Quite expensive and not all models of heating boilers are equipped with a GSM module. However, you can purchase it and connect it yourself, both to expensive and to the most budget models. The main thing is that the boiler must be able to connect external control, which, however, is the norm for almost all modern boiler units.

The cost of the device is on average 4-7 thousand rubles, which is quite a lot and comparable to good programmable thermostats, which are a more modern solution. However, GSM boiler control involves transmitting commands from anywhere in the country where there is cellular communication, while the thermostat’s coverage area is limited to the house itself or the range of home Wi-Fi. Therefore, the additional installation of a GSM module today is still more than justified.

Design and principle of operation

The gas boiler is controlled via GSM using a small-sized GSM module. Of value are universal devices that can interact with several models of units, for example, the domestic Telemetrics module is capable of functioning with a dozen boiler units of Russian and Western production. The module organizes the transfer of data on the performance of the unit and thermal conditions in the house using SMS messages or through software applications.

The GSM agent performs remote control of the boiler operating modes, so the house will be heated with a preset internal air temperature when the residents arrive, and in their absence, the rooms will be heated in standby mode. The advantage of such control is that it is implemented by one responsible person, using constant access to the current operating parameters of the heat supply system.

The installation of a GSM thermostat is capable of taking over control of the thermal processes of the boiler, and user access to it is possible from any region of the planet equipped with mobile communications. Modern gas boilers are a complex of complex interconnected systems; incorrect regulation of even one parameter will cause an emergency when operating expensive equipment.

Modern units are produced non-volatile. Even if the owner receives a signal that the power or water is turned off in the house, he will be able to quickly respond online to prevent accidents.

Expert advice: how to protect yourself from controller breakdowns

Repair of control units for gas boilers is not a common occurrence. However, before purchasing equipment from a certain manufacturer, ask if there are service centers in your region.

To protect yourself from troubles at the wrong time, you should, with the help of specialists, inspect the boiler before and after the heating season. A network voltage stabilizer will help protect the electrical controller from pressure surges, thereby protecting the device from damage.

You can prevent possible damage to the control unit the first time it is put into operation. The unit system is complex and fragile in its own way; settings may be lost during transportation or assembly of the equipment. Therefore, during installation, they first carefully check all the subtleties associated with the wiring, water and gas supply, and then check the operation of the CU sensors.

The latest models of controllers have been brought to almost complete independence. The gas boiler control unit reports faults using indicators, as can be seen in the diagram below.

If you notice any failure, even a minor one, it is better to immediately call a boiler service specialist, this will prevent a serious breakdown and save yourself from more serious problems.

Heating appliances are often the subject of experiments, which result in towel dryers for example. At a technology competition in 2007 in the United States, among the various designs one could see a radiator in the form of a rack of hangers, designed in the shape of a chair with a heated seat.

Modern home heating equipment is as convenient as possible for users. Having set the necessary parameters for the device, you do not need to constantly monitor its operation, relying on the automatic mode. And timely diagnostics of heating devices will allow you to avoid troubles due to incorrect operation or breakdowns.

An example of installing the controller can be found in the video:

Rating: Manufacturers and models of GSM modules

A mobile phone can be used as a remote control in a remote access system. To do this, just insert the SIM card into your mobile phone and connect it to the boiler.

Each device contains instructions for use, as well as instructions for installing the module

To purchase such a module yourself, it is recommended to pay attention to the rating. It presents a selection of models for home use from various manufacturers. In addition to them, devices from the companies Wolf, Baxi, Buderus, Navien, Protherm, Vaillant are considered good products.

"Kotel OK"

The most popular on the market, one of the best and most inexpensive GSM modules for heating boilers made in Russia. In addition to the price, it is distinguished by its compact size, extremely simple and easy setup, and the presence of an application that can send commands, including in the form of SMS, which is an excellent option that allows you not to use tariffs with Internet access.

The functionality of the device is quite simple, the minimum required: temperature control, setting alerts, checking boiler operating parameters, and the module also has a built-in relay that allows you to turn the boiler on and off.

Among the disadvantages, it is worth noting a rather simple application with the minimum required functionality and an outdated interface, the presence of an external temperature sensor with a cable length of only 0.5 meters, which does not imply its installation in other rooms remote from the boiler room. The antenna is also not remote, screwed into the device via a threaded connection.

Cost: 3,990 rub.

XITAL GSM 4T

Another well-known, more professional and versatile device with a much richer package. The heating control functionality in it is approximately the same as in the previous “Boiler OK” - the minimum required, however, there are as many as 4 zones for additional devices (flow sensor, smoke sensor, motion sensor, flood sensor, door opening sensor, etc.). Also included is an electronic key and a reader (similar to those installed in intercoms), so you can influence the settings, if desired, only with an electronic key.

The main difference is the presence in the kit of two remote temperature sensors with a wire length of 10 m, as well as a remote wired antenna and a cord for connecting a backup external battery (unfortunately, there is no built-in one). Management and control can be carried out both via SMS and through the application.

The disadvantages, in addition to the lack of a built-in battery, are the ineffective and inconvenient, although understandable, application interface, less attractive appearance with exposed terminals and large dimensions. Please note that for heating you must choose a model that has a “T” at the end.

Cost: 8,640 rub.

EVAN GSM CLIMATE

Also known as ZONT H-1, it features a more modern and convenient application, with ready-made “Economy” and “Comfort” modes, as well as the ability to program boiler operating parameters. It is enough to configure the boiler operating pattern once and the module will automatically issue commands to the boiler to change parameters depending on the time or day of the week. Control via a web interface is also available. The standard package includes one remote temperature sensor and a remote antenna.

Perhaps the only drawbacks are the lack of a built-in battery and only one contact for connecting an external temperature sensor.

Cost: 6,780-8,840 rub.

ZONT H-1V

A more advanced analogue of the previous GSM CLIMATE (ZONT H-1). Despite its less attractive appearance, it has an additional “Anti-Freeze” mode and a built-in battery for autonomous operation during power outages. Number of connected temperature sensors – up to 10 pcs.

Otherwise, due to the same firmware, everything is similar to the previous model: the same control via SMS, application or web interface, which, by the way, is one of the most convenient and functional, with statistics. The kit still includes one remote temperature sensor and a remote wired antenna.

Cost: 7,400-9,200 rubles.

Installation recommendations

A simple automated unit for monitoring and controlling a heating system of the XITAL type can be installed with your own hands if you carefully understand the operating instructions. Mounting the device and installing the sensors is not particularly difficult, as is their connection. The included cables are long enough to carry the sensors throughout your home. But there are nuances that must be taken into account when organizing heating control.

The first is the presence of good GSM coverage at your place of residence. It happens that in one place there is coverage from several cellular operators, but none of them works reliably. In this case, KCITAL is equipped with two slots for SIM cards to duplicate messages. The second caveat is that before inserting the SIM card into the slot, you must contact the operator and disable the sending of any advertising content in the form of SMS. Such messages arriving at the device number may cause malfunctions in its operation.

Advice. It is better to purchase a new SIM card for the heating control unit with a “clean” history of use.

The same recommendations can be given regarding devices that interact with the owner via the Internet. The cable connected to the LAN input should not come from a router or modem powered by a 220 V network. Otherwise, if there is a power outage, the communication channel will also be lost. The devices themselves must always have their own battery, which can ensure their operation for at least 3 days. Detailed recommendations for installing XITAL can be obtained by watching the video:

Which heating systems can be controlled remotely

There are practically no system restrictions on the types of heating equipment in order to implement GSM boiler control. The only restrictions are related to the fuel on which the unit runs. This control model is suitable for gas, liquid fuel and electric boilers that have the technical ability to establish a 100% level of automation. Units operating on solid fuel, due to the inertia of thermal processes in the furnace, do not yet have such a level of regulation.

Modern country houses are most often heated using a closed two-pipe heating circuit with floor and room heat control. This is achieved through the use of a circulation pump and a hydraulic boom. The heat supply complex is equipped with a reliable protection module that works with several emergency sensors: gas pressure, flame separation from the burner, unacceptable coolant temperature, pressure limit in the heating and gas mains.

Heating control via GSM - control systems provide:

- Standard temperature operating conditions, maintaining sanitary temperature in the house;

- zone heating: children's room, bathroom, bedroom, living room, kitchen, utility room;

- standby heating to preserve pipes with a water medium from hypothermia during the cold season;

- pre-heating of the facility before the arrival of residents or their guests;

- mode with a daily breakdown of heating quality, which is more preferable: night-day.

The most common breakdowns in the control unit

Since the control unit is a whole system, a failure can occur from any deviation of a component of this system. The most common malfunctions and their causes :

- the burner went out - air got into the gas pipeline;

- heating problems - poor gas supply, lack of oxygen;

- boiler overheating - closed contacts, prolonged operation at high temperatures, factory defective sensors;

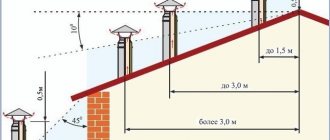

- breakdown of the pneumatic relay (draft sensor) - incorrect connection, fan breakdown, incorrect smoke exhaust system;

- breakdown of the temperature sensor - incorrect connection of contacts, short circuit, overheating of the board;

- breakdown of the pressure switch - low water pressure in the pipes, defective contacts in the circuit board.

Most of these problems are easily fixed, even described in the instructions, but some require the intervention of a specialist.

You should not replace sensors or other parts yourself - this can be dangerous.

Control Features

This scheme allows for weather-dependent control of home heating. Today, this direction is the most promising in the household energy sector, as it allows you to save significant amounts of energy and finances.

To implement it, an additional sensor for external control of air temperature is introduced into the circuit. A weather-dependent controller, working with two temperature sensors - external and internal air, provides finer control of heating processes, which reduces the level of system inertia and low specific costs for generating one unit of thermal energy.

To implement the mobile system, programs have been released to control a gas boiler via smartphones running both Android and Apple software. They present the user with the entire process of controlling the boiler unit as completely as possible, with visual effects and good graphics. For Java devices and simple phones, the scheme operates by sending SMS. Installation of the GSM module can be performed by a trained user, following the factory recommendations. In addition, it is possible to contact the service department of the manufacturer of such devices for advice.

If a mansion or house has a stable Internet connection with a Wi-Fi router, then it is more practical to install remote control of the boiler unit via a PC. Why will you need to use special equipment? equipment:

- Internet gateway connected to the router;

- receiving device on the boiler unit;

- 2-channel thermostat with mode programmer;

- boiler remote control via GSM.

This control scheme allows:

- Perform adjustments to the operating modes of the unit and additional equipment.

- Install zone-by-zone adjustment.

- Set the DHW temperature.

- Adjust the operation of the air conditioner.

- Launch energy-saving modes of equipment operation.

- Perform remote control via an internal communication line between primary devices and signal receivers.

Additional Information! To implement a GSM regulation scheme via the Internet, you will need a computer or any mobile devices with GSM transmission capabilities that will transmit signals through a router that communicates with primary sensors and a control receiver.

Popular models according to user ratings

The availability of a convenient option has created the preconditions for creating demand for new equipment that can solve many problems. The offer was not long in coming and many companies appeared on the market offering their equipment for sale. The following manufacturers received the greatest fame due to high consumer ratings:

- Vaillant;

- Wisman;

- Buderus;

- Protherm;

- Navien;

- Kiturami;

- Evan;

- Xital.

The list of VIESSMANN products includes heat generators in which adapted units are installed that can interact with boiler control controllers. Also different is the equipment, which is equipped with the latest algorithms that increase the reliability of cascade control.

Plus, the devices of this company are designed to duplicate the system using an additional network; they have the ability to install an additional SIM card.

Options for controlling the boiler via smartphone

Three solutions are available for remote control of a domestic gas boiler:

- GSM module connection;

- use of a “smart thermostat” via WI-FI communication;

- installation of thermostats.

Each remote control method is good in its own way, and its choice depends on several factors: availability of the Internet, gas boiler model, financial capabilities.

Let's consider all three options - one of them may suit you, and as a result of a partial upgrade, managing the heating system will become much easier.

Option #1 – connecting the GSM module

This is the most common solution, applicable even in areas not covered by the Internet.

The gas boiler is controlled using a GSM unit - a compact controller module. A SIM card is inserted into it, which personalizes the owner and makes it possible to keep in touch with remote equipment

In order to save money, the homeowner can choose the most suitable cellular operator and favorable tariff.

The GSM module is programmable and its operating principle resembles a computer with limited functions. This block is connected to sensors installed both in equipment and in the environment - in rooms, on the street. Depending on the parameters produced by the sensors, the gas unit automatically changes the program or is controlled from a smartphone.

To communicate with the control unit installed in the house, you will need any electronic device - a laptop, tablet, but it is most convenient to use a smartphone, which is more compact and versatile

For ease of control, selection of modes and programs, developers have created applications for various operating systems: iOS, Android, Windows Phone.

There are several modes by which a gas boiler is controlled:

- Fully automatic control. The unit operates according to the specified parameters entered into the program in advance. If changes are required, the program should be adjusted.

- Transmission of alarm notifications in the event of emergency or repair situations. If there is a gas leak or the boiler suddenly stops working, a signal is sent to the smartphone.

- “Communication” using SMS messages. There is a list of commands that the automatic gas boiler recognizes and then makes changes to the operation of the equipment.

- Advanced management options. Using a special program, you can control all systems connected to the GSM unit.

The advantage of remote control via mobile communication is considered to be almost constant control and unlimited possibilities, depending only on the selected application and installed equipment.

A few more advantages of using a GSM module:

Image gallery Photo from Depending on the modification of the unit, you can connect several mobile phones to the module, and then from 2 to 10 people will be able to monitor the operation of the unit. In addition to the gas boiler, sensors installed in various rooms heated by the boiler can be connected to the module: in the kitchen, in the hall, bedrooms and even in the basement or attic In addition to the controller, key reader, antenna, sensors and power supply, you can connect a microphone, gate control unit and other “smart” devices By installing temperature sensors outside, you can set automatic mode changes depending on weather conditions Monitoring the operation of the boiler by all family membersConnecting additional sensors to the program Possibility of connecting basic or extended configurationsAutomatic operation of “weather” sensors

Problems can happen if the cellular connection is poor. The homeowner needs to carefully monitor the expenditure of funds - if the balance is negative, the ability to control the heating equipment will be interrupted.

Option #2 - using the Internet

If the Internet network extends to the area with your country home, then you can control the gas boiler using it.

A WI-FI router is installed in the house, and an Internet thermostat is connected to the boiler equipment. He is the link between the owner of the building and the heating equipment

As soon as the temperature in the room drops below normal, the sensor transmits a signal to the receiver, which interacts with the boiler and turns on the desired heating mode.

The user can control the entire process from a smartphone, monitor changes, and make adjustments. The provider acts as an intermediary between the home owner and the equipment. For continuous communication, it is important to provide access to the Internet both in the home and at the user’s location.

The advantage of the system is the unlimited number of gas boiler sensors - the heating level can be adjusted in all areas served by the building’s heating system.

As with remote control of a gas boiler via a GSM module, the homeowner can control the heating process remotely and make relevant changes. It is possible to install a program that changes the boiler operating mode depending on the time of day, days of the week, and season.

Thermostats, the operation of which depends only on the stability of the Internet connection, are different, but their operating principles are similar.

Ready-made devices that allow you to control your heating boiler via the Internet

Owners of heating systems are well aware that there is a fairly large selection of special room thermostats on sale. With their help, you can both maintain the desired temperature in the room and control the heating boiler via the Internet.

However, all these devices are quite expensive and cost a tidy sum, often exceeding 10 thousand rubles. Due to their high cost, these devices have not yet been able to gain a sufficient level of popularity.

The function included in these devices is very useful for owners of dachas and country houses. It allows, for example, to warm up a cold house before the owners arrive.

In addition, these devices allow you to keep the heating system in a non-freezing state. They make it possible to maintain a specified minimum temperature, at which the coolant is guaranteed not to freeze.

The described function is very useful. But not all home owners can take advantage of it. The reason for this is the high cost of the relevant equipment.

Below we will talk about how this function can be implemented without installing expensive equipment. The proposed system is not as perfect as ready-made analogues, but it is reliable and not at all expensive. It will cost about one and a half thousand rubles. And its versatility guarantees the ability to control any heating device. Its diagram is presented below.

When Internet Control is Selected

If you have internet at your dacha or home, you can control the boiler remotely using a Wi-Fi connection. This type of system works without problems with intelligent automation - based on microprocessors/controllers. To work with mechanics, you need to look for special models (one of the domestic ones with a good reputation and not a very high price is “Xital”).

Installation of a heating control system via the Internet

To be able to control the heating boiler remotely, it is necessary to install additional equipment:

- special receiver;

- Remote Control;

- room two-channel (or with a large number of channels) thermostat with a programmer that regulates and sets temperature conditions.

You can program the system while in the house - using the remote control, or from a distance - using a computer or smartphone with an installed mobile application. It can be installed on a smartphone, PC, laptop, tablet. The system in these devices is of any type, the system requirements are extremely low.

“Communication” between the control unit and the shut-off and control equipment occurs wirelessly. That is, during installation, you will not have to connect the unit and thermostats with wires. But you will have to run wires to the temperature sensors - internal and external. They rarely work wirelessly. If you choose to control the boiler via the Internet, allocating an IP address is rarely required.

For control, you can use any mobile device or personal computer with Internet access

The possibilities for controlling a gas heating boiler via the Internet are quite extensive. This:

- remotely set temperature in the house via SMS;

- remote adjustment of the functioning of both the gas boiler itself (and any boiler with a controller) and the circulation pump;

- the ability to change temperatures for individual zones (the number of zones depends on the location of the sensors);

- remote control of the operation of hot water supply systems (double-circuit boilers);

- possibility of remote monitoring of heating status;

- the possibility of energy saving - while you are away from home, you can set the temperature to, say, +8°C, and an hour or two before returning, give the command to increase it to +23°C.

This is the “core set” of capabilities. You can find an improved version with an Internet gateway, which makes it possible to remotely control some of the auxiliary devices: electric convectors, oil radiators, etc. Some models also allow you to connect fire protection systems, which is most important for owners of wooden houses.

Mobile GSM control

To establish remote control of the heating system, a convenient device is used - a GSM module. One or two SIM cards with different (and, preferably, new numbers) are installed in it. Two numbers are a good solution in conditions where there is coverage from two mobile operators, but the signal is not strong enough.

GSM heating boiler control is possible using SMS

Jiesem heating module is an alternative option for remote control of a gas boiler via the Internet. Turning on and controlling the heating temperature via SMS has its advantages:

- compactness of the device (small unit in the house and a smartphone);

- mobility - the ability to install in any place convenient for you;

- ease of use;

- the ability to use two different networks from two different mobile operators for communication simultaneously (models for two SIM cards).

In order for the phone to turn into a kind of remote control, which is part of the “smart home” system, you will need to install a special mobile application. They are available for devices running on the following base:

- Android;

- Windows Phone;

- iOS.

GSM heating boiler control works with units controlled by a controller.

The application is easy to install and configure. Depending on the user settings, the user will receive data from the GSM module in the form of SMS or voice messages. At the same time, it is possible to set up such control from your phone through a cloud service. Specific recommendations and configuration options are in the description and they may have some differences between different manufacturers.

How to choose a GSM module, what should you take into account?

Devices running on the Gsm platform can be purchased both in city stores and on well-known trading platforms such as Aliexpress. Before buying such a module, you should decide what capabilities are expected from it? For example, whether the length of the antenna cable to be connected is important, as well as how many telephone numbers can be used at the same time. When choosing a module, you should consider the following factors:

- number of control zones;

- availability of outputs for connecting sensors of different purposes;

- the ability to expand functionality by updating the device’s firmware;

- the presence of a relay through which feedback is provided;

ability to monitor temperature and send readings to a mobile phone

A good module has adjustable temperature modes and response thresholds.

With its help, you can remotely control the operation of the boiler and make changes to the temperature. A high-quality device will make it possible to change power indicators, and will also instantly send an SMS notification about the activation of emergency sensors.

How to connect?

To connect and install the GSM module yourself, you must use the instructions included in the kit. Installation and startup of the device occurs as follows:

- De-energize the heater.

- Remove the protective casing from the boiler.

- Secure the module mount to the wall.

- Insert a SIM card and battery into the module, if necessary.

- Connect a gsm-based controller to the connector located in the boiler.

- Connect all sensors to the module.

- Connect the device to the network.

- Put on the boiler protective casing.

- Connect the boiler to the electrical network.

It is worth remembering that to work on a SIM card, you need to choose one of the best mobile operators with good signal quality. When the module is connected for the first time, the user needs to send an SMS to the controller’s SIM card with its number.

If the signal is weak, you must install the included antenna

To better understand the connection process, it is recommended to watch a detailed video to avoid mistakes.

Gsm modules work perfectly with both electric and gas boilers; they can also function with exhaust models. The boiler itself must have an output for connecting the controller. This device helps save energy consumption and greatly simplifies the process of controlling the heating device.

Programmers and thermostats are the main heating control elements

Heating programmer

To organize autonomous heat supply, you will need electronic devices. They may have a heating boiler control panel and the ability to simultaneously change steam meters in several connected components.

These devices are called programmers or electronic thermostats. Like other similar devices, they can have heating control via SMS or the Internet. But these are just additional functions. To select the optimal model, you need to know the basic functional qualities of the programmer:

- Number of connected circuits . Can vary from 1 to 12. An additional module is installed to increase the number of connectors;

- System operating modes . Depending on the settings, you can set the control of heating radiators in economy, normal and comfortable modes;

- Plug-in module – heating control by phone . The GSM station transmits the required information via SMS - coolant temperature, emergency mode notification, etc.;

- The presence of radio transmitters to create wireless communication channels between connected heating components.

Collectively, the installed equipment is called the heating control frame. It may consist of components with different functionality. The purpose remains the same - the ability to automatically or semi-automatically change heat supply parameters.

Connecting the programmer to the boiler

But in addition to local devices, there are also zonal ones that are installed on specific components - boilers, radiators. By controlling heating via the Internet using these devices, you can regulate the degree of water heating in the system and the temperature regime in a specific battery. Often such devices are called not programmers, but electronic thermostats.

They are more affordable and easy to install. Thermostats do not require a heating control cabinet, which reduces the complexity of installation. In some cases, it is possible to connect several thermostats to a single control unit.

What should you consider when creating a smart heating budget? In addition to the cost of the control element, you need to know the approximate price of consumables - communication wires, heating control panel. The latter is necessary when installing a system consisting of several blocks - a programmer, a GSM module, expansion strips for additional contactors.

| Model | Purpose | Cost, rub. |

| Computherm Q3 | Wired thermostat | 1625 |

| Computherm Q3 RF | Wireless thermostat | 3367 |

| PROTHERM Kromschroder E8.4401 | Programmer. Control of 4 boilers, DHW, 15 heating circuits | 34533 |

| Heating control panel | RCD, boiler control units, connection to temperature sensors | From 7000 |

It is also important to consider the location - the heating control box should be installed in an accessible place. Its installation in a boiler room is not recommended, although this is the simplest option in terms of labor intensity. It is best to install it in a living room. Then it will be possible to monitor and change system parameters much more often.

Programmer models differ in the number of connected system components. They are called control circuits.

When is a module needed?

A GSM module for controlling the boiler is required when the owner of the house is away for a long time, provided that it is necessary to maintain a certain temperature or turn on the heating in a timely manner.

The most common situations where this is necessary include the following:

- Long departure . The owner of the house goes on a business trip or vacation. In this case, you cannot completely turn off the heating - the system will freeze. At the same time, there is no one to operate the boiler at home.

- Cottage with heating system . If a heating system is installed in a country house, then when the boiler is turned off during the cold season, it will freeze. To prevent this, you can drain the system. But then it will be impossible to come to the dacha in winter because of the cold in the house. The solution to the problem is to remotely maintain a low positive temperature to prevent freezing using a GSM module.

Tips for organizing remote heating control

Diagram for connecting modules to the heating control unit

In most cases, you can make a cottage heating control system yourself. This is only possible with the correct selection of system components. Those. First you need to analyze the condition and capabilities of the already installed equipment.

The classic heating system control unit diagram has one control unit, which is connected to all heat supply elements. The programmer must meet the following requirements:

- The number of connected terminals and their configuration must coincide with similar communication nodes of the boiler and thermostats. Otherwise, heat supply control via SMS will be impossible. If necessary, adapters are purchased;

- Maximum distance of the user from the control unit. If this distance does not exceed 300 m, you can purchase models with mine control. To increase the communication area, it is recommended to use heating control via a mobile phone or the Internet;

- The ability to independently (or with the help of specialists) set additional operating parameters. This is done with a controller based on heating control boards;

- Connecting an autonomous power supply unit. To do this, you need a sufficiently large heating control box. This parameter is taken into account when choosing the installation location of the control unit in the house.

What boilers does it work with?

Before purchasing a module, you need to find out whether the heating boiler supports the connection of such a device. Not all models have such support.

Autonomous systems with forced circulation of coolant (that is, equipped with a pump) are suitable for connecting the device. In this case, it is necessary to rework the safety system in order to prevent breakthroughs at the points where the module is connected.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

If the module has an air temperature sensor, then it can be used with other types of boilers. However, due to measuring t outside the system, it will work a little less accurately.

Features of operation in various types of boilers

The device has specific operation in different types of heating systems:

- When used in electric boilers, voltage monitoring is possible. The device can also signal a short circuit.

- When used with several boilers at the same time, the device can summarize information from them. This is relevant when used in production or in utility rooms.

- In pellet boilers using wood pellets, the module can regulate the fuel supply to the system.

Modulating burners, OpenTherm protocol and weather-compensated automation

Today, the most modern and technologically advanced heating control systems are devices operating under the OpenTherm protocol.

Without going into highly specialized details, we will consider three main features that distinguish equipment with OpenTherm from the one described above.

Feature one: flame modulation control

The emergence of new gas boilers with burners capable of controlling flame modulation has opened up new opportunities in organizing economical and efficient heating. Let us explain that flame modulation is the regulation of heating power. If the power is too high, the boiler switches on and off frequently (clocking), and if the power is low, achieving the set temperature becomes impossible. Those. The best flame modulation is considered to be the combustion level at which the boiler does not turn off and the set temperature value is reached. In other words, flame modulation control is the ability of the boiler automation, depending on external conditions, to optimally change the burning intensity of the burner flame without turning it off. None of the boiler control methods described above can control flame modulation. To work with the new burners, the OpenTherm protocol was invented, which made it possible to effectively combine the functioning of the new burners with the capabilities of “smart” weather-dependent automation and electronics.

Feature two: working with automation

In essence, OpenTherm is a bridge that has been built between boiler manufacturers and manufacturers of other electronics and automation. A single protocol that does not depend on anyone standardly describes all the basic commands for working with modulating burners. This allows you to connect a wide variety of equipment to it: from a thermostat to programmable temperature controllers, to which a large number of temperature sensors can be connected. Modern thermal controllers are programmable devices that are able to process the readings of temperature sensors located both in various zones of a heated facility and on the street. The heat controller maintains a set target temperature value and can change it depending on user commands, time of day or day of the week. Analyzing the received temperature data outside and inside the room, the controller sets a weather-dependent operating mode for the modulating burner of the boiler and pumps (see Fig. 3).

Fig.3. Temperature regulation using the Teplocom Cloud heat informer

On the graph we can see that the burner practically does not turn off, but only changes the intensity of its combustion. At the same time, regardless of external conditions, the target temperature graph changes extremely slightly and lies within the hysteresis limits of the heating system. Additional advantages of this control system are a noticeable increase in the burner's operating life (there are no ignition, rapid heating and cooling cycles), and significant savings in gas fuel are achieved.

Feature three: access to automation settings and error logging

The presence of “smart” control and the existence of feedback between the boiler and the control equipment opens up the third feature of the OpenTherm protocol - the ability to get full access to the boiler automation settings using one protocol and change them from any control device (smartphone). Additionally, access to information about all errors that occurred during the operation of the thermal system is opened, which provides an invaluable tool for personnel servicing and monitoring the operation of the equipment.

pros:

- Minimal fluctuations in air temperature in the house, regardless of the temperature outside, which ensures maximum comfort;

- Minimum fuel consumption compared to other control methods;

- The temperature is adjusted by changing the modulation of the burner flame, which minimizes the number of on/off cycles;

- Possibility of remote monitoring of the boiler condition and changing its settings.

Minuses:

- Higher price compared to other equipment, which is compensated by lower gas consumption.

Basic automation functions

The main purpose of automation in heating systems is an instant response to changing situations. One of the main tasks of automatic control devices is to stop the supply of gas to the work area. Situations in which it may be necessary to cut off the supply of household gas may be the following:

- poor operation of the exhaust device, deterioration of draft, in which there is a high probability of harmful combustion products entering the interior;

- sudden changes in operating pressure in the main gas pipeline;

- unauthorized flame extinguishing on the main burner.

In these situations, it is thanks to the automation of the gas boiler that the supply of gas fuel is controlled, which ensures the safety of residents. It is for safety reasons that, in accordance with existing standards, it is necessary to equip all old models of gas heating equipment with automatic systems, the standard equipment of which did not include equipping with these devices. As for the latest gas heating units, these are boilers with automation.

Main article: DIY gas burner.

Heat informator TEPLOCOM CLOUD

In this article we looked at the main ways to control a heating boiler - from manual to automatic, using modulating burners with OpenTherm. One of the modern devices that are capable of implementing the latest technologies for controlling the heating system is the TEPLOCOM CLOUD . This is an electronic device whose expanded functionality goes far beyond simply maintaining a stable temperature in the house. Based on “cloud technology”, it implements a mechanism for transmitting information from connected equipment and remotely controlling it via a smartphone.

TEPLOCOM CLOUD - the heat of your home is always under control!

Capabilities of the TEPLOCOM CLOUD heat information device:

- Informing about accidents and the condition of the heating system. Control the boiler via a smartphone from anywhere in the world.

- Constant monitoring of the condition of the gas boiler, the temperature outside and in the house, the temperature of the coolant, the occurrence of leaks, the presence of a 220V network. It is possible to connect contact sensors for additional notification.

- The temperature is controlled depending on the outside temperature using WeatControl technology, which minimizes temperature fluctuations in the house during the day.

- Individual schedule of comfortable temperature for the whole week.

- Possibility of placing up to 10 wireless temperature sensors within a radius of 300 meters.

- Reducing gas consumption by up to 30% and combating harmful emissions into the atmosphere by reducing the carbon dioxide produced.

- Free applications for working with TEPLOCOM CLOUD on Android and iOS.

- The delivery set includes: heat informer, wireless radio temperature sensor, leakage sensor, outdoor temperature sensor, coolant temperature sensor, GSM SIM card, built-in Li-ion battery.

Thanks to WaetControl technology, the heating system is controlled taking into account changes in the weather outside. Which minimizes temperature fluctuations in the house during the day.

Thus, we see that there are a large number of devices that ensure the operation of thermal systems with varying degrees of comfort and efficiency. The choice of the best one, as always, remains with the consumer.

Operating principle of the control unit (controller) for boilers

Controllers are electronic devices that are designed to optimize the control of a gas heating device under changing environmental conditions. The capabilities and functions of different devices differ, but they are united by the presence of pressure and temperature sensors.

Example of controller connection diagram

The electronic gas boiler control unit (ECU) is responsible for the operation of the gas burner, heating of the coolant and the safety of the system as a whole. Its operating principle is based on the use of an electromagnetic valve.

The controllers of the latest heating devices are equipped with an automatic mode function, which allows you to regulate the operation of the device during the week without human intervention.

Connecting the computer to external temperature sensors and boiler control terminals allows you to configure independent changes in the operation of the burner.

For such a controller, it is necessary to install a voltage stabilizer and an uninterruptible power supply to ensure the operation of the boiler during voltage surges in the network or in its absence.

Which thermostat is better to choose?

To make the right choice of a room regulator, we suggest considering the pros and cons of two types of household appliances. Disadvantages of mechanical models:

- low accuracy of maintained temperature;

- wired connection - the cable will have to be pulled from the boiler room to the desired room;

- lack of various convenient functions available in programmers.

Note. Judging by the reviews of real owners on the forums, the accuracy of temperature maintenance is not a critical problem and does not worry users too much. Another thing is the wires that need to be hidden under the baseboards, in the grooves of the walls, and so on.

There are also three obvious advantages of bimetallic thermostats:

- low price and availability;

- reliability in operation - in the simplest models there is nothing to break;

- ease of control of the boiler using one handle, which is important for older homeowners.

The negative aspects of electronic regulators are a higher price, a not always clear interface and the need to timely replace batteries. Cheap Chinese models encounter an additional problem - a breakdown in communication with the relay unit when installing the control panel behind 1-2 partitions.

An absolute plus of digital thermostats is comfortable operation. It is enough to set the weekly and daily operating program for the heat generator once; no further actions are required.

Wireless programmers need to change batteries on time.

We list a typical set of functions using the Baxi Magic Plus thermostat as an example:

- temperature control range – 5…35 °C;

- protection against freezing of the heating system, by default starts the boiler when the home cools down to +3 degrees;

- LCD display with backlight, control – push-button;

- shift of temperature sensor readings ±5 °C (read the explanation in the next section of the publication);

- 2 operating modes – economical and comfortable;

- hourly/daily/weekly programmer.

Reference. Manufacturers often call such devices digital chronothermostats. The weak point of the devices is their low maintainability in the event of a breakdown, especially Chinese products for which it is not easy to find spare parts.

Knowing the features of electronic and mechanical regulators, it is not difficult to choose the appropriate model. Focusing on your budget, first of all consider reliable products from European, Japanese and Korean brands, there are also decent brands, but on average the quality of the products leaves much to be desired.

How to make an automatic control unit with your own hands

You can make a unit yourself based on a conventional thermostat, available in retail chains selling electrical goods.

There are three contacts inside this device - common, open and closed. Their position can be changed by rotating the adjusting knob.

You need to do the following:

- Set the handle to the minimum mark.

- Connect the phase to the common contact.

- Connect one wire from the turbine to the open (open) contact.

- Connect direct zero to the second wire from the turbine.

The solid fuel heating system will operate reliably and uninterruptedly thanks to properly installed and configured automated control devices. You can find out about the fireplace in the apartment by following the link.

Pros and cons of the device

Like almost any technology, the GSM module has a number of advantages and disadvantages. Although, of course, it has more advantages, thanks to which the device is becoming increasingly popular among domestic consumers.

This is facilitated by the development of the production of such systems by Russian and foreign companies, as well as the increasing number of boilers on which such a device can be installed.

Advantages of the module

The main advantages of the device are:

- When using it, there is no need to maintain heat in a room where there are no people. The heating can be turned on, for example, by sending an SMS an hour before arriving at the house.

- The ability to always control the temperature in the room, leaving the boiler to operate in autonomous mode and without fear of an accident. Indeed, in this case, the GSM module will immediately inform the owner about all problems.

- Receive a warning about equipment shutdown as a result of a power outage. Knowing about the situation that has occurred, the user can take measures to correct it and eliminate the negative consequences that could result from stopping the heating system.

Disadvantages of the system

Naturally, when choosing such a device for your home, you should also know about its disadvantages. There is only one main drawback - the high cost of the entire complex, with the help of which the system is remotely controlled. Therefore, when purchasing a GSM controller, it is worth considering whether it is really needed in your home, or whether the system can be replaced with conventional automation that copes with all problems without human help.

Sometimes a problem with using the device may arise when the owner travels, for example, abroad. In this case, system messages may simply not reach the recipient. And using roaming will not be very beneficial for simply informing via SMS about the operation of the boiler.