How to heat a house using a long-burning coal boiler

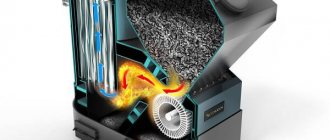

The device differs from a traditional oven in its long operation. The device uses the principle of top combustion. If the stove and standard solid fuel boilers take oxygen from below, through the provided grate, then such units have a special element. Through it, air enters the compartment from above. This helps make the combustion process completely controllable.

When air is supplied, the bulk of the coal is not affected, and combustion occurs almost layer by layer. Smoldering is observed - from the top of the raw material to the bottom, which helps ensure uniform heat transfer.

The boiler design includes the following components:

- Loading chamber, which occupies most of the internal space of the case.

- The entrance to the firebox, which is located at the top of the boiler.

- An air chamber that simultaneously performs the functions of a recuperator.

- A movable distributor, thanks to which oxygen is dispensed.

- Heat exchanger, also called a “water jacket”. It is built into the boiler body and runs along the entire perimeter of the combustion chamber. This heats up the coolant, which increases the temperature in the house.

- Telescopic air duct connecting the chamber to the distributor.

- Ash pan located at the bottom of the housing. It closes hermetically, unlike wood-fired boilers.

The chimney duct has a broken shape. Therefore, as gases pass through, energy is accumulated, and they are discharged through the pipe already cooled, while the heat remains in the house.

Ways to save coal

Coal consumption is high during the heating season, so home owners want to reduce it. There are several ways to help you save some money:

- Insulate the windows and prevent cold air from entering through other cracks. Thanks to this, the room will be warm if the boiler operates in moderate mode.

- Providing quality heating throughout your home also saves fuel by keeping rooms at the optimal temperature.

- It is allowed to reseed combustion residues that are regularly removed from the ash pan. They often contain lumps of coal that can be re-loaded into the firebox. However, it is necessary to carefully sort out the waste, since those that are unsuitable for combustion will worsen the process and reduce the efficiency of the new portion of fuel.

- During the combustion process, it is necessary to control the air supply. If the draft is too strong, the coal burns out faster, so refilling is required. At the same time, the house does not become warmer, since a significant part of the heat is lost due to increased draft.

- Insulate the windows and prevent cold air from entering through other cracks. Thanks to this, the room will be warm if the boiler operates in moderate mode.

- Providing quality heating throughout your home also saves fuel by keeping rooms at the optimal temperature.

- It is allowed to reseed combustion residues that are regularly removed from the ash pan. They often contain lumps of coal that can be re-loaded into the firebox. However, it is necessary to carefully sort out the waste, since those that are unsuitable for combustion will worsen the process and reduce the efficiency of the new portion of fuel.

- During the combustion process, it is necessary to control the air supply. If the draft is too strong, the coal burns out faster, so refilling is required. At the same time, the house does not become warmer, since a significant part of the heat is lost due to increased draft.

Some people remove the damper altogether, mistakenly assuming that this will help warm up the room faster. As a result, the coal burns instantly, but there is no heat in the house. If none of the methods help reduce the amount of fuel used and the rooms are still cool, it is recommended to re-check all windows and doors, and also ensure that there is no possibility of cold air entering through openings in the floors. Quite often they are invisible under the baseboards and do not allow achieving optimal temperature conditions.

Types of coal boilers

Not all units are classified as long-burning equipment. There are efficient pyrolysis boilers, characterized by a high efficiency. They have 2 interconnected fireboxes. In chamber 1, coal smoldering occurs, and flammable gases are formed, which are then burned in compartment 2. This way the fuel is almost completely consumed. This not only improves the efficiency of the equipment, but also extends its operating time. 1 bookmark burns for 24-30 hours.

And if there is a special tank, then the process can take 7 days. Sometimes bunker boilers with automatic fuel supply are classified as a separate category.

Bunker automatic boilers

Automatic coal boilers differ from previous versions in that all working processes are fully or partially (if we are talking about semi-automatic models) controlled by a programmable microprocessor controller connected to sensors and thermostats.

Long-term combustion is supported by forced air fans (superchargers) and a traction system for removing combustion products.

Model Zota Stakhanov 20. Coal is supplied by an automatic mechanism from a hopper connected to the boiler; supply volumes are regulated by the automatics of the boiler unit.

To ensure uninterrupted refueling, a loading hopper is provided - a metal box with a screw conveyor installed below.

The capacity of the built-in fuel tank in a bunker coal boiler is enough for an average of 2–7 days, and if the fuel is supplied from a separate mechanized storage facility, then depending on the area of its capacity it can last for 3–4 weeks or even for the entire heating season.

Advantages and disadvantages of equipment

A long-burning coal unit has the following advantages:

- saving resources, since the heating device consumes 20-30% less raw materials than other models;

- autonomy (most long-burning appliances on the market do not require an electrical connection);

- ease of maintenance (there is no need to clean the boiler often, and the procedure itself does not take much time);

- the ability to maintain a stable temperature;

- environmental cleanliness - the pulverized coal mixture practically does not accumulate in the room (as does smoke);

- reliability (due to its simple design, the boiler lasts a long time without breakdowns).

Such equipment also has disadvantages. For example, the impossibility of refueling, since you need to wait for the fuel to burn completely. In addition, the coal unit must be installed in a separate room. Equipment, especially with a bunker, takes up a lot of space, so the cost of installing a boiler room increases.

Users also note a higher cost compared to other types of heating devices.

Principle of operation

Increasing the duration of the combustion process is achieved not only by a large firebox. The organization of furnace combustion in the form of layered combustion with upper combustion and upper supply of blast air has a significant impact on efficiency and heat transfer, so gas-air flows do not circulate at all in the lower fuel layers.

Operating principle of a boiler unit with long-term combustion of solid fuel: The air required for fuel combustion is taken directly from the combustion chamber and passes through a preheating stage in the upper heating chamber of top-combustion boilers.

A pipe air distributor is built into the heating chamber to supply hot air to the combustion device. The feeding system can be gravitational or forced.

The air distributor is equipped with channels directed vertically. Before loading fuel, it is raised using a built-in mechanism, then fuel is poured in and the distributor, which rests on the upper fuel level, is lowered. As it burns out, it falls down the combustion space. This movement of the distributor provides air supply to the top layer of hot fuel.

In the contact zone of the air distributor with the fuel layer there is a steel disk - a staskoblin. Bypassing it, the fire enters the pyrolysis chamber located between the disk and the air heating chamber.

Here, flammable substances burn out completely, transferring heat through the walls of the firebox to the heating fluid circulating in the built-in heat exchanger. Flue gases are discharged through the gas outlet pipe into the chimney. The ash is collected in the ash box located at the bottom of the boiler unit, under the firebox. The volume of the box allows it to be cleaned at intervals of 2 to 5 loads.

Which coal is best and how to calculate consumption

Most long-burning boilers are not demanding on the quality of raw materials. But not all types are suitable for heating. For example, charcoal models are not found on the market. Anthracite is recommended only for specialized equipment. However, the quality of long-flame coal is close to it. This option is considered the best choice for autonomous heating at home.

It is better not to use brown coal for domestic boilers, unless specifically specified by the manufacturer. Brown has low efficiency, so its use is impractical.

The fraction of raw materials for automated systems is also important, since the latter are designed for fuel with a size of 5-25 mm.

Coal consumption is indicated by the manufacturer in the technical documentation. But you can make an average calculation yourself. If we assume that for heating an area of 10 sq. m requires 1 kW of thermal energy per hour, then per day with a building area of 100 sq. m requires 240 kW. When 1 kg of raw material is burned, an average of 7.75 kW is released. About 31 kg of fuel will be required in 24 hours.

However, it is necessary to take into account the calorific value of coal and its ash content. Also, the proportion must be adapted to the area of the house. For example, at 200 sq. m - 500 kW per day, since large heat losses are taken into account.

Water jacket

provides two corners: one at the bottom, the other at the top

Features of the water jacket of a household appliance for the heating system of a private country house or cottage are as follows:

- The internal distance from the body to its wall should be 4-6 cm.

- The thickness of the sheet metal can be 2.5 mm. If you want to make a shirt with your own hands more correctly, then you need to take into account that there should be 1 mm per 1 bar of operating pressure. This is provided that the shirt is not higher than 2 m.

According to the video, the shirt can be made from sheet metal. So try to find a suitable pipe.

Firebox rules

The instructions state that:

- The fuel is loaded in such a way as to fill the entire volume of coal at once.

- For kindling, dry paper or wood chips are laid on top of the raw materials, which are set on fire automatically. The top door is open, but the air duct is closed.

- When the combustion process has begun, the door must be closed and the telescopic air duct regulator must be turned on.

The required temperature in such boilers is selected automatically. But in some models, adjustment is carried out using an air duct damper.

When the combustion cycle is completed, the remaining raw materials are removed from the loading chamber, the ash pan is cleaned and a new batch is poured.

Operating rules

For the smooth operation of the heating device, it is necessary to follow several rules that will help extend its service life. It will not be possible to ignite the coal directly, since this requires a temperature of at least +400 °C. This is why it is necessary to use firewood for the fire.

When burning wood, it is recommended to leave all valves open to ensure air access. After some time, the firewood burns down to smoldering logs.

It is necessary to pour coal on them in a layer, the thickness of which is no more than 15 cm. After flaring up, you can add more of it. It is recommended to use pieces of approximately the same size.

To prevent the water in the boiler from boiling, you should control the combustion and, if necessary, close all dampers. For the boiler to operate efficiently, the ash pan must be cleaned regularly so that waste does not obstruct the flow of air. If you add too much fuel, the boiler may go out. In this case, you should wait for it to cool completely, clean it and start kindling again.

It is not recommended to place wooden furniture in close proximity to a working heating device to avoid the risk of fire.

Rating of the best coal boiler models

Good units are offered by foreign and domestic manufacturers.

The most popular devices are:

- Heiztechnik Q Alfa 15. This is a 15 kW boiler with a fairly high efficiency. Suitable for small houses with an area of 110 sq. m. The main advantages are versatility (works on coal, wood and briquettes), durable cast iron grates and a body made of boiler steel 5 mm thick. The device can last up to 20 years if used properly.

- Stropuva S15U. It is a boiler with a capacity of 15 kW. Powered by coal and pellets. A special feature of the equipment is the presence of a bimetallic draft regulator. This makes it possible to do without connecting to the mains.

- LIEPSNELE L20U. This is a unit of a Lithuanian brand. Power is 20 kW. The device operates on coal, wood, pellets, peat and wood shavings. When fully loaded, it maintains combustion for a week.

- Galmet “CARBO” 21. It is a Polish-made device with a power of 22 kW. Feature – high level of automation. The device has a pressure gauge, temperature sensor and flue gas sensor. This model also has a PID controller, which allows you to control the operation of the main components and control the combustion process.

- "WEEK KO-60." This is a Russian boiler with a capacity of 60 kW. The device is used for heating a private house with an area of up to 250 square meters. m. On 1 coal bed, the model works for 2-4 days. Modern equipment is equipped with a microprocessor unit that is insensitive to voltage surges and network failures.

Prices: summary table

Price rating of long-burning coal boilers (table):

| Long burning coal boiler model | Cost, rub. |

| Stropuva S15U | 85 400–90 560 |

| Heiztechnik Q Alfa 15 | 62 240–68 720 |

| Buderus Logano S181-15E | 218 000–250 640 |

| WEEK KO-60 | 115 900–130 500 |

| TIS (TIS) PRO 11 | 64 100–67 200 |

| LIEPSNELE L20U | 81 500–99 770 |

| VIADRUS Hercules U22D | 126 600 –128 530 |

| Galmet CARBO 21 | 103 890–116 750 |

Criterias of choice

The main aspect when purchasing is the boiler power. The principle of calculating the indicator is the same as for a wood-burning unit - per 10 square meters. m of area requires 1 kW of energy.

The material of the heat exchanger is taken into account. There are several options - stainless steel alloy, copper and cast iron products. The latter are more reliable, last longer, but cost more and increase the weight of the boiler. Copper is considered a durable and expensive option. Devices with steel elements are the cheapest.

Other selection criteria:

- Degree of workflow automation. There are models that provide for manual loading of fuel, and the rest (ignition, combustion maintenance) occurs without human intervention. But there are also fully automatic devices. Their design provides for the presence of a bunker through which fuel is periodically supplied to the boiler.

- Loading chamber volume. The size of the firebox directly depends on the power. The proportion is calculated as follows: per 1 kW of energy – 3.3-5.1 liters. For the most common version of a 25 kW boiler, a loading chamber of 110 liters is considered the norm.

- Possibility of using other types of fuel. There are models that operate not only on coal, but also on wood, sawdust, shavings, and pellets (a separate burner is installed for this).

- Functionality and type of control. Modern units are often equipped with thermostats, a self-cleaning system and weather-dependent automation. Safety switches and valves are responsible for safety. There are also boilers that are equipped with a GSM module.

Calculation of required heating power

Calculation of the thermal power of the boiler unit must cover all heat losses of the building with a margin of at least 20%. If the boiler must produce thermal energy to heat water, the power must accordingly increase in terms of the volume of water used in each specific case.

Calculating the heat loss of a building is quite complex; it depends on the climatic region of the facility’s location and the material of the walls and roof.

For an approximate calculation in the central region of Russia for houses with brickwork of at least 2 bricks and an interfloor height of 2.7 m, you can use the practical formula at the rate of 1 kW per 10 m2 of facility area with a margin of 20%.

For example, for a cottage with an area of 150 m2, the heating power of the boiler unit will be equal to:

150:10x1.2 = 18.0 kW

For a family of three, a domestic hot water tank of at least 100 liters with a power of 5.8 kW is required.

Thus, the total load on the boiler will be:

18.0 + 5.8 = 23.8 kW

Installation features and location selection

A coal boiler for heating a private house must be installed in a separate room. Moreover, the room should be quite spacious and with good ventilation. Non-combustible finishing materials must be used in the boiler room. Often it is necessary to make an additional concrete base for a heavy apparatus.

The installation of the unit is carried out by professionals. It is necessary not only to install the boiler, but also to connect it with heating and ventilation systems. At the same time, various auxiliary equipment is installed - a fan, valves, sensors, a water purification filter, an expansion tank. After installation, a test run is required.

Recently, combined units have become increasingly popular. An example is a gas-coal boiler, which is characterized by higher efficiency and autonomy.

You may be interested in information about what a DKVR boiler is and where it is used.

Reliable heating system for a country house

Maintaining a house in a habitable condition, provided that it is remote from the main communications, becomes a rather difficult task, associated with many difficulties and problems. If it is relatively simple to provide a house with electricity and water - it is enough to install a generator and arrange the supply of imported water - then with heat everything is somewhat different. Heating premises requires more significant labor, time and financial costs, but there are also solutions here. One of the most rational ways to heat the premises of a house is to install a solid fuel boiler, that is, a boiler that produces heat by burning solid fuel. The fuel here can be coal, wood and other energy sources that can provide enough heat to ensure a comfortable temperature throughout the entire house.

Manufacturing

According to many videos, wood-burning boilers for heating do this:

- Cut off the length of pipe required for the housing.

- Cut out holes for the doors and chimney. The latter should be near the top at a distance equal to the height of the air distributor with fins plus 2 cm.

- Cut out the bottom and top. A hole is cut in the center of the top.

- Cut out the pancake and weld the ribs to it. A hole is made in the center. Weld the air supply pipe. They make a damper in it.

- Weld the bottom, insert the air distributor, weld the top.

- Fix the corners and water jacket.

- The necks and doors are welded.