In the heating circuits of individual houses, the leading position is occupied by polymers, the leader among which is polypropylene (PP). When installing heating systems, it is important to know how to correctly connect a heating radiator to polypropylene pipes.

The solution to this problem is not unambiguous, taking into account various wiring diagrams and methods of connecting radiator outlets to the supply and return lines. The choice of the optimal option is complicated by the fact that it is necessary to take into account the aesthetic appearance of the batteries connected to the heating main.

Rice. 1 Designer batteries made of cast iron

What kind of piping can be made from polypropylene pipes

There are many schemes for piping radiators of a water heating system.

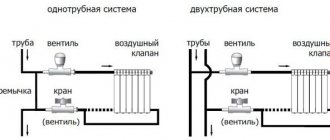

From the existing methods, the consumer always chooses the one that, under the existing conditions, requires minimal material consumption with maximum efficiency in the location of radiators. Examples of diagrams for one-pipe and two-pipe methods of piping water heating convectors

In fact, the situation is such that, unlike expensive metal pipes, polypropylene consumables are much cheaper and easier to install, so saving on the length of the pipeline at the expense of efficiency is not worth it. You should choose the type of strapping that will be most effective in a particular case.

Choosing a harness involves deciding on the following issues:

- what kind of heating system scheme will be used (one-pipe or two-pipe);

- what type of radiator connection will be used (diagonal, side or bottom).

As a rule, when using any heating scheme - single-pipe or two-pipe, you can use all types of battery connections.

Schematic illustration of methods for connecting (piping) water heating radiators

Installation of heating systems using polypropylene pipes, depending on the design, is carried out in compliance with certain rules.

- Typically, such a system uses a series connection of radiators;

- A bypass is always installed in front of the battery, connecting the supply pipe and the return pipe - during normal operation of the heating system, the bypass is not used, but during maintenance or in an emergency, the water supply to the radiator is stopped, and the coolant circulates freely through the bypass.

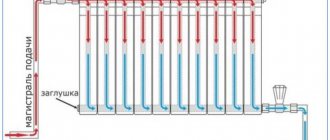

Scheme of serial connection of radiators with a single-pipe piping method

- Both parallel and serial connections of batteries are used;

- The radiator pipes are connected to different pipes - the upper one to the supply pipe, the lower one to the return pipe.

Typically, in two-pipe systems, radiators are connected in parallel, so installing bypasses is not required.

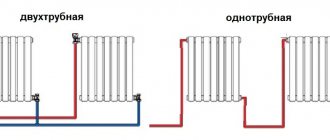

Schematic representation in plan of a two-pipe method for piping radiators of an autonomous heating system

Tying radiators with polypropylene pipes is done in two ways: soldering and using fittings. Depending on the chosen method, the batteries are connected using a special soldering iron or American plumbing wrenches.

Good article: Which is better, a two-pipe or one-pipe system?

What shut-off valves can be used

The owner always has a choice between:

- Ball valves.

- Shut-off valves.

- Valves.

The first ones only allow you to block the pipe. It is impossible to regulate the coolant supply and heat transfer of the radiator with them. Its installation means that the harness can either be closed or completely open.

Shut-off valves are most often installed on the outlet fitting. They allow you to change the cross-sectional area of the outlet pipe. This is not very convenient to do, since you need to remove the cover and tighten the spindle with the spool with your own hands. The reliability of this valve is better than the one described above. It is usually mounted together with the valve.

The valve allows you to limit/increase the coolant supply. Many of his models are handmade. However, there are those that can be either manual or automatic. To automate, the valve handle is unscrewed and the thermostatic head is fixed in its place. It analyzes the temperature in the room and changes the operating mode of the radiator. Often such a head may have an external thermostat.

In residential buildings of the old stock, both in the private sector and in apartment buildings, work is currently underway to re-equip heating systems. Physically and morally worn-out heating equipment (steel and cast iron radiators, pipelines, shut-off valves) are replaced with new heating systems. Outdated devices have been replaced by more advanced heating units, for example, bimetallic heating radiators with improved characteristics. Steel pipes, a familiar and durable material, are still in demand when installing heating circuits, but worn-out steel pipelines are increasingly being replaced with new materials, in particular, polypropylene, a polymer widely used in the production of pipe products.

Polypropylene pipes with connecting fittings of various configurations

Despite the fact that polymer pipes have been used in construction for decades, many homeowners who still use steel pipelines and are planning to modernize their heating circuits have questions about the technology for the upcoming installation - how to install polypropylene lines in their homes conditions, what does it look like to connect a heating system radiator to polypropylene reinforced pipes? To partially answer them, let’s take a closer look at how polypropylene pipe materials are connected to heating radiators.

Options for piping heating radiators

Installation of heating radiators involves connecting them to pipelines. There are three main connection methods:

If you install radiators with a bottom connection, you have no choice. Each manufacturer strictly binds the supply and return, and its recommendations must be strictly followed, since otherwise you simply will not get heat. There are more options with a side connection (more about them is written here).

Strapping with one-sided connection

One-way connection is most often used in apartments. It can be double-pipe or single-pipe (the most common option). Metal pipes are still used in apartments, so we’ll consider the option of tying the radiator with steel pipes on pipes. In addition to pipes of a suitable diameter, you need two ball valves, two tees and two bends - parts with external threads at both ends.

Lateral connection with bypass (one-pipe system)

All this is connected as shown in the photo. With a one-pipe system, a bypass is required - it allows you to turn off the radiator without stopping or draining the system. You cannot put the tap on the bypass - you will block the flow of coolant through the riser, which is unlikely to make your neighbors happy and, most likely, you will be fined.

All threaded connections are sealed with fum tape or linen winding, over which packaging paste is applied. When screwing the valve into the radiator manifold, much winding is not required. Too much of it can lead to the appearance of microcracks and subsequent destruction. This is true for almost all types of heating devices, except cast iron. When installing all the others, please do not be fanatical.

Welding option

If you have the skills/opportunity to use welding, you can weld the bypass. This is what the piping of radiators in apartments usually looks like.

With a two-pipe system, a bypass is not needed. The supply is connected to the upper entrance, the return is connected to the lower entrance, taps, of course, are needed.

One-way piping with a two-pipe system

With bottom wiring (pipes laid on the floor), this type of connection is made very rarely - it turns out inconvenient and ugly; in this case, it is much better to use a diagonal connection.

Strapping with diagonal connection

Installing heating radiators with diagonal connections is the best option in terms of heat transfer. In this case it is the highest. With bottom wiring, this type of connection is easy to implement (example in the photo) - the supply on this side is at the top, the return on the other is at the bottom.

With two-pipe bottom wiring

With a single-pipe system with vertical risers (in apartments), everything does not look so good, but people put up with it because of the higher efficiency.

Coolant supply from above

Please note that with a one-pipe system, a bypass is again required

Coolant supply from below

Strapping with saddle connection

With bottom wiring or hidden pipes, installing heating radiators in this way is the most convenient and least noticeable.

With a two-pipe system

With a saddle connection and lower single-pipe wiring, there are two options - with and without bypass. Without a bypass, the taps are still installed; if necessary, you can remove the radiator and install a temporary jumper between the taps - a squeegee (a piece of pipe of the required length with threads at the ends).

Saddle connection for one-pipe system

With vertical wiring (risers in high-rise buildings), this type of connection can be seen rarely - the heat losses are too large (12-15%).

Useful connection tips

There are some recommendations on how to connect a battery to a plastic pipe efficiently. Before attaching the fitting, the pipe must be freed from the outer chamfer. This will free the pipe from burrs that could cause the connection to become loose.

When installing brackets for mounting the radiator, you should equip every three sections with separate fasteners. To ensure that the threaded connections of the system are as tight as possible, it is practiced to use flax with paint or a polymer sealing thread. Without paint, flax will quickly fade, and FUM tape usually begins to leak in the case of minimal thread reverse.

What kind of piping can be made from polypropylene pipes

There are many schemes for piping radiators of a water heating system. From the existing methods, the consumer always chooses the one that, under the existing conditions, requires minimal material consumption with maximum efficiency in the location of radiators.

Examples of diagrams for one-pipe and two-pipe methods of piping water heating convectors

In fact, the situation is such that, unlike expensive metal pipes, polypropylene consumables are much cheaper and easier to install, so saving on the length of the pipeline at the expense of efficiency is not worth it. You should choose the type of strapping that will be most effective in a particular case.

Choosing a harness involves deciding on the following issues:

- what kind of heating system scheme will be used (one-pipe or two-pipe);

- what type of radiator connection will be used (diagonal, side or bottom).

As a rule, when using any heating scheme - single-pipe or two-pipe, you can use all types of battery connections.

Schematic illustration of methods for connecting (piping) water heating radiators

Installation of heating systems using polypropylene pipes, depending on the design, is carried out in compliance with certain rules.

- Typically, such a system uses a series connection of radiators;

- A bypass is always installed in front of the battery, connecting the supply pipe and the return pipe - during normal operation of the heating system, the bypass is not used, but during maintenance or in an emergency, the water supply to the radiator is stopped, and the coolant circulates freely through the bypass.

Scheme of serial connection of radiators with a single-pipe piping method

- Both parallel and serial connections of batteries are used;

- The radiator pipes are connected to different pipes - the upper one to the supply pipe, the lower one to the return pipe.

Typically, in two-pipe systems, radiators are connected in parallel, so installing bypasses is not required.

Schematic representation in plan of a two-pipe method for piping radiators of an autonomous heating system

Tying radiators with polypropylene pipes is done in two ways: soldering and using fittings. Depending on the chosen method, the batteries are connected using a special soldering iron or American plumbing wrenches.

Good article: Which is better, a two-pipe or one-pipe system?

Heating wiring

The simplest and most reliable heating wiring diagram is “Leningradka”, or single-pipe system wiring. Such a system is structurally a looped circuit running along the entire perimeter of the building. Radiators are connected to the pipeline in parallel. The main disadvantage of the Leningradka is the uneven heating of the radiators connected in the circuit.

A much more effective option for how to properly install heating, especially in multi-storey buildings, is a two-pipe heating system. There are two varieties of such a system, one of which is called a dead-end system. This scheme must be balanced, i.e. limit the flow of radiators located close to the boiler - otherwise heating of heating devices located far away will be insufficient.

In a passing circuit, there are several parallel circuits of the same length. There is no need to balance the associated wiring, since in it the heat transfer of all batteries is initially almost at the same level. If no obstacles prevent you from creating a circular passing circuit, then it needs to be done, but otherwise a dead-end two-pipe wiring is quite suitable. In any case, in order to know exactly how to properly install heating in a house, you need to think through all the known nuances in advance.

Choosing a location and method of installing a radiator

Options for connecting heating radiators depend on the general heating scheme in the house, the design features of heating devices and the method of laying pipes. The following methods of connecting heating radiators are common:

- Lateral (unilateral). The inlet and outlet pipes are connected on one side, with the supply located at the top. The standard method for multi-storey buildings, when the supply is made from a riser pipe. In terms of efficiency, this method is not inferior to the diagonal one.

- Lower. In this way, bimetallic radiators with a bottom connection or a steel radiator with a bottom connection are connected. The supply and return pipes are supplied from below on the left or right side of the device and are connected through the lower radiator connection unit with union nuts and shut-off valves. The union nut is screwed onto the lower radiator pipe. The advantage of this method is that the main pipes are hidden in the floor, and heating radiators with bottom connections fit harmoniously into the interior and can be installed in narrow niches.

- Diagonal. The coolant enters through the upper inlet, and the return is connected from the opposite side to the lower outlet. The optimal type of connection ensures uniform heating of the entire battery area. In this way, correctly connect a heating battery whose length exceeds 1 meter. Heat loss does not exceed 2%.

- Saddle. The supply and return are connected to the lower holes located on opposite sides. It is used primarily in single-pipe systems when no other method is possible. Heat loss as a result of poor coolant circulation in the upper part of the device reaches 15%.

https://youtube.com/watch?v=olrD9qxCAhM

WATCH THE VIDEO

When choosing a location for installation, several factors are taken into account to ensure the correct operation of heating devices. Installation is carried out in places least protected from the penetration of cold air, under window openings. It is recommended to install a battery under each window. The minimum distance from the wall is 3-5 cm, from the floor and window sill - 10-15 cm. With smaller gaps, convection worsens and the battery power drops.

Typical mistakes when choosing an installation location:

- The place for installing control valves has not been taken into account.

- A small distance to the floor and window sill prevents full air circulation, as a result of which heat transfer is reduced and the room is not heated to the set temperature.

- Instead of several batteries located under each window and creating a thermal curtain, one long radiator is chosen.

- Installation of decorative grilles and panels that prevent the normal spread of heat.

Coolant circulation methods

Coolant circulation through pipelines occurs naturally or forcedly. The natural (gravity) method does not involve the use of additional equipment. The coolant moves due to changes in the characteristics of the liquid as a result of heating. The hot coolant entering the battery, cooling, acquires greater density and mass, after which it sinks down, and a hotter coolant takes its place. Cold water from the return flow flows by gravity into the boiler and displaces the already heated liquid. For normal operation, the pipeline is installed at a slope of at least 0.5 cm per linear meter.

Scheme of coolant circulation in the system using pumping equipment

For forced supply of coolant, the installation of one or more circulation pumps is required. The pump is installed on the return pipe in front of the boiler. The heating operation in this case depends on electrical power, but has significant advantages:

- The use of small diameter pipes is allowed.

- The line can be installed in any position, vertically or horizontally.

- Requires less coolant volume.

General information about the two-pipe heating system

Any heating system with a liquid coolant consists of one or more closed circuits connecting radiators and a boiler.

In a two-pipe distribution, hot coolant is supplied through one branch of the circuit and returned through the other, hence the name.

Diagram of a typical two-pipe heating system in a private house.

Classification signs:

- The organization of coolant movement is gravity and forced.

- Design – open or closed, horizontal or vertical.

- Pipe routing – radial, dead-end, ring.

By combining properties, you can achieve the best suitability for operating conditions.

Installation

Due to the fact that this material is very light and affordable, you can organize the heating of a private house, cottage or apartment using polypropylene pipes with your own hands. Before starting work, you need to make a project. It is necessary to indicate the dimensions and joint locations, connection features and installation method. With its help, it is easier to calculate the required materials. You can draw it yourself or by using a special program such as AutoCAD or SolitWorks.

Heating scheme made of polypropylene pipes

Pipe routing can be done according to two principles: with one pipe and with two. The first option is when only one pipe is used to supply water from the boiler and return it. The second is the classic way of organizing heating. Naturally, it is easier to connect the system with this pipe yourself, but in this case you will not be able to heat your home evenly.

Types of pipe connections

The design of the heating system when installing only plastic pipes or when connecting them with metal ones is practically no different. You just need to choose the right diameter when combining different materials. To do this, consult a specialist in the store.

Installation of polypropylene pipes into the heating system is carried out using a special welding machine for plastic, but in addition to it you will also need connecting fittings.

How to solder heating with polypropylene pipes:

Pipes need to be cut to the required size

It is very important that the joints are level and at right angles to the floor; Afterwards, you need to treat the sections with degreasing compounds and remove chips from their surface; Install the pipes into the centralizer. This is a special device that will help achieve maximum geometric accuracy of the connection.

Then put fittings on the joints; Welding is carried out only according to the instructions. Read the user manual for your inverter carefully. Afterwards, heat the device and solder. It is also possible to use electric welding couplings, in which case the installation is carried out directly in them.

The assortment of modern online and simple plumbing equipment stores allows you to choose everything for a heating system made of polypropylene pipes. In addition to fittings, special turn signals, American connections and other connections are often used. The technology for their installation is similar.

If it is necessary to connect polypropylene pipes to a metal heating system, then you need to use flanges; they have a different installation scheme. They have a thread on one side - for cutting into steel pipes, and on the second - a smooth valve for installation on plastic.

To make central heating from polypropylene pipes, you need to buy all the components, the price of which depends on the manufacturer and type of reinforcement; below is a small rating:

| Brand | Diameter | Price, rubles |

| Kalde | PN20 D20 Kalde | 65 |

| Valtec | VALTEC PPR PN 20 | 80 |

Naturally, the dimensions directly affect the cost of polypropylene heating pipes. For example, Kalde with a diameter of 75 mm costs about 800 rubles/meter. This equipment is sold in company stores.

Disadvantages and methods for eliminating them

- The main disadvantage of polypropylene pipes is their high expansion coefficient. At a coolant temperature of 100°C, 10 meters of pipe lengthens to 15 cm. This leads to deformation of the structure. In order to prevent destruction, flexible supports are installed and compensation loops are made. Later, foil-reinforced pipes began to be used, which significantly reduced the expansion coefficient. Nowadays, the most practical pipes are reinforced with glass fiber: under the same conditions they extend by only 1 cm.

- Polypropylene products, especially connecting elements, are inferior to metal pipes in strength. It is not even correct to compare them: when subjected to strong impacts with hard objects, polypropylene is deformed and may collapse.

Requirements for paintwork

It is not always possible financially, and in many cases even technically, to install a new radiator. It is easier to refresh the outside of the heating device if it is still capable of serving. If the battery has already had to be repaired or it does not heat well, then it is better to replace it with a new one.

The painting process as such is not particularly difficult, but this does not mean that you can buy any composition and immediately begin restoring the attractiveness of the radiator.

The paint must be selected according to certain parameters, and the battery must be carefully prepared. If this is not done, the new coating will not last long, and you will soon have to repeat the process again.

An old cast iron battery with peeling paint looks very unaesthetic. In addition, the material of its body is subject to oxidation and rusts.

When choosing a composition, it is best to focus on options specifically designed for heating devices. But if there is no such inscription on the label, you should carefully study the instructions and find data on its heat resistance.

To obtain a high-quality, durable and beautiful coating, you must use paint that has the inscription “For radiators” on the label.

Requirements for paint coating:

Heat resistance. The composition applied to the radiator body must withstand temperatures up to 80-90 degrees and be flawless for the time promised by the manufacturer.

Adhesion. It is necessary that the composition has good adhesion to the surface to be painted. Did not peel off when heated and alternating heating/cooling.

Corrosion protection. The composition must contain anti-corrosion substances so that the coating in direct contact with the body does not cause its destruction.

Color fastness. Unconditional condition, because Radiators are painted for aesthetic purposes, among other reasons.

Abrasion resistance. From direct contact with various furnishings, drying items, etc. the coating should not become thin.

Safety

It is very important that the composition does not contain any components harmful to health.

Good paint for radiators must meet all the requirements, and not individual items.

Types of radiators

Radiators for the manufacture of heating pipelines are popularly called batteries. New models are made from different metals, which are superior in technical characteristics and aesthetics to cast iron products. Types of radiators:

- Aluminum batteries are efficient batteries that are installed in new multi-story buildings. They quickly fail if the coolant contains alkalis and acids.

- Steel - there are sectional and tubular. The level of heat transfer does not depend on the shape of the battery.

- Bimetallic ones are the most effective in heating rooms. Made from a mixture of aluminum and steel.

Any of the presented types is relevant when assembling a heating circuit with polypropylene pipes.

Advantages of polypropylene

Pipes and connectors

- the heating system made of polypropylene is not subject to corrosion;

- more reasonable price than metal analogues;

- there are no reactions from exposure to acidic or alkaline environments;

- there is no accumulation of deposits on internal surfaces;

- there are no significant changes in coolant temperature, depending on the microclimate of the room, due to the low thermal conductivity coefficient;

- the movement of the coolant is not accompanied by noise;

- due to the property of plasticity, it is possible to make bends in the required places;

- changes in coolant temperature do not affect the design in any way;

- durability and ease of installation.

Features of piping with polypropylene pipes

A clear advantage of polypropylene pipes is that they allow you to create a heating circuit of any complexity. That is, if you are a beginner and have come up with a rather complex pipeline diagram, it is quite acceptable to use pipes of this type for it. However, one feature should be taken into account - a complex long-lasting pipeline has a higher heat loss. Therefore, think carefully about everything again - perhaps there is a chance to make the system simpler, thereby increasing the quality of heating.

Heating radiator wiring diagram

Connecting polypropylene pipes can be done in two ways. First of all, the pipes can be soldered. This is a more reliable method, which, if performed well, eliminates leakage. The second connection method is the use of fittings. It is less reliable, because if even a slight displacement occurs, coolant will begin to leak

It is important to pay attention - if there is an opportunity to avoid connection, it is better to use it

In addition, the use of modern technologies in creating the material has made it quite durable - the pipe can easily withstand an internal pressure of 25 Bar. Another feature is that even prolonged exposure to highly heated coolant (up to 95 degrees) does not cause deformation of the pipes.

Polypropylene pipes and fittings

However, there are some restrictions regarding the use of polypropylene pipes in the immediate vicinity of the boiler, which should be known before placing them in the system and before starting the heating battery. Thus, the gas supply pipe to the heating boiler must have an extremely rigid connection. As the standards for installing heating radiators say, the connection to the boiler must be made through a metal pipe (or American) with paronite gaskets. The use of fum tape or tow is unacceptable. The fact is that rubber gaskets can significantly decrease in size when heated - and can even block the passage for the gas supply. But fum tape and tow can simply catch fire from high temperatures - and this can lead to dire consequences.

Another important point is how to turn off the radiator. This must be done if you need to perform such an operation as turning off the heating battery or dismantling it. This step, how to properly shut off the heating radiator, is required in the case of piping using shut-off valves.

Shut-off valve on the heating radiator

Selection of materials

The popularity that polypropylene pipes have gained. associated with a number of their positive qualities:

- Their price is significantly lower than their metal counterparts.

- High durability due to the fact that the plastic does not rust, and there is practically no sediment deposited on it.

- Does not need painting.

However, it should be taken into account that not all types of polypropylene pipes are suitable for heating systems. The fact is that they must have a reinforcing layer that prevents significant thermal expansion of the pipeline.

Reinforced polypropylene pipe

Moreover, it is desirable that the reinforcement layer be aluminum, since fiberglass reinforcement leads to saturation of the coolant with oxygen. This in turn causes rusting of the metal surfaces of boilers and other heating supply elements. Pipes that have aluminum reinforcement and are suitable for heat supply systems are marked PN25.

Note! When choosing pipes, you should pay attention to the uniformity of their wall thickness. To do this you need to look at their cut. As for the diameter, the optimal parameter is 25 mm

As for the diameter, the optimal parameter is 25 mm.

In this case, it is also necessary to purchase fittings, which include:

Single-pipe and two-pipe radiator connection diagram

Single pipe system

Its operation is based on a one-time supply of coolant to the entire building: the cooled liquid flows down inside the pipes from top to bottom. Most often, apartment buildings are equipped in this way.

The disadvantages of a single-pipe scheme include the following factors:

- There is no way to regulate the temperature of heating devices.

- Different apartments are heated unevenly. The upper floors receive the hottest coolant, which gradually cools as it flows down.

- To disconnect from central heating and switch to autonomous heating, you have to overcome a lot of difficulties.

How can you improve the efficiency of radiators?

First option: there are batteries designed for the lower connection circuit. They plug the lower hole between the first and second sections.

And the water is forced to rise into the upper collector and is distributed among all sections. Batteries for the top connection are made in the same way. Special valves are produced for the plug device.

What kind of binding could it be?

The main stage of installing a heating system in a house is tying the heating radiator with polypropylene. During this process, you need to install parts that allow you to regulate heat transfer.

Shut-off valves

There are several types of shut-off valves that are suitable for piping heating radiators:

- Chokes with thermal control capability. To adjust heat transfer, you need to set the parameters. After this, the mechanism will work automatically. Regardless of what temperature changes occur outside, the same temperature regime will be maintained in the room. Throttle is a valve designed for manual adjustment of heat transfer. The temperature begins to change two hours after changing the valve position.

- Valves are a part that is installed in front of the battery. Designed to shut off the coolant supply.

Fitting

To connect the battery to the pipeline, you need to use the following fittings:

- American couplings with which shut-off valves are connected. If there is a union nut, you can quickly dismantle the heat exchanger.

- Triple couplings - suitable for connecting pipes for supplying coolant simultaneously with control valves.

- Tees that have vias.

The choice of connecting part depends on the complexity of the water supply system.

Connection fittings

Tools

To assemble a polypropylene heating system you will need a set of tools:

- special soldering iron for welding plastic;

- a tool for removing the reinforcing layer from tubes - a shaver;

- key with hooks for installing shut-off valves;

- scissors for cutting polypropylene.

Additionally, you will need measuring and marking tools.

Stages of connecting heating radiators

Installation of radiators with polypropylene pipes is carried out in several stages:

- Marking the laying of tubes and battery installation locations.

- Fastening heat exchangers to the wall. For small models, two brackets are enough, for large ones - one per section.

- Installation of shut-off valves.

- Pipe connection.

- Installation of jumpers, compensators.

The last stage is connecting the pipeline to the battery. To make the joints more airtight, you can use sealants that are resistant to prolonged exposure to high temperatures.

Restrictions on use

Welding table for polypropylene pipelines.

With all their positive qualities, polypropylene pipes are not ideal - this must be taken into account when planning the installation of heating systems. This also applies to the choice of polymer raw materials and their qualities. According to standards, pipes can be made from several grades of polypropylene - the grade is indicated on the outer walls of the products.

To compare the properties of polypropylene pipes, a special gradation of types of polypropylene and areas of its application was introduced. It looks like this:

- PN 10 - thin-walled pipes for cold water supply and heated floors (working temperature up to 45°C, working pressure 1 MPa.

- PN 16 - for cold water supply with high pressure and central heating supply with low pressure.

- PN 20 - for hot and cold water supply pipelines (operating temperature up to 80°C, pressure 2 MPa.

- PN 25 - for central heating and hot water supply (up to 95°C), operating pressure 2.5 MPa, three-layer pipes reinforced with aluminum foil.

Installation diagram of polypropylene pipes with upper distribution circulation.

Polypropylene has a high coefficient of linear expansion: when exposed to high temperatures, pipes stretch and increase in diameter.

Scheme of a polypropylene pipeline with temperature compensators.

If the pipeline is designed for cold liquid, the effect is not visible. At temperatures up to 45°C - also. However, at high temperatures and there is no room for expansion, the pipe may rupture or damage the outer lining. This must also be remembered when installing pipelines outdoors - in winter, pipes can shrink, which will lead to their ruptures and damage to fittings.

There is one reliable method of preventing such consequences - the implementation of compensation loops. You can make them yourself by creating loose U-shaped sections of pipes (their frequency and size are indicated in the specifications). Many companies offer ready-made shaped products in the form of loops.

A few words need to be said about the methods of installing polypropylene. Such products can be installed in any of the following ways: hidden laying of the pipeline, open laying, laying in shafts, boxes or soil. Pipelines for water at elevated temperatures must be secured with the possibility of subsequent longitudinal displacement.

There is one reliable method of preventing such consequences - the implementation of compensation loops. You can make them yourself by creating loose U-shaped sections of pipes (their frequency and size are indicated in the specifications). Many companies offer ready-made shaped products in the form of loops.

Types and types of connection fittings

The English word "fit" means to gather. It is thanks to him that the fitting got its name. With the help of such connecting elements, pipes are joined in the same and different planes.

They allow you to create branched systems and avoid obstacles. When using fittings, pipes of the same or different diameters are joined.

Manufacturers produce threaded and soldered connecting elements. The first type allows you to connect polypropylene communications with steel pipes and fittings in the form of taps and valves.

The second type is intended for connecting polymer elements to each other by soldering. First of all, when using special welding equipment. It heats the parts, so their structure softens. Only after this the fitting can be put on the pipe.

Couplings and adapters

The simplest fitting for polypropylene pipes is a coupling. It is made in the form of a barrel, the internal diameter of which corresponds to the cross-sectional size of the pipe along the outer edge.

PP coupling

The couplings have thicker walls. They are used to connect pipes of the same diameter, inserted into the so-called barrel on both sides if it is made entirely of polypropylene. When the coupling is threaded, soldering is performed on one edge only.

Combined coupling PP

An adapter is an element that allows you to connect pipes of different diameters. Used in branched systems with several consumers.

Adapter PP

Using adapters, it is possible to narrow the diameter of the communication and create excess pressure in the circuit.

Angle, tee and cross

In most cases, utility lines have a branched structure. Angles are used to rotate the system 90° and 45°. They form a system of the required configuration. After all, polypropylene is a hard and elastic material that bends only after heating.

However, this method is not used when laying communications. As a result, when bending, the cross-sectional size and wall thickness of the pipes change. This reduces the strength characteristics of the system. Consequently, it often leads to the appearance of a leak when the pressure and temperature of the moving medium increases.

Corner pp

Angles are also available with a 3/4 female thread on one end. They are used during installation of mixers.

Tee pp

Tees and crosses are used to branch utility lines. They allow you to connect two or three taps together. The sizes of fittings for polyethylene pipes are selected depending on the design.

Crosspiece pp

Tees and crosses allow you to create bends at right or acute angles. This type of fitting is also available with threads on one end. In this case, they are used when installing shut-off valves.

Bypass and compensators

Bypasses are used to bypass obstacles on the way of laying systems. With their help, a more round bend is created than when using corners. Contours allow you to smoothly change the direction of pipelines. Therefore, it is possible to lay communications that have a more attractive and neat appearance.

PP bypass

Compensators are parts of engineering systems that can “absorb” pressure and temperature changes in hot water supply and heating pipelines. They increase reliability and maintain the integrity of networks. Several ready-made solutions are available. Polypropylene expansion joints are made in the form of a loop.

American fitting

The installation process of PP systems is made easier by the American. This is an element made of metal and plastic with a rubber insert. The parts are used for detachable sealed connections.

American pp

Such fittings with internal or external threads on one side are used when installing shut-off valves, hydraulic accumulators, circulation pumps, heating radiators, and so on.

Taps, valves and plugs

During the operation of utilities, it is often necessary to shut off the water. This is achieved by installing taps and valves. They can be made of polypropylene or brass.

Valve PP

In the first case, parts are soldered into systems. In the second, adapters are additionally used. Consequently, they allow threaded connections of network parts made of different materials.

Crane pp

Plugs are used in places where polypropylene pipelines end.

Plug PP

Such parts can be soldered to permanently block the outlet or temporarily installed using a threaded connection.

Pipe types

Products are always selected for certain parameters of the pipeline or system. There is no need to install an expensive reinforced pipe into a water supply system with cold water and low pressure. An ordinary single-layer pipe, for the production of which only polypropylene is used, is quite suitable here.

The technological process for manufacturing multilayer options is more complex, which ultimately affects their price. A multilayer pipe consists of 3–5 alternating layers of polypropylene, reinforcement (fiberglass, aluminum foil) and hot-melt adhesive designed to connect them.

Types of single-layer products

Depending on the structure of polypropylene molecules, its physical and mechanical properties also change.

Depending on the type of polymer used, polypropylene products are divided into several groups:

- PPH. Pipes made on the basis of homopolypropylene and capable of operating in the temperature range from 0 to 100 ºС, have good abrasive resistance and high resistance to chemically aggressive liquids. The main disadvantage is poor resistance to low temperatures.

- PPB. Products made from polypropylene block copolymer, which have good flexibility and resistance to low temperatures. They have high thermal expansion.

- PPR. In the production of these pipes, random copolymers consisting of ethylene and polypropylene molecules are used. The result is durable and versatile pipes that can operate in a wide temperature range while maintaining their original linear dimensions. Pipes marked PPR are the most popular and frequently used in water supply and heating systems.

- P.P.S. A special type of product made from polyphenylene sulfide, the special structure of its molecules allows us to achieve the best performance in terms of resistance to various types of loads.