Most often, construction and finishing work is carried out in the summer. However, insulating the outside of the house in winter is possible. In this case, it is necessary to comply with a number of rules and requirements. When choosing a material, first of all, pay attention to resistance to high humidity and temperature changes.

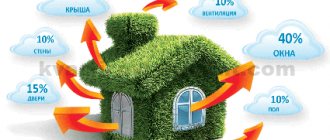

Insulation can protect your home from the cold and reduce the cost of heating the premises.

Advantages and disadvantages of the process in winter

Insulation in the cold season is faster. You don't have to wait long for the walls to dry. In winter, the dew point moves outside, so moisture does not accumulate in the thickness of the frame or masonry. The disadvantages of such insulation include:

- the difficulty of performing work due to high air humidity;

- impossibility of using some materials.

The disadvantages of insulation in the cold season include the difficulty of performing the work.

Window putty

Paper or window putty is an affordable and quick method. To work you will need old newspapers or paper, water and two parts of crushed chalk or part of clay.

Grind the newspapers, mix the components and as a result you get a viscous, plastic mass that can be used to seal any, even the smallest and narrowest, cracks and gaps. For aesthetics, the putty is covered with decorative elements on top.

You can buy ready-made construction putty. This is a rather labor-intensive process, since before starting it is necessary to remove the old putty, then apply new material, level it, if necessary, close it with a bead and paint.

After the procedure, the window can be easily cleaned of putty. In addition, the product does not absorb moisture. However, the effect will only last for one season. In addition, the putty prevents the window frames from opening. Therefore, with the onset of warm weather, the product is removed and the windows are thoroughly washed. Before next winter, to prevent the wind, you will have to seal the frames again.

Material selection and characteristics

Manufacturers offer many types of insulation. When choosing, you need to consider that the material should:

- have low thermal conductivity;

- suppress noise coming from the street;

- be safe for humans and nature;

- extinguish independently in case of fire;

- It is easy to pass air in both directions;

- resist the spread of pathogenic microorganisms;

- do not absorb water.

Mineral wool

Due to the fibrous structure of the boards, air passes through. At the same time, mineral wool creates a barrier that prevents heat from escaping into the surrounding space. It can be used for both external and internal insulation. The main disadvantage is the complexity of installation. To lay mineral wool, you need to build a frame.

Mineral wool is a convenient material for insulation.

Glass wool

The material is supplied in rolls or slabs. Glass wool contains small particles that irritate human skin. Therefore, when working, you need to use protective equipment - work suits, gloves.

The insulation does not ignite in a fire, so it can be used for interior work. Installation also requires the creation of a wooden frame.

Cellulose

The main advantages of such a heat insulator are:

- multifunctionality;

- safety for humans and the environment.

Cellulose insulation is an ideal option for residential buildings.

The insulation does not accumulate moisture, which prevents the formation of mold. Manufacturers impregnate cellulose with antiseptic compounds and fire retardants to prevent fire.

Styrofoam

The inexpensive material is often used for insulating facades. Polystyrene foam is lightweight and pathogenic microorganisms cannot multiply on its surface. To install the slabs, special glue is used. However, in winter, such compounds take longer to harden.

Expanded polystyrene

Despite its high strength, the insulation easily allows steam and air to pass through. The coating goes well with facade tiles, plaster, and siding. Polystyrene is not used in combination with organic compounds and resins. Installation of the material is carried out using the “wet facade” technology.

Expanded polystyrene is a modern insulation material.

Fibrolite

The material is obtained by pressing wood shavings. To improve performance characteristics, a binding component is added - magnesium salts or Portland cement. Fibrolite is easy to install; just fix the boards with self-tapping screws.

Cork material

The presence of a large number of pores allows the cork to retain heat. The material is resistant to damage and is not subject to significant shrinkage. The decorative properties of cork allow it to be used for finishing and insulating rooms. The slabs are not susceptible to rotting and mold, and do not emit harmful substances when burned. The main disadvantage is the high price.

Cork material is a natural insulation material.

Liquid insulation

Thermal insulation impregnation is a modern material that allows you to work in hard-to-reach places. When covering a house with liquid compounds, the construction of a frame is not required. Application is carried out using special tools.

Preparatory work

If electrical wiring runs along the walls, it must be checked to ensure that it is in working order and properly insulated. Before directly installing the insulation material, you need to create some kind of vapor barrier to protect the insulation from moisture that will form on the wooden walls. Also here we must not forget about high-quality ventilation, without which, when creating a vapor barrier, a thermos effect will be formed and the walls will rot.

Note: A special membrane film can be used as a vapor barrier. It does its job very well, but is not cheap.

Options and step-by-step instructions for insulating a house outside in winter

When using any method of thermal insulation of a building, work begins with the creation of a protective circuit that increases the air temperature to acceptable values. A durable film is stretched around the building sheets to trap cold air. Powerful heaters are placed inside the circuit.

Dry method

The use of this method in winter is preferable. Plastic dowels are used to install foam boards. Materials containing water are not used in this case. The work order includes:

- cleaning and leveling the facade;

- installation of sheathing made of wooden bars or metal profiles;

- laying insulation;

- installation of a waterproofing membrane;

- finishing of the facade.

“Dry” insulation is a universal method of thermal insulation.

Wet facade

External insulation of a house using this technology is performed as follows:

- Clean the walls from old insulation and cladding. Eliminates pronounced irregularities.

- Prepare the adhesive composition. To do this, gradually add the dry ingredients into the water and stir the solution thoroughly. Apply the mixture to the foam board, leaving gaps.

- Apply the elements to the walls, starting from the corner. The panels are pressed tightly, after which they are additionally fixed with special dowels.

- Apply a second layer of adhesive. A reinforcing mesh is installed on top, which is necessary to form the finishing coating. The material is laid with a slight overlap, pressing into the solution.

- Wait for the composition to harden, maintaining a positive temperature inside the thermal circuit.

- Apply plaster or other decorative coating.

Mistakes that are made when insulating wooden walls

When independently carrying out facing work and pre-insulating a wooden house, mistakes are often made, which we will consider below. The result is ineffective insulation, dampness in the house, destruction of wood and loss of its performance properties. The following 7 errors can be considered typical - they occur most often.

No. 1: installation of insulation without wood preparation

Old log houses are often subject to external insulation. Over the years, the log house has undergone final shrinkage, and its parameters will no longer change, which means they will not affect the front finish

But it is important to understand that the years of wood exploitation “in the open air” could not pass without a trace

Due to the fact that the insulation and sheathing will completely cover the walls, before starting work it is necessary to inspect the enclosing structures in order to identify weak areas that need to be repaired and treated. It is necessary to treat the wood with antiseptics and anti-feathers

It is important not to leave untreated areas. The solution should be applied 2-3 times

Each layer must dry completely. Insulation should begin when the wood is dry.

In order for wood to last a long time without being subject to biological decomposition or damage, it should be treated with a special antiseptic impregnation

No. 2: neglecting caulk

To prevent the log house from being blown through, use caulk. At the same time, the insulation of the structure is ensured. When inspecting walls before insulation, it is necessary to carefully inspect all areas where caulk is used - whether it sticks out, how tightly it is held. It happens that protruding, loosely twisted material is pulled apart by birds.

Insulation caulk

No. 3: wrong side selected

Log houses are insulated exclusively from the outside. This is a rule that must be strictly followed. Only this method allows you to ensure the correct use of wood and thermal insulation material. If you choose the other side and fix the insulation inside the house, then both the wood and the insulation will get wet. As a result, disruption of the microclimate in residential premises and increased humidity.

Log houses are insulated exclusively from the outside

No. 4: the insulation is incorrectly selected

The construction market offers insulating materials in a wide range of prices and performance characteristics. Of all the variety, however, only a few are suitable for insulating wooden houses: mineral wool (basalt and glass), as well as extruded polystyrene foam. The latter has excellent performance, except that when melted it releases substances that are extremely dangerous to humans. Therefore, the only alternative for insulating a wooden house is mineral wool.

One of the best insulation materials is mineral wool.

No. 5: improper transportation and storage of insulation

When purchasing, it is important to check the tightness of the heat insulator packaging. It must not be damaged and the contents must be dry.

If the insulation gets wet, its thermal insulation properties will decrease significantly. It is recommended to remove the insulation from the packaging one day before installation. And after it is fixed to the wall, it is necessary to immediately continue working on the walls so that the insulation does not remain “open”.

Check the material carefully before purchasing

No. 6: using roll insulation instead of slab insulation

Mineral wool works best for insulating wooden walls. You can find slabs and rolled material on sale. Why are mats not recommended? Because, being in a vertical position, over time the insulation will inevitably sag and gaps will appear through which cold air will rush into the house. The slab insulation maintains its shape throughout its entire service life, does not deform or sag.

The slab insulation maintains its shape throughout its entire service life.

No. 7: Incorrect calculations

Too thick or thin a layer of insulation will cause disruption of the microclimate in the room. Typically, the heat insulation is laid in two layers of 5 cm. In the south, one layer is enough, and in the north, three are required.

Correct calculations will allow you to maintain the correct microclimate in the room

How to work with a ventilated facade

In this case, external wall insulation in autumn or winter is performed as follows:

- Install vertical sheathing bars. The distance between the elements should not exceed 30 cm. The beams are secured with dowels. The aesthetics of the finished coating depends on the quality of installation of the lathing.

- The selected heat insulator, for example basalt wool, is placed between the beams. Each canvas is secured with umbrella dowels. There must be at least 2 fasteners per slab. A vapor barrier is not installed between the base and the insulation.

- Cover the façade with wind-protecting fabric. This prevents moisture from entering the thickness of the insulation without reducing the vapor permeability of the wall pie. The fabric is fixed to the beams with construction staples.

- The outer layer of the sheathing is formed. This is done to create a ventilation gap. At this stage, the wooden sheathing can be replaced with metal profiles.

- Install decorative covering elements.

The ventilated façade is a universal multi-layer insulation system.

This method of insulation is used in any weather, including autumn and winter.

How to cover windows with toilet paper. How to glue windows with soap for the winter

We glue windows with soap

Man has always thought about improving living conditions and the comfort of his home. This has always been the case at all times. Strong winds and harsh winters leave little choice, forcing residents to seal their windows and insulate their homes. Of course, at the current stage of development of the construction industry there are many modern technologies for sealing windows and further retaining heat. Also, no one has canceled expensive plastic windows, which can forever solve the issue of saving heat in your apartment.

But not every family can afford to buy modern windows, and they are simply accustomed to gluing windows with soap for the winter the old fashioned way

Or in some other old and proven way, it doesn’t matter. There are a large number of old and quite effective methods for sealing windows that remain relevant to this day.

We will discuss the most famous and widely used, affordable method of sealing windows using strips of paper or fabric and simple laundry soap.

Eliminating shortcomings

The primary task before starting window covering is the following.

There are more convenient pasting methods

It is necessary to carefully examine all potentially dangerous places from where cold air can pass into the room. Determine how you want to insulate your windows. Then you need to purchase materials and available tools, if necessary. One of the simplest and most affordable methods of insulation is to cover windows with soap for the winter. This is the most popular and beloved method that our grandmothers and mothers used in those years when there was no talk of other innovations. The work, in principle, did not require much physical effort and consisted of several stages:

- Carefully seal all detected cracks with rags or cotton wool using a knife;

- cut strips of paper;

- soak the pieces of paper in soapy water and carefully stick them on the window frames.

The main advantage of this method is that the white paper or fabric is not noticeable and does not interfere with the aesthetic appearance of the window.

The soap itself simultaneously serves as an adhesive and sealant, and also does not allow cold or wind to pass through. Also, already cut paper or fabric strips can be used several times without losing the quality of window insulation. The disadvantage of this budget method is that if there is a sharp change in temperature, the paper may peel off. When the warm season approaches, strips of paper or fabric can be easily and without much physical effort peeled off by simply moistening them with warm water. Typically, this very affordable and effective method is used to cover old wooden windows. In addition, instead of cotton wool, you can use other materials that are available on the farm. https://www.youtube.com/watch?v=diWmEA1RPlI

Last few tips

Before the cold weather, every person begins to think about such an important

question: how to save heat and insulate windows? This issue is all the more relevant and acute given the increasing prices for energy resources. It is known that poorly laminated windows do not retain even half the heat. Now there are modern insulating materials that allow you to effectively cover windows and contribute to impressive heat retention. But with such a variety of means, the choice always remains only with the person, which method of insulating windows, modern or old-fashioned, to choose.

Insulation of the facade of a wooden house

The log house is subject to rotting at high humidity. Therefore, wooden buildings require not only thermal insulation, but also protection from atmospheric factors. If insulation is carried out in winter, take into account the following points:

- foam boards must be treated with protective compounds to prevent destruction;

- “wet” technology can only be used if a thermal circuit is formed;

- You can begin finishing the facade of a wooden house after complete shrinkage, which takes 3-5 years.

Insulating boards must allow air to pass through easily, be resistant to moisture, and retain heat. It is best to choose mineral wool, polystyrene foam or polyurethane foam. Warming is done as follows:

- Treat the walls with antiseptic compounds. Lay a waterproofing layer.

- A sheathing is formed from thick timber. The voids are covered with insulation, which is secured with dowels.

- Cover the structure with a vapor barrier membrane. A metal mesh is installed to protect the house from rodents.

- Assemble the frame for the facing layer. Install clapboard or siding.

Other window sealing products

The sealant will be a real salvation if there is strong wind from the windows. The sealant is applied to the areas where the glass meets the frame. Window frames must be washed, degreased, and then carefully applied. To make the seam as airtight and aesthetically pleasing as possible, squeeze out the compound with even pressure and distribution; Paraffin is used to insulate wooden frames. The product only eliminates blowing through the pores of the wood. For the procedure, melt the paraffin and glue the surface of the valves with the mixture. This is a budget but labor-intensive method. In addition, it does not eliminate drafts around the perimeter of the glass and frame; Thermal-saving film is a popular and affordable material for covering windows. It not only covers the areas where the glass and frame meet, but also reflects the resulting heat. This increases the thermal insulation of the room and reduces heat loss by 75%

It is important to glue the material correctly, without folds or air bubbles. You can easily apply the film yourself, but it is quite expensive; Oddly enough, washing the window glass and thick long curtains will help to insulate the windows

Clean double-glazed windows allow sunlight to pass through as efficiently as possible, which will heat the room. And thick and long curtains will retain heat inside the room; Electric heating of windows and double-glazed windows is another modern and expensive way to reduce heat loss. In the first case, a heating cable is installed around the window. In addition, you can install ready-made double-glazed windows with heated glass, which will be heated from the inside.

Features of insulating a loggia in winter

First, the balcony needs to be glazed. Double-glazed windows are considered a profitable option. Insulation work is carried out as follows:

- All seams are covered with foam, especially carefully treating the gap between the wall and the window sill. After this, the sheathing is fixed, and foam plastic slabs are inserted between the bars.

- A waterproofing coating is formed from foam rubber or other material.

- Finishing is done with siding or clapboard.

An insulated loggia becomes a comfortable room for relaxing or storing things.

How can you seal windows from the sun?

Everyone has a desire to escape the summer heat - some sit under the air conditioner, some douse themselves with cold water, and some eat ice cream. But to create an acceptable temperature in the house without having an air conditioner, you can stick a film on the window so that the sun's rays cannot penetrate the room.

You can see foil on some people's windows. The opinion that foil glued to the window will save you from the heat is wrong, since it is metallized, which means it only attracts the sun and heats the room more.

Sun protection film has two functions:

- From the side of the house it creates a pleasant shadow.

- From the street side, it reflects the rays of the sun and the room, accordingly, becomes cooler.

In addition, in this way you can hide from prying eyes, if there are no curtains, and from the sultry sunlight.

How to apply solar film?

This can be done by any person who does not have special skills in this type of activity. To do this job, you will need several tools:

- Window surface cleaner.

- Spray bottle for water.

- Plastic or rubber spatula (whichever is more convenient for you).

- A sharp knife for the job.

- Film for windows.

- First, you should thoroughly wash the window glass on both sides.

- Use a spray bottle to spray a homemade solution containing liquid soap and water onto the sticky surface of the film. It is better not to shake it too much, so that a lot of foam does not form. This solution will help you move the product freely on the glass in the way a person needs.

- Now you need to apply the film to the glass. After waiting for the foam to settle, use a spatula to smooth the film with gentle movements so that all formed bubbles are removed. Movements are carried out from the center to the edges of the film. Having achieved a perfectly flat surface, you need to let the product dry.

- At the end, you can trim off the excess film when it is completely dry and set. It is better not to adjust the desired size before gluing, as a small gap may form.

Before starting work, the window must be clean and dry. Only then will the film adhere well to the surface of the glass and last a long time. Now you don’t need to rack your brains and think about how to seal your windows from the sun.

Types of fabric

Like all cotton knitted fabrics, natural capitonium can be divided into three types according to the quality of the material:

- Peña. High quality fabric, 100% cotton. Long fiber raw materials are used for production. This material holds its shape better and has a smooth, shiny surface.

- Card. The fabric is of average quality. The raw material is medium length cotton fibers. The surface of the material is smooth, not too different in appearance from foam, but shine is often absent.

- Openend. The fabric is of low quality, but still natural. The basis for such material is taken from short fibers of raw materials and residues from the production of peña and carde. The surface of the fabric is matte, may be covered with barely noticeable lint, and the material shrinks after washing.

The base composition can include both pure cotton and synthetic fibers. Most often, polyester is combined with cotton. Its content should not exceed 1/3. A large number of artificial components reduces the quality of the material several times and negates its environmental friendliness and breathability.

Sometimes the internal partition in the material, to reduce cost, is made entirely of polyester or other synthetic fabrics, and the external ones are made of cotton. It will not be possible to determine this visually, but air circulation is disrupted, so the body will not “breathe.” Naturally, such material is not suitable for children's things.

At what temperature is it allowed to install?

Manufacturers claim that panels of any type of siding can easily withstand temperature fluctuations ranging from -50 to 50 degrees Celsius. But material that is stored in a warehouse or other premises is much more vulnerable than installed material.

The vinyl version suffers especially. The material becomes very fragile, and even a slight mechanical impact can cause great damage to the panels.

Therefore, if you decide to install siding in winter, choose acrylic siding. It is more plastic and able to withstand such a load. In addition, choose a day when the ambient temperature will not drop below -5 degrees.

If the situation is critical and finishing needs to be done in a short time, the extreme value of temperature indicators can drop to -15 degrees. Although professional craftsmen generally do not recommend working at subzero temperatures.

Oil varnishes

Oil varnish can be used to apply to stones and other plaster products. It is made from artificial resins and special herbal additives and has an oily texture. After drying, a protective layer is formed that protects the surface from harmful effects and various damaging factors.

They produce glossy and matte oil-based varnish for plaster. A special solvent is used to dilute it. To make this varnish with any shade, you can purchase a special tint material that will give the stone or tile an attractive, original shade

It is important to consider that oil varnish darkens a little after drying.