Many apartment and house owners install heated floors in several rooms. They are usually mounted under tiles or tiles. This decision is correct, because electric-type underfloor heating is compatible with most floor coverings. Using tiles as a finish is a fairly common option.

There are many options for finishing coatings - ceramic tiles, porcelain stoneware and other popular materials with similar characteristics. When laying cable heated floors under tiles, certain recommendations should be followed.

Advantages of heated floors

Before laying the electrical cable for underfloor heating under the tiles, you should understand the advantages of such a solution. This will help you complete the job better. The advantages of a warm floor on which tiles are laid:

- Possibility of heating the room at any time. Even when the heating season has not yet begun, you can comfortably use a heated floor.

- Leaks are prevented during installation.

- This floor does not freeze during severe frosts.

- The surface temperature is conveniently adjustable.

- The height of the room is reduced minimally, because the heating cable has a small diameter, and the screed for it is made of small thickness.

- The heating power does not change throughout the entire area of the room.

- Maintaining such a floor is much easier than a water system.

However, before purchasing a heated floor for tiles, you should decide which system is best suited for this task.

How to calculate the power and amount of cable for heating a room

Before proceeding with the installation of a self-regulating heated floor, it is necessary to calculate the power and length of the circuit. We also suggest finding out how much electricity a heated floor consumes per 1 m2 per hour, per month.

Heating Cord Power Calculation (Carbon Heating Cord)

Power calculation

It is necessary to calculate the thermal power of a self-regulating heating system taking into account the heating characteristics. That is, the main or additional source of heat will be the warm floor.

But as mentioned above, the self-regulating cord periodically relieves tension to maintain the floor surface in a comfortable condition. Therefore, the heat will not be enough to heat the room, and it is not recommended to use a self-regulating floor as the main one.

As auxiliary heating, it is recommended to use a cable for such a floor with a power of at least 110 - 140 W per square meter. Moreover, in order for the heating level to be high, it is necessary to make thermal insulation.

The size of the room in which the heating element will be installed is also of great importance. It is not recommended to place the circuit under heavy furniture and plumbing fixtures; this is an unnecessary waste of electrical energy.

Based on this, the load calculation looks like this: the area of the heated room is multiplied by the norm per square meter.

Defining the Length of a Path

To calculate the required size of the kennel, you need to look at the cable product data sheet. It reflects the power per meter of wire. It varies from 5 to 150 W. This variation in the voltage of the self-regulating cable is caused by the huge scope of its use.

Let's look at determining the length of a contour using an example. When the electrical cord heats up to 28 degrees, and the lower surface of the floor covering up to 25, a wire with a power of 17 W is required. An area of 10 m2 will require 70 meters of heating circuit.

Kinds

Modern models are represented by cable systems or mats. Infrared flooring is included in a separate category. It has several varieties - such systems can be film or rod.

Each of these types of floors has the following characteristics:

- a dry base is required for installation;

- The system must be grounded;

- equipped with temperature regulators;

- used as additional heating.

The differences include installation features, quality of heat generated, and requirements for the finishing coating.

Cable heated floor

Thanks to their reliability and safety, cable systems have become very popular. They have a simple device:

- the cable, distributed in sections, is mounted on a concrete screed under the finishing coating;

- a sensor that controls the temperature is also placed here;

- the ends of the temperature sensor and heating element are connected to the controller.

Such a system turns on only when necessary - when the temperature drops to a predetermined minimum.

Cable floors come in the following varieties:

- direct action systems - the cable is in a screed, located very close to the finishing coating;

- heated floors for wooden floors;

- heat storage system - used in rooms in which it is not prohibited to use electricity during low tariff periods.

Cable systems are installed separately for each room.

Thermomat

These floors consist of a thin heating cable attached to fiberglass. The heating core is surrounded by a screen and an insulating layer.

The mats are produced with single- and double-core cable. The latter option is more suitable for bedrooms and children's rooms. This is explained by the fact that two-core mats have a low level of electromagnetic radiation.

A thin cable floor is installed on top of the dried screed. Thermal mats are often installed under tiles. Penetrating through the mesh, the glue reliably secures the finishing coating.

Thermal mats do not affect the floor level, since they seem to “sink” into a layer of tile adhesive. The mesh becomes a kind of reinforcing frame. Another advantage of thermomats is ease of installation. They are laid when there is no desire to raise the floor.

Cable floor heating thermomats differ in that they are usually not used for main heating. In addition, if when making a cement screed the load on the floor will be quite large, it is better not to use cable systems. In this case, thermomats are used.

Infrared floors

Rod and film products are types of infrared heaters. When current passes through an element, electromagnetic waves begin to appear. Their range is 5-25 microns. They heat any objects located in the wave propagation zone. Conductive elements transfer heat to the overlying floor covering, furniture and walls, which heat the air.

Infrared floors are very energy efficient because they are able to convert about 95% of the emitted energy into heat. Heating of any surface occurs in a few minutes. If one segment is mechanically damaged, the rest continue to work.

Comparison of heater types

Both types of resistive cable include a heating core that is protected by a sheath. Wire or foil can be used as insulation. The only difference between these cables is that the first has one heating core, and the second has two. The main difference between the wires is the material from which they are made.

Don't forget to calculate the cable length

As a rule, brass, nichrome and copper are used as materials. Each of these metals has different properties and has different electrical resistance values.

When deciding which cable is best to choose, it is worth considering not only the level of its electrical resistance, but also parameters such as the total length and the recommended distance between the heating elements of the wire. This data will allow you to ensure the most suitable floor heating.

The permissible distance between heating elements is determined and indicated on the product box by the manufacturer. At best, doing anything on your own in this matter can render the entire floor system unusable. As a rule, manufacturers regulate the pitch to be no higher than 12 centimeters. Heating wires are sold in a certain length, which requires proper calculations. At the mounting stage, it will no longer be possible to add or remove any part.

Another significant parameter that requires special attention when choosing a cable is the number of heating cores.

Comparative characteristics

When installing heated floors of a certain type, you must comply with the requirements for the floor covering, installation methods and temperature conditions. In accordance with these requirements, before purchasing a specific model, a comparative analysis of the main underfloor heating systems is carried out.

Coating

When choosing electric heated floors, you should focus on the finishing coating. Laminate and ceramic tiles are more suitable for cable systems and thermomats. Carbon rods, as well as infrared film, are placed under linoleum, carpet and laminate - such materials serve as good heat conductors.

Advantages of infrared films:

- Easy to install - they can be used immediately after installation.

- Ease of replacement - if several elements fail, they can be easily replaced with new ones.

The disadvantages of infrared films include the unreliability of the connecting sections.

The main advantage of cable-type floors is that they are a solid conductor with a single weak point - the coupling. Its location is entered in the passport so that if it breaks, it can be quickly replaced.

In addition, the screed serves as a protective layer that protects the floor from mechanical damage. If you use films with a 12V power supply, a power supply is added to the system - not a very reliable element.

Advice! To protect yourself from electric shock, you should use residual current switches (RCDs) that meet the requirements of GOST R 51326.1-99.

Installation methods

Warm floors are installed in different ways:

- into the screed;

- between the screed and the tile;

- directly under the finishing coating (film floors).

The first option is more often used when heating living spaces, kitchens and bathrooms. Cable heated floors are installed in such rooms. Waterproofing and insulation are laid under the system.

If there is a heated room below, thermal insulation is not needed, and the heating elements are installed under the tiles in a layer of adhesive. Before purchasing a model, you should check about the possibility of such installation.

When installing a heated floor system under a laminate, you should choose infrared films. A layer of polyethylene is placed on the screed, followed by electrical elements. Then waterproofing and laminate are laid.

Forged swing metal gates

Forged structures are decorations for barriers made of metal. Despite the huge number of models of modern devices that provide unimpeded entry into the territory of a personal plot, it is the swing design that is in high demand and deserved trust of owners of private houses located within the city or beyond.

Swing gates

It is swing structures that are installed in most cases. Such devices can be:

- Completely transparent, made from individual rods bent into an intricate pattern.

- Partially or completely deaf, not allowing strangers to see what is behind the openwork fence.

Advantages and disadvantages

To achieve this goal, craftsmen create structures in two ways:

- cold forging;

- hot.

Cold forging Hot forging

The main advantages of forged gate leaves are a high level of strength and resistance to mechanical damage. During the work, specialists carry out calculations with particular accuracy of the level of load on the supporting structure

It is also important that such products:

- universal;

- exclusive;

- can have any shape;

- compatible with all building materials that were used in the construction of the fence.

However, there are also certain disadvantages that make you think about the extent of the need for work related to the installation and installation of openwork gates. Among them:

- Heavy weight.

- The need for careful preparation and high-quality installation of supports that will have to withstand significant weight.

Despite all the existing difficulties, installing gates attracts many homeowners due to the opportunity to create various compositions, decorate the entrance to the territory not only with simple drawings, but also with complex ornaments, equip the structure with automation, install video surveillance and an intercom system.

Project preparation

Designing a heated floor is an important step, which allows you to reduce costs for materials and prevent local overheating of the electrical cable. When developing a project, it is necessary to rely on the arrangement of heavy furniture and household appliances. Such items can create an increased load on underfloor heating cable systems.

This is why you should choose a bed with legs. Mats and cables are placed 2 cm from the walls. There should be at least 10 cm between adjacent turns of underfloor heating.

The project should include the installation location of the thermostat. It is often installed on the wall 1 meter from the floor.

Features of application

However, despite the ease of installation of a self-regulating heated floor, some features of its construction should be noted:

- Cutting must be carried out during the installation of the heating floor. In this case, the length of the self-regulating circuit can be either several centimeters or several tens of meters. For different types of cord, the maximum length is different and ranges from 70 to 160 meters.

- When installing heated floors with a self-regulating cable, it should be taken into account that there is a large difference in current between the nominal and starting value, 2 - 4 times. This should be taken into account when choosing ballasts.

By following these expert tips, you will be able to correctly construct a heated floor with your own hands.

Thermal insulation

At this stage, it is necessary to decide on the choice of insulation for the heated floor. This will determine when to start thermal insulation - before preparing the base or after it. The thickness of the insulation is selected according to the state of the ceiling between floors.

Thick thermal insulation is installed over the basement. It should be installed if there is soil under the floor. For such thermal insulation, you should choose expanded polystyrene or polystyrene foam. It is better to install thick thermal insulation before leveling the floor.

A thin layer of thermal insulation is mounted on the prepared surface. Penofol is laid so that the reflective surface faces upward. Using such a substrate will allow you to direct heat into the room.

The insulation material should be laid at a certain distance from the wall. For example, in the case of expanded polystyrene, this figure will be 10 cm. When using polystyrene foam, it will have a thickness of 5 cm. At the junction of the wall with the insulation, a damper tape should be glued.

Preparing the base

The cable must be laid on a completely flat surface. It needs to be dusted off. As you can see, the floor preparation work includes cleaning the surface if there are protrusions and thorough dust removal.

It is better if a primer is applied to the floor. If there are large differences in floor height, a screed should be installed. If there is little time for construction, a self-leveling floor should be installed.

When installing the cable on the boardwalk, most of the heat will be wasted. At the same time, the wall is being chipped for the cables going to the thermostat.

Advice! When installing an electric heated floor system in a renovated room, you should lay the wires in cable ducts.

Installation of thermostat and sensors

The controller, which regulates temperature indicators, is installed in a specially designated place. The cable connecting the thermostat and the system elements must be placed in a corrugation. The corrugation is located in the pipe. It must be carried out to the temperature sensor. It should be mounted at a distance of 30 cm from the wall. If this condition is not met, temperature measurement will be complicated.

The corrugation is laid in such a way that no kinks are formed. They happen especially often near the baseboard. The edge that abuts the system should be sealed with sealant. This will prevent concrete mixture from getting into it.

In addition, a temperature sensor is placed in the corrugation. This improves the maintainability of the device.

Laying heated floors

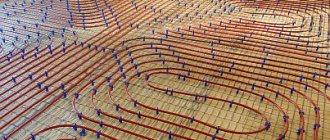

To ensure reliable operation of the underfloor heating system, the cable must be laid correctly. A mat can be laid under the tile - it is a cable that is fixed in a polymer mesh. The methods for installing them vary.

Cabling

Before laying the cable, it is necessary to check what resistance it has. After this, the tape with fasteners is fixed to the floor. Thanks to the frequent arrangement of the fasteners, the installer can easily place the cable turns at a certain distance.

There is another way to attach the cable. A metal mesh is mounted on the floor surface, a metal mesh to which the cable is fixed. It is secured using plastic clamps. Such a system has a fairly high rigidity.

The electrical cable is usually placed 20 cm from the wall. The installation is done in the form of a snake.

Laying mats

Installation of heating mats is much simpler than laying cables. To prepare the system for launch, it is worth laying the mats on the floor, and then determining their resistance. The laid mats are fastened using construction tape.

RCD and grounding are necessary when installing a heated floor system.

Important! When installing a heated floor system in a bathhouse, extreme care should be taken. It is better not to install an electrical cable in the washing compartment.

Before pouring the screed, it is necessary to check the cable resistance. This must be done using a multimeter. If the data does not correspond to the data from the passport, installation errors should be corrected.

Scarecrow

If you need to scare away birds, you should make a device from compact discs. They need to be secured to a hoop and attached to the board.

Filling the screed

To calculate how thick the tie will be, you should pay attention to the thickness of the cable. The following standards exist:

- when installing a heated floor system from a cable, a screed with a thickness of 50 mm should be used;

- For a floor that consists of heating mats, a screed of less than 30 mm should be installed.

Concrete mortar should be used to fill the screed. However, it takes quite a long time to dry. Another drawback is that the room becomes lower. An alternative option is to screed the floor with a special tile adhesive.

Many users noted that when constructing a heated floor system from mats, they laid the tiles directly on the mats. The glue layer should have a thickness of 20 mm.

Which cable to choose

The choice of cable product is influenced not only by its characteristics, but also by the rating of the company that produces it. Preference should be given to trusted manufacturers who produce quality products.

Among such manufacturers the following companies can be noted:

- "Devi" (Denmark) - produces resistive heating cables Deviflex 18T, which are designed for installing basic or additional type of heated floors. The length of the wire included is 105 meters, power 1880 W. The company's products are reliability, quality and a guarantee of up to 20 years.

- "Ceilhit" (Spain) - produces inexpensive and effective devices that can create comfortable indoor conditions. The company's main product is a two-core shielded cable with a power of 220 - 230 W. Manufacturer's warranty on the product is 16 years.

- GC "Thermal Systems" (Russia) is a reliable company that specializes in the production of heating cables for underfloor heating: self-regulating and resistive. Products are manufactured using modern equipment and new technologies. At the same time, the price of heating products is reasonable.