There are cases when residents do not have the opportunity to connect to the main gas pipeline, and it is then that the issue of heating the house is solved with the help of alternative sources.

Most often today they resort to electric boilers.

There are several types of them.

Let's take a closer look at their advantages and features.

On smartphones, you can scroll the table right/left ↔

| Place | Name | Price |

| TOP 8 double-circuit electric boilers | ||

| 1 | ACV E-Tech S 160 (14.4 kW) | Find out the price |

| 2 | Savitr Premium Plus 21 (21 kW) | Find out the price |

| 3 | Savitr Premium Plus 12 (12 kW) | Find out the price |

| 4 | Savitr Premium Plus 22 (22.5 kW) | Find out the price |

| 5 | ACV E-Tech S 380 (28.8 kW) | Find out the price |

| 1 | Savitr Premium Plus 9 (9 kW) | Find out the price |

| 2 | Savitr Premium Plus 15 (15 kW) | Find out the price |

| 3 | Savitr Premium Plus 18 (18 kW) | Find out the price |

Description and principle of operation of electric heating boilers

Gas boilers are popular due to the low cost of fuel, but it is not always possible to connect them due to the labor-intensive procedure and the need for coordination with government agencies. Energy sources for solid fuel units are even cheaper, but there are many more disadvantages - they pollute, require the removal of combustion products, fuel loading, and storage space.

The listed disadvantages are absent in electric boilers, which are sometimes the only option for heating if there is no possibility of supplying gas. Moreover, electrical devices are considered not only as additional or emergency sources, but also as the main devices for the preparation of coolant. With them you don’t have to worry about ignition and other inconvenient issues associated with fuel combustion.

The most economical electric boiler should be chosen from energy-saving induction and electrode models. But we must take into account that in any case, its operation will cost approximately 2.5 times more than gas units, at best 1.5 times. Economy is considered here for situations where there are no other alternatives to electricity or if this type of energy is cheap (there are alternative sources - solar collectors, etc.).

Solid fuel boilers

This is a popular type of boiler among home owners. Used for heating in rural areas or in places where firewood, pellets or coal are inexpensive and freely available.

Pellet water heater design

- Type of fuel. Wood is used as fuel - firewood or pellets, as well as coal. There are mixed-type boilers with several fireboxes.

- Method of fuel combustion. Classic, long-burning and pyrolysis are available.

Pellet versions are popular, providing a high level of automation with long-term programming of operating modes. These are the most modern water heaters in the solid fuel family in terms of fuel type.

In a classic solid fuel boiler, heat is generated by simply burning wood, like in a stove. Hence all the disadvantages of such units - they will have to be cleaned, monitored for smoke removal, constantly adding firewood and regulating the combustion force and draft with a damper, etc. In principle, we are not talking about any autonomy. Efficiency does not exceed 75%. The advantage lies in reliability, simplicity of design and wiring diagram, independence from electricity and low cost.

Long-term or top-burning water heaters use a different method of loading fuel - from above. Due to this, complete combustion occurs and efficiency increases.

Construction of a pyrolysis boiler

How electric boilers work, device

The general principle of operation of electric boilers for heating: the coolant (water) circulates using a pump along the circuit of the heating system, through the boiler (internal chamber, flask, coil) and is heated there by heating elements, heat exchangers with electrodes, and induction coils.

The main parts of the electric boiler: housing with heaters, circulation pump, power supply, expansion tank, control and safety system (pressure gauge, check valve and for releasing excess pressure).

Economical electric boilers are required in the following conditions:

- if it is not possible to use gas;

- a unit that is easier to maintain than fuel-powered devices is required;

- preference is given to a cleaner energy source;

- An additional heater is required in case the main device is turned off.

No. 4. Number of circuits

Among electric boilers, single-circuit models . They are only responsible for the heating system. To provide yourself with hot water supply, you need to retrofit the system with a water heater or take a double-circuit boiler . The latter has two independent circuits for heating water. Double-circuit electric boilers consume a lot of electricity, so they are used quite rarely.

Types of electric boilers for home heating

There are several types of electric boilers based on the principle of electricity use and operation. Traditional and familiar to everyone - heating elements. More innovative and energy-saving are induction (vortex) and ionic (electrode), they are more expensive, but the cost is paid off by extreme efficiency and efficiency, which weakly or does not decrease at all over time.

The efficiency of all electric boilers is the same - 94–99%, but some types are more efficient due to the design and method of operation. And also over time, due to scale, this characteristic decreases by 10–20% for heating element boilers, but this is not typical for induction and ionic products.

Types of electric boilers:

- with heating elements;

- ionic (heating by electrodes);

- induction (vortex).

Heating elements new electric boilers

Heating boilers with heating elements can only be classified as economical only conditionally: different models may have more efficient heating elements, programming capabilities, and power settings.

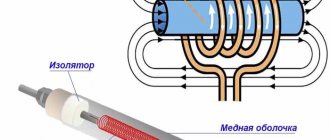

Inside the device there is a tubular electric heater - a copper or stainless steel tube (there may be sand or oil inside) with a filament (nichrome). The principle of operation is the same as that of a conventional boiler or air heater: the spiral inside the shell heats up and transfers heat through the tube in which it is enclosed to the water entering the chamber (flask) with the heating element.

When choosing electric heating for a home with a special emphasis on economy, units with heating elements should not be seriously considered. You can choose a high-quality device with more or less energy consumption, but it will still be more power-hungry than induction and ion boilers. On the other hand, the cost reduction can be compared to some extent, since a boiler with a heating element is cheap to maintain.

Advantages and disadvantages of heating elements electric boilers

Advantages of heating heaters with heating elements:

- cheap and convenient repair (the body is easily disassembled, parts are replaceable);

- advanced functionality: power adjustment, programmability, ability to connect a thermostat;

- usually produced in a monoblock compact case (there are convenient wall-mounted sizes) ready for operation, including a safety group, expansion tank, and pump. There is no need to separately purchase and install these elements; you only need to connect the device to the input and output of the heating system.

Minuses:

- the most uneconomical type of electric boilers, especially if two heating elements are used;

- Scale and plaque forms on the heating element, which requires periodic cleaning and replacement. A hard crust reduces efficiency by 10–20%. This statement is controversial, since the water of the heating system is not prone to intense scale formation, but it should not be ignored.

Induction boilers

Types of induction boilers for home heating (sometimes perceived as brand names):

- VIN - “vortex induction heaters”, more innovative with a ferromagnetic body. Smaller in size and 1.5–2 times more expensive than SAV, but more efficient;

- SAV - the principle is the same, but they are positioned as less advanced.

The second heating with vortex boilers is “inverter”. The product includes a current converter from direct to alternating current - an “inverter” (like welding machines).

Immediately after their appearance on the market, induction heaters for heating were positioned as the most advanced and efficient, but application experience showed more shortcomings than expected.

Operating principle of vortex SAV and VIN electric boilers

How does an induction SAV boiler work:

- A high-frequency alternating current (from 50 Hz) is supplied to a metal coil (inductor) - a rod (its role can be played by the coolant pipe itself) with turns of wire. A magnetic field is generated.

- The polarity and vector of the magnetic field change with high frequency.

- An object located close to the described phenomenon is penetrated by constantly changing fluxes of magnetic induction. Foucault eddy currents arise, turning electricity into heat, which heats the water.

The principle of heat transfer in induction boilers is non-contact - the object is heated by electromagnetic fields, and instantly. There is no need for physical contact with the inductor, which increases efficiency.

The electromagnetic principle is used in industry to melt metals. Even a small homemade induction device with a coil with a dozen turns and a few cm² in size is capable of heating metal to red in a few seconds, which illustrates the power and efficiency of a vortex boiler for heating.

Advantages of induction boilers for heating

Advantages of SAV boilers:

- heating is powerful, almost instantaneous;

- microvibrations repel dirt, so there is no scale or deposits on parts in contact with water, no cleaning required;

- economical, the highest efficiency among electric boilers.

Induction boilers are the best for preparing water as it flows through the apparatus, as they provide extremely fast heating. At the same time, heat loss is zero, which distinguishes VIN from heating elements units. Despite the disadvantages, if we consider purely the efficiency of using electricity, induction boilers are the most economical type of electric heaters.

Disadvantages of vortex boilers for heating, feasibility of use

Many sources list many advantages of VINs and SAVs, but in reality the picture is somewhat different; many shortcomings have been discovered:

- most standard sizes have significant dimensions;

- more expensive than heating elements and electrode units;

- heating is extremely powerful, so if the auto-shutdown system breaks down, there is an increased risk of explosion;

- the electromagnetic field is harmful, electrochemical processes provoke corrosion;

- complex repair. It would seem that the device is extremely simple - a coil and a housing - but usually the cylinder of SAV boilers is securely sealed, and it is extremely difficult to disassemble it. It contains electronic circuits of the control unit, which complicates repairs. The coil may burn out, and the cost of a new one is higher than, for example, a new heating element;

- if the SAV is not in a compact case, and the majority are, then a large control unit, a separate expansion tank, a pump, and a safety group will be required;

- in most cases, they are not equipped with a soft start - when turned on and even when simply switching modes, there is a sharp increase in the load on the network, which is fraught with voltage drops (flashing lights and similar effects).

Still, despite the listed disadvantages, a vortex energy-saving electric heating boiler should be considered as a heater for heating a house due to its high level of efficiency (30% more efficient than heating elements). Some of the listed disadvantages are relative, for example, there are small and compact sizes similar to those of products with heating elements. This is the only type of heater whose efficiency does not decrease over time.

Ion (electrode) boilers

Ionic (electrode) energy-saving heating boilers must be distinguished from induction units, despite the fact that they also use the properties of alternating current. The organization of energy use itself is different. The body of the device contains a sealed chamber with a coolant and electrodes located in it with a certain gap.

With a constant current, the cathode attracts water ions with a positive charge, and the anode attracts negative ones, but if you change the characteristic to a variable one (starting from 50 Hz), then a constant movement of these particles will occur. The medium has resistance, so the kinetic energy of moving ions (cations and anions) is transformed into thermal energy, and the electrolyte is heated.

In the ion boiler, a special electrolyte solution is heated, circulating in the pipes of the heating system; in certain cases it can be water. In fact, such a boiler is a simple heat exchanger.

Advantages of ion (electrode) boilers for heating systems

Advantages and features of ion boilers for heating:

- extremely compact: low-power models are only slightly larger than the diameter of the pipes. This is a small cylinder cut into the wiring. They do not require any space around them, so they can be installed literally anywhere;

- the cheapest - 4–9 thousand rubles. (A new heating element costs about 15-30 thousand), but if you have to buy an expansion tank, thermostat, safety valves, pump, then it’s another 10-12 thousand;

- scale does not form - this is prevented by electromagnetic processes;

- service life before the first breakdown is 12–15 years. According to this characteristic, electrode heaters are comparable to induction devices;

- maintainability. The design is simple and can be disassembled without much difficulty. Parts are replaceable and cheap;

- the safest: if induction or heating element boilers, if the automatic shutdown (protection against overheating and dry operation) fails, continue to heat up until an explosion or fire, then ionic boilers will simply stop working on their own without any intervention if the coolant leaks;

- no electromagnetic field.

Disadvantages of electrode heaters

Installation of the electrode device itself is simple, but it is somewhat complicated by the need to install a pump, safety group, and expander. There are also products with the last two elements on the body or in the form of a ready-to-use monoblock, but this arrangement is less common. In this aspect, heating element boilers have an advantage, since they are often produced in standard sizes with everything necessary in one housing.

Minuses:

- There are devices with a heat exchanger and an expansion tank on the body, but in most cases an additional purchase of these elements is required, as well as a pump and safety group;

- scale and plaque do not form, but electrical processes increase corrosion of the metal of the heating system circuit. In this aspect there is a similarity with SAV boilers;

- Pipe water can act as an electrolyte, but usually special solutions from the manufacturers of such boilers are always used. The mixture must be undistilled and unfiltered. Special substances are the most effective. Propylene glycol and ethylene glycol are used. You cannot use antifreeze, oil, or distilled water;

- requires replacement of the coolant every 3–4 years.

Electrode boilers consume 20–30% less electricity than heating element units, but they are slightly less energy efficient than induction models. That is, in the economy rating, if we take into account the convenience, low cost of the product and service, they are in the middle.

Prices: summary table

| Model | power, kWt | Complete set with all elements of CO | price, rub. |

| heating elements new | |||

| EVAN EPO-18 | 18 | No | 14 600-21 000 |

| Reco 15P | 15 | Yes | 24 000-28 000 |

| Protherm Scat RAY 18 KE /14 | 18 | Yes | 41 000-45 000 |

| Vaillant eloBLOCK VE 18 | 18 | Yes | 48 000-52 000 |

| Electrode | |||

| Galan Geyser 15 | 15 | No | 8 200-8 900 |

| Beryl-15 Ion | 15 | No | 8 400-8 500 |

| Galan Galax G352 15 | 15 | Yes | 30 000-34 000 |

| Induction | |||

| Alternative energy VIN 15 | 15 | No | 49 000-55 000 |

BoilersElectric boilers

Guidelines and what to consider when choosing an economical electric heating boiler

An economical electric boiler must have programmable operation, the ability to connect a rheostat for on/off. during periods of low tariffs or when a certain temperature is reached, as well as to regulate heating. At a minimum there should be at least a three-stage power switch.

The ideal option is if the device has smooth adjustment and factory economy modes. The product must be suitable for connection to room rheostats, which have many fine settings and respond to the air temperature in the room.

Single- and double-circuit electric boilers

If you need to provide hot water at the same time as heating, then choose double-circuit electric boilers. Moreover, the electricity consumption in such products is practically no different from single-circuit ones. DHW water is heated by washing the heat exchanger in the heating boiler circuit, without mixing with its coolant. Such heating does not require additional power, although for greater efficiency there are models with increased energy consumption.

What to look for when purchasing?

When you have figured out what type of device you want to buy, it’s time to think about its size and technical parameters.

Most often, electric boilers are installed in the kitchen, but you can also equip a mini-boiler room, which will allow you to hide unattractive communications and additional equipment (storage tank, indirect heating boiler, etc.).

Selecting a device by installation method

Regardless of the type of construction, all double-circuit boilers can be divided into two large groups - wall-mounted and floor-mounted. The dimensions and choice of model directly depend on the area that you need to heat, and also on the amount of free space for the device itself.

A wall-mounted boiler differs from a floor-mounted boiler in its small size - if necessary, it can be hidden in a wall cabinet or cabinet, but even an undisguised device does not look bulky and harmonizes perfectly with other household appliances

Attachment units are designed for heating relatively small areas - up to 100 m2, therefore they are most often installed in apartments or small country houses. They are attached to special brackets to any vertical surface that can withstand such a load.

Floor-standing boilers are rather bulky devices, but they can provide a house with an area of up to 200 m2 with heat and an uninterrupted supply of water, and storage tanks can either be built into the device itself (which significantly increases its dimensions) or mounted separately

If the cottage area exceeds 200 m2, you can equip a boiler room with several electric boilers or use additional heating sources - solid fuel equipment or solar panels.

Calculation of required power

The simplest way is to divide the heated area by 10. It is believed that when heating 10 m2, 1 kW will be spent, but the resulting figure will be very arbitrary, because such a calculation makes sense only for rooms with a height of no more than 3 meters.

In addition, heat costs largely depend on the presence of insulation, the quality of windows and their sizes, the climatic features of the area and the materials used in the construction of the house.

If the house has high ceilings, you must first determine the volume of the room (multiply the area by the height). Then calculate the required power on the basis that 1 m3 will require 35 W.

When purchasing, consider models whose power is 15-20% higher than your calculated values - it is better to set the boiler to a weaker mode than to freeze in the cold winter with the equipment working at its limit

To the obtained result you need to add a “margin”:

- 10% - with a large glazing area (panoramic windows, veranda, etc.).

- 15% - in the absence of house insulation.

- 10-15% - for areas with cold winters.

- 20% - for additional load when DHW operates in flow-through heating mode.

When calculating the required power for boilers with built-in storage, you need to rely on the data specified by the manufacturer in the technical documentation.

The method of feeding it also depends on the technical parameters of the boiler. Appliances up to 10 kW can be connected to a regular 220 V network, and more powerful boilers can be connected to a three-phase network (moreover, this may require permission from local power grids if a 380 V line is not supplied to the house).

Other important nuances

Based on the principle of heating water, double-circuit electric boilers can be divided into flow-through and storage. The first is a good option for a small house and family; it can easily serve 1-2 water points in addition to heating. But despite its compactness and ease of use, the 2-in-1 device has a significant drawback - a high load on the electrical network.

But the storage unit takes up much more space due to the additional tank in which the supply of hot water is stored. The advantage of this type of equipment is that it can supply water in large quantities and allows you to save up to 10% on electricity, since it does not waste energy on constant heating, but only maintains its temperature.

Thanks to the insulating casing, the heat loss of water in the tank per hour will be no more than 0.5 degrees. The technical data sheet of a device intended for connection to a hot water supply system must indicate its throughput - minimum and maximum temperature, volume of water and the required time for heating it.

Modern electric boilers allow you to control the device and control the heating temperature in the room using smartphones or a smart home system

Additionally, the boiler can be equipped with:

- Automation unit for remote control from a remote control or via a network.

- Frost protection, which will allow you to maintain a minimum temperature in the system, which is important for country houses and country houses where there are no permanent residents.

- Sensors that monitor weather changes turn the device on when temperatures drop and turn it off during sunny hours.

- Equipment that lowers the water temperature for connection to the “warm floor” system.

- Sensors with the ability to program the microclimate in the entire room or individual rooms at your discretion.

Of course, “bonuses” from the manufacturer increase the cost of the device, but with their help it is much more comfortable to operate the boiler.

Calculation of power for the area of the house

We present a simplified calculation of power, since this issue is a topic for a separate article. Approximate calculation usually always gives results as close as possible to real needs.

If the electric boiler performs an auxiliary heating function in addition to the main gas or other unit, or fireplace, then for 120–150 m² a power of 3–6 kW will be sufficient.

Comparative table of average statistical electricity consumption by electric boilers

| Electrode | heating elements new | ||||

| Boiler power | Heating area, m² | Consumption, kW/hour | Boiler power | Heating area, m² | Consumption kW/hour |

| 3 kV 1 phase | 50 | 0.5–0.6 | 3 kV 1 phase | 30 | 1.5–1.8 |

| 5 kV 1 phase | 80 | 0.9–1.2 | 5 kV 1 phase | 50 | 2.0–2.5 |

| 9 kV 3-phase | 120 | 1.8–2.3 | 9 kV 3-phase | 90 | 3.6–4.2 |

| 25 kV 3-phase | 350 | 4.5–5.5 | 25 kV 3-phase | 240 | 9.5–11.0 |

If an energy-saving boiler is the main source of heat, then it is necessary to carry out calculations taking into account heat losses, which for an average private home with two-brick masonry and 2.7 m ceilings in the climate of the Moscow region is 1 kW/hour. It is recommended to select power with a margin of 10–20%, and for heating element heaters - by 20–30%, since their efficiency decreases due to scale. For 80 m² you will need an electric boiler of 9.6–10 kW (8 kW + 20%).

For SAV boilers, a power of 2.5 kW is 2100 kcal/hour, which is enough to heat 25–30 m². The calculation is affected by the required temperature. If you need to maintain 15–20 degrees in a room of 120 m², then a 6 kW unit will suffice.

An economical ion-type electric heating boiler with a power of 3 kW is suitable for heating 50 m². The same product with a heating element will heat 30 m².

By what criteria to choose

The power level for me is the first very important factor when choosing an electric wall-mounted boiler; this issue is worth thinking about long before visiting the store. For heating 10 sq. m. area will require 1 kW, using this principle you can quite simply and quickly calculate the indicator for any private home.

I advise you to find out the number of circuits immediately after the power; if you plan to use one housing for heating water and heating, then you should give preference to the dual-circuit type of device. To increase efficiency, the presence of an automated system will be an integral indicator; you can also significantly save on utility bills.

What to choose: comparison of consumption, cost, ease of use

If we focus on ease of installation, ease of operation, and average price, then the first place in the ranking is occupied by boilers with heating elements. As a standard, they are carried out in a monoblock case that is completely ready for operation after installation - it already has a safety group, an expansion tank, a circulation pump and other elements. You just need to connect it to the input and output of the heating system. But they are in last place in terms of economy and cannot be called energy-saving.

If we consider the question of which electric boiler is the most economical and with the best energy saving, then we should consider induction and ion units.

Vortex heaters are in first place in terms of economy, but they have a number of disadvantages that slightly offset this advantage: price, difficulty in repair, large dimensions. These are the most expensive and inconvenient electric boilers considered: the cost of such a 25 kW product is 86 thousand rubles. (A new heating element for 24 kW can be bought for 46 thousand).

Below is a table comparing different types of electric boilers. But the data in it should not be unconditionally trusted - manufacturers are trying to show their products in a favorable light. For example, in other sources, ion boilers are shown to be much more economical and efficient than heating element boilers.

| heating elementnew | Electrode | Induction | |

| Efficiency | 98 % | 94 % | 99 % |

| Loss of power after 12 months of use | 20 % | 15 % | 0 % |

| Maximum pressure | 3 atm | 3 atm | 6 atm |

| Heating temperature | Up to 90 degrees | Up to 85 degrees | Up to 115 degrees |

| Life time | 3–7 years | 10–12 years | 30–60 years |

| Probability of failure within 12 months | 15–20 % | 15–35 % | 0 % |

Another disadvantage of SAV and VIN is the large dimensions of the housing itself and the individual elements that include the control cabinet. A product with a tubular electric heater contains everything you need in a compact case, and an ion boiler generally resembles a thick water pipe. The weight of a 25 kW induction boiler is 80 kg, a heating element of the same power is 40 kg.

Vortex boilers are increasingly being chosen for private homes. Although such devices are the most energy-saving, they are more often used in places where induction heating is indispensable - in industrial, production environments, and chemical plants.

Economics of VIN use

| The name of a room | Heated area/volume | VIN model | power, kWt | Cost kW/h, rub. | Monthly payment, rub./month. | Payment for the heating period, rub. |

| 1 room apartment | 50 m² | VIN-3 | 3 | 2.0 | 1227.6 | 9147.6 |

| House | 100 m² | VIN-7 | 7 | 2.2 | 2864.4 | 21334.4 |

| Garage box | 450 m³ | VIN-10 | 10 | 3.2 | 5952 | 45888 |

| Hangar | 1000 m³ | VIN-20 | 20 | 3.2 | 11904 | 91776 |

Ion (electrode) boilers are the best choice in the economy class in all respects, especially in terms of cost, if you need an energy-saving heater for heating a private home. Their economy and efficiency may be somewhat lower than that of induction and heating elements products, but this is compensated by ease of maintenance and small size. An important fact in favor of ion boilers is the price - these are the cheapest energy-saving heaters for heating (4-5 thousand rubles).

Ion boilers are a good option as an additional heating source. If you use them as main devices, you can embed several of these cylinders for greater efficiency.

Gas boilers

Gas boilers are divided into:

Floor-standing models in which the heat exchanger is usually made of steel or cast iron. It is difficult to say which material is the best. Steel boilers are lightweight and resistant to shocks that may occur during transportation. And cast iron models have a much thicker heat exchanger, and this has a positive effect on their service life. Gas fuel is the most common type of fuel nowadays, which is why such boilers are extremely popular. Most modern water heaters have an electronic ignition system, which is very convenient during operation.

The main thing that makes sense to pay attention to when purchasing a gas boiler is the performance indicator. In this matter, you need to take into account the total area that this boiler will heat

Modern heating equipment makes it possible to heat areas up to 350 sq.m. To ensure that combustion products are completely removed, gas heating systems are equipped with natural and forced draft. Wall-mounted water heating boilers are attached to the surface of the wall, and they can also be hidden in a closet or other niche. The advantage of wall-mounted boilers is their compact dimensions. They have a tubular burner as well as a slow-running heat exchanger.