the following main parts:

- air heater;

- fan;

- air ducts;

- additional modules.

Heaters for air heating are divided into heat generators and heaters

The main mechanism of the air system is the heaters. They can be of two types:

- Heaters, duct units. The air heats up during ventilation, passing through heated channels.

- Heat generators. They heat the air by burning various types of fuel.

Air heating in a private home and in industrial premises is equipped with fans that ensure the intake of cold air and the movement of warm air. They differ in power, operating principle (blowing and exhaust) and performance. Air ducts can have two purposes:

- supply air (supplying air to heating devices);

- reverse (transporting already heated air).

Installation of air heating systems involves placing air exhaust ducts under a raised floor, above a false ceiling, in ceilings and walls.

Many such systems have auxiliary modules, the purpose of which is to additionally purify the air and humidify it. Filters are used to purify the air. More often, this is a multi-stage device that first captures large particles, then a plastic electrostatic layer traps smaller (up to 0.01 microns) components, and a carbon mechanism that removes odors allows fresh and warm air into the room.

The air heating system uses two types of fans - supply and return

Modern equipment for air heating, presented on the domestic market, is equipped with steam humidifiers, which are installed behind the air heater. They have a sensor that regulates the level of humidity in the room.

What is combined heating

Combined (mixed) is a heating system that contains both traditional high-temperature (conventional radiators, convectors) and low-temperature (warm floors, less often warm walls) heating devices.

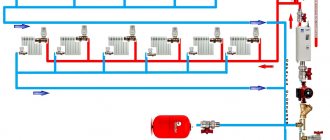

Water floors in a combined system are connected in two ways:

- For existing heating boilers. The advantages of this solution are a reduction in the estimated cost of equipment and a reduction in installation time. Disadvantage - additional heating cannot function in autonomous mode. This causes an increase in thermal energy consumption, and the efficiency of using heated floors decreases.

- Install hotel boilers for floor heating. The disadvantage is a significant increase in cost. Advantages: complete autonomy; water floors can be used independently of radiators. This may be necessary for a small heating of the room when the batteries are already turned off, for example, in the autumn-spring period.

1st floor - heated floor, 2nd floor - radiators

Types of heat generators for air heating

A heat generator is an air heating unit that produces thermal energy by burning one of the types of fuel. Power, efficiency, installation method, operating features are largely determined by the type of fuel. For heating residential premises and social facilities, the following types of units are mainly used:

- Pyrolysis boilers. They operate on solid fuel of plant origin (wood, waste from the wood processing industry, pellets, briquettes, peat).

- Gas boilers. Natural gas is burned.

Helpful advice! Before installing an air heating and air conditioning system that requires a long service life, it is necessary to correctly calculate fuel resources. Switching to another type of fuel requires an almost complete replacement of the system.

To heat the premises, pyrolysis or gas boilers, as well as diesel and universal heat generators can be used

For air heating of large production areas the following types of generators can also be used:

- Diesel. They run on diesel fuel. They are refueled once a day (this is an average; there are models that may not be refueled for 2-3 days).

- Universal heat generators. They also use diesel as fuel, as well as waste oil and vegetable fats that need to be recycled.

These types of fuel are cheap, which significantly reduces the economic costs of enterprises for heating production premises.

Where can combined systems be made?

The area and number of floors in our example are very arbitrary. It is also necessary to coordinate their operating modes.

It’s one thing: connecting a radiator heating system to a boiler when all the functionality for this is already included in the boiler. They propose to install polypropylene supply and return pipes in a layer of sand under the screed along the foundation. It can be single-pipe or double-pipe.

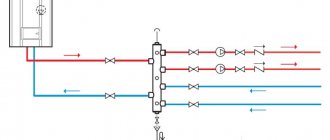

In some situations, when all the radiators are closed and the heated floor is running, the boiler pump and the underfloor heating pump work sequentially, interfering with each other. Installation of combined heating in a system with a gas boiler The most difficult moment in the process of installing combined heating is the need to supply coolant with different temperatures from the manifold for the heated floor and radiators through two pipes. Depending on the temperature at the outlet of the in-floor circuit, the mixing valve opens or closes, increasing or decreasing the amount of hot coolant from the supply in the recirculation circuit.

This is necessary to ensure the tightness of all joints made. Air heat pump is the main source of heat Air heat pump Before considering the positive and negative aspects of existing heating units, let's talk a little about air heat pumps.

Where can combined systems be made?

The collector is mounted in a special box made of galvanized steel that matches its size. In this case, the type of coolant or heat source does not matter.

Designation of the main elements of the circuit: wall-mounted gas boiler with built-in circulation pump and expansion tank; hydraulic separator thermo-hydraulic separator or hydraulic arrow ; collector - collector beam for connecting heating circuits; radiator heating circuit circulation unit; mixing unit kennel water thermoplastic floor; safety thermostat. The three-way thermostatic valve of the second type is distinguished by the fact that it provides regulation of the supply intensity of only the hot flow. In more complex systems, the controller is also guided by a weather sensor, making a preventive change in the heating power.

4 Proven water heated floor connection diagrams

As a result, the coolants are mixed as follows: liquid from the return pipe is supplied continuously, and hot liquid is supplied only when necessary. In this case, the in-floor structures will be durable, reliable and durable.

A special heat-sensitive device is used. Heating with a solid fuel boiler Combined heating with a solid fuel boiler is a closed gravity system with a heat storage device. We combine heating. Warm floor + radiators. A simple solution

Operating principle of a solid fuel air heating boiler

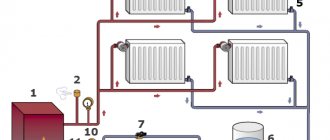

The basis of any heating system is the heating unit. For an air system, this could be a solid fuel boiler. The main types of fuel for this type of heater are wood and wood waste. A solid fuel boiler traditionally includes the following elements:

The principle of operation of a solid fuel boiler for air heating of a house

- Firebox. The chamber in which the combustion process directly takes place.

- Luke. Wood is loaded into the firebox through it.

- Grate bars. A grate through which ash and unburnt fuel residues spill out.

- Podzolnik. Located below the firebox. This is where combustion residues accumulate.

When choosing a boiler for air heating for a private home, preference is often given to the pyrolysis type. This heating design has two combustion chambers. In one, the main fuel is burned, and in the second, when combined with oxygen, wood gases ignite, releasing a large amount of heat. In inexpensive solid fuel boilers, air is supplied manually. More expensive models have fans that turn on automatically. To increase the efficiency of the boiler, chimneys are equipped with smoke exhausters, the task of which is to remove combustion products from the firebox as much as possible.

For convenient and safe use, modern models of solid fuel boilers can be equipped with additional devices:

- automatic ignition;

- air blowers;

- temperature sensors that regulate the combustion process;

- devices that supply fuel.

Modern solid fuel boilers are equipped with an air blower, temperature sensor and automatic ignition

Important! For a system in which the air ducts are located in the lower part of the room, you will definitely need a boiler with forced air circulation.

Gas air heating equipment, its operation

Quite often, gas boilers are installed as heat generators in air heating systems. In this case, the fuel is mainly main gas (switching to propane-butane requires re-equipment of the burner). The principle of operation of these units is as follows: when burned, the gas heats the heat exchanger, through which air is forced to be driven, which subsequently enters the premises.

To install a gas boiler for air heating of a private house, you must obtain permission and make plans for connecting to the general input and wiring for house construction. This documentation requires strict adherence to certain standards and technical conditions.

The main distinctive characteristics of gas heating boilers are:

- high efficiency achieved by increasing the efficiency level to 92%;

- moderate dimensions;

- low noise level;

- high degree of protection provided by sensors.

Gas heating boilers are highly economical

The advantage of gas as a fuel for an air heater is that during combustion it does not emit heavy harmful products such as burning, ash, and soot. Gas air heating systems are installed both in private homes and in industrial premises.

Calculation of air heating: main indicators and requirements for them

Any heating system, and air heating in particular, requires correct and accurate calculations. The instructions for the heating units contain enough information about this plan. It is based on average statistical data and theoretical conclusions. When planning an air heating system, it is better to entrust the calculations to specialists who have practical experience in carrying out installations.

Related article:

Solar collectors for home heating as an alternative energy source

The principle of operation of the devices. Types of products, their characteristics. DIY solar collector. Manufacturers and models.

The main indicators taken into account when calculating the system are:

- Air consumption for the heating system. The average is 1500-3500 m³/hour.

- System pressure. It is 150 Pa.

- Boiler power. It differs for different models and types.

- The amount of heat loss. This indicator depends on the specific technical conditions of the room.

Heat loss can be calculated using the following formula:

When planning an air heating system, it is recommended to provide all calculations to specialists

Q= S*T/R, where

Q – heat losses; S – area of the room (or building); T – temperature difference between outside and inside; R – thermal resistance of structures.

Illiterate calculations can lead to the absence of the expected result and even significant negative consequences:

- during operation, the heat generator may overheat, the operation of the system as a whole will be blocked by sensors;

- significant noise and vibration of air ducts may occur;

- there is a danger of disruption of the air exchange cycle, which leads to temperature imbalance.

The total length of the central air duct should not exceed 30 m. Additional branches should not exceed 15 m. The power of a solid fuel boiler for heating a residential building can be 20-50 kW. To provide air heating for greenhouses, conference rooms, halls, etc., boilers with a power of up to 1 MW are used. Production workshops and shopping centers can provide heat to devices with a power of 5 to 10 mW.

Boilers with process control functions are more expensive, but quickly pay for themselves

Helpful advice! When choosing a boiler for air heating, it is better to give preference to a unit that has the ability to regulate the combustion process. The cost will quickly pay off in economical fuel consumption.

Operational features of air heating Vulcan

All air heating systems are divided into local and duct. Local design involves installing a heat source directly in the room that needs to be heated. The equipment only heats the air around it. The duct system provides for the transportation of warm air to other rooms. A highly efficient local air heating system is Vulcan. The equipment is produced by the Polish company EuroHeat. It is a connection between a water heater and a fan. This system is recirculation; it does not involve the intake of street air.

The coolant of this unit is hot water. It must be supplied from an uninterrupted source whose temperature does not exceed 90 °C. With the help of an axial fan, the air flow is sucked in, passes through the heat exchanger and is supplied again to the room already warm, distributed by the guide blinds. The unit is controlled automatically, that is, switching on and off is controlled by sensors that record the upper and lower thermal thresholds. Among the positive features of this type of air heater it is worth highlighting:

- Silence. This is ensured by the shape of the blades and the high quality of the fan bearing.

- Strength of structural elements. Polymers that are resistant to mechanical stress and high temperatures are used to make the case.

- Easy to install. Does not require special conditions, the connection diagram is attached to the unit and is available to everyone.

- Moderate cost.

Vulcan air heating systems are local and ducted

This type of air heaters is used for large rooms. In total, the company produces 6 models, differing in power, dimensions and number of blinds. The manufacturer attaches great importance to appearance. Volcano units not only do not spoil the interior, but can also become part of the design.

Do-it-yourself air heating of a private house

Making your own air heating is quite affordable. If this is done at the construction stage, and not in the finished building, then the goal becomes even more achievable. To understand how to make air heating in a private home, you first need to determine the desired result, and then technically calculate the possibility of achieving it. Calculations are the primary stage of this process. The algorithm of actions for independent organization of air heating may be as follows.

First you need to perform calculations:

- amount of warm air;

- heat loss;

- power of the necessary equipment.

It is better to carry out these calculations (if there is no knowledge and personal experience) with the participation of a practitioner.

Based on project calculations, a plan for an air heating system is created

Helpful information! If you have good modern thermal insulation, you can take into account the following practice-tested indicators when making calculations: 750–800 W of heat is required per 10 m² of room area.

Then, based on the project calculations, an air heating scheme is created. It should reflect the location of the system elements, the power of the main unit, the diameter of the air ducts, etc. You can use the diagrams offered on the Internet, but only if the technical conditions are suitable. Changes to completed drawings must be made with great care.

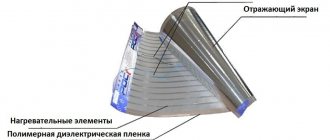

After this, equipment is purchased. At this stage, it is necessary to pay attention to the certification of the equipment and the content of the instructions. In addition to the main units, you should purchase air ducts (preferably flexible, noise-absorbing ones). To prevent the accumulation of condensate, the supply outlet should be insulated. For these purposes, it is recommended to use foil insulation up to 5 mm thick. It is convenient to use tape to connect air ducts. A good option is reinforced aluminum. Clamps made of metal or heat-resistant plastic are also suitable.

Next, the actual installation of the system is carried out. It must be carried out before finishing work. If the heating is installed in a finished room, it is worth paying special attention to the aesthetics of the ducts covering the air ducts.

If you have the skills, you can do the installation of an air heating system yourself.

Air heating systems for industrial premises

The air heating system for an industrial premises does not differ significantly from a similar method of heating a private home. The same air heaters, heat generators, and fans can be used. The only difference is the large size of the premises, which require appropriate equipment capacity.

When designing heating systems for industrial premises, an important point is compliance with fire safety standards and regulations. Depending on the operational characteristics of production areas, the placement of gas heat generators may be prohibited. In such cases, they are taken outside the premises. Diesel generators are actively used for air heating of production facilities. They are distinguished by their high power, allowing the installation of branched air duct systems.

A special indicator when designing an air heating system is the height of the ceilings. Warm air should be directed to the desired area of the room. Fan heaters cope best with this task. Using these units for heating has the following advantages:

- quick, inexpensive installation (fan heaters are mounted on walls or ceilings), it can be performed by company employees;

- there is no need to lay heating mains and air ducts, therefore, small capital investments will be required;

- the ability to direct warm air flow to the desired area;

- does not require constant monitoring and maintenance;

- low noise level, which is relevant for many types of production.

When designing a heating system for a production facility, it is important to comply with fire safety standards

Air heating by ventilation is characterized by a minimal level of heat loss and energy consumption. In addition to heating, it is also used for drying wood and other materials on an industrial scale. Heat guns are also used to heat industrial premises. Such devices are connected to a voltage of 380 W. The heated air is released in a targeted, long-range, powerful stream.

System installation features

If the calculations are carried out at a high professional level, and the design of the cottage air heating system is drawn up, you can carry out the installation yourself.

For this you will need:

- heating device;

- air ducts;

- fan;

- gratings;

- fasteners;

- tool for working with air ducts, etc.

A gas generator is usually used as a heater as the most cost-effective option. Air ducts can have a rectangular, square, round or oval cross-section.

Typically, suitable designs can be ordered from a company that manufactures ventilation systems.

The diagram shows the elements of the air heating system, which will allow installation of air ducts in strict accordance with the design documentation

Typically, air ducts are made of galvanized steel; they are light enough so as not to overload the supporting structures of the house, and also have increased resistance to wear and corrosion. For rigid air ducts, you will need special elements that provide a slope of 45 or 90 degrees. But for flexible products such elements are not needed.

Air ducts are also made from ordinary steel, copper, plastic and other materials. There are even textile designs of this type. In places with high humidity, it is recommended to use copper elements as they are more resistant to such conditions.

Plastic structures are relatively inexpensive and can be used away from potential sources of fire.

Air ducts are fixed under the ceiling and floor, as well as inside the walls. If there is a need to lay the air duct not inside, but along the wall, it is covered with a false panel. Ventilation grilles are installed in the ceiling and floor at the ends of the air ducts.

Rigid air ducts made of galvanized steel are very reliable and durable. For their successful installation, you will need elbows with a rotation angle of 45 and 90 degrees.

Air masses moving inside a structure can make some noise. To reduce this negative impact, it is recommended to hide the air ducts under a layer of sound insulation.

Typically, this material also has thermal insulation properties, which only increases the efficiency of the system.

To ensure that air heating structures make as little noise as possible during operation, it is recommended to cover them with a layer of insulating material

It is worth considering the option of purchasing air ducts that already have such an insulating layer applied. This will simplify and speed up installation work.

If there is a need to install a fan, or several such devices, then it is usually included in the system next to the heater. The fan is supplied with power and also provides a backup source of electricity.

The system also includes one or more filters. These can be mechanical cleaning filters that prevent the spread of dust particles. Along with these devices, it is recommended to install a carbon filter that absorbs various odors. Of course, filters need to be cleaned and/or replaced periodically.

Part of the air duct is led outside to provide fresh air. This section is supplied to the filter system, and then the air is supplied to the heat exchanger of the heating device. If installation work is carried out during the construction of a house, then its implementation usually does not cause any great difficulties. The main thing is a good project.

To improve the microclimate in the house, useful elements such as an air humidifier, ionizer, ultraviolet sterilizer, etc. are built into the air heating system. These elements are not mandatory, but if funds allow, you should not refuse them.

Another useful device is a ducted air conditioner. It is also built into the air duct system. This will allow you to use the system in the warm season to cool the air in the room.

Automatic control systems significantly improve the operation of the air heating system and reduce heat costs, as well as simplify the operation of equipment

The final stage is connecting the automatic control system. You will need air temperature sensors in the rooms and a control panel with a processor that will process the received data and regulate the operation of the heating equipment.

Air heating system for a private home: an alternative to expensive heating

The philosophical saying “Everything is learned by comparison” is also quite applicable for understanding the advantages and disadvantages of such a technical object as a heating device in a house. Air heating can be compared with water heating, which is most often used for heating residential premises. Without delving into the power and operational characteristics, let’s draw up primitive system diagrams:

- water heating: boiler - radiators - air;

- air heating: heat generator (or heater) - air.

In the second case, the interaction of heat with air occurs via a shorter route. Consequently, heat loss is minimized, and the amount of fuel for heating the air is reduced. The disadvantages of the water system include inert air circulation, as a result of which the air exchange between the warm upper layers and the cold lower ones is slow.

One of the alternative methods of heating a house is the “warm floor” system.

Similar comparison results can be obtained by comparing the air system and the “warm floor” heating method, which uses both water and electricity. Both water and electricity first heat the floor, and only then the air in contact with it. Moreover, the second heat source will also require significant electricity costs.

Helpful advice! When choosing a particular type of heating, it is necessary to take into account that the air system can, in addition to heating, also condition the room.

Use of free energy: air solar heating

Solar energy today is used both on an industrial scale and for the life support of private homes. Almost every home building owner can use this free source, in particular for heating premises. Financial costs are necessary only for the purchase of equipment and installation of air heating. The system as a whole is quite simple and consists of an external block, which is a flat box arranged as follows:

- the walls are made of wood boards or plywood;

- Corrugated sheeting painted black was used to make the bottom. The paint used must provide intense light absorption;

- cover made of glass or transparent polycarbonate.

Air solar heating is efficient and low-cost

Solar energy heats the air in the box, which is supplied into the room with the help of a fan. The simplicity of the design and the availability of materials allow you to install a solar air heating system at home with your own hands. This type of heating has undeniable advantages:

- low cost;

- high efficiency;

- no danger of overheating or hypothermia (the material is heat-resistant, the absence of liquid eliminates the problem of freezing).

The collector should be located on the roof on the south side, where solar energy is concentrated as much as possible. Solar air heating cannot provide heating throughout the entire season. It can rather become an addition to the main heating. However, in the spring-autumn period it will fully meet the needs, while significantly reducing the financial costs of coolants.

Air heating of a private house: pros and cons

The information presented above in this article largely reflects the positive characteristics of this heating system. The growing popularity of this heating method demonstrates its effectiveness, affordability and environmental friendliness. The general list of advantages should be supplemented with several more:

Air heating of a private house has both pros and cons

- air heating allows you to organize zoned distribution of warm air;

- air duct pipes are not subject to corrosion;

- in the winter season, such a system does not require special control.

Once again, it is worth noting that a significant advantage of an air heating system for a private home is its price. Its reduction occurs not so much due to the cost of the equipment, but because of the ease of installation and the absence of the need to prepare project documentation (unless a gas heat generator is used). However, an objective assessment is that there are advantages and disadvantages inherent in an air heating system. These designs have the following disadvantages:

- after the heater stops operating, the air cools down quite quickly;

- the efficiency of the system depends on electricity, since air flows are pumped by a fan powered by it;

- without installing filters, the air in the room will be supplied with dust particles and unnecessary impurities;

- Heat generators installed in a building take up a lot of space and do not always fit into the interior.

The air heating system is financially beneficial due to ease of installation

Helpful advice! If power outages occur quite often, it is worth purchasing a UPS to ensure stable operation of the fans.

Air heating of a private house with air conditioning

Inverter air conditioners can also be used for space heating. Their cost is almost twice the price of similar units that perform the cooling function. When using an air conditioner, there is no need to design an air heating system. The air is heated in the external unit, then transferred through the duct to the internal one and directed into the room with the help of a fan. The operational capabilities of such an air conditioner are limited.

The external unit cannot operate at temperatures below -7 ° C (this indicator may differ in individual models). A conventional split system provides comfortable indoor conditions in the autumn-spring period, when central (or autonomous) heating is not yet turned on or has already been turned off.

Helpful advice! When using a split system for heating, you must strictly adhere to the temperature level specified in the instructions. The most common consequence of non-compliance is a burned out compressor.

Heat pump air conditioners can heat and condition a room

Air conditioners with heat pumps are suitable for year-round use. Such units provide air heating and air conditioning even at -25 °C. If in a conventional air conditioner, during heating, electrical energy turns into thermal energy, then the pumping system pumps warm air from one medium to another. That is, during cooling, excess heat with the participation of the refrigerant is released into the street - during the heating process, everything happens exactly the opposite: warm air increases the temperature of the cold street air.

Air heating of a private house from a stove

In some areas where there is no centralized gas supply and firewood is inexpensive fuel, it is advisable to use a stove as air heating. This outdated method of heating a home is perceived in a new way today:

- the constructive combination of the stove and fireplace helps create a cozy interior;

- the environmental friendliness of the material used for masonry and the naturalness of the fuel create a comfortable atmosphere in the room;

- The stove can be used not only for heating, but also for cooking.

The main disadvantages inherent in this type of heating are:

- low efficiency rate;

- large heat losses due to the chimney;

- long time to heat up the oven;

- dependence of the amount of heat on the size of the stove;

- uneven distribution of warm air throughout the room.

To heat a 25 m² room, 1 m² of stove is needed.

A fireplace stove will not only heat the room, but also create a pleasant atmosphere

Helpful advice! If the area of the room exceeds 30 m², then it is better to use coal as fuel to heat it. It produces more heat, so it will take less time and fuel to heat the air to the desired temperature.

When using a stove as an air heating system for a building with several rooms (more than three), for high-quality heating of the rooms, an additional coolant is needed - possibly water.

Installation

The construction of a fireplace can be done with your own hands, but for this you will need to correctly draw up design documentation and accurately calculate the amount of building materials. It is also necessary to determine the type of heater being installed and its expected dimensions.

Standard fireplaces are attached to brick walls, installed deep within them, or mounted separately. It is not advisable to place the firebox of a wood-burning unit against a wall with windows. If their thermal insulation is not at a sufficient level, this will lead to drafts and energy losses.

Preparation

Before starting masonry, it is necessary to calculate the area of the room in which the installation will take place. The volume of the combustion opening should not exceed a fiftieth of the size of the room. The depth of the fuel chamber and the height of the fireplace portal are related to each other as 1 to 2. Excessive firebox capacity will lead to a decrease in heat transfer, and small dimensions will cause smoke.

The dimensions of the smoke channel depend on the size of the furnace and should be 10-15 times smaller. The optimal pipe diameter is 10 centimeters with a length of 4-5 meters.

Material

Making your own air-heated fireplaces for efficient space heating involves choosing high-quality materials. For installation you will need:

- whole stove bricks;

- pre-washed coarse sand;

- clay for finishing the hearth;

- Portland cement for pouring the foundation;

- medium-sized crushed stone;

- two dozen reinforcing bars with a diameter of 8 mm and a length of 70 cm;

- smoke damper of suitable size.

Foundation

All types of fireplaces that can be built at home require a preliminary pouring of the foundation, which is built separately from the base of the building. Its width is equal to the front base row with the addition of five centimeters of reserve.

Before pouring, you will need to dig a hole with dimensions 10-15 centimeters wider than the foundation of the house and a depth of 60 cm. After filling the crushed stone on the bottom and compacting it, the horizontalness of the base is measured.

Having made a formwork box without a bottom, it must be sheathed from the inside with roofing felt, firmly placed on the base and filled with cement-sand mortar. Having leveled the top of the foundation, it is covered with film and left until completely dry.

Bricklaying

The next step in constructing a wood-burning stove is laying individual bricks edge-on on the mortar. The geometric dimensions of the future fireplace are controlled using a square. All diagonals must be equal, angles must be clearly vertical, and rows must lie in a horizontal plane.

Laying continuous layers is carried out using a trowel or any suitable construction tool. Wooden slats that limit the size of the future fireplace are removed after building several rows of tightly laid bricks. The third layer also contains a pair of pins, on which the fireplace grate will later be placed. The thickness of the side projections of the portal is half a brick, and they are laid straight away.

Interior arrangement

Since the construction of the fireplace eliminates the need for internal plastering, the walls of the wood burning chamber and smoke collector are wiped down from the inside and thoroughly cleaned of any leaking solution. Smoke collectors and vaults with curved surfaces are laid out with a gradual overlap of bricks up to six centimeters. The portal openings are covered with brick lintels, which are installed separately.

In the process of laying a chimney with your own hands, it is necessary to control its verticality by switching to a cement-sand mixture as soon as the installation moves to the roof. To ensure better heat reflection, the fireplace walls are placed at an angle from the inside. At the same time, the side parts turn outward, and the back part leans forward slightly. The smoke chamber is installed above the firebox with an additional cornice. Its device prevents sparks and soot from flying out and reliably protects the room from smoke penetration.

Air heating of a private house, reviews: unity and opposition of opinions

“I made the air heating at the dacha myself. Only 2 rooms, 42 square meters. The boiler was BTS, a weak one - 15 kW. Installed it myself. I ran three channels, just along the wall and up: one goes where the boiler is, two go to another room. Didn't close them at all. The appearance is not confusing, it’s even interesting. The house, or rather the air, heats up immediately. But things and walls take a long time to heat up. We don’t live there permanently; we have to wait a day for everything to become warm.”

Evgeniy, Orekhovo-Zuevo

“Air heating for the second year. He calculated everything, provided for it, and paid a third of the price of the entire heating for the scheme. Until the house was insulated this year, it was cold. Despite all my efforts, the temperature in the house did not rise above +16 °C. Now in the coldest farthest room it is +19 °C. With air heating, the house must be airtight, then the result will be.”

German, Kursk

Air heating of the house has not only positive, but also negative reviews

“Air heating is like a fan heater. While it’s working, it’s warm; when you turn it off, it’s immediately cold. And there is no hot water; separate heating is needed. Better are radiators, and the old type, cast iron: both heat and dryer.”

Roman, Ekaterinburg

“If you do air heating efficiently, it costs a lot of money. I have a house of 102 m². Laying the channels took almost a week. I made the boiler room separately. The house is warm, the temperature is quickly regulated. The old apartment had batteries, the efficiency was the same. It's good that the walls are free. In terms of gas, the savings are noticeable.”

Vyacheslav, Belgorod

Analyzing the reviews, we can conclude that everyone determines the advantages and disadvantages based on personal preferences and expectations.

Conclusions and useful video on the topic

Interesting information on calculations and design of air heating is shown here:

In this video you can see two options for relatively inexpensive installation of air heating systems using Russian-made devices and materials:

Air heating is a worthy and profitable option for heating a private home. It is more efficient than traditional water systems and can significantly improve the quality of life in your home. But to ensure the successful implementation of this idea, the system must be correctly calculated and professionally designed.

Do you have any questions? Or do you have personal experience using air heating for your home? Please share your own opinion on this issue. Leave comments, ask questions, share tips in the block below.

Air heating system: new possibilities

The air heating system is just beginning to gain its place among other engineering projects in this field. It is no coincidence that there are conflicting opinions about the degree of complexity of installation, the quality of equipment, and efficiency. Even the price of air heating of a private house is considered affordable by some, while others consider it prohibitively high.

Air heating systems for homes are becoming increasingly popular

The lack of stable estimates or trends is due to the insufficient time period of use. The purpose of any heating is to heat the air in the room. Does the system described above provide new opportunities? Undoubtedly. Two features of the system can be considered a technical achievement:

- The air is heated directly, bypassing the metal of the radiators and the water in them.

- It is possible to regulate the power of air flows. With the help of dampers you can increase or decrease their supply to individual rooms or zones.

Comfort in the home is largely determined by the temperature and air condition. If a heating system can not only quickly heat it, but also clean, humidify and distribute it, it will definitely find wide application.

Comparison with water heating in terms of convenience and efficiency

The classic solution for heating rooms today in Russia is the use of water heating. However, this system, consisting of a closed chain of pipes, radiators and a boiler, filled with water or non-freezing liquid flowing through the pipes, does not suit many people, and for good reason. Low efficiency, high energy consumption and inertia of the water heating system, as well as the constant rise in energy prices, force many Russians to look for other, more modern and economical solutions when choosing ways to create a comfortable climate in their future home, and increasingly their choice is air heating .