The Stropuva solid fuel boiler is a long-burning heating unit. This fuel combustion process is characterized by the release of a large amount of thermal energy and high efficiency. The main feature of the Stropuva boiler is that firewood, pellets, fuel briquettes or coal burn in the firebox from top to bottom. In this case, combustion occurs exclusively in the upper thin layer of fuel.

It is very easy to understand the essence of such combustion using the following laboratory example. If you light an ordinary match and measure the combustion temperature, which occurs from bottom to top, the result will be as follows: in 15 seconds the temperature of the thermometer will rise to 60 degrees. Now let's light a match and measure the temperature as it burns from top to bottom. The results are impressive: in 30 seconds, and it will burn exactly twice as long, the thermometer will heat up to 120 degrees!

This is exactly what was adopted by the Lithuanian engineer Edmundas Strupaitis. He patented a long-burning scheme, and subsequently the Stropuva boiler was developed. A result that has literally become a legend in the heating world. Conventional solid fuel boilers have low efficiency, since heat losses during the combustion of solid fuel are high. Firewood and other solid fuels burn very quickly in them, so frequent refills are required. All these disadvantages are absent in Stropuv boilers.

Peculiarities

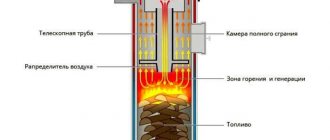

The Stropuva boiler has one striking feature - it has top combustion of fuel. This means that the flame moves from top to bottom, which allows the fuel to burn for a longer time. In this way, you can save significantly, because you will need much less coal or firewood to heat the room. The principle of top combustion also determines the vertical cylindrical shape of the device.

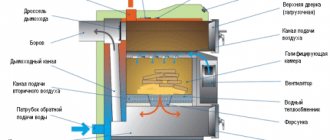

The device is a barrel made of cast iron or steel, inside of which there are two cylinders (small and large), differing in diameter. The large one is separated from the boiler itself using a layer of thermal insulation. A heat exchanger, also known as a heating circuit, is located between the cylinders. The coolant is evenly distributed in this zone and a so-called “water jacket” is formed. The combustion chamber is mounted in a small cylinder, that is, the firebox is located there.

The combustion temperature is maintained due to the presence of an air duct. It works in such a way that air flows only to the burning fuel. With its help you can regulate the entire process. The smoke leaves the boiler in its upper part and is directed immediately into the chimney due to the presence of strong draft. The diameter of the latter varies from 160 to 200 millimeters depending on the model. In any case, it must match or even exceed the diameter of the pipe on the boiler. Ash and other waste are removed from below - the door is placed 2 centimeters higher than the bottom itself.

To light the boiler, you have to follow simple instructions. First, the air distributor is raised and fuel, such as firewood and wood chips, is loaded. The dampers open, including the air damper, and the top layer is set on fire. At this moment, the door through which the fuel is loaded should remain ajar a few centimeters. When the fire reaches the desired state, the air distributor is lowered and the loading door is closed. A new portion of wood material can be added at any time, but it is not recommended to do this with coal - you need to wait until the previous portion burns out.

For Stropuva, various types of solid fuel are selected: types of wood (sawdust, wood chips, briquettes and firewood), coal or peat briquettes. The quality of the chosen fuel largely determines how long it will burn and warm the room. In addition, the presence of insulation in the house and the correct selection and installation of the device play an important role. If the room is not insulated enough, then you will have to buy a powerful boiler and be prepared for the fact that the bookmarks will last for less time.

Qualified employees who will install the boiler and its piping are also important.

How the device works

Stropuva boiler with fuel storage tank

The operating principle of Stropuvo heating equipment is based on burning fuel in its upper part. This effect is achieved by supplying oxygen to the top layer of wood waste, coal or briquettes. As it burns out, the hearth moves to the lower part of the firebox until all the material is exhausted.

The efficiency and high efficiency of the equipment is due to slow combustion and smoldering, in which almost all the thermal energy is used to heat the water in the circuit. Due to the fact that the flame in the firebox is not intense, in most cases overheating and boiling of the coolant is impossible, so in a heating system of this type you do not need to use an expansion tank.

If firewood is used as fuel, on average the supply in the combustion bunker needs to be replenished once every 30 hours. With a more powerful energy source - coal - it is enough to fill the firebox once every five days.

Advantages and disadvantages

Reviews from owners indicate that heating boilers from this company have many advantages. Stropuva is better than its counterparts in many ways. The main advantage, of course, is continuous combustion and the ability to use one bookmark for a long time. For example, if you choose coal as fuel, then one load will last for almost a week, and briquettes will last for two days. If you have to heat the room with wood, then the stash will last for thirty hours. Standard models can function on one tab for no more than eight hours. According to users, the device is very easy to use and there are no loading issues with it.

Stropuva boilers are also quite economical. They themselves are relatively inexpensive, as well as the fuel used, which can be ordinary wood, coal, wood chips or other common materials. If we compare Stropuva products, which are solid fuel devices, with a conventional pellet boiler, the benefits will be obvious. There will be no unnecessary fuel consumption - only as much as needed. You can change the mode depending on changing conditions and thereby extend the burning hours of one bookmark. For example, if it gets warmer outside, less energy will be required, which means the boiler will run on fuel longer. When switching to Stropuva, heating costs are reduced by approximately half.

The boiler from Stropuva always works in the best mode. A conventional boiler operates until all the fuel is burned, and in a short period of time produces a huge amount of heat. Therefore, you have to either constantly update the bookmark, or supplement the design with a heat accumulator that will store heat. In Stropuva, only a small part of the fuel is burned and no additional devices are required. The efficiency of the boilers reaches 90%, and the boiler itself is non-volatile and can work with almost any solid fuel. Even if there is no electricity in remote areas, Stropuva will still be successfully operated. It is also worth mentioning that the boiler itself is quite compact and does not take up much space, it is very easy to clean, and it can function for up to 5 years.

Boilers of this type are distinguished by their safety for users. The device is made of steel, characterized by increased heat resistance and heat resistance. If there is a fire, the boiler will not explode anyway. In addition, the design is equipped with a special protection valve, which in case of danger activates the extinguishing mode. Stropuva can be easily equipped with radiators and boilers, connected to underfloor heating, as well as any heating system. You can set different temperatures for different connections. For example, the heated floor will maintain a temperature of 33 degrees, and the radiators will maintain a temperature of 55 degrees.

Consumer reviews ↑

We were able to collect several reviews from conversations with users of Stropuva boilers in Russia.

Vasily Nikolaevich Nazarov: Before last season, I bought an S20U boiler for my woodworking workshop. Once every 5-6 days you fill a full bunker with coal - and that’s it, no problems. With pieces of wood, of course, there is more hassle, but I still need to put them somewhere.

Oleg Vladimirovich Serov: The main thing is to correctly determine the required power. There is no point in taking based on the principle: the more, the better. Each model will be effective where it is designed, and the price will be higher - why overpay?

Andrey P.: I have a dacha, there’s not even light there always. At first I tried to heat it with gas from cylinders, it was a hassle and too expensive. Now I have installed a small wood-burning unit with ten kilowatts, the car has enough firewood for the winter. I heat it 2-3 times a week, the house is 6x12 meters plus massandra, I haven’t seen any shortcomings yet.

For using wood materials as fuel and heating buildings up to 100 square meters. meters, it is enough to purchase a Stropuva S10 boiler (power 10 kW) costing about 80 thousand rubles. A universal solid fuel unit model S40U, capable of heating a room of at least 200 square meters. meters will cost the buyer more - about 120,000 rubles.

Design and principle of operation of Stropuva boilers

Loading fuel into the Stropuva furnace is possible only from above. For better ignition, the main fuel is mixed with sawdust; you can add flammable liquid. Ignition also occurs through the top door, which must be closed tightly after all actions.

The chimney will form a draft, the fire will flare up from the top of the fuel. Quickly igniting the firewood will ensure good air flow. Fire and smoke rush through the inner housing structure to the smoke hole. Some of the hot gases also rush upward, simultaneously heating the metal and water.

The internal chamber of the air duct increases as the fuel burns. An afterburning chamber is formed in the increased space, which has a positive effect on efficiency. In this case, the fire will not flare up too much, the protection will work in the device. Thanks to the device, the air damper either opens or closes, increasing or decreasing the draft or combustion temperature.

Types of equipment Stropuva

Stropuva heating devices operate on one or more types of fuel, depending on the model.

Wood-burning

A wood boiler uses hardwood logs, wood and peat briquettes as fuel.

Pellet

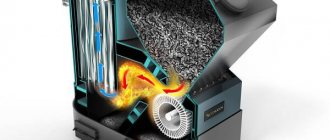

The pellet device obtains thermal energy by burning fuel pellets consisting of wood and agricultural waste. It is equipped with an air charge fan, a grate and a specially designed air distributor.

Universal

Universal models, in addition to firewood and pellets, also use coal and anthracite. It is equipped with special parts for working with bulk raw materials.

Heating history

Since the emergence of the need for heating in cold weather, all fuel combustion processes have occurred according to the same principle; the best example is the design of the Russian stove.

We add fuel, open the blower from below, and light the fuel from below. The combustion process begins - the fuel begins to burn all at once, according to the principle of a fire. It burns well and hot, but not for long and not efficiently - part of the fuel burns out “just like that”, and the heat flies out into the chimney! To keep the combustion process at one fairly stable level, it is necessary to add more and more fuel very often. Otherwise, the combustion will die out very quickly and the fuel will burn ineffectively!

It is this principle that underlies the design of any of the existing heating devices operating on solid fuel - it is always a “bonfire”. It doesn’t matter what we are talking about - a modern pyrolysis boiler, a regular “potbelly stove” type boiler, or pellet boilers with a hopper, a feed mechanism and an electric burner, or a Russian stove.

Main models

You can buy a Stropuva boiler in specialized stores that are dealers of the manufacturer, as well as in online stores. The minimum price is 60 thousand rubles for the minimum power model. Let's continue the review with a description of the models being produced.

Stropuva Mini S8

Before us is the smallest wood-burning boiler with a power of 8 kW, designed to heat rooms up to 80 square meters. m. It works on wood briquettes and firewood, is equipped with a safety valve and a thermometer. The heating temperature of the coolant is from +60 to +95 degrees. The maximum pressure in the circuit is up to 1.5 Bar. The efficiency of the model is 85% - a pretty good result for solid fuel equipment. The estimated cost of this boiler is 61 thousand rubles.

Stropuva Mini SP8

This boiler differs from the previous model by supporting operation with pellets. In this mode, it needs to be connected to an electrical network with a voltage of 220 Volts - the electricity is used to operate the fan used in the fuel ignition system. When working with wood and briquettes, the boiler operates in autonomous mode. The remaining parameters are almost 100% similar.

Stropuva S20

One of the most popular models. It allows you to heat residential buildings up to 200 square meters. m. The boiler is built according to an energy-independent scheme; briquettes and ordinary firewood are used as fuel. Burning time is up to 31 hours. If you want to forget about adding fuel for several days, we recommend purchasing the Stropuva S20U modification - it can run on coal, providing up to 120 hours of continuous combustion. The Stropuva S20P model can work on pellets for up to three hours.

Stropuva S40

Before us is the most powerful boiler in the entire line. Its thermal power is 40 kW, combustion duration is up to 31 hours, heated area is up to 400 sq. m. The device is equipped with a rather impressive heat exchanger jacket that holds 58 liters of water. The maximum pressure in the system is up to 2 atmospheres at an average temperature of up to +75 degrees. Over 90 kg of firewood is placed in the combustion chamber of the device. Modifications for working on pellets and coal are also available.

Other models and manufactured modifications

Also on sale are solid fuel boilers from the Stropuva company with a capacity of 15 and 30 kW. They are designed for areas up to 150 and 300 square meters. m. All models discussed in the review are available in three modifications:

- The main one is that the equipment runs only on wood and fuel briquettes (euro firewood).

- With index P – the possibility of working on pellets is provided, burning up to 72 hours.

- With index U - units with the ability to operate on coal, burning time up to 120 hours.

Naturally, the actual burning time may be shorter - it depends on the characteristics of the fuel (type of wood, degree of dryness).

Some people have design requirements for their heating equipment. If you really care so much about how the boiler looks, then we have good news - Stropuva produces its equipment in several colors. The main color (and most common) is yellow. It is possible to purchase boilers in brown, blue, red, green and black colors. Spotted colors are also available (yellow and dirty green).

Reviews from real owners

While manufacturers do their best to praise their equipment, real owners work with it. They are the ones who can tell how the equipment behaves under constant operating conditions. Reviews from Stropuvo boiler owners will definitely be useful to you when choosing heating equipment for your home.

Tired of traffic jams and noise, I moved with my wife and child outside the city, to a small village. It is quiet and comfortable here, there is no city noise. And there is no gas here. I had to buy a wood-burning boiler from the Lithuanian company Stropuva, since I didn’t want to bother with constantly throwing in new bundles of firewood. The choice turned out to be successful - for a house of 65 square meters. m of the selected boiler turned out to be more than enough. I load the logs once a day, after removing the coals and ash. Hot water is heated in an 80 liter electric boiler. The Stropuva boiler heats just fine, but in reality it still doesn’t last up to 30 hours.

I went to specialized forums to get reviews about these boilers. Some people praise them, while others complain about their low reliability. I made my choice quickly, but in the end I was wrong. It’s really better to spend more money and buy a boiler with a pellet burner and automatic pellet supply. Stropuva also knows how to work with pellets, but automation is difficult. It would be much easier with a bunker for bulk fuel. And the temperature control on Stropuv is not the best. Cleaning away ash is inconvenient. In general, the expensive purchase did not justify itself. It would be better if I took a universal boiler with a pellet burner, which could later be converted to gas.

As with everything, it has its drawbacks. When you start cleaning, smoke pours out in all directions from the still burning coals, since there is no grate here. I can’t understand how anyone could even think of doing without an ash pan. I fixed the problem, but spending almost 100 thousand rubles to fix the manufacturer’s defects yourself is an incredibly interesting activity. Secondly, reloading firewood is very inconvenient, the heat radiates into your face. Moreover, it is not recommended to do this, they say, it is necessary for the firewood to burn out completely. But in the evening there is no time to think about it - I want to sleep, and not wait for the logs to burn out. What I liked is that it heats up quickly, literally after an hour of operation the rooms become warm. Stropuva burns for a long time, at least a day. In cold weather, the burning time is reduced, but this is not so critical. For hot water, I installed a boiler in the system; in the summer it will work from the built-in heating element.

Reliability and safety

Stropuva pellet boilers are not equipped with complex, malfunctioning automation. The boiler is controlled by a fairly simple in design and non-volatile bimetallic draft regulator. This solution gives the boiler high reliability and stability in operation.

The boiler is designed in such a way that, unlike diesel, electric or gas boilers, if the load is repeatedly exceeded, it will not explode, but will shrink inward. The manufacturer is confident in the quality of the equipment produced and provides a factory warranty of up to 5 years.

Recommendations for installation and operation

To install the device, choose an isolated room equipped with forced ventilation or an opening window. The height of the boiler room ceilings must be at least 2.5 m, the area - from 4 sq. m. Installation work is carried out strictly according to the instructions.

Installation features:

- the boiler is installed on a concrete foundation 10 cm high from the floor or on a non-combustible base;

- the bottom is lined with concrete mortar, the joint is sealed with heat-resistant sealant;

- maintain the following intervals: in front - at least 1 m of free space, in the back - 0.6 m, on the side to the wall - 0.6 m;

- The connection points between the device and the chimney and heating system are carefully sealed.

The heat generator is a source of increased danger. The boiler room must be equipped with fire extinguishing equipment and a container with sand for emergency fire extinguishing.

Other operating features:

- Do not store fuel or other flammable materials near the heating device;

- once a month it is necessary to check the condition of the chimney using a mirror, and if necessary, clean it from soot accumulation;

- operation in systems with forced circulation is not allowed if the pump fails or there is a power outage;

- When heating with wood, ash is removed as needed;

- when using peat or coal, the ash pan must be cleaned every time before refilling;

- It is advisable to lubricate the distributor lifting cable with oil to prevent wear;

- It is necessary to inspect the doors for tight closure.

Reservation of work

The use of two or more boilers in a heating system is justified by the risk of failure of one of the devices. The circuit is also used to quickly increase power if necessary.

Stropuva units are easily assembled in a cascade, thereby increasing the reliability of the heating system.

Advantages of cascade installation:

- uninterrupted operation (if one device fails, the other will continue to operate);

- increased power (in the off-season you can use one unit, in winter - two);

- ease of repair and maintenance;

- saving space in height (for limited spaces - attics, basements).

The disadvantage of parallel connection is that for each device you have to connect a separate piping unit and chimney. Study the Grundfos circulation pump at the link.

Guide to self-assembly of a Stropuva boiler

Before starting work, prepare the necessary equipment for this.

You won’t need any extremely difficult to use tools or hard-to-find materials. However, it is better to collect everything in advance so as not to be distracted by searching for missing elements in the future.

Stropuva boiler assembly kit

- Metal barrel. Use a large container with a capacity of 200 liters or more.

- Welding machine.

- Thick-walled metal pipe.

- Fiberglass.

- Metal channels.

- Asbestos.

- Chisel.

The function of the body of the heating unit in question will be performed by a large metal barrel. You can use either new or old container. The main thing is that the barrel does not have through holes and signs of severe corrosion damage.

The function of the body of the heating unit in question will be performed by a large metal barrel

If possible, it is best to use a Soviet-made barrel. Such products are much more durable and high quality compared to their modern counterparts.

If you have access to a rolling machine, you can purchase a large sheet of metal and use it to assemble the boiler body. The recommended sheet thickness is 2.5-3 mm. The optimal dimensions are 125*250 cm. At the end you should get 2 cylinders with a diameter of 50 and 45 cm.

Furnace assembly

The work of making a sling boiler is carried out in a few simple steps.

First step. Clean the barrel from all sorts of contaminants, and then cut a hole in its top. That is, you simply need to “knock out” the top of the container to gain free access to its interior.

Sheet metal housing

Second step. Cut a small piece from a metal pipe with a diameter of about 15 cm. From it you will make a pipe for connecting the chimney.

Manufacturing sequence

Type of homemade installation

- A lid with a small side is cut out of the barrel, for which a grinder is used. A hole is made in the lid right in the middle for a pipe with a diameter of 100 mm.

- Next, a grate is made from wire or corners. In fact, this is a regular grill, where it is important to determine the size of the cells. The smaller they are, the better, especially when it comes to such small fuels as sawdust or husks. By the way, the grate is not used in all models - sometimes you can do without it. If there is one, then it is installed inside the barrel closer to the bottom. Fastening is done by electric welding.

- Now let's move on to making the load - the press. To do this, a round pancake is cut out of a 4 mm thick steel sheet, the diameter of which is 2–3 cm less than the diameter of the metal barrel. A through hole with a diameter of 100 mm is made in it.

- We weld the pipe to the pancake. Please note that the length of the pipe should be 20–50 cm greater than the height of the barrel. Now 4 channels need to be welded on the back side of the pancake. They are needed to weigh down the press and create a small space under it - this will be the combustion zone. The channels are welded in such a way as not to cover the hole in the pancake. The usual fastening pattern is criss-cross.

- In the barrel just above the location where the grate is installed, you need to make a door through which you can clean the boiler from ash and ashes. This device must be sealed using an asbestos cord.

- A through hole is made on the side of the upper part of the barrel, almost near its upper edge, and a small pipe with a diameter of 100 mm is welded to this place from the outside. This will be the location where the chimney will be installed.

- Now you need to take care of the removable cover. The upper part of the barrel, which was cut out, must be brought into proper shape. To do this, its sides are slightly expanded - you can simply tap them with a hammer. It is necessary to weld two handles on the top side, with the help of which the cover will be installed manually. On the outside of the side around the entire perimeter, you need to glue an asbestos cord or a strip of fiberglass, which will contain the smoke coming out of the combustion zone.

At this point, all parts of the boiler are ready, and you can begin adding fuel, as well as assembling the structure.

Procedure for assembling the structure

Attention! The closer you pack the firewood, leaving minimal space between them, the longer it will burn. As for sawdust, everything is simpler - you just need to compact it well.

Combustion chamber

The press is installed on the stacked fuel with the pipe facing up, and the barrel lid is put on it. The chimney is connected to the pipe. Long-burning furnaces have a unique design that ensures the removal of carbon monoxide only through a horizontal pipe. That is, the chimney will not be vertical, but horizontal with a slight upward slope. This is another distinctive feature of long-burning stoves.

Before placing the press, it is necessary to ignite the top layer of fuel. Then the press and lid are installed. In this case, the firewood or sawdust in the combustion zone will simply smolder, releasing a large amount of thermal energy. At the same time, as it burns out, the zone will gradually settle under the influence of the load. Smoke from the combustion of solid fuel comes out of the zone between the gap formed by the walls of the barrel and the edges of the metal pancake. It is then discharged through the chimney. Oxygen enters the combustion zone through a pipe welded vertically to the pancake.

Since the metal from the barrel will become very hot, the structure is considered unsafe in terms of fire. Therefore, experts recommend:

- Install such a stove near walls that are built from non-combustible materials.

- A foundation needs to be poured under a long-burning furnace. It can be concrete or fire brick.

- To increase operational safety, you can install a protective heat shield made of metal or bricks.

Bubafonya stove with water jacket

Pyrolysis furnace Bubafonya from a gas cylinder with a water jacket.

Finally, we got to the domestic analogue of the Stropuva boiler, which is much simpler to implement, since it has a non-folding pipe for supplying air to the firebox. There are already so many instructions on how to make a Bubafonya stove with your own hands that only a blind person would not have seen them, unless, of course, they were interested in this topic. And why all? Yes, because the process is so simple and if you take the matter seriously, you can get a finished product from scratch in a day. What is the Bubafonya stove made from with your own hands:

- from a gas cylinder;

- from a barrel;

- from pipes

It can be either round or square. Let’s not repeat the same thing, just read the article: “Bubafonya stove from a gas cylinder” - and everything will become clear to you. Today we will consider a version of the product with a water circuit, as if we will try to repeat the principle of operation of the Stropuva boiler. All that is required is to make a simple Bubafonya and insert it into a pipe of a larger diameter. Thus, we obtain a gap in which the coolant will be heated.

Naturally, this space above and below is sealed so that various debris does not get there. What is important when making a Bubafonya stove with a water jacket with your own hands:

- use of heat-resistant steel;

- wall thickness of at least 4 mm;

- the presence of a tap for draining and replenishing water.

Immediately provide a hole in the upper part through the outer and inner walls for installing a chimney into it. There should also be enough space for water. The distance from the outer to the inner wall is about 10 cm. When connecting, do not confuse the supply and return pipes (supply from above).

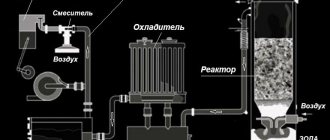

System piping

The boiler piping is no different from other solid fuel units

When piping the device, in addition to conventional heating radiators, you need to include a safety battery in the system, on which you do not need to install a thermostat. This convector must be embedded first on the jacket supply pipe through a balancing valve and mounted in such a way that the coolant can move in it by gravity in the event of a power outage.

All other radiators go through a different circuit through regular valves and are connected by return to the circulation pump. The pump itself is bypassed through a three-way valve, which is connected through a second channel to the return pipe of the unit and is controlled by a temperature sensor installed on the return pipe of the batteries.

Among the most popular models of solid fuel boilers Stropuva are the wood-burning unit Stropuva 10S and the universal device Stropuva 20U, with 10 and 20 kilowatts of power, respectively, intended for heating country cottages.

Comparison of the Stropuva boiler and the Bubafonya stove

We will begin our analysis with the scope of application. If we are talking about a residential building, the Stropuva boiler definitely has the advantage. The characteristics of this unit allow it to work for a long time on one load, it is stable and reliable. At least, cases of complete failure have not yet been encountered. The operating principle of the Stropuva boiler allows you to connect to it both high-temperature heating and a hot water supply system with heated floors. Bubafonya cannot boast of this.

It is more suitable for heating greenhouses, garages, or, at most, summer houses. For more serious projects it is simply not applicable. Advantages of the Stropuva boiler design:

- continuous operation on coal for 5 days;

- temperature stability;

- ease of fuel loading compared to Bubafone.

There are also disadvantages, such as the complexity of the piping, the need for a separate room and the impossibility of repairs until a complete stop. It is also impossible to add fuel while the stove is operating and therefore you have to relight it every time you reload the firebox. But at the same time, of the two units being compared, only the Stropuva factory furnace is still suitable for serious projects. But Afanasy Budyakin’s invention is excellent for utility rooms, since the Bubafonya stove can be made quickly and inexpensively, which in this case is of decisive importance.

Attention: fakes!

Modernization of the Stropuva boiler

But there are distinctive features of the original and counterfeit products:

- Branded powder painting guarantees a long service life of the coating; the paint itself is applied very carefully. According to reviews of those who bought a fake, the paint does not stand up to criticism. And the original coating is also thermoplastic (can expand/contract without compromising the integrity of the paint)

- Each product is marked with the Stropuva logo and is additionally protected with a hologram.

- The cast iron firebox door has rounded corners and usually no attention is paid to such points - it is expensive for the production of fakes.

Original Stropuva stove

To avoid buying a fake, contact certified product sellers in your region.

Checking the boiler after assembly

Checking the boiler after assembly

Before accepting a homemade Stropuv boiler for permanent use, be sure to ensure that it is in good working order and reliable. Don't ignore this step. The safety of further operation of the heating unit directly depends on a correctly performed check.

Fill the barrel with wood to about a third of the height. Add some kerosene and throw a lit match into the container. Ideally, the wood will ignite almost immediately. At the same time, you should not notice the presence of smoke, or any draft, or any kind of uncharacteristic odors.

STROPUVA

If any of the above symptoms are present, do not use the boiler. Such equipment is very likely to soon fail and harm its owners. But if you assembled the unit in strict accordance with the instructions above, there will be no problems.

The amount of firewood given earlier will be enough for approximately daily heating of a small room. If the room is medium sized, double the loading volume.

Thus, you can assemble an excellent sling boiler for heating a variety of small and medium-sized rooms with your own hands. Now you don’t have to spend a lot of money on buying expensive equipment. You just need to follow the instructions in everything and your home will always be warm and cozy.

Good luck!

Chimney installation

Good news: you can connect Stropuv boilers yourself if you have experience in similar plumbing work. If you don’t have the skill, go straight to the specialists. Please pay attention to the installation instructions - installation differs from other long-burning solid fuel boilers.

Stropuva

Important! If you install the chimney incorrectly, you expose yourself and the equipment to danger. Violation of requirements leads to the following consequences:

- unstable combustion, lack of traction;

- formation of condensation, less often - the formation of air pockets;

- accumulation of carbon monoxide.

The cases listed are rare, but they have happened in practice before. Today, automation will protect you in advance from such large-scale troubles. The most likely failure, due to an incorrectly installed chimney, will be the boiler extinguishing and combustion stopping. This will be very annoying, especially on frosty winter nights with winds and snowstorms.

Boiler Stropuwa

Therefore, the final height of the chimney must be calculated taking into account the height of the house along the ridge. It is better for the pipe to protrude above it. If the equipment includes a smoke exhaust fan, you can limit yourself to a 4.5 meter pipe. But, it’s better not to take risks and protect yourself from all sides.

Table 4. Installation parameters of chimney pipes of Stropuva boilers

| Name of equipment (all models shown are universal) | Chimney diameter (recommended), mm | Height from the floor to the bottom edge of the exhaust gas hole, mm |

| Stropuva SU 10 kW | 180 | 155o |

| Stropuva SU 20 W | 180 | 1695 |

| Stropuva SU 40 kW | 200 | 1675 |