When we talked about autonomous heating of an apartment, we drew your attention to the fact that electric convectors are one of the most suitable heaters. With the help of such devices, you can economically heat not only individual unheated rooms (for example, a balcony), but even the whole house. Next, we will briefly look at how to install an electric convector on a wall with your own hands, providing not only instructions, but also a visual video lesson.

Pros and cons of individual gas heating

Please note that the quality of the device, as well as the duration of its successful operation, directly depend on the price of the gas convector.

Is it possible to buy a cheap unit and connect it in the house? Yes, but keep in mind that an inexpensive model will last you no more than a year. At the same time, it is unlikely that it will be possible to repair such a convector if it fails. At the same time, it is unlikely that it will be possible to repair such a convector if it fails.

Let's consider the advantages of gas heating appliances, based on the fact that you did not save money when purchasing and purchased a high-quality unit.

Advantages of gas convectors:

- the room heats up quickly,

- economical use of fuel,

- The device can be easily installed indoors by yourself,

- reasonable price,

- a gas convector does not require installation of a heating system,

- does not destroy oxygen in the room,

- the heater can be mounted to a gas cylinder,

- the device operates in autonomous mode,

- If the convector operates on the principle of natural circulation, then it does not depend on the power supply.

Important: gas convectors with a closed combustion chamber can be installed safely in any room, including the bedroom. Disadvantages of gas convectors:. Disadvantages of gas convectors:

Disadvantages of gas convectors:

- in order to correctly install a gas convector connected to a centralized system, it is necessary to obtain permission from the relevant municipal authorities,

- the connection diagram for a gas convector requires punching a through hole in the external wall of the building, in the place where the device is planned to be installed,

- impressive size,

- if you plan to use several gas convectors for heating an apartment or house, then each of them will have to be individually supplied with gas from outside the building.

Important: experts insist on choosing models with a built-in fan. They are more efficient than similar devices with natural convection

Types of in-floor heaters

There are many models of in-floor heaters produced today, and they all differ in some way from each other. If we do not consider parameters of secondary importance, then all heating convectors built into the thickness of the floor can be divided into two groups:

The units within each of these two groups differ in size, configuration, power, design of the external grille, type of convection - natural or forced (with fan) and performance class.

Water heaters for internal floor placement

An underfloor water convector is a heating device connected to a central or autonomous heating system.

The operating diagram of a water in-floor convector is the flow of cold air from the glazing of the window opening to the heating device, its heating and exit into the room.

A valve is installed at the point of insertion into the system, which can be used to regulate the amount of coolant circulating through the floor water heater.

The main element of the unit is a radiator with inlet and outlet fittings, through which flexible hoses or fittings are used to connect to the heating system, and hot water circulates through the heat exchanger.

Connecting the radiator of a floor-mounted heater using flexible hoses.

The radiator is made of a copper pipe, on which aluminum fins are made to increase the heat transfer area. Modern water heating convectors are equipped with automatic release valves for air entering the system along with water, which eliminates the formation of air locks and ensures efficient operation of the unit due to the stable intensity of coolant circulation.

Installation of a water convector in a niche and its rigid connection to heat-insulated pipes in grooved channels.

The intensity of the coolant supply to the convector can be manually changed by a valve at the point of connection to the heating system, but it is more effective to install a mechanical thermostat at the inlet of the heater that regulates the flow of hot water into the heat exchanger depending on the temperature of the water in the radiator.

On the left is a schematic cross-section of a manual valve and a mechanical thermostat, on the right is a natural image of the thermostatic head.

Floor-mounted heaters with a natural type of convection are designed for heating medium-sized rooms (16-25 sq. m.).

To ensure the natural movement of convective flows, the depth of the housing box must be at least 20 cm, and yet even multi-pipe devices of the natural type of convection do not always cope with the role of the main and only means of heating, forcing homeowners to additionally use other heating devices.

Multi-pipe radiator for a floor-mounted water convector with increased heat transfer.

The main advantage of this group of in-floor heaters is safety due to the absence of factors associated with the use of electrical appliances. In-floor water heating convectors do not require grounding, are not afraid of direct contact with moisture (this often happens on the floor), the surface temperature of these units is safe for humans upon short-term touch, and the outer grille can be made of valuable wood.

Methods of arrangement of floor-mounted heaters: on the left - corner placement, on the right - installation in steps.

General requirements

In some cases, the best way out of the situation will be to install a gas convector. This heating device is mounted on the wall and is powered by a gas cylinder. The possibility of power supply from the main line is also provided. If gas appears in your locality in the near future, purchase gas convectors. The following requirements apply to their installation:

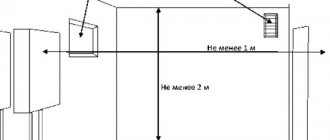

- Mandatory maintenance of distances to the nearest objects and walls in accordance with the installation instructions;

- The gas pipe is supplied along the street;

- When installing in a household with wooden walls, it is necessary to consider thermal insulation;

- The convector should not be installed at a great distance from the floor, as this will reduce the efficiency and intensity of the convection process.

Let's see how to install such a convector on a wall.

Some useful tips

Sometimes it becomes necessary to install an electric convector on a balcony, the interior decoration of which is made of PVC panels. Since the weight of an electric convector can reach several kilograms, you must understand that plastic may not withstand such a load. In this case, it is recommended to choose a compact-sized electric convector, for example, like the Nobo model in the photo below.

Another nuance is the correct placement of the convector. Usually, the purchase package includes instructions in which the manufacturer himself specifies the optimal distances from the floor, windows and other objects. If in your case there is no such information, install an electric heater, taking into account the following rules and regulations:

- height from floor 20 cm;

- gap from the wall 20 mm;

- lateral distance to nearest objects – 20 cm;

- there is a gap of at least half a meter at the top and front;

- the socket is no closer than 30 cm.

Special attention should be paid to connecting the electric convector to the network. As a rule, the power of devices does not exceed 3 kW, so if you have modern electrical wiring in your house or apartment, feel free to connect the power from an outlet (they, as a rule, can withstand up to 3.5 kW). If you want to hide the cords and make a neat installation, you can even connect the electric convector directly to the mains without a plug or socket. To do this, you will have to pull a separate cable from the distribution box or even the panel (if you decide to make a separate line for heating). In this case, select 2.5 mm 2 for the cable cross-section.

Finally, we recommend watching a visual video of the installation of an electric convector:

That's all the installation instructions for this heater. We hope that now you know how to properly install an electric convector and connect it to the network with your own hands!

It will be useful to read:

Gas supply: main stages

The installation of the gas convector has been completed, now we need to get started with the gas supply. This stage is quite complex and responsible at the same time. To supply gas, do the following:

Scheme of operation of a gas convector.

- According to regulatory documents, the pipe leading to the convector must go along the street. There are two options here: the first is that the pipe has a pre-installed threaded connection, the second is that there is no such connection. If there is a thread, then you can screw on the gas valve yourself, which will shut off the gas supply to the convector. If there is no withdrawal, one must be made. To do this, call professional gas welders from your local Gorgaz or similar office.

- After installing the gas tap, it is necessary to run a metal-plastic pipe to the convector itself. Using a tape measure, calculate the length of the pipe, simultaneously determining the presence of fittings.

- You need to buy pipe and fittings. The principle of purchase is that the seller must clarify the availability of a certificate of conformity of these pipes and fittings for this type of work.

- Lay the pipe, secure it with clips every m. To install the clips, you need to drill holes in the wall.

- When installing the necessary fittings, carefully lubricate the pipe and the fitting itself with silicone, which will provide additional sealing. Silicone will also serve as a lubricant and will make pipe installation easier.

As a result of the work, you should receive a convector mounted on the wall with a gas pipe connected to it.

Now the last stage of installation remains. A test run is required.

Gas convector installation diagram.

Before starting, open the gas tap and go over all fitting joints and threaded connections with a brush moistened with a water solution of soap or shampoo. This way you will be able to notice inflated bubbles (if any), which indicate gas leaks. If this happens, immediately turn off the gas supply valve. After checking the joints, start the convector. To do this, hold down the gas button for one minute. This way the gas will have time to pass through the pipes and enter the combustion chamber. Press the piezo igniter, a spark should ignite the gas. A blue flame will flare up in the firebox.

Adjust the operation of the convector by setting a comfortable temperature. During the first few hours of operation, you may smell an unpleasant odor of burning oil. This is normal, since the convector is new and the combustion chamber burns out. If the smell lingers for a long time, then you should turn off the gas and check all joints and threaded connections again.

It is advisable that all work on the installation of gas convectors be carried out by a professional who has sufficient experience in performing such work. This is also due to the fact that installing a convector yourself may void your warranty on the device. The gas convector must be accepted into the balance sheet by Gorgaz. You must have a documented permit for the tie-in. In addition, all installation decisions, as well as the conclusions of the commission for acceptance of the device into operation, must be documented and signed in the appropriate manner.

Device and characteristics

First, let's figure out what a convector is. This is a device that belongs to climate control technology. Its main task is that by deliberately circulating air masses it heats the air

It is important to know that all processes occur on the basis of physical laws. These also often include wall-mounted electric fireplaces, which not only create the necessary temperature conditions, but also delight the eye with their aesthetics

A wall-mounted electric heating convector with a thermostat is placed at a low height. The device then passes cold, dense air through itself, releasing a vertical stream of hot air masses. At this time, they mix with cooler currents and give off heat to the walls and ceiling, gradually falling back to the floor. It turns out a vicious circle, thanks to which the room is evenly heated.

For maximum functionality, manufacturers have thought through the location of every part. Most often, you will see a device in the shape of a flat rectangle, and this is because in a confined space of this shape, the air is quickly and efficiently heated and then pushed out. In addition, this form allows you to save useful space in the house. The device itself consists of several main elements:

- the body consists of panels and a grille, which allows you to direct air flow;

- inside there are start-up and shutdown modules, automatic shutdown in case of a fall and a thermostat;

- the heating element is most often located at the bottom of the device;

- There is a sensor nearby that shows the air temperature in a specific room.

Different models use different heating elements. So, the most common is a tubular electric heater or heating element. It looks like 2 tubes connected by a nichrome spiral. However, this is not the best option, since during operation it produces extraneous noise and has a low efficiency.

The needle heater is a housing, which is covered on 2 sides with curved wires. So it is very similar to a spruce or pine branch. Despite affordable prices and convenient temperature control, the device can make the air excessively dry, and it is generally not suitable for buildings with high humidity.

A monolithic heater is the most expensive, but the highest quality option. All the shortcomings of previous models have been eliminated. It is made in the form of a body with a ribbed surface made of nichrome. In electric convectors, this option is more common than all others.

As for thermostats, they can be called the main part of the entire mechanism. Without it, it would be impossible to control the temperature and, if desired, lower or increase it. Manufacturers nowadays offer 2 different options for thermostats.

A mechanical thermostat is installed in more budget models. It looks like a knob that needs to be turned to set certain parameters. Once the set mark is reached, it turns off. When the main unit cools down completely, the device starts working again.

Without a doubt, an electronic thermostat is much more convenient and outperforms its competitor in many points. It is able to determine and take into account both the temperature of the device itself and the environment. In accordance with the data received, he makes changes to the operation of the convector. It is possible to control the device remotely using the remote control.

The main characteristic that we pay attention to when choosing a wall heater is power. In order not to make a mistake, it is worth calculating in advance the area of the room in which the convector will be placed

Typically, the power of such devices starts from 250 W and can reach up to 2000 W, which is a lot.

What is a heat exchanger

This is a technical device made of a material with a high thermal conductivity, in which two environments with different temperatures come into contact through a partition. It is through the wall of the device that temperature is transferred from one medium to another.

There are two types of heat exchangers:

- Recuperators. That is, those in which temperature transfer occurs through a partition.

- Regenerators. In them, media with different temperatures come into contact with one single surface in turn.

The principle of operation of the heat exchanger There are several types of heat exchangers, differing from each other purely in design. These are the commonly used options:

- A coil is a tube wound onto a chimney pipe through which water moves.

- Pipe in pipe. This is a cylinder-shaped structure mounted on a chimney. Water flows inside it, which enters the structure through the lower pipe, and exits through the pipe installed at the top of the heat exchanger. The liquid is heated through the chimney wall.

- Spiral. They are rarely used in everyday life, because structurally it is a container in which a pipe is laid in a spiral (along the inner walls), with a hot medium moving inside. Unfortunately, the chimney will not work in this form.

- Shell and tube. This is not a household unit. Its design is a container in which a large number of tubes are inserted. A high-temperature medium moves through them, and water moves between the tubes.

- Plate ones, they are also called convectors. This model is the same as the previous one. Only instead of tubes, there are hollow panels installed in it, through which a high-temperature medium moves. And between them there is water. The efficiency of thermal energy transfer here depends on the direction in which the media move relative to each other. Optimally – towards each other.

Spiral type heat exchanger

There is another classification in which heat exchangers are divided into water and air. The first ones were written above. As for the latter, they are mainly used to organize additional heating of premises. A prominent representative of such units is corrugated heat exchangers.

To do this, they use corrugated steel pipes (they are flexible), which are wrapped around. It turns out that high-temperature carbon monoxide gases coming from the furnace firebox give off some of the heat to the air passing inside the corrugation. The latter is connected to the street; it is usually introduced into the room through an opening located close to the floor. Sometimes a low-power fan is installed to give the air a low speed. The opposite end of the corrugation is installed in the room where the temperature needs to be raised.

Materials for heat exchangers

Usually the chimney is assembled from metal pipes. Rarely, ceramic or glass chimneys are installed in the steam room of a bathhouse or other rooms other than the main house. Too expensive. Therefore, we can safely say that these structures have high thermal efficiency. Therefore, a heat exchanger can be mounted on them.

Copper pipe coil

The material for the heat exchanger itself is selected to withstand high thermal loads, because the temperature of carbon monoxide can reach +500C. Plus, it is necessary to take into account the negative impact of water on metal. Therefore, the coil tubes must be made of either copper alloy or stainless steel.

If you decide to build a pipe-in-pipe heat exchanger, then for its manufacture it is better to use a stainless steel or galvanized structure.

How does a convector work?

The operating principle of an electric convector is based on natural circulation (convection) of air. ... The convector is designed in such a way that the air coming from the bottom and side openings is heated after passing through the heating element and then exits through the holes located on the front panel of the convector.

Interesting materials:

How much energy is in 1 g of fat? How many euros per day for an Italy visa? How many phases are there in an outlet? How many hertz are there on the network in Russia? How long is certificate 086 y valid? How many penalty goals did Ronaldo score? How many peas should I put in 5 liters of soup? How many peas can you feed pigs? How much is the state fee at the registry office 2022? How long does it take to grill a steak?

Connection diagram

Water convectors are specialized equipment, so their installation is best left to professionals, especially when it comes to installing in-floor or basement types. You are only allowed to install wall-mounted water convectors yourself. In this case, it is necessary to follow a strict sequence of actions.

- It is necessary to mark the wall - using a level to determine the location of the convector itself, the place of water connection and, if necessary, electricity. Here you can either attach the radiator itself to the wall, or make markings with a ruler using the data in the product passport.

- Then the wall is drilled according to the applied markings and screwed into the dowel holes.

- Carry out the installation of pipes and electrical cables.

- The back of the convector is screwed to the wall with screws that are included in the kit. In this case, first they simply attach it to the screws, then measure the accuracy of fastening with a level, and only when they are convinced of this, screw the installation panel to the end.

- Now you need to secure the heat exchanger unit to the installation panel. For this purpose, it is allowed to use only those screws and fasteners supplied by the manufacturer.

- Now the electricity cable is connected to the terminal box. In this case, the main connection parameters are the manufacturer’s instructions and electronic circuit diagram. You must act strictly in accordance with it.

- Install the fan and, if necessary, adjust its position using a special device - a potentiometer.

- Now you can start connecting additional fittings. A thermostatic valve is installed at the inlet of the pipes, and a special threaded connection is installed at the outlet. It is imperative to check the tightness of the entire structure using an air compressor.

- Now you need to connect the pipes to the heating system. This must be done in strict accordance with the project.

- Finally, you can begin to assemble and install the water convector itself. To do this, in accordance with the diagram, install the frame, grille and thermostatic head, and attach the walls of the radiator.

- Using special adjusting screws, calibrate the location of the device on the wall, focusing on the level.

In principle, the installation of a built-in underfloor water convector is carried out in approximately the same way. Only first, when performing a rough screed, special built-in boxes are made in the floor, into which the radiator itself will later be placed.

Without any skills, it will be quite difficult to install such a water heating convector yourself for the first time. Therefore, here you either need to call a specialist, or be patient and act as carefully and slowly as possible.

Convector, radiator or heat fan?

In the device we are considering, convection occurs naturally. However, there is also so-called forced convection. It is typical for devices that have a fan in their modification. There are also devices that increase the temperature in the room by heating their body or coolant (antifreeze or water). Many people do not see much difference between these heaters. And here the question arises: what should you give preference to - an electric convector, a heat fan or a radiator?

Table 1. The main differences between an electric convector, a thermal fan and a radiator.

| Electric convector | Heat fan | Radiator |

| · high price (compared to a fan and radiator); · requires ideal thermal insulation of walls. · ideal for large rooms (with suitable power it can heat 70-100 sq. m.); · service life – 15-20 years (subject to conditions of use); · safe (voltage drops are not a problem due to the built-in emergency shutdown sensors of the device); · versatility (will fit into any design); · ease of installation; · high performance; · silent operation; · speed of air heating; compactness, light weight; · efficiency (modern devices are equipped with an energy saving function). | · complex design; · horizontal air flows are not always convenient; · uneven distribution of warm air; · not suitable for large rooms; · high energy consumption. · compactness; · mobility; · environmental friendliness; · high productivity (quickly heats the air); · affordable price. | · takes a long time to heat up (uneconomical); · heavy weight (5-15 kg); · unsafe (there is a risk of damage to the case, and therefore burns from boiling water or hot oil); · good only for small rooms. · mobility (models on wheels are easy to move); · productivity; · Suitable for drying clothes and shoes; · long service life (with proper operation – up to 15 years); · environmentally friendly (does not burn oxygen); · low price, availability. |

Electric convectorHeat fanRadiator

Installation of gas stove and convectors

It is prohibited to install the convector at a distance of less than 4 meters from open sources of fire, including a gas stove. The hose suitable for the convector must have a dielectric insert, this will prevent a fire in the event of a short circuit in the wiring in a wooden house.

An important factor is the grounding of sockets located near the gas stove and convectors, although in a wooden house they should be grounded a priori.

There are three types of supply hoses that are allowed for a gas stove in a wooden house, namely:

- Rubber-fabric - its advantage is that it does not conduct electric current, but it is more susceptible to mechanical damage compared to analogues;

- Metal sleeve - when using it, a dielectric insert must be inserted from the gas stove to the main line, but otherwise it has the best performance among analogues. In addition, it is recommended by the latest approved standards. Its only drawback is the price, it bites;

- Rubber with metal braiding - it is more capable of withstanding serious impacts, and also, thanks to the rubber core, does not conduct current.

When purchasing a metal hose, you should pay attention to its coating; some manufacturers focused on other markets, with other standards, use yellow insulation, which does not perform its main functions. Always ask for supporting documents when purchasing, and keep them in a safe place

Review of popular models and manufacturers of wall convectors with thermostat

To make the right choice, it is not enough to look at the promotional materials. To make an objective assessment, it is necessary to study electric wall-mounted heating convectors with reviews from owners.

Timberk

| Model | Power, W | Width x Height x Thickness, cm | Peculiarities |

| Timberk TEC.PF1 M 1500 IN | 1500 | 63×41x10 |

|

| Timberk TEC.E0 M 2000 | 2000 | 80×45x8 |

The products of this brand are inexpensive and have fairly good technical characteristics.

Convenient operation and clear indication are the obvious advantages of this convector

Electrolux

| Model | Power, W | Width x Height x Thickness, cm | Peculiarities |

| Electrolux ECH/ B-2000 E | 2000 | 80×41,8×11,1 |

|

| Electrolux ECH/G-1000E | 1000 | 60×48x7.5 |

|

The price of electric wall convectors with a thermostat of this brand is slightly more expensive compared to competitors' offers. However, the reliability of Electrolux equipment should be taken into account

The manufacturer pays sufficient attention to the appearance of the equipment. His products look appropriate in modern interiors

The large distance between the wheels ensures reliable support in mobile operation

Ballu

| Model | Power, W | Width x Height x Thickness, cm | Peculiarities |

| Ballu BEP/EXT-1000 | 1000 | 48×41,5×11,1 |

|

| Ballu BEC/EVM-1500 | 1500 | 64×41,3×11,1 |

|

This manufacturer's wide range includes electric wall convectors with a thermostat at different prices. Here it is not difficult to find an economical model with basic characteristics and an ultra-modern heater with improved aesthetic parameters.

Universal equipment with supports and brackets for mounting on the wallElectronic control unit Ballu Platinum BEC/EVE-1500

Related article:

Choosing a water convector

To select a water convector, you need to decide on the installation location and type of construction, after which you can begin thermal calculations and selection of parameters

When choosing a model, it is important to consider the following characteristics

The thermal power of a convector is a parameter showing how much area the device can heat. For 1 m2 of area of an apartment or house with a standard ceiling height, 100 W of thermal power is required. Heat loss through windows is higher than through walls, so an additional 200 W must be added to each window.

Calculation example: for a room of 20 m2 with two windows, 20·100+2·200=2400 W, or 2.4 kW, is required. It is better to distribute this value evenly across several convectors, connecting them in parallel or in series. In this case, the temperature in the room will be more stable and uniform.

What you need to know about heating convectors

Overall dimensions are another important characteristic. The possibility of installing the convector in the chosen location depends on it

In this case, it is important to take into account not only the dimensions of the device itself, but also the required distances to the floor, walls and other structures (indicated in the passport for a specific convector model). For wall-mounted convectors, the distance from the floor must be at least 80 mm, to the window sill - 100 mm

Moisture protection is an important parameter when choosing convectors for installation in a bathroom, swimming pool, sauna washing area or greenhouse. Convectors can be designed for dry rooms with an average annual humidity of up to 85% or for wet rooms with a humidity above 85%. In the second case, corrosion-resistant materials and coatings are used, and in the case of in-floor convectors, drainage systems are used.

The type of circulation (natural (KBE marking) or forced (KVP)) is important to create the necessary microclimate. Convectors with a fan can create an effective thermal curtain near doors and windows, but at the same time they actively raise dust and cause drafts. The noise level of convectors with forced circulation is also higher. The fan in convectors runs on 12 V DC, for which you need to provide a power supply.

Floor convector with tangential fan

Working pressure is a characteristic that needs to be clarified when installing water convectors; in centralized heating systems according to SNiP 2.04.05-91 it is in the range of 8-9.5 bar, in autonomous systems it usually does not exceed 3 bar. Most models of water convectors are designed for an operating pressure of 1 MPa and a pressure test of 1.6-2.0 MPa, which is equal to 10 and 16-20 bar, respectively. If this condition is met, convectors can be installed in autonomous heating in an apartment building without restrictions.

The internal volume of the heat exchanger is the most important parameter for autonomous heating systems when calculating the volume of coolant. On average, it is 0.7-2 liters and depends on the number of pipes and the length of the device.

Convector circuit

The maximum temperature for water convectors is usually +120-130 degrees Celsius, which is much higher than the permissible temperature in heating systems. At the same time, for safety of use, the maximum temperature of the device body should not exceed +60 degrees according to the passport.

The weight of the convector is important when installing wall-mounted models on walls and partitions made of plasterboard or other material with low strength. Taking into account the coolant, the weight of water convectors usually does not exceed 14-24 kg.

The degree of automation is a characteristic that takes into account the possibility of precise temperature control. Regulation is carried out by means of a thermostat and a valve; with their help, the amount of coolant necessary to maintain a given microclimate is supplied to the heat exchanger.

Thermostat

Kinds

The principle of operation for all models is the same - they heat the air circulating between the elements of the heating devices. The heated air, becoming lighter, rises, and heavier, cooled air takes its place. Devices are divided into groups according to installation method, type of heating element, power, and additional functions.

By installation method:

- Ceiling - located almost at the ceiling of the room.

- Wall-mounted - need to be hung on the wall, just below the window openings.

- Floor-standing - can be placed in any desired place in the room, near the wall, in the center.

- Skirting boards - mounted in place of classic skirting boards along the walls.

- In-floor - immersed deep into the thickness of the floor, along large window openings, external walls.

Heating elements:

- Needle-shaped.

- Finned heating element.

- Monolithic.

Power - 1.5-2.5 kW. Models with larger and smaller characteristics are less common. A power of 1.5 kW is enough to heat a room with one external wall, an area of about 10-15 square meters. meters, 2.5-3 kW can withstand standard wiring.

Installation of a water convector

The basic component of this convector is the heating battery. The main goal when using water heating is that it is necessary to make the correct calculation of heating convectors in order to create the most comfortable and optimal conditions in the room by choosing the correct power of the heating convector. A specialist, instructions and special formulas will help you calculate the power of a heating convector. When installing the battery, it is also necessary to take into account the fact that radiators are made of different materials.

When installing such convectors, it is necessary to use connecting components made of copper, and they are not cheap. Such radiators are used mainly to lighten the design of the heating system. Aluminum and bimetallic radiators are used much more often. However, such radiators will also require the purchase of expensive connecting components.

The cheapest is considered to be a heating convector made of steel. Such a battery can have two types of connection:

- Bottom connection;

- Lateral connection.

Installation of a water convector, first of all, begins with fixing the radiator to the wall. To do this, you will need to drill the necessary holes and secure the hooks with which the battery will be held on the wall. It will then be necessary to hang the convector sections on these hooks. After this, the heating convectors can be connected to the heating system using the pipes. For this purpose, a heating convector connection diagram is used.

If you are using steel pipes, you will need to call a specialist, but in the case of plastic pipes, you can make the connection yourself using an iron for welding plastic. However, if you are not sure, it is better to also invite a specialist.

Installing convector heaters on the wall

Here you will learn:

Convectors are becoming increasingly popular heating equipment. They are extremely compact and highly efficient, quickly heating rooms without the help of electric boilers and batteries. Heaters are mounted under windows and on blank walls, where they successively pass almost all the air in the rooms through themselves, heating it. Let's see how to install a convector on a wall. Moreover, we will touch upon not only electric, but also gas appliances.

Installation of heating convectors, taking into account power calculations

The main purpose of household convectors is heating a living space. There is a division of this type of equipment in accordance with the characteristics of the installation, as well as based on the coolant used in the design.

Speaking about installation methods, you can find floor and wall models, and the use of one or another coolant divides these devices into mechanisms that operate using water, electricity and gas

It is important to remember that installation of gas-type heating convectors can only be carried out on walls in a vertical position, while water and electrical systems can be installed both on the wall and on the floor (read: “Household convector: principle of operation and installation”)

Special standards for the operation of convectors

When using this heating equipment, it is important to ensure its normal operation, and this can be achieved not only by correctly installing the system, but also by following the rules for its operation described below:

- The upper and lower grilles of the convector must be cleaned of dust at least twice a year, and this can be done either with a brush or with a regular vacuum cleaner. The design of the device allows you to easily reach important functional parts and provide them with proper care;

- The body of the device can be wiped with either a dry or a cloth moistened with water, but you should not use any special detergents at all.

Work specifics

Today, heat exchangers of various types are produced. In general, the features of their operation, as well as the design characteristics, are similar. The structural properties of such an element:

- Full body available.

- Presence of outlet and outlet pipes.

- Braking mechanism for combustion products. Its role is played by valves with cutouts that are installed on the axles.

The flaps can be turned. A zigzag chimney of varying lengths is formed. The valves can be adjusted to ensure the ratio of draft and heat transfer is as efficient as possible. Safety standards are met.

In this video you will learn how to make a heat exchanger:

General requirements

In some cases, the best way out of the situation will be to install a gas convector. This heating device is mounted on the wall and is powered by a gas cylinder. The possibility of power supply from the main line is also provided. If gas appears in your locality in the near future, purchase gas convectors. The following requirements apply to their installation:

- Mandatory maintenance of distances to the nearest objects and walls in accordance with the installation instructions;

- The gas pipe is supplied along the street;

- When installing in a household with wooden walls, it is necessary to consider thermal insulation;

- The convector should not be installed at a great distance from the floor, as this will reduce the efficiency and intensity of the convection process.

Let's see how to install such a convector on a wall.

Installation instructions

So, if you decide to install an electric convector on the wall, you need to proceed as follows:

- Unpack the convector and turn it over on the back side.

- Remove the fastening.

- Lean the removed bracket against the wall in a suitable place (where installation will be done) and mark the mounting holes with a marker.

- If the wall is wooden, screw the mount using wood screws (length 40-45 mm). If the wall is made of concrete, pre-drill the holes with a hammer drill, then drive in the dowels and install the frame, as in the photo below.

- Place the electric convector on the installed bracket.

- Connect the plug to the outlet, turn on the power.

- Set the thermostat to the appropriate temperature.

As you can see, installing an electric convector on a wall is not difficult, let alone connecting it. However, there are several nuances that need to be taken into account during installation, which we discuss below.

Installation of electric convectors

Another option for such equipment is electric convectors

These models can be installed and connected by hand, but it is very important to correctly calculate the power of a convector of this type

The algorithm for installing this device should be as follows:

- the device must be removed from its packaging;

- then the protective film must be removed from the convector;

- Next, you need to decide where the mechanism will be installed.

When calculating the power of a heating convector operating using electricity, as well as connecting it, it is extremely important to follow a large number of recommendations, which, nevertheless, will allow for high-quality installation of the equipment. Here are some of them:

Here are some of them:

- the minimum distance from the floor to the convector is 20 – 25 cm;

- the device must be located at least 25 cm from nearby objects, from above and in front - at least 24 - 55 cm;

- the convector should be installed at a distance of 25 cm from the wall, and it should be located at least 35 cm from the ceiling;

- It is strictly not recommended to install the device behind curtains and doors, as well as under openings intended for ventilation.

The installation process for an electric convector is as follows:

- Having unscrewed the fastening bolts, you need to pull out the bracket;

- using a drill, you need to make pre-marked holes intended for fastening the mechanism;

- Next you need to fix the bracket;

- then you need to insert the electric convector into the clamp with its lower part;

- Guys should be placed on the equipment;

- it is necessary to place the upper part of the device into the mounted guy wires;

- after this, all the clamps must be tightly secured, and the fixing bolts must be screwed in;

- The convector operation regulator should be set to off mode and power should be supplied to the device;

- After the LED on the device lights up, the equipment can be switched to operating mode.

If the electric convector used is floor-standing, then its connection is as follows:

- The unit must be turned over and the mounting legs equipped with wheels must be secured to it. Standard bolts can serve as fastening elements;

- After this, the convector can be turned on and set to the desired operating mode.

It is important to remember that the power consumption of the convector is one of the factors that must be taken into account when selecting and installing equipment

Advantages of household convectors

The undeniable advantages of convectors used for heating domestic and commercial premises include many factors that make it possible to reliably and efficiently heat the required area. The operating principle of the convector is not based on the use of the usual tubular electric heaters (TEH), but on the use of special functional parts constructed using a special alloy. One of the advantages of this method of arrangement is that the room warms up very quickly, since there is no energy consumption to warm up the device itself. Moreover, the productivity rate of these products is very high and is more than 90%.

Troubleshooting

As you can see, there is nothing complicated in the design of a gas convector. Due to its simplicity, this equipment serves for a long time and with high quality. But sometimes it happens that incomprehensible interruptions arise in its work. If you notice that the flame burns unevenly or is difficult to ignite at all, the problem is often a clogged nozzle.

Simply put, the hole through which the gas escapes becomes clogged with soot or other contaminants. In this case, you can easily clean it yourself. All you need for this is a thin needle. Use it to carefully clean the hole.

Very important: before starting work, be sure to shut off the supply of blue fuel to the equipment. For this purpose, a special tap is provided on the supply pipe.

It is absolutely forbidden to work with the device when gas enters it!

It is absolutely forbidden to work with the device when gas enters it!

If after cleaning the problem does not disappear, then the most reasonable option for further action would be to call a specialist from a specialized organization. Remember that gas equipment has a high fire hazard. All more or less serious work with it should be carried out only by craftsmen who have the appropriate license.

If you decide to repair the gas convector yourself, but do something wrong, this is fraught not only with subsequent fines from the gas service, but also with the possibility of a fire. You should not take such responsibility upon yourself; be sure to invite specialists to troubleshoot serious problems. Good luck and a warm home!

The principle of the device

If we talk about design features, then the wall convector includes a housing, a heating element (closed type), a thermostat and temperature sensors and switching off the device in case of overheating. Let's look at the elements of the device in more detail.

Prices for electric convector

electric convector Convector device diagram

First of all, the body itself is important. Usually this is a box made of thin aluminum, steel or high-strength plastic (less commonly). The light weight of the housing allows you to install the device on any wall, even with large dimensions of the convector. Such a housing is similar to a vertical pipe, where the temperatures at the inlet and outlet differ significantly. This contributes to high draft, and therefore strong convection air flow.

There are brackets on the back of the device panel that allow you to easily hang the convector on the wall.

Bonjour CEG FN-meca 500 W

So, at the bottom of the convector there are inlets where cold air enters. Depending on the model, the lower part can have either windows or one long opening. There is also a temperature sensor at the entrance. It is responsible for turning the heating element on and off: when the desired temperature is reached, the device will stop heating the air. And vice versa, as soon as the incoming air masses are recognized by the sensor as not warm enough, the heating element is turned on and the convector operation continues. This is very convenient and significantly saves electricity consumption.

Cold air enters the device through the lower openings, and warm air exits from the upper ones.

The cold air that gets inside becomes warm due to the operation of the heating element. There may be several of these in a convector. The heating elements are different in different models: they can be spirals, modules - anything.

There are exit holes at the top of the device. This is where the heated air is directed, and from there it enters the room. Some convectors are equipped with small curtains, with which you can change the direction of warm air masses.

The device is controlled as standard: by a switch. Each is equipped with indicators and a thermostat, and some have various additional functions.

Some devices are not equipped with a thermostat, but one can be purchased separately

This principle of constructing a wall-mounted convector is classic; it is typical for almost any similar device. There are models with a different design and more equipment.