The Mayevsky valve is a special device used in heating systems to remove air from pipelines and heating devices. The device received its name thanks to the name of the inventor Ch.B. Mayevsky, who proposed its use in the 30s of the last century. Previously, ordinary water taps were widely used for this purpose, which led to frequent misuse of hot water from the system by consumers. And this negatively affected its functioning.

The Mayevsky valve, at its core, is a manually operated needle-type shut-off valve. It opens with a regular screwdriver or a special key.

A very small outlet hole (no more than 2mm) allows you to effectively bleed air through it, but it is inconvenient when draining a fairly large volume of hot water for domestic and other purposes.

Simplicity of design and ease of use ensures widespread use of this tap in various heating systems.

In what cases is it necessary to install a Mayevsky crane?

In open systems, the role of an air vent is usually performed by an open-type expansion tank.

Installation required:

- in heating systems where frequent airing of pipes and heating devices occurs:

- in closed heating systems;

- in two-pipe horizontal systems - description;

- in heated towel rails, etc.

With a vertical system wiring diagram in a multi-storey building (more than one floor), installing a shut-off valve on the radiators of the upper floor is also necessary.

Considering the low cost, reliability and practicality of the Mayevsky tap, its installation is justified on any heating system devices. This will improve the heat transfer efficiency of heating devices and reduce heating costs, especially in autonomous systems of private houses.

Automatic vent valve

Mayevsky taps are not used in main central heating systems due to the low quality of the heat-carrying fluid.

This leads to rapid clogging of the faucet and the need for frequent cleaning.

In central heating systems, powerful water hammers of tens of atmospheres often occur, which can lead to failure of the taps.

For the central system, special automatic air vent devices are used.

Operation and Maintenance

If the operating rules of the mechanism are followed, the heating system will not fail. Mayevsky taps have a long service life, but they often become clogged. It is necessary to clean them with a needle .

You can find the blockage yourself without calling a specialist. The method is quite simple: the valve is opened to the air outlet. A piece of paper is passed over all areas where connections are located, as well as along pipes and radiators. The distance from the surface of the sheet to the pipe should be no more than 1 cm. In the area where there is no sealing, the sheet will stick.

The problem area is inspected and the blockage is removed. Then replace the broken element.

If the air vent has not been used for a long time, the threads oxidize , making it impossible to bleed off the air. Rust can be removed with VD-40 lubricant or an illogical means. Then tap the surfaces and slowly open the valve.

Design features

The design of the crane is quite simple. It consists of a body with a calibrated thin hole and a locking screw with a conical head screwed into it. The housing has a hole for air to escape outside.

The outer end of the locking screw can be designed as:

- slotted head for a screwdriver;

- square head for a special key;

- thumb-type handles for unscrewing the screw by hand.

Some designs have a separate air collection chamber inside the housing with an opening for air outlet.

The outside of the housing has a standard thread for installing the tap into the radiator hole instead of a plug (plug).

READ ALSO: Which cast iron heating radiators are better, and why

Design of the Mayevsky crane

To bleed air, the shut-off screw is unscrewed half a turn (or a full turn). This opens a calibration hole through which air from the radiator first enters the hole in the valve body and then exits out.

After complete removal of air, the shut-off screw must be tightened until it stops.

Specifications

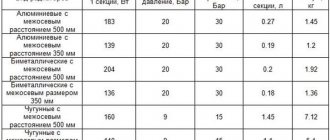

The main technical parameters of this device include:

- maximum permissible operating pressure and temperature in the heating system;

- connecting thread size;

- material of manufacture;

- type of management.

Most Mayevsky cranes are designed for operating pressures up to 15 atm. and coolant temperature up to 120°C .

The size of the external pipe thread by which the device is installed on the radiator is standardized and can be half an inch, three-quarters of an inch, or an inch.

There is a special modification for old cast iron radiators with a small body diameter and an external metric thread, with which the valve is screwed into the radiator plug (plug).

The material is metal with anti-corrosion properties (most often brass or steel with a chrome or nickel coating).

To control the tap, a regular screwdriver, a special four-sided wrench or a thumb-type handle can be used.

Criterias of choice

A radiator valve is, as a rule, a ball-type device that regulates water flow and connects pipes to the radiator. Installed on the bypass, risers, at the top of the battery, in places where air accumulates to bleed it.

Choosing a suitable faucet is not difficult, just know a few nuances:

- the diameter of the pipes to which it will be connected (DN, in millimeters or inches);

- working pressure (PN, in the range of 15–40 and above);

- type of connection, presence of thread inside or outside, American.

The choice should take into account the purpose of the reinforcement, its location, and the properties of the environment

The ratio of the input and output of the valve in the radiator, their relative position is also important

When choosing, you should consider the characteristics of the cranes:

- Ball valves, although the most common and affordable, are not very effective. It has only two modes: closing/opening;

- a cone valve is a more acceptable option due to the possibility of an intermediate position. Disadvantage: the tap must be returned to its original position and constantly monitored;

- An automatic thermostat is the most efficient, reliable, but also much more expensive than others. When installing it on a one-pipe system, a bypass must be present.

Types of taps: which one is better to choose

Classic version of the Mayevsky crane

This is a manually operated device. Suitable for any stand-alone systems.

The classic version is very popular due to its reliable design, ease of use and low cost.

Automatic model

Mayevsky automatic crane

The automatic version of the Mayevsky crane has a more complex design.

It is made of a metal cylinder that contains a float connected to a needle valve at the top of the valve. When air accumulates in the cylinder cavity, the level of the heat-carrying liquid decreases, the float moves down and opens the needle valve hole through which the air escapes.

A decrease in the volume of air in the cylinder leads to an increase in the liquid level, the float rises up and closes the valve outlet.

It is better to install them in places where air jams often occur and where access to them for manual control is quite difficult.

Such models are very demanding on the quality of the heat-carrying fluid , so they need to be checked periodically.

Taps with safety valves

The safety valve protects system elements from sudden pressure surges.

When the pressure rises above 15 atm. the safety valve is activated and drains excess coolant into the sewer.

Taps with safety valves are needed in systems where pressure surges are possible, especially if plastic pipes are installed in the system. The crane will protect itself and other elements of the system from failure as a result of water hammer.

A temperature regulator for a heating radiator allows you to control both the temperature and the volume of incoming hot coolant, reducing or increasing the degree of heating of the device. Which cast iron radiators are better: choose according to technical parameters, material, manufacturer. READ ALSO: Which cast iron heating radiators are better, and why

Vacuum Battery Review

Buckets for used equipment

As a rule, the installation of internal water supply systems is carried out in parallel with the installation of internal sewerage systems. This is due to the fact that they usually pass close to each other. Laying of water pipes should be done at temperatures above 2 degrees. For installation of pipes in rooms with high humidity, pipes with insulation are used, which prevents metal corrosion and extends the service life of the pipes for a longer time.

Sometimes air gets into the heating system.

Installation of heating systems for a house, cottage or any other building and structure is an important part of construction work, which follows after the complete construction of the box and closing of the thermal circuit, but before the interior finishing of the premises. Good organization of the heating system is the key to further carefree operation of the facility. Unskilled work will definitely lead to failures of the heating system as a whole or individual devices.

PS installation and work execution

Mark the wrong answer. Mark only incorrect answers. Mark only the correct answers. Crane operators and slingers servicing jib-type cranes and pipe-laying cranes during work should be given such a list.

The dangerous zone along an overhead power line, in which there is a danger of electric shock, is the space enclosed between the vertical planes spaced from the outermost live wires at an appropriate distance. Construction and installation work using cranes in the security zone of an existing power line with a voltage of more than 42 volts should be carried out under the direct supervision of the person responsible for the safe performance of work with cranes, with written permission from the organization that owns the line and a work permit for work in hazardous areas. or harmful factors, issued to the immediate supervisor of the work, and a permit to carry out work with a crane near an overhead power line, issued to the crane operator. When installing load-lifting cranes in the security zone of an overhead power line, it is necessary to remove the voltage from the overhead power line. If it is justifiably impossible to relieve the voltage from an overhead power line, the work of construction machines in the security zone of the power line is permitted provided that the following requirements are met: To perform work in areas of hazardous production factors, the occurrence of which is not related to the nature of the work performed, a permit must be issued in accordance with the form. The work permit is issued to the immediate supervisor of the work, the foreman, foreman, etc.

Installation process

The shut-off valve is installed at the highest points of the heating system and/or directly on the radiators during their installation.

In ready-made systems, the device is installed during the off-season period when the heating is not working or when it is turned off and the coolant is drained from the required section of the pipeline (or battery).

On radiators, the tap is installed in one of the upper holes in the housing instead of the standard plug (plug). It should be located on the side opposite to where the radiator is connected to the system supply line, regardless of the connection diagram of the heater (top or bottom).

To install the valve, the radiator cap is turned out and a valve with the corresponding outer thread diameter is screwed in its place. To seal the connection, a rubber or silicone gasket is used , as well as plumbing flax to seal the threads. On old cast iron batteries of the standard type, the tap is installed directly into the plug. To do this, a hole is drilled in it and the corresponding thread is cut, after which a tap is screwed into it using a sealing material.

The device must be installed in such a way that the outlet in its body is located below and slightly away from the wall for ease of use of the drain container when bleeding air.

In hard-to-reach places where using a screwdriver to open a tap is difficult, devices with a square head are used to connect a special key.

Gravity heating: advantages of a gravity heating system

Before considering the positive qualities of gravity heating systems with natural circulation of water, it is worth separately considering all the disadvantages of the system.

For many, the first and main disadvantage of a gravity heating system is its archaic nature. Indeed, this is one of the most ancient heating systems using liquid coolant. It was from this system that one- and two-pipe wiring diagrams were subsequently developed; it was this system that was used for mass installation when the industry mastered solid fuel heating boilers and, a little later, gas heating boilers. But on the other hand, the gravity heating system is also one of the most reliable - its service life is on average 45-50 years. That is, exactly as long as it takes for the metal pipes to lose their tightness under the influence of the coolant. The second point is the low efficiency of the gravity heating system. Indeed, the scheme itself, based on the natural circulation of water, implies the inertia of the process of heating the room, until the heating boiler gains the necessary power and the temperature difference between the heated and cooled coolant reaches a minimum, quite a lot of time will pass. But on the other hand, even after the boiler stops supporting combustion, the circulation process continues, and a large volume of water in the system will cool much longer than in a system with forced circulation.

Another disadvantage can be attributed to the gravity heating system due to its bulkiness. In practice, with the same area of the heated room, a system with forced circulation compared to a gravity one will take up much less space. In addition to batteries, the gravity heating system will also contain overhead distribution pipes, without which it is impossible to create the required fluid pressure.

And of course, there is the question of temperature control in individual radiators, and the possibility of adjusting it. A gravity heating system in its classic form with a single-pipe construction scheme cannot provide such a function due to the impossibility of shutting off a separate radiator.

But on the other hand, this is an ideal system for installation in homes where there is no electricity or constant problems with its supply. A gravity heating system can operate without electricity, since the main force of coolant movement through the system is not the circulation pump, but the thermal expansion of the coolant volume.

The large volume of coolant in the system allows for smooth heating of the room. On the other hand, such a volume of heated coolant cools much more slowly than the volume of a system with forced circulation. This is especially evident when there is a power outage or the fuel in the furnace goes out. A forced circulation system cools 3-4 times faster than such an archaic gravity heating system.

This property is often used when staying in a house temporarily - simply, instead of ordinary water, antifreeze is poured into the system, and even after complete cooling, neither the pipes nor the radiators are in danger of rupturing due to freezing of water.

And of course, it is simply necessary to note that such a system is simply trouble-free in operation. If it is used correctly, it can last about 50 years, and it has only two risk factors. The first is the threat of boiler overheating, but here too this mainly depends on the human factor, and not on the system. The second is freezing of the coolant, but in this case, the use of antifreeze reduces the risk of this accident to almost zero.

Bleeding air

The key for the air vent will greatly simplify the process.

A sign of airing of the system or heating devices is weak or uneven heating of their surfaces during the circulation of hot coolant.

To bleed air pockets you must:

- prepare a small container or rag to collect the fluid leaving the system;

- in systems with forced circulation, you must first turn off the circulation pump;

- Using a screwdriver, a special key or a handle, we begin to unscrew the shut-off screw of the faucet until a characteristic hiss of air escaping from the hole in the body appears;

- wait until all the air is released and a uniform stream of heat-carrying liquid begins to come out, after which we tighten the screw until it stops;

- make sure that coolant has stopped flowing from the outlet hole in the housing.