The main technical characteristics of aluminum heating radiator models are information that it is advisable to know before choosing and purchasing them. Along with the appearance (design) of the heating device and its cost, technical data allows you to compare different models and choose the option that is optimal in terms of the main parameters.

There are quantitative and qualitative characteristics of aluminum radiators. Quantitative ones allow you to compare heating devices according to their weight and size parameters and heat flow power. In turn, quality characteristics take into account design features and manufacturing technology.

What influences the dimensions of aluminum heating radiators

One of the most important parameters is the gap between the axes of the radiators. Most often you can find aluminum devices on sale, in which the distance between two collectors - lower and upper - is 350 or 500 millimeters. True, there are products with values equal to 200, 400, 600, 700 and even 800 millimeters.

The dimensions of aluminum radiators in length have practically no restrictions. The longer the battery, the higher its power. To achieve the required power level, it is necessary to purchase a certain number of heating sections.

The total length of the device depends on the power needed to heat the room, the size of the heating radiators, sections and heat transfer. To connect individual elements of an aluminum radiator to the pipelines of the heating structure, use an installation kit, which includes:

- special brackets for hanging the battery on the wall in the amount of 2-4 pieces;

- Mayevsky valve - a device for bleeding air trapped in the system;

- a key designed for a faucet;

- pass-through radiator plugs with a diameter of 3/4 or ½ of the right or left type;

- plugs for the heating device, they are also called blind plugs;

- sometimes there are also dowels included to secure the brackets.

Depending on the type of manufacture of the aluminum alloy radiator, the heating device can be cast or extruded:

- Thanks to casting, the battery becomes durable and reliable. In this case, the sections are made up of individual parts, cast entirely and then assembled into a single heating device. Its lower part is welded last;

- in the process of using extrusion equipment, a heated aluminum alloy is forced through a special metal plate with holes. This method allows you to make a long aluminum profile of the required shape. When it cools, it is divided into segments that correspond to the size of the device. Only then are the top and bottom of the battery welded. In this case, it is impossible to adjust the radiator in length, and sections cannot be added or subtracted from it. Extrusion devices are quite rare on sale.

Which radiator is better to choose?

The choice of radiators depends on what goals you are pursuing. If the number one goal is to save money, then you can find an old Soviet cast-iron radiator in a landfill or scrap metal that will last another hundred years without the slightest breakdown.

If the buyer’s task is to effectively combine an inexpensive product and a good design, modern steel radiators are best suited - they perfectly combine high heat transfer, modern design, durability and maintainability.

If the goal is to achieve maximum thermal efficiency, you should pay attention to bimetallic products with a copper core. This technique provides maximum heat transfer, but the price will make you think.

Today, suppliers are ready to provide any desires of the buyer - from elite European goods to cheap and low-quality Chinese ones. In any case, when purchasing products for such an important thing as heating, you should consult a specialist.

Parameters and dimensions of aluminum radiators ROVALL

The company producing aluminum radiators TM ROVALL is one of the divisions of the Italian concern Sira Group. This company produces batteries from aluminum alloy with a distance between the two collectors of 200, 350 and 500 millimeters. The kit for their fastening, which is purchased separately, includes the following products: plugs, adapters, for connecting sections - nipples with gaskets and for wall mounting - brackets, as well as a Mayevsky tap. Main parameters of ROVALL aluminum radiators:

- permissible operating pressure is 20 bar, and when tested - 37.5 bar;

- maximum temperature – no more than 110 °C.

All Rovall devices of the Alux 200 models, according to official sources of the manufacturer, have a distance of 200 millimeters between the axes, a height of 245, and a depth of 100 millimeters. In this case, the minimum length is 80, and the maximum is 1280 millimeters. In turn, heat transfer can be a minimum of 92, and a maximum of 1472 watts. The number of sections varies from one to 16.

The Rovall Alux 350 radiator models, with a distance of 350 millimeters between the collectors, have a height of 395 and a depth of 100 millimeters. In this case, the minimum length of the devices is 80, and the maximum is 1280 millimeters. In turn, heat transfer can be from 138 to 2208 watts. The number of sections is from one to 16.

Models of Rovall Alux 500 devices, with an interaxial distance of 500 millimeters, have a height of 545 millimeters and a depth of 100 millimeters. At the same time, the minimum length of the devices is 80, and the maximum is 1280 millimeters. In turn, the power can be a minimum of 179, and a maximum of 2840 watts. The number of sections ranges from one to 16.

Dimensions of bimetallic batteries

Bimetallic radiators consist of a steel core and an aluminum body. The main change that a steel core brings compared to an aluminum one is an increase in the permissible coolant pressure. Of course, the price also increases. The most common sizes: 80-82x75-100x550-580 mm.

Heat transfer is slightly reduced due to the lower thermal conductivity of steel, but is compensated by greater ribbing in the section area. Heat transfer rates: 160-200 Watts per section. The working pressure can be significantly yours: from 25 to 50 atmospheres.

Bimetallic radiators are characterized by the same range of standard sizes as aluminum ones.

The dimensions of low aluminum radiators are also typical for bimetallic ones. At the same time, the heat transfer characteristics also change slightly: radiators from 40 to 140 watts per section are common.

Bimetallic radiators, due to their higher performance characteristics, are more often used to build non-standard heating systems. In particular, such radiators are often used to stylize heating elements in the form of interior design elements.

It simply doesn’t make sense to somehow evaluate standard sizes - they simply don’t exist. Most European radiator manufacturers have their own series of radiators in a wide variety of, often exotic, sizes.

Radiator volume parameters from Climatic Control Corporation LLP

This company from the UK produces aluminum heating devices BiLUX AL, which have an excellent degree of heat transfer and are manufactured taking into account the characteristics of autonomous heating systems. The surface area of these batteries is significant, and the cross-section of a vertical pipe, when calculating aluminum heating radiators, was determined optimally. The plant where BiLUX AL M 300 and BiLUX AL M 500 radiators are manufactured is located in China. The distance between both axes of the collectors is 300 or 500 millimeters. During the manufacturing process, the injection-molded top parts of the instruments are connected to the bottom, which is manufactured using a specially developed welding technology.

When the products are ready, after assembly they are subjected to chemical and mechanical processing. Only after this, aluminum devices are tested and checked for strength and tightness. They are painted in several stages. In addition, they are exposed to an electrostatic field and at the same time enamel produced on the basis of epoxy resins is sprayed. Then, when heated to a high temperature, the surfaces of the radiators are polymerized.

The peculiarity of BiLUX AL devices is that their ends have a special design solution that allows the use of a special ring for gasketing. The material it is made of completely seals the joints. The nipples for them use cadmium, as a result, the likelihood of coolant leakage is reduced to zero. Main dimensions of BiLUX AL aluminum radiators:

- the permissible operating pressure is 16 bar, and when testing the device - 24 bar;

- the pressure that can rupture the device is 48 bar.

Single-section BiLUX AL M 500 batteries with a distance of 500 millimeters between the axes and a power of 180 watts have the following parameters (in millimeters):

- height – 570;

- depth – 75-80;

- length – 75.

Single-section BiLUX AL M 300 with a distance of 300 millimeters between the axes and a power of 128 watts have the following aluminum radiator section size (in millimeters):

- height – 370;

- depth – 75-80;

- length – 75.

Requirements for the selection of radiators

Before purchasing, you need to make all the calculations, then select the size of the radiator.

When choosing the size of heating radiators for placement under the window, you should start from the width of the window opening and the estimated distance of the edges of the elements to the window sill and the floor surface. Before going to the store, you must take all the necessary measurements and use them as a guide when considering options. The standard opening width is 110-120 cm. The size of the purchased battery must be at least 70-75% of this value. If we are talking about a sectional device made of aluminum, you will need a radiator of 10-12 elements (the width of one is usually about 8 cm).

When choosing the size of radiators, you need to take into account the height of the window sill. There should be a distance of 6-12 cm between it and the upper edge of the radiator elements. The installation height of heating devices above the floor should be at least 8 cm. In this case, heat transfer is achieved that maximally corresponds to that declared by the manufacturer.

Also in the private sector, the volume of liquid placed in the section is of great importance. If in apartment buildings where residents use centralized heating, this parameter does not play a role, then when using your own system it is needed to calculate the volume when you need to find out the efficiency of the pump or boiler.

The most important indicator when choosing heating equipment is thermal power. It is not always advisable to choose high-power options. In homes with high-quality thermal insulation, a model with an average value of this parameter is sufficient.

Since the surface area of the radiator affects the uniformity of heat transfer, it is better to choose a larger number of sections with medium power than fewer with high power. This will ensure that there are no cold zones and condensation on the window glass.

Dimensions of aluminum radiators from Fondital

The Fondital company (Italy) produces Calidor Super aluminum batteries, adapted for the climatic conditions of Russia and the CIS countries (see photo). When manufacturing them, European standards such as EN 442 and Russian ones are taken into account, in accordance with GOST R RU.9001.5.1.9009. The method of their manufacture is casting, performed under high pressure. Painting is carried out in two stages: initially, using anaphoresis, one layer of enamel is applied as protection, and then, using powder enamel, the product is given a decent appearance. The installation kit for the radiator will have to be purchased separately. It includes: adapters; brackets; blind plugs and Mayevsky tap.

The distance between the axles is:

- 350 millimeters for the S4 model, which has 4 side ribs and a section depth of 97 millimeters;

- 500 millimeters for models S4 and S3 (with 3 ribs and depth - 96 millimeters).

Main parameters of aluminum radiators Calidor S:

- permissible operating pressure - 16 bar, and when testing the device - 24 bar, maximum burst limit - 60 bar;

- maximum temperature – no more than 120 °C.

The Calidor Super 350 S4 radiator models, with a gap of 350 millimeters between the two axes, according to the manufacturer’s official sources, have a height of 428 millimeters and a depth of 96 millimeters. At the same time, the minimum length of the devices is 80, and the maximum is 1120 millimeters. In turn, the heat transfer can be a minimum of 145, and a maximum of 2036 watts. The number of sections is from one to 14.

The dimensions of aluminum heating radiators Calidor Super 500 S4 with a center distance of 500 millimeters are as follows: height 578 millimeters, section depth 96 millimeters. In this case, the minimum length is 80, and the maximum is 1120 millimeters. In turn, the power can be a minimum of 192, and a maximum of 2694 watts. The number of sections varies from one to 14.

All models of Calidor Super 500 S3 devices have a distance of 500 millimeters between the axes, a height of 578, and a depth of 100 millimeters. In this case, the minimum length is 80, and the maximum is 1120 millimeters. In turn, the minimum power can be 178, and the maximum - 2478 watts. The number of sections varies from one to 14.

How to assemble a radiator

Aluminum heating radiators are assembled according to the following algorithm:

- place the battery on a flat surface;

- Inspect each threaded connection for chips, cracks and thoroughly clean with sandpaper. Degrease the ends using gasoline. Gaskets can be washed in soapy water;

- connect the sections. To do this, you need to put the seals on the nipple nut and place them on both sides of the device section. Make a couple of turns with the key in the upper and lower holes. When the key stops turning, you can pull it out using the lever;

- A plug should be placed on the unused hole. And on the other side, attach a Mayevsky valve to remove excess air from the system. Now the radiator can be connected to the system according to the selected scheme.

Characteristics of aluminum radiators from Faral SpA

This company exclusively for the Russian heating equipment market produces durable radiators FARAL Green HP (Italy), capable of withstanding a working pressure of 16 atmospheres. In their production, the injection method is used. External and internal surfaces are covered with a zirconium protective layer that penetrates deeply and is not washed off during operation. As a result, when the device comes into contact with water, no gases are released. The possibility of electrochemical corrosion is excluded. The depth of Green HP batteries is 80 millimeters, and Trio HP is 95 millimeters. The distance between the axes can be 350 or 500 millimeters. A separately sold kit for installing the device contains: an air bleed valve; brackets; adapters with plugs; screws with plugs and silicone gaskets. Main parameters of FARAL aluminum radiators:

- working pressure up to 16 bar is allowed, and when testing devices - 24 bar;

- maximum temperature – no more than 110 °C.

All models of FARAL Green HP 350 devices, according to information from the manufacturer’s official data, with a distance of 350 millimeters between the two collectors, a height of 430 and a depth of 80 millimeters. In this case, the length varies from 80 to a maximum of 1120 millimeters. The power can be a minimum of 134, and a maximum of 1904 watts. Number of sections from 1 to 14.

The FARAL Green HP 500 radiator models, with a distance of 500 millimeters between the axes, have a height of 580 millimeters and a depth of 80 millimeters. Moreover, the length of the devices is from 80 (minimum) to 1120 millimeters (maximum). In turn, the heat transfer can be a minimum of 180, and a maximum of 2520 watts. The number of sections is from one to 14.

FARAL radiators of the Trio HP 500 model range have a center-to-center distance of 500 millimeters, the height of the devices is 580 millimeters, and the depth is 95 millimeters. In this case, the minimum length of the devices is 80, and the maximum is 1120 millimeters. As for heat transfer, its minimum value is 212 watts, and the maximum is 2968 watts.

The number of sections, depending on the power, can be from 1 to 14. FARAL radiators of the Trio HP 350 model range have a center-to-center distance of 350 millimeters, the height of the devices is 430 millimeters, and the depth is 95 millimeters. Moreover, the length of the devices ranges from 80 to a maximum of 1120 millimeters. As for heat transfer, its minimum value is 151 watts, and the maximum is 2114 watts. The number of sections can be from one to 14 depending on the power.

Resistance to water hammer

Aluminum heating devices can withstand pressure increases in the system up to 16 atmospheres. for some models this figure is 20. Not much. As a result, pressure surges can result in cracks and battery failure. If a water hammer occurs, aluminum

the battery will simply burst. It is for this reason that it is strictly not recommended to use heating devices made of aluminum in multi-storey buildings.

Due to the presence of a durable steel or copper core inside bimetallic heating devices, these batteries are not afraid of pressure increases in the system of up to 40 atmospheres. Even a powerful water hammer will not damage a bimetallic battery.

Apartment owners in buildings with centralized heating, where the likelihood of excess pressure occurring is quite high, should pay attention to the degree of battery resistance to water hammer. Due to the autonomy of the system, water hammer cannot occur in the heating pipes of a private house, so the use of aluminum radiators is acceptable

Calculation of aluminum radiators from Global

Global radiators from the company of the same name (Italy) can be installed both in apartments of multi-storey buildings and in your own homes. Their distinctive characteristics are an elegant and original appearance. The most popular models are ISEO and VOX with a center distance of 350 or 500 millimeters. The installation kit is standard and sold separately. Main parameters of Global aluminum radiators:

- the maximum operating pressure is 16 bar, and when testing the device - 24 bar; The maximum temperature of heated water is no more than 110 °C.

The Global VOX 350 device models, according to the manufacturer’s official sources, with a distance of 350 millimeters between the axes, have a height of 440 and a depth of 95 millimeters. In this case, the minimum length is 80, and the maximum is 1120 millimeters. In turn, the power can be a minimum of 145, and a maximum of 2030 watts. The number of sections varies from one to 14. Global radiators of the VOX 500 model series have a center-to-center distance of 500 millimeters, the height of the devices is 590 millimeters, and the depth is 95 millimeters. In this case, the minimum length of the devices is 80, and the maximum is 1120 millimeters. As for heat transfer, its minimum value is 193 watts, and the maximum is 2702 watts. The number of sections can be, depending on the power, from one to 14. Models of Global ISEO devices, according to the manufacturer’s official sources, with a distance of 350 millimeters between the axes, have a height of 432 and a depth of 80 millimeters. In this case, the minimum length is 80, and the maximum is 1120 millimeters. In turn, the power can be a minimum of 134, and a maximum of 1976 watts. The number of sections varies from one to 14. For Global radiators of the ISEO model range, which have a center-to-center distance of 500 millimeters, the height of the devices is 582 millimeters and the depth is 80 millimeters. In this case, the minimum length of the devices is 80, and the maximum is 1120 millimeters. As for heat transfer, its minimum value is 181 watts, and the maximum is 2534 watts. The number of sections can be from one to 14 depending on the power.

Tall and narrow

Tall radiators, even in their usual design, look unusual. And if you paint it in a non-standard color, give it an unusual shape, and combine it with a mirror or shelf, it generally looks more like a designer item than a banal heating device.

Let us immediately upset cast iron lovers: the tallest cast iron radiator is around a meter. Haven't seen it higher. The same can be said about bimetallic ones - they don’t come above a meter. And in general, all that is in bimetal is 760-860 mm or so.

One of the most attractive models is the Arbonia Entreetherm vertical tubular radiator

Steel panel batteries as standard come in heights of up to 900 mm. But there are also special models that can reach two meters and higher. For example, Kermi has two models Verteo Plan and Verteo Profil - the maximum they can be up to 2.2 m. Purmo also has giants: Kos V, Faros V, Tinos V, Narbonne V and VT, Paros V. They differ in the type of front panel (smooth or profiled) and depth. But they all only have a bottom connection.

Steel tubular radiators are available with a height of up to 3000 mm. Moreover, if necessary, some manufacturers can make it higher. There are tall models from any manufacturer: everyone on the market offers such non-standard options “to order.” Here we will list only the most interesting from a design point of view: Entreetherm, Planterm from Arbonia, Dekor series from Kermi, Harmony from the Russian KZTO, Charleston from Zender.

Other types do not have tall radiators. The choice, it must be said, is considerable. Don't get confused.

Parameters of aluminum radiators from Torex

The Italian company of the same name offers aluminum sectional heating devices, which are manufactured using the casting method. Their peculiarity lies in the presence of unusual light transitions on the front part. For models that have a center distance of 350 millimeters, the depth is 78 millimeters. But for batteries with a gap between the axes of 500 millimeters, the depth of the radiators can be 70 or 78 millimeters. They can have one or an even number of sections. The mounting kit must be purchased separately. Main parameters of Torex aluminum radiators:

- the permissible operating pressure is 16 bar, and when testing the device - 24 bar;

- maximum temperature – no more than 110°C;

- the required water pH is 7-8 (acceptable 6.5 - 8.5).

The Torex B 350 device models, according to the manufacturer’s official sources, with a distance of 350 millimeters between the axes, have a height of 420 and a depth of 78 millimeters. In this case, the minimum length is 80, and the maximum is 1120 millimeters. In turn, the power can be a minimum of 130, and a maximum of 1820 watts. The number of sections ranges from one and then an even number to 14. Torex radiators of the B 500 model series have a center-to-center distance of 500 millimeters, the height of the devices is 570 millimeters, and the depth is 78 millimeters. In this case, the minimum length of the devices is 80, and the maximum is 1120 millimeters. As for heat transfer, its minimum value is 172 watts, and the maximum is 2408 watts. The number of sections can be from one and then an even number to 14. Torex radiators of the C 500 model series have a center-to-center distance of 500 millimeters, the height of the devices is 570 millimeters, and the depth is 70 millimeters. In this case, the minimum length of the devices is 75, and the maximum is 1050 millimeters. As for heat transfer, its minimum value is 198 watts, and the maximum is 2772 watts. The number of sections can be from one and then an even number to 14.

Characteristics of cast iron radiators of various manufacturers and models

In Soviet times, there were countless factories producing cast iron radiators - after all, there was no alternative. Here, for example, are just a few of their types: NM-140, NM-150, Minsk-110, R-90, RKSh. Almost all of them are no longer produced. Perhaps only one proven model lasts a long time - the MS-140, classic and good-quality.

New models look prettier; for example, the Ms-110 from the Santekhlit plant has a shallow depth (only 11 centimeters) and fits well under narrow plastic window sills.

In Cheboksary they make FM radiators with one, two and three channels. Their outer side is flat, which looks quite aesthetically pleasing, and it’s easier to wipe off dust.

Beautiful two-channel radiators are produced in Minsk, about 10 models in total.

Sectional batteries made of cast iron are also brought to us from abroad. Foreign products are smoother both outside and inside, so their heat transfer is higher. Let us note the Chinese company Konner (the “Hit”, “Modern” and “Fort” models are especially good).

The Czech plant Viadrus, the Turkish company DemirDöküm and the Spanish concern Roca also make good radiators. European manufacturers make very elegant batteries with a cast-iron cast pattern. True, such radiators are an order of magnitude more expensive than domestic ones.

Section dimensions of aluminum radiators from Rifar

The company produces aluminum batteries of BASE models with a distance between two axes of 200, 350, 500 millimeters. ALP products have an improved design, increased heat dissipation and a center spacing of 500 millimeters. Alum models are specially designed devices that can be used both in standard heating systems and as an oil-fired electric heater. Flex's unique development allows you to give the device the desired radius of curvature. Main characteristics of Rifar aluminum radiators:

- permissible operating pressure is 20 atmospheres;

- maximum temperature – no more than 135°C;

- the required water pH is 7-8.5.

Battery sizes and types of materials

There are 3 groups of standard sizes of heating radiators:

- standard;

- low;

- tall.

The materials of heating devices are also varied. All types of radiators remain in demand, but each has certain features:

- Aluminum has good thermal conductivity and heat dissipation. The batteries are lightweight, compact, and stylish in design.

- Bimetallic devices are a modification of aluminum devices. There are steel elements inside, which increase corrosion resistance. The devices also withstand water hammer and are unpretentious to the environment. Externally, the batteries are stylish, beautiful and ergonomic.

- Cast iron devices are slightly inferior to the previous two. In particular, due to its massiveness, heavy weight and low thermal conductivity. At the same time, many still prefer cast iron radiators, since they last up to half a century regardless of the quality of the coolant.

- There are two types of steel batteries: panel and tubular. The first type is inexpensive and simple in design. Tubular radiators are characterized by high power and long service life (about 25 years).

When purchasing appliances, consider the material and specifics of your heating system. Once this factor has been decided, it’s time to move on to the dimensions of the batteries.

Aluminum radiator section volume

Knowing the volume of one section of an aluminum radiator is very important for autonomous heating systems. To determine how much antifreeze is needed to fill the heating system, use calculation tables. To find out the volume of water in one section, use the information available in thematic reference books:

- in a standard device, the volume of the aluminum radiator section is 0.45 liters of coolant;

- a linear meter of a pipe with a diameter of 15 millimeters contains 0.177 liters, and a pipe with a diameter of 32 millimeters contains 0.8 liters.

Coolant for cast iron radiators

One of the significant advantages of cast iron models is their insensitivity to various coolants. There is no need to monitor the acidity levels of the circulating fluid. The width of the channel makes it possible to freely pass through and not allow impurities to accumulate inside, of which there are a huge number in central heating systems.

Cast iron radiators do not enter into chemical reactions with antifreeze, water or other liquids containing anti-freezing additives. However, this does not mean that you can forget about water treatment. Indeed, in addition to the batteries, the coolant flows through pipe lines, inside the boiler and other installed equipment.

Calculation of the number of sections

There is a simple option for calculating the number of sections. To do this, you need to know the area of the room and the standard power, which is equal to:

- if the ceiling height is 2.5 - 2.7 meters, there is one external wall and one window - 100 watts;

- if the ceiling height does not exceed 2.7 meters, there are two external walls and one window - 120 watts;

- if the ceiling height is no more than 2.7 meters, there are two external walls and two windows - 130 watts.

Before calculating the number of aluminum radiators, you need to find out the power of one section in the device passport. Now you need to multiply the standard power by the area of the room and divide by the power of one section. The result must be rounded up (pro

Optimal installation schemes for heating components

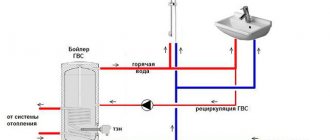

If you need to reduce the costs of operations such as installation of 350 mm heating radiators and their further connection, then you can opt for a single-pipe type wiring system. Such a system, however, requires the presence of a bypass line.

Valves will be installed at the highest points through which air will be released. Such a valve will operate automatically, they will release air, and the air inlet will be blocked by water pressure.

Such a valve will also be required during various dismantling works. In the case of a single-pipe distribution system, such a valve is best connected diagonally. In this case, the coolant will flow in the upper left corner and be discharged in the lower right.

The reverse option can also be used. The most important nuance that must be observed is not to connect heating radiators 150 mm high on the same side. In this case, you can lose up to 10% of heat transfer. If small or mini heating radiators are installed, it is best to make a bottom connection.

Dimensions

Radiators

determine the amount of coolant

they can accommodate.

This determines the power of heating batteries.

Comparison of technical characteristics

Characteristics important for comparative analysis are collected in the table.

| Characteristic | Production method | |

| Cast | Extrusive | |

| Heat transfer of 1 section for radiators with a section height of 500 mm, W* | 80–210 | up to 200 |

| Working pressure, atm | 10–16 | 6–10 |

| Crimping pressure, atm | 15–20 | 10–15 |

| Breaking pressure, atm | 60–100 | 40–50 |

| Operating coolant temperature, °C | up to 120 | up to 100 |

| Manufacturer's warranty, years | 10–25 | 5–10 |

*Heat transfer is measured at a temperature difference between the coolant and air in the room of 70 oC.

Simplified calculation of heat loss compensation

Any calculations are based on certain principles. The calculations of the required thermal power of batteries are based on the understanding that well-functioning heating devices must fully compensate for the heat losses that occur during their operation due to the characteristics of the heated premises.

For living rooms located in a well-insulated house, located, in turn, in a temperate climate zone, in some cases a simplified calculation of compensation for heat leakage is suitable.

For such premises, calculations are based on a standard power of 41 W required to heat 1 cubic meter. living space.

In order for the thermal energy emitted by heating devices to be directed specifically at heating the premises, it is necessary to insulate walls, attics, windows and floors

The formula for determining the thermal power of radiators necessary to maintain optimal living conditions in a room is as follows:

Q = 41 x V,

where V is the volume of the heated room in cubic meters.

The resulting four-digit result can be expressed in kilowatts, reducing it at the rate of 1 kW = 1000 W.

Comparison with radiators made of other metals

Let's consider the main characteristics of aluminum radiators against the background of other, no less popular in Russia, convectors made of other metals. For ease of perception of information, all information is presented as a comparative table.

The presented table makes it clear that in many performance indicators, aluminum radiators differ significantly from analogues made from other materials:

- The spread in temperature of the working fluid is approximately the same, but this condition will be interesting only if antifreeze is used as a coolant. In most residential buildings and apartments, the temperature of the water circulating in the system does not exceed 80-90°C.

- The magnitude of the operating pressures introduces a kind of scatter. Cast iron does not tolerate stretching well, so it has a low index. Steel is slightly higher, bimetal has the highest value.

- In terms of efficiency, aluminum radiators can be called optimal in terms of price-result ratio. They emit much less heat than copper ones, but they are also much cheaper.

- An equally important factor is the weight of the radiator. This issue is most relevant when designing a heating system for a building built from porous aerated concrete. Lightweight bimetal and aluminum will not put excessive stress on the bracket like their steel or cast iron counterparts. Also, as already mentioned, lower weight facilitates the process of transporting and installing equipment.

Choosing a suitable radiator Source oboiman.ru

Features of calculation in a private house

They involve taking into account various factors that cause heat loss. It is not enough to simply calculate the power of the heater, radiators, pipe size and other indicators; you also need to take into account:

- Method of mounting the device to the system. The efficiency of a two-pipe piping is: 98% with diagonal;

- 87% for lateral;

- 80% with bottom connection.

- up to 10% of the heat escapes through the chimney;

Photo 2. Heat loss in a private house through different parts of the building. Heat loss must be taken into account when installing radiators.

The values can be reduced by performing several actions regarding walls, floors and ceilings:

- When windows face north, their losses are 10% greater than others.

- The location of the radiator relative to the cardinal points does not affect the power, but if they are heated in the sun, they cool down a little more slowly.

- The number of sections should be increased after calculations according to the passport data, since the actual power of the products is lower. This is due not only to the losses described above, but also to a slight overestimation of the indicators by the manufacturer.

Only by taking into account all the factors will it be possible to create and install high-quality piping with aluminum radiators. Calculations will help to accurately calculate the sufficient number of battery sections and take into account all losses.

Important! When using additional devices, it is possible to increase the required power. If you turn on the thermostat, you need to increase the indicator by 20-25%, since the device will be able to manually control the heating