Sawdust is an excellent material for heating houses and greenhouses.

They are made of wood, which means that when used correctly, they are only slightly inferior in heat capacity to firewood.

You can get them cheaply , and in some cases even for free .

Next we will tell you about different methods of heating different rooms with sawdust:

- houses;

- makeshift;

- greenhouses

We will also consider in detail all types of heating stoves and long-burning boilers that can use sawdust as fuel.

How sawdust burns

Before talking about the features of sawdust boiler houses, it is necessary to understand the combustion mechanism of this fuel itself, because it is very different from the combustion mechanism of wood.

No matter how tightly the firewood is stacked, air always passes , and in sufficient quantity to support combustion.

Even loose sawdust allows much less air , so smoldering quickly dies out without supplying additional air to the combustion zone.

Sawdust burners only work effectively when the fire moves from top to bottom . Therefore, only a layer of sawdust 2–5 cm thick constantly burns.

Due to the fact that only a small amount of fuel is involved in combustion, the power of sawdust boilers and stoves operating on them, while being the same as wood and coal heating appliances, is 2–3 times less .

Another factor that reduces the power of a boiler or furnace is the low combustion temperature of sawdust.

If wood burns with the correct air supply, the flame temperature exceeds 1000 degrees, often reaching 2000 degrees in the tongues of fire. Moreover, this is a powerful fire , because the entire mass of firewood emits pyrolysis gases.

The fire temperature of burning sawdust, even with proper air supply, does not always reach 1000 degrees due to the weak flow of pyrolysis gases .

Pyrolysis gases effectively exit only from the top layer 5–15 mm .

Gas comes out with difficulty from burning or heated sawdust located below, because the sawdust located above interferes with it.

Despite such disadvantages, sawdust is ideal for long-burning boilers and furnaces.

After all, well-compacted sawdust burns for a very long time .

Often, a homemade iron stove burns for 5–8 days with one load of sawdust, providing heating for the entire house.

The best known manufacturers and models: characteristics and prices

When choosing a boiler for sawdust and wood chips, in addition to technical characteristics, you should pay attention to the country and brand of the manufacturer. Northern European countries have learned to squeeze the highest economic performance out of fuel. To this end, they have been working for a long time on improving automation specifically for private homes, and given their desire for comfort and environmental requirements, you should pay attention to the products of the companies Hargassner, Froling, ETA. Of course, if the budget allows.

We recommend: How do you know if a fireplace is built correctly?

Russian-made boilers, especially if the developer is a well-known European brand on the market, may well be competitive. At a significantly lower price, they are quite capable of providing both the reliability and comfort of a private home. In addition, they are unpretentious in raw materials and maintenance, and the automation even in European solid fuel boilers is often from China.

Specialized

These are boilers designed primarily for the use of bulk solid fuels.

Pyrolysis Master BIO-15

One of the best sawdust boilers for heating a private home. It also works on wood chips, peat, and sunflower husks. With the use of replaceable burners it can burn straw. Thanks to a five-pass heat exchanger, it has a high efficiency of 91% and has a hopper capacity of 200 liters. The only drawback is its considerable dimensions.

Cost: 185,000-240,000 rubles.

FACI FSS 115

It is produced in Russia, but the developer is Italy. This is an automatic industrial boiler for burning wood waste. Power adjustable within 25-115 kW, efficiency 92%. As additional options, it is equipped with auto-ignition, burner self-cleaning, and remote control. Hopper capacity is 810 liters, fuel is supplied by two augers. Can burn any biomass with a fraction not exceeding 40 mm. The 115 kW model has a huge weight of 1150 kg, which increases the flooring and transport requirements.

Cost: 450,000-477,000 rubles.

Universal models

Boilers using any solid fuel: all types of coal, peat, firewood, wood waste, seed husks, briquettes with varying efficiency, but structurally designed for long-term combustion. They are much cheaper than specialized ones, but also much less effective and practical when working with sawdust.

Tis Pro DR

Excellent inexpensive universal boiler. Furnace steel 5 mm thick is used as a heat exchanger, which is a very good indicator in terms of reliability and durability. It also features a huge firebox; depending on the power, the volume of the combustion chamber can be 80-116 liters. Does not use fan pressure and is non-volatile. Available in 17, 22 and 27 kW versions, efficiency reaches 82%.

Owners often note that the design of the grate is extremely practical: they are separate, cast iron (reliable and easily replaceable). No deficiencies were found due to operating practices.

Cost: 58,500-72,000 rubles.

PEREKO KSP Duo

High-tech Polish universal TT boiler of the highest price category. The innovative burner allows high-quality combustion of fine-grained fuel from eco-peas to oats as efficiently as possible. A water-filled grate in the combustion chamber makes it possible to burn wood and its waste.

Equipped with automation controlled by the ST-480 controller, which, in addition to controlling the central heating and hot water pumps, the boost fan, can also control the operation of the mixing valve and take into account signals from room and street temperature sensors. Available in power variations: 12, 18, 26, 36, 52 kW. In addition to the price, the disadvantages are large dimensions, weight and low permissible operating pressure - only 1.5 bar.

Cost: 283,000-498,000 rubles.

LIEPSNELĖ L20U

Universal Lithuanian long-burning shaft-type boiler with a power of 20 kW. The fuel is coal, pressed briquettes from coal, peat, wood waste, sawdust and other raw materials. The efficiency reaches 91%, but this is only when heating with low-ash coal; when using sawdust and wood chips, the efficiency will be lower. The heat exchanger is cast iron, in a steel casing. The boiler is known for its reliability, quality of alloys used and assembly. Even when using sawdust and wood chips, the burning time of one load can be achieved in 2-3 days.

The only drawbacks, as in the previous case, are the low operating pressure of 1.5 bar and heavy weight.

Cost: 110,000-125,000 rubles.

Suitable heating systems

For heating private houses and any buildings with sawdust, the following systems :

- heating stoves;

- heating stoves with a water heating register or heater;

- water heating with radiators;

- water heated floor;

- air heating;

- air heated floor.

Heating stoves heat the space around them , so they are suitable only for small houses . At a distance of 10 meters from the stove, the temperature drops by 10–15 degrees, so in large houses the stove can only act as an additional heater.

Heating stoves with a water heating register or heater combine the advantages of stoves and boilers. They provide the same heat as a conventional heating furnace and heat the coolant, which is supplied through pipes or ducts to remote rooms.

The large mass of the stove turns it into a heat accumulator , thanks to which you do not have to re-light the boiler every 2 hours or add firewood to it every hour. The stove will maintain the coolant temperature for up to 6–10 hours , so you can heat it 2–3 times a day.

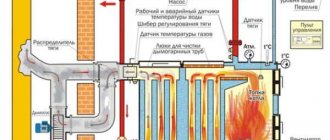

Water heating with radiators in each room can be used with either a water boiler or a sawdust stove if it has a water register . Like any other water heating, it can operate on natural or forced circulation of coolant.

natural circulation systems, hot water first rises to the ceiling, then descends into each room and flows either to the radiators or to the heated floor. In systems with forced circulation, water is driven by a pump, so all pipes can be laid under the floor.

Water and air heated floors not only heat the room, but also improve its microclimate. In winter, it is very pleasant to walk barefoot on the floor, feeling its warmth with your feet. The main disadvantage of a heated floor is the high cost of materials and work, because it is necessary not only to lay air ducts or a water pipe, but also to properly insulate the space between the floor and the ground or foundation.

Air heating is just as expensive as underfloor heating, because it is necessary to lay air ducts throughout the house, as well as install automatic humidifiers due to the strong drying of the air. Ovens with heaters can be used as a heat source.

The only difference between furnaces and boilers is that the boiler has

a water jacket , that is, the space between the hot body and the outer casing is filled with water.

Here are the distinctive features of each heating device:

- stove - direct heating of the air and surrounding space;

- heater - heating air for delivery to other rooms without heating the surrounding space;

- stove-heater - heating the surrounding space and heating air for delivery to other rooms;

- stove with register - heating the surrounding space and water for delivery to other rooms;

- boiler - heating water for delivery to other rooms.

Therefore, air heaters and boilers are installed in utility rooms and are often insulated from the outside. After all, it makes no sense to waste thermal energy on strong heating of the utility room, and the less heat spent on this, the more will go to other rooms.

DIY making

On sale today you can find various modifications of autonomous heating boilers that burn wood chips and sawdust. Despite all their advantages, they have one significant drawback - the high cost of equipment. Therefore, many summer residents and owners of private houses make universal boilers on their own, since the simple design of such equipment allows you to construct it even in the absence of relevant knowledge and experience.

To make a wood chip boiler with your own hands, you will need the following tools and materials:

A round pipe with a diameter of 5 centimeters.

- Rectangular profile 40 by 60 millimeters.

- Grinder or metal cutter.

- Electric drill.

- Welding machine.

- Roulette and hammer.

On the Internet you can find various drawings of the design of boilers operating on sawdust and wood chips. The easiest way to make such heaters is on the basis of a pipe or gas cylinder. You just need to use durable, thick-walled steel, which will ensure the durability of your homemade boiler .

The valve is removed from the gas cylinder and all the gas is released. The top is cut off along the line of the weld, after which the edges are cleaned using a grinder or manually, and all burrs are removed. Subsequently, the blank from the gas cylinder will be used as a firebox body.

- 2. The cut off upper part of the cylinder is also cleaned, and then adjusted to the base of the firebox body. Along the edges of the workpiece, a edging is welded on top, which is made from strips of thick-walled steel.

- 3. A hole is drilled in the lid into which a pipe for air supply is welded.

- 4. In the upper part of the firebox body, a hole is made with a drill, which is necessary for attaching the chimney pipe. An iron pipe is inserted into the resulting hole and welded.

- 5. The design of the sawdust firebox implies the presence of a load that presses the fuel from above, thereby regulating its combustion rate. The weight is made of thick-walled sheet metal, which is cut to fit the internal diameter of the cylinder. A hole is made in the center of the disk, which is identical in diameter to the pipe cut into the boiler lid.

- 6. It is recommended to weld iron ribs to the inner surface of the round weight, which allows air masses to disperse, increasing the efficiency of the heating installation.

- 7. A water jacket is made from a metal sheet, through which the coolant will circulate. The water jacket is located outside the firebox and has the shape and dimensions of the body.

- 8. Stiffening ribs are welded in a circle to the furnace body, which protect the water jacket from its temperature deformation.

- 9. The water jacket is attached to metal stiffeners.

We recommend: How to connect a well pump - installation and electrical diagram, installation in a well

At this point, the work on manufacturing the heating boiler is completed. It is necessary to carry out a test run, check the quality of welding, and also make sure that there are no leaks in the water jacket, along the contour of which the coolant circulates. In the future, it is possible to modernize the heating boiler, to which a hopper with sawdust and a screw mechanism for automatically loading chips into the combustion chamber are additionally mounted.

By making a homemade pyrolysis boiler using sawdust and wood chips, you can not only solve problems with heating a small private house or country house, but also reduce the cost of living outside the city in the winter season. In specialized stores you can purchase ready-made industrial boilers that have one or two circuits, are completely safe to operate and are equipped with automatic control.

If necessary, it is possible to produce universal versions of autonomous heaters, which will differ in their power ratings, duration of operation from one fuel fill, as well as a number of other characteristics.

Requirements for heating devices

For heating with sawdust, it is necessary to use long-burning boilers and stoves that meet the following conditions :

- fuel combustion from top to bottom ;

- large outer surface area (important for stoves);

- large area of the heat exchanger or water jacket;

- large volume of firebox ;

- possibility of supplying air to the combustion zone.

Due to the small size of sawdust, they can be fed into the stove or boiler automatically, which further increases the battery life of the heating device. Most often, an auger feed is used for this - a rotating auger lifts or lowers sawdust from the hopper and scatters it in the combustion zone.

When there is too much ash, the heater is stopped and cooled to clear the ash and reload it with fuel.

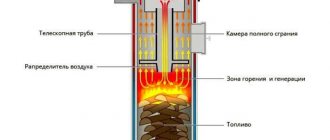

Boilers and long-burning stoves of the Stropuva type (Russian analogue of Bubafonya) are well suited for heating with sawdust. These devices implement the principle of top combustion of wood , and air enters directly into the combustion zone.

Long-burning stoves and boilers running on sawdust can not only be bought, but also made with your own hands. Homemade devices also implement the requirements for heating devices described above.

Furnaces and boilers for working on sawdust

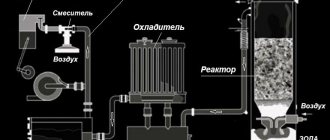

There are 2 types of fireboxes, which differ in the method of air supply :

- from above , through a descending air duct;

- from below , through a pre-made channel in the sawdust.

The most famous furnaces and boilers of the first type are devices under the Stropuva brand. They are produced both in the form of stoves and boilers.

As we already said in the article (Fuel from sawdust), the difference between stoves and boilers is that the former heat the air directly , and the latter heat the coolant . Then the coolant, which can be either water or air, flows through pipes into the rooms and heats them.

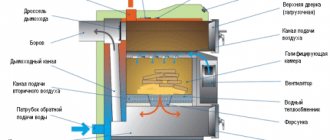

With drop-down duct

Long-burning furnaces and boilers in Stropuv are designed as follows :

- the body is made of pipe with a diameter of 50–70 cm ;

- two doors cut into this housing - a loading door on top and a cleaning door on the bottom;

- a telescopic pipe passes through the lid (in homemade devices it is replaced by a regular long-length pipe) - an air duct;

- a steel circle with a thickness of 10 and a width slightly less than the internal diameter of the housing is welded to the bottom of the air duct

- a chain or steel cable is attached to the upper side of the disk to lift the air duct;

- corners or channels are welded to the bottom side of the disk , creating an optimal gap between the disk and the fuel;

- The smoke exit hole is made slightly above the cleaning door.

The following boilers and furnaces operate on sawdust:

- by lifting the air duct using a cable or chain, the stove or boiler is loaded with sawdust, compacting it as much as possible;

- Having loaded sawdust, kindling is placed - paper and various wood chips;

- after waiting for the kindling to flare up, lower the air duct and close the loading door;

- the air supply is set to maximum , due to which the top layer of sawdust flares up and the stove/boiler goes into operating mode;

- fire and smoke rise through the space between the disc and the housing and heat both the duct and the housing ;

- the furnace begins to radiate heat , and the boiler heats the water jacket ;

- As the sawdust burns, its level becomes lower and the air duct descends after it, this system ensures a constant flow of air into the combustion zone and an optimal fuel combustion mode .

With bottom air supply

Boilers and furnaces without a lowering duct are designed and operate slightly differently. Their air duct approaches the firebox from below .

Such heating devices are loaded through a hinged lid . The chimney is connected just below the hinged cover.

The hinged lid is sealed with asbestos cord or tape.

During loading, a long cone-shaped wooden plug is inserted into the air duct (the upper diameter is 1.5–3 times larger than the lower one).

The sawdust is compacted tightly and after loading is completed, the plug is pulled out - air flows through the resulting channel to the upper burning layer of sawdust.

Kindling is placed on the sawdust and set on fire. When the kindling has flared up, close the hinged lid, setting the chimney damper and the air supply regulator to maximum draft mode.

After the sawdust has flared up, the air supply is reduced and the stove or boiler goes into a prolonged burning (smoldering) mode.

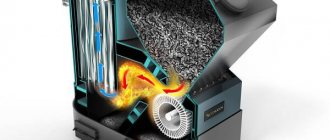

Fuel supply mechanism

Solid fuel heating boilers operate autonomously and can be done with virtually no maintenance. Sawdust is supplied using several means.

The receiver has open access to the outside of the building. It is equipped with a screw drive connected to the storage. When the bunker is fully loaded with fuel, the conveyor starts working - it supplies fuel to the mechanized compartment.

There are two types of storage, they differ in the technique of feeding sawdust into the boiler:

- a hopper with an inclined base, cone-shaped, with a screw mechanism in the lower part;

- agitator with blades, sawdust is loaded by rotation.

Not all fuel from the storage goes directly into the firebox. Wood chip boilers of the pyrolysis type are equipped with a drum and a screw transmission, which supply fuel in parts.

Stoves, boilers and heaters: which is better

When choosing sawdust heating, you must consider the following:

- the volume of water in the water jacket of the boiler should be 10–15% of the total volume of water in the heating system, therefore it is advisable to use forced movement of water through thin tubes;

- Stropuva water boiler 65 thousand rubles , and the price of sawdust boilers made by yourself is 30–50 thousand rubles , including the cost of material;

- air heating not only heats, but also dries the air ;

- water heating pipes can be hidden under the finishing, but air heating pipes will have to be laid in plain sight due to their large cross-section (pipe diameter in cm is equal to half the area of the room in m²);

- it is very difficult to find long-burning industrial heaters (boilers and furnaces that heat air, which is then supplied through pipes through pipes) using sawdust , and their cost often exceeds the price of the Stropuva boiler;

- the cost of manufacturing air heaters is comparable to the cost of manufacturing a boiler;

- the costs of material and installation of water and air heating are approximately the same and amount to 15–20 thousand rubles for one room measuring 15–20 m2;

- the cost of manufacturing a stove is 20–50 thousand rubles , depending on the size.

Heaters and boilers are well suited for heating large houses , because they heat the coolant, which then flows through pipes or ducts to remote rooms. For small houses, it is preferable to have a stove installed at the junction of all rooms.

If someone is not satisfied with the appearance of an iron stove , it can be covered with a brick grate - it will improve the appearance of the stove and will not interfere with air movement.

Calculation of the minimum required power

Determining the minimum heating power required to ensure a comfortable stay begins with the user making decisions about:

- number of circuits (housing heating, hot water supply, underfloor heating).

- region of residence (local climate, wind rose, etc.).

- number of floors, wall material, ceiling height, area and number of windows of the building.

Using the standards and coefficients of SNiP 2.04.01-85, using our and other examples, a fairly accurate calculation can be made.

In practice, in the initial calculations, the total area of the heated building is determined and, based on the norm of 1 kW of heat per 10 m2, the required power spent on heating is obtained, then 20% is added for the DHW circuit and another 20% for possible inaccuracies and the creation of a safety margin .

For example, for two heat consumption circuits in a building with a total area of 200 m2, (200x1)/10 = 20 kW is enough for heating, DHW and safety margin will add another 20 * 0.4 = 8 kW, for a total of 28 kW. When choosing a specific boiler, the nearest standard power of the unit greater than the minimum required is accepted.

For industrial buildings, it is necessary to make an individual calculation taking into account all correction factors.