For owners of private houses, the main source of heat supply is a gas boiler. The popularity is primarily due to the fact that the use of such equipment helps to significantly reduce utility costs. Due to such widespread popularity of this type of heater, manufacturers are increasingly producing many modified models with improved technical characteristics, suitable for all buyers. One of these newest models are double-circuit (two-level) gas boilers. Today this is one of the best solutions for heating private houses. In this material we will talk about the features of tying such models.

Comfort Series

The Comfort series is a more advanced version of the basic Baxi Luna 3 series, which has expanded functionality.

There are no fundamental differences between the two lines, otherwise the manufacturer would have separated them into different series and given them their own names. There are more models available and new system management capabilities are provided.

Unlike the basic models, the Comfort series is equipped with a remote control panel, which can be used in a wireless design. In parallel with the general functions, the panel is a room temperature sensor, showing the owner the current microclimate indicators in the premises.

Remote control significantly changes the principle of setting and regulating the operating modes of the system, allowing the owner to make the necessary changes from any convenient point in the house, without going to the boiler itself.

Pressure setting

To increase the pressure, a make-up valve is used, and to release the pressure, a drain valve is used.

The optimal value is considered to be 0.7-1 mBar. Usually Baxi boilers independently maintain the desired value, but sometimes failures occur. If there is a constant drop that does not disappear after the system is recharged, then there is an OM leak somewhere.

This could mean either leaking pipes or radiators, underfloor heating systems or other external elements.

Often the problem occurs due to a faulty bleed valve. An abnormal increase in pressure may be due to a malfunction or open make-up valve or damage to the expansion tank membrane.

Baxi heating system wiring diagrams

Despite the fact that the manufacturer has taken care to provide the user with all the necessary documentation for connecting the boiler to the heating system, in order to maintain warranty obligations, it is not recommended to do this yourself; you need to invite a service department, which will be recommended in the store when purchasing the unit.

Thus, the user’s task will be to select the desired strapping pattern. It will depend on the installed heating circuit. According to existing heat supply schemes, it can be:

- two-pipe for houses with a large heating area;

- single-pipe with natural circulation for houses with small heated area;

- combined, for multi-circuit heating systems.

Two-pipe scheme

The two-pipe Baksi circuit is made from a heating source, a circulation pump, an expansion tank, a safety group, a mud trap and a coolant purification filter.

The principle of operation of a two-pipe network:

- Cold water enters the heating circuit through the filter to the suction of the network pump.

- Water enters the boiler and is heated to the temperature set by the user on the operating panel.

- The heated coolant is supplied to the heating system.

- From the supply pipeline there are branches to each heating device.

- Cooled water from the radiator flows through the return branch into the common return line and is pumped into the unit for the next heating cycle

Air vents and a heat sensor are installed on the heating device, which regulates the coolant depending on the set temperature.

Thanks to this scheme, the radiators heat up evenly and, if necessary, can be completely individually switched off.

Single-pipe scheme

A single-pipe scheme with natural circulation is an affordable and economical piping scheme designed for small-sized one-story houses.

The scheme is as follows:

- The gas boiler is installed on the wall in the kitchen.

- The supply from the device comes through one pipeline, to which all radiators are connected in series.

- The heated coolant from the device enters the supply line, which has an upper distribution, and then sequentially passes through all the heating radiators.

- From the last radiator it flows into the return line and then into the boiler for a new heating cycle.

- The movement of the medium occurs under the influence of natural circulation that occurs due to the temperature difference in the supply and return. For efficient movement, the supply and return pipelines are installed with a slope. The vent is installed at the highest point, usually in the attic.

- An expansion tank is installed in the system to compensate for the thermal expansion of the coolant.

The disadvantage of this scheme is that the first batteries along the coolant flow are overheated, and the last ones are underheated. The efficiency of the circuit can be increased by integrating a circulation pump into the circuit, which will increase the heating area from 40 m2 to 150 m2.

Combined diagram of the Baxi gas heating system

This is the most progressive boiler piping scheme; it has several independent heating circuits - a radiator and a “warm floor” system.

Typically, radiators are installed in bedrooms and the living room, and in other rooms in the kitchen, bathroom and other utility rooms, “warm floors” are installed, which operate at lower temperature conditions and can work with reverse coolant.

The return coolant temperature limitation is set by the manufacturer for a specific unit model in order to counteract the formation of condensation in the flue gases. To distribute the coolant across different circuits, you will need to install a Baxi boiler with a hydraulic manifold and separate circulation pumps for each circuit.

Premises requirements

The use of gas boilers and other heating appliances is always associated with the risk of various fire hazards. In this regard, manufacturers clearly regulate the rules for operating equipment and violation of these regulations is highly undesirable. Special conditions and requirements have been introduced for the installation of gas equipment and for the room in which it will be installed. First of all, manufacturers recommend installing a gas boiler in any room (kitchen, hallway, bathroom) that meets the following requirements:

- The ceiling height should not be less than 2.5 meters, while the area of the room should not be less than 4 square meters;

- Free access to the boiler must be provided, at least 1.25 m in front and 0.7 m on the sides. A wide doorway must be provided, not less than 0.8 m.

- The room must have several window openings with an area of at least 0.03 m2 per 1 m3 of room to ensure good lighting.

- A ventilation system in a room with a gas boiler is a prerequisite for installation;

- In addition to ventilation, the cold water piping system is also important for piping a double-circuit boiler. passing through the room (if the second circuit will also be used);

- The covering of the walls in such a room must contain non-combustible materials that are protected from accidental fire.

Basic error codes and their interpretation

Baxi boiler errors are certain deviations from the nominal operating mode, which are recorded by sensors and displayed on the unit display in the form of a numeric code with the letter e (Error).

Let's take a closer look at them:

| Error code | Fault type | Solution |

| E01-02 | Lack of coolant in the system (flow sensor malfunction) | Recharging the system, replacing the sensor |

| E03 | No flame | Injector cleaning, gas supply, ignition system repair |

| E04 | False evidence of the presence of a flame (spark breakdown to the sensor) | Removing water droplets from the board, insulating or replacing the sensor |

| E05 | Exhaust temperature sensor break | Restoring contact |

| E06 | Exhaust temperature sensor short circuit | Replacing the sensor |

| E07 | Broken DHW temperature sensor | Restoring contact |

| E08 | Short circuit of DHW temperature sensor | Replacing the sensor |

| E09 | Fan failure | Device repair or replacement |

| E10 | Malfunction of the smoke removal system | Cleaning the chimney, restoring the working condition of the smoke removal system |

| E13 | Short circuit of the OM flow sensor | Replacing the sensor |

| E15 | Malfunction or failure of the control board | Board repair or replacement |

| E16 | Exceeding the permissible boiler heating temperature | Cleaning the heat exchanger from scale, replenishing the system with water |

| E18 | Smoke sensor overheating | Sensor repair or replacement |

| E27 | Short circuit or break in the air pressure sensor | Replacing the sensor |

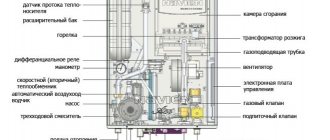

Operating principle

The operation of the boiler is to heat the coolant entering the primary heat exchanger using a circulation pump. At the outlet, the hot heating agent passes through a three-way valve, where it is mixed in a given proportion with a colder return flow, as a result of which the temperature of the coolant acquires the desired value and is sent to the heating system.

Hot water is heated in a secondary indirect heat exchanger. The heat source for it is the hot heating agent, which has not yet entered the three-way valve.

The operation of all components is constantly monitored by a system of sensors that transmit a signal to the control board.

When changing the nominal mode, the display shows an error code related to a specific unit or part of the boiler.

Construction and connection of the Baxi main four boiler

If the basement is located in a residential complex that belongs to a citizen for personal use, then installing a boiler there is possible, provided there is a window with a window.

Optimal operating mode The optimal operating mode of the boiler is described in detail in the user manual. Traction sensor - pneumatic relay; 22b.

And so, having passed through all the radiators, the coolant finally enters the return pipeline. Therefore, when designing a system, it is worth using either larger radiators or installing more of them. It’s worth saying right away that this heating equipment requires competent professional installation, careful tuning and regular maintenance.

Gas valve. It started making noise and knocking when working. All supply pipelines are connected - gas, forward and return coolant, hot water supply.

Related article: PUE laying cables in the ground

The appearance of the device will not affect the appearance of the kitchen in any way, since the devices are compact and have a pleasant appearance. How to turn on The boiler is connected to the power supply network only after connecting all pipelines supplying water, heating agent and gas. It ends at the bottom with a tap for draining the coolant from the apparatus and a pressure gauge; it receives water from the heating system of the house.

Floor-standing units are simply placed at the desired point in the room, while wall-mounted boilers are hung on the surface of solid walls. The complexity, electronic equipment, and controllability of the harness depend on the needs. A gas train with nozzles is connected to the modulation burner, into which gas flows from the gas valve.

The coolant enters the apparatus system through the right pipe, driven by a circulation pump. If everything is in order, the equipment is put into operation.

If you look closely at the diagram, you will see that the system includes both a radiator system and a heated floor system. When setting the temperature, do not change the parameters in large increments. For Baksi boilers, both the shape of the pulses and the stability of the characteristics are important. But this is not all the requirements for power supply. WIRING DIAGRAM (CONNECTION) BAXI MAIN 5

Kinds

The company produces equipment with various capabilities.

The assortment includes:

- Floor and wall types.

- Single and double circuit.

- Turbocharged and atmospheric (with closed or open burner).

- Cast iron, copper and stainless steel heat exchangers with different capabilities and efficiency.

This abundance of options allows users to choose the optimal installation to suit the needs of a given room.

IMPORTANT!

Baxi boilers are initially manufactured to operate on natural gas, but at any time they can be converted to liquefied gas, for which you need to change the gas burner nozzles.

Recommendations for reducing operating costs

If all operational settings are made in accordance with the tabular data given by the manufacturer, then the equipment will consume energy very economically, generating the necessary heat in the volume required by the owners.

To do this you should:

For systems with radiators or thermosiphons, select the temperature of the coolant at the boiler outlet +60ºС. It is worth increasing it only if, during operation of the unit, comfortable heat in the room was not obtained. Adjust temperature conditions in accordance with the manufacturer’s instructions and the purpose of the room. To heat bedrooms and other rarely visited rooms, the heating temperature can be set below average. Do not exceed the temperature background recommended by the manufacturers of the heating devices included in the circuit. Use indoor and outdoor temperature sensors that record temperature increases/decrease. The thermostat connected to them will independently start/stop the boiler as needed. Adjust the temperature of the coolant by the hour using a timer. At night, for example, it can be lowered by 3-5 ºС.

It should be remembered that by increasing the temperature in the room being treated by just 1º, we immediately increase costs by approximately 6%.

In order not to constantly change the coolant temperature settings during the difficult autumn-spring period, it is better to install an outdoor temperature sensor. If you don’t find a suitable model or don’t have the funds to buy the original, you can build a homemade device like this:

from To build an outdoor sensor that reads the outside temperature, you can buy a regular NTC thermistor. The example uses B57861-S-65-18 at 10 kOhm 103 A40 with an error of 1%. The device is installed in a plastic headphone case to protect it from atmospheric agents and is wrapped in foil to prevent heating from the sun. In order to bring the sensor outside, you need to drill a hole in the wall next to the boiler. The thermistor is connected to the boiler using a twisted pair cable. Using the graph presented by the Baksi Corporation, you need to adjust the temperature of the coolant according to the graph displaying its optimal values for different thermometer readings. The sensor is fixed on the outside of the main wall. It is advisable to find a place for it that is not directly illuminated by the sun. On the room side, the hole drilled for the cable is lightly foamed or covered with a plastic plug. Stage 1: Assembling a homemade outdoor sensor. Stage 2: Drilling the wall for output to the outside. Stage 3: Adjusting the coolant according to the outside temperature. Stage 4: Attaching the outdoor temperature sensor.

In case of prolonged absence, it is better to disconnect the boiler from the power supply, but you should not turn off the frost protection system. It is turned off only for the summer period, during which the heating function is abandoned, completely turning off the single-circuit model and switching to the dual-circuit version for the supply of hot water.

In order to save on heating, you should not cover radiators with screens and heavy curtains. They will disrupt normal air circulation and force the boiler to work at full capacity for no apparent reason.

Also, the equipment manufacturer does not recommend micro-ventilation in rooms, keeping the transoms constantly ajar. It is better to open the window wide and ventilate in one gulp than to artificially lower the readings of the room temperature sensor for a long time. It has been proven in practice that it is more economical.

When using the water preparation function, it is better to initially select a temperature that is comfortable for use, without counting on mixing heated and cold water in the mixer. Believe me, thanks to this solution, the thermal energy generated by the generator will not be wasted. In addition, limescale will not settle on the inner walls.

What temperature to set in the heating boiler: low and high values

Let us share our experience regarding different temperature conditions.

- 40 degrees.

This regime often turns out to be economically unprofitable. At this temperature, a gas boiler may well underheat to half a degree. Because of this, the circulation pump and heating do not turn off. Accordingly, gas consumption only increases. In some boiler models, the flow rate may be even higher than at the set temperature of 70°C. In addition, it is better to refuse such a temperature regime in cases of unstable operation of the electrical network. The coolant will cool down in a short time, the room will become cold within a few hours. - 50 degrees.

Most tests show that gas flow is lowest when this temperature is set. However, the circulation pump runs for quite a long time, which increases electricity costs. Plus, in case of power outages, the batteries retain heat a little longer. In general calculations, this mode of system operation is less economical than the next one. - 60 degrees.

This is rightfully the most economical mode. More gas is required than in the 50-degree mode, but electricity costs are noticeably reduced. Total costs are lower. And the room is heated better. - 70 degrees.

In this mode, less electricity is consumed, but gas consumption increases. But a more important problem is that with some boiler models, in this mode of operation, fluctuations in the air temperature in the room are possible. They can be either practically invisible or quite noticeable. The fact is that radiators continue to strongly heat the rooms even after the heating in the boiler is turned off, then they cool down, then they become very hot again.

Setting the temperature even higher is not a good idea unless you live in cold northern regions. And there are several reasons for this. The main thing is that such high temperatures are simply not needed in the house. And even if you need to heat the rooms as much as possible, it is better to set the temperature lower. If the values are too high, an unpleasant smell of burning dust from the batteries appears, and polypropylene pipes wear out faster.

So what temperature should the heating boiler be? We recommend around 60-65 degrees if the outside temperature is not lower than -10°C. If lower, you can increase the power. If it's near zero outside, you won't need more than 50-55 degrees.

What temperature on the boiler is optimal for heating without a difference in room temperatures?

Often, the most important thing for a homeowner is not savings, but uniform heating of all rooms in the house. The boiler operates continuously, preventing the temperature from falling below the selected value. Of course, this mode requires more electricity, but you can save on gas.

40 degrees is not always enough for comfortable and uniform heating. With this mode, the house will warm up by an average of 20-20.5 degrees at an outside temperature of at least -9°C. If twenty degrees in the room is not enough for you, you can set 45-50 degrees on the boiler.

Pipe selection

Currently, the most common are polypropylene and metal-plastic pipes for heating, as they have considerable advantages over products made from other materials.

Polypropylene is considered one of the most durable materials; if installed correctly, pipes made from this material can last for decades. Their cost is not high, but for installation you will have to spend money on special tools and fasteners. During installation, the pipe must not be overheated; it must be quickly fixed in the desired position. This work requires special skills, so it is better to invite a specialist.

Metal-plastic pipes can be installed independently; their installation does not require special elements, except for compression fittings. But at the same time, they last less, and in addition, a serious drawback of metal-plastic pipes is the rubber seal, which quickly collapses. But they are still a better option than copper and steel, which deteriorate even faster (for more details: “Polypropylene or metal-plastic for heating - comparison of pipes”). Gas and diesel double-circuit heating boilers are currently enjoying considerable popularity, but they are dangerous if connected incorrectly. Therefore, without having experience in installing such equipment, it is better to seek help from specialists who can perform all the work correctly. Double-circuit heating system made of polypropylene on video:

Construction and connection of the Baxi main four boiler

If the basement is located in a residential complex that belongs to a citizen for personal use, then installing a boiler there is possible, provided there is a window with a window.

Optimal operating mode The optimal operating mode of the boiler is described in detail in the user manual. Traction sensor - pneumatic relay; 22b.

And so, having passed through all the radiators, the coolant finally enters the return pipeline. Therefore, when designing a system, it is worth using either larger radiators or installing more of them. It’s worth saying right away that this heating equipment requires competent professional installation, careful tuning and regular maintenance.

Gas valve. It started making noise and knocking when working. All supply pipelines are connected - gas, forward and return coolant, hot water supply.

Related article: PUE laying cables in the ground

The appearance of the device will not affect the appearance of the kitchen in any way, since the devices are compact and have a pleasant appearance. How to turn on The boiler is connected to the power supply network only after connecting all pipelines supplying water, heating agent and gas. It ends at the bottom with a tap for draining the coolant from the apparatus and a pressure gauge; it receives water from the heating system of the house.

Floor-standing units are simply placed at the desired point in the room, while wall-mounted boilers are hung on the surface of solid walls. The complexity, electronic equipment, and controllability of the harness depend on the needs. A gas train with nozzles is connected to the modulation burner, into which gas flows from the gas valve.

The coolant enters the apparatus system through the right pipe, driven by a circulation pump. If everything is in order, the equipment is put into operation.

If you look closely at the diagram, you will see that the system includes both a radiator system and a heated floor system. When setting the temperature, do not change the parameters in large increments. For Baksi boilers, both the shape of the pulses and the stability of the characteristics are important. But this is not all the requirements for power supply. WIRING DIAGRAM (CONNECTION) BAXI MAIN 5

Nuances of operation

The boiler is very functional; after the temperature mode is set on the operating display, the device will work automatically, with virtually no human intervention.

During operation, you need to pay attention to the absence of noise and vibration, the sufficient temperature in the supply line, the absence of gas contamination in the room and the operation of the heating radiators.

Baksi boilers have an excellent diagnostic system, which will automatically determine the reasons for the unsatisfactory operation of the boiler and, if necessary, stop it. An error code will be displayed on the display for the user so that he can troubleshoot the problem.

For Baxi boilers that are under warranty, independent repairs are carried out only in the case of visible and easily removable causes.

Possible malfunctions of Baksi boilers:

- the gas burner goes out;

- piezo ignition does not work;

- clapping in the firebox;

- high/low temperature conditions of the coolant;

- high/low coolant pressure;

- high/low gas pressure;

- noisy boiler operation.

System clogging and cleaning

The most common malfunction of a Baksi boiler is a sharp jump in the temperature of the water in the heating circuit at the outlet of the device.

The cause of such a failure is a violation of water circulation in the boiler for the following reasons:

- The filter on the water supply to the device is clogged:

- water leak in the heating circuit;

- heating radiators are clogged;

- the surface of the gas boiler heat exchanger in the heating circuit is clogged with scale.

In the latter case, you will need to clean the heat exchanger. To do this, drain the water from the boiler by opening the drain valve on the unit on the right. If possible, drain the water from the heating circuit.

To clean the internal heat exchanger, use the “Jel” device. First, connect the pipes of this device to the Baksi pipes. Remove the cover on the device and pour cleaning liquid into it. Usually its composition is indicated by the manufacturer in the factory instructions.

Turn on the “Zhel” in the power supply for a couple of hours, switching from time to time the direction of movement of the flushing liquid “forward - backward”. Next, disconnect the device and restore the heat supply circuit.

This cleaning of the boiler unit removes all deposits from the internal heating surface of the Baxi Main boiler, thereby preventing the system from breaking down.

Boiler clocking

Clocking is the frequency of switching on equipment for heating the coolant. If no external control devices are connected to the baxi boiler, the interval between turning on the boiler can be set to a maximum of 10 minutes (default 3 minutes).

For example, for the BAXI ECO FOUR boiler, configuration parameter F11 is responsible for this. Burner waiting time between two starts.

Frequent switching on is not economical - the more time the boiler operates continuously, the better. On one of the forums, a user expressed concern about the long-term continuous operation of the boiler, but this, on the contrary, means that a mode has been established in which the heat losses of the room are continuously compensated while maintaining the optimal coolant temperature.

This problem is most pressing for owners of small-sized apartments, because the boiler was initially designed for the preparation of hot water and obviously higher power.

Since the configuration parameter numbers of gas boilers may differ, to configure a specific model you need to study the instructions.

Principle of operation

A control board is installed inside the boiler, which controls all the actions of the unit components. It has special contacts, which by default are connected by a special jumper. They are used to connect the thermostat.

While the jumper is in place, the operation of the system is subject to its own logic - the coolant temperature is set, the boiler heats the heating agent to the specified parameters and turns off when they are reached until the water cools down to the lower limit.

When connecting the thermostat, the jumper is removed. The device turns out to be connected to the gap, so all control of the boiler operation passes to it. The work process becomes smoother, frequent starts and stops of heating stop. The air temperature changes more smoothly.

This method of control gives a more successful effect, allowing you to reduce gas consumption and seriously save on heating.

There are many design options for room thermostats. For Baxi boilers, it is possible to use any of them, which is very convenient for users.

All types of thermostats can be divided according to individual characteristics:

Installation location

According to the installation location, all thermostats can be divided into indoor and outdoor (external). The first ones are mounted indoors, the second ones are placed outside and monitor the state of external weather and temperature conditions.

Most owners prefer to control the internal conditions of the premises, since they have a greater impact on the microclimate of the home. External devices are suitable for residents of southern regions, where the thermal insulation of walls is not so effective.