All owners of apartments and private houses located in areas with negative temperatures experience heat loss in the winter. It goes through the ceiling, walls, floor, windows and doors. In this case, the greatest losses are recorded through the walls - from 20 to 70%. The specific amount of loss depends on the thickness of the walls and the material from which they are made. Thermal insulation of the building helps maintain a comfortable temperature inside a house or apartment without large financial costs for heating. The most effective in this regard is mineral wool for insulating walls inside and outside the building.

To protect residential premises from the cold, insulation materials with a certain set of characteristics are needed: size, density, thickness, etc. In addition, it is necessary to take into account that the technological process is different. Therefore, the editors of the StroyGuru portal decided to analyze down to the smallest detail the features of insulating facades with mineral wool, so that home craftsmen could complete the work quickly and efficiently.

Pros and cons of using mineral wool for wall insulation

Mineral wool is presented, depending on the source raw material, in three types: glass wool, basalt wool and slag wool.

Each type has its own characteristics, advantages and disadvantages. It is because of them that slag wool is not used for insulating facades: with high hygroscopicity, it quickly becomes damp. At the same time, it not only loses its thermal insulation properties, but also corrodes all materials with which it comes into contact - hydrochloric acid is produced during contact with water.

Glass and basalt wool have both common strengths and weaknesses, as well as individual ones.

General benefits include:

- excellent thermal insulation properties - the thermal conductivity coefficient ranges from 0.035 to 0.052 W/(m K);

- versatility. In addition to the facade, basalt and glass wool is used to insulate the floor, roof, ceiling in the attic, as well as walls from the inside of the room. Mineral wool insulation perfectly copes with its functions in houses made of wood, brick, concrete, aerated concrete, foam block, gas silicate blocks and other materials;

- resistance to high temperatures - glass wool can withstand heating up to 300oC, basalt fiber up to 1000oC;

- perfectly resist mold and mildew - glass and basalt fibers do not provide a basis for the development of microorganisms;

- light weight, which does not create loads on the insulated elements of the building;

- ease of delivery from the retail outlet to the place of insulation;

- simple insulation technology - all thermal insulation work can be done with your own hands;

- environmentally friendly - the material does not cause allergic reactions, during the heating process it practically does not emit harmful substances;

- fire resistance - flammability class NG.

Insulating the outside walls of a house with natural wool also has disadvantages , which include:

- connecting seams through which heat loss begins during operation (mats shrink, losing their shape). However, when using modern technologies for attaching thermal insulation boards to the wall, heat loss can be minimized;

- dust - formed during the installation process requires mandatory protection of the body and respiratory tract.

At the same time, basalt wool has several advantages that fiberglass insulation does not have. This:

- durability - the service life of the material is at least 50 years;

- low hygroscopicity. Experiments show that fibers immersed in water absorb only 0.095% of moisture per day;

- good noise absorption, up to 75 dB, of sound waves traveling through the air. Basalt insulation is powerless against impact and structural noise (spread by house structures);

- resistance against mice and rats - they do not eat cotton wool, do not make passages and nests;

- inertness to chemically active substances used in everyday life;

- high level of elasticity - the mats retain their dimensions throughout their entire service life;

- sufficiently high tensile strength, which makes it possible to insulate the facade using the “wet method” (apply a layer of decorative plaster directly to the insulation).

The disadvantages include the high price.

Glass wool also has individual advantages and weaknesses. The advantages include low cost.

The list of shortcomings is wider:

- high hygroscopicity, which requires insulation to be insulated from moisture. Otherwise, destructive processes begin in the wet fibers, as a result of which the glass wool cakes and settles, forming uninsulated areas;

- short service life - about 10-15 years;

- low resistance to the class of chemicals represented by alkalis - fiberglass is destroyed under their influence;

- attractive to mice and rats - serves as a habitat for them.

Detailed information about mineral wool can be found in the material “Minewool for insulation”.

Thermal insulation of the balcony

Scheme of insulating a balcony from the inside.

Insulating a balcony is becoming one of the most pressing topics, since the times when it was turned into a landfill by storing various rubbish on it are over. Now people have finally appreciated the beauty of an insulated balcony.

Before we consider the method of insulating a balcony with stone wool, let’s define the terms. What do we mean by balcony? Some people don’t understand the difference between a balcony and a loggia, but it’s simply huge:

- balcony – no walls, only metal or stone fencing. That is, windows in front and on the sides;

- loggia - there are two walls on the sides and a front slab made of concrete or metal fencing. There is only a window in the front.

You definitely need to install windows before insulating. Naturally, they need to bet on something. It is possible, of course, to use a metal structure, also known as a fence, but somehow this is not fundamental. If we do it, then do it efficiently and reliably. Therefore, down with the metal fence, you need to build walls from foam blocks. It is already possible to install windows on it, but it should be understood that if there are windows on three sides, then you cannot expect any high insulating qualities from the balcony.

There are energy-saving windows, but they are far from the thermal insulation characteristics, so, most likely, the insulation will be almost formal, which cannot be said about the loggia. It is still possible to achieve good insulation and connect it to the general living area. Statements that this cannot be done will not be accepted. If you want, you can. Let's say you insulated a loggia and connected it to a common living area without the permission of the BTI, what could be the consequences:

- the neighbors will report - do not let the inspection into the house, although it will not come;

- problems when selling - you draw up documents according to the plan, but in fact there is a redevelopment. If this option does not suit the buyer, a new one will be found, since this one is so fundamental;

- If the battery power is not enough, you can use an electric heater.

By the way, it is better not to take the battery out onto the loggia, since in this situation the inspection will come with the local police officer. As a result, they may even be fined and, of course, forced to redo everything in accordance with regulatory documents.

Which mineral wool to choose for wall insulation

The quality and efficiency of insulating walls outside with mineral wool are determined by two factors:

- correctly selected insulation;

- compliance with the technology of thermal insulation work.

The choice of insulation is simple at first glance. But this is in the opinion of the “home master”. A specialist will immediately say that the effectiveness of insulation is simultaneously influenced by several factors:

- type of insulation - it is better to buy glass wool for siding and other short-lived materials. This is the perfect combination of price and quality. For “wet insulation”, cladding made of porcelain stoneware, artificial and natural stone, block house, material made of basalt wool is required. The “biting” price is justified by the long service life. You can also use glass wool, but this is exactly the case when “the greedy pays twice”;

- mat thickness is one of the most important indicators. After all, firstly, the effectiveness of insulation, and secondly, the location of the “dew point” depends on it. Both factors are included in a special formula, which many specialists have difficulty coping with. For skilled hands, we give two tips on how to do without complex calculations:

- Take advantage of the established practice and buy slabs with a thickness of 100 mm for central Russia, 150 mm for the north, and 50 mm for the south.

- Use the online calculator located here.

- linear dimensions. Modern production produces mineral wool with a width of 20 to 180 cm and a length of 100 to 600 cm.

The most convenient size of mineral wool insulation for walls outside the building:

- the width is 50-60 cm. With this size, it’s easy to fill the sheathing, it’s easy to mount the insulation inside the cells and attach it to the wall;

- in length - the slabs should be within 100-120 cm, rolls - of any length, because during the work they will have to be cut in any case, since long strips are difficult to work with;

- density. The thermal insulation properties of the material and the rigidity of the slab (the ability to resist deformation under the influence of mechanical loads) depend on the indicator, which is especially important when applying decorative plaster directly over the insulation (“wet method” of insulation) and insulating a frame house, when the weight of the upper slabs presses on the lower mat.

Experts recommend buying mineral insulation with a density of:

- 50-75 kg/m3 for insulating the walls of a frame house with mineral wool - insulation with a different density will begin to shrink over time;

- 80-130 kg/m3 for insulating walls with a ventilated gap;

- 130-160 kg/m3 for decorative plaster;

- 150-175 kg/m3 for a façade made of concrete structures.

Incorrect application of glue

It is incorrect when gluing is carried out only by applying “bloopers” and does not apply a layer of glue along the perimeter of the sheet. The consequence of such gluing may be the bending of the insulation boards or the marking of their outline on the final finishing of the insulated facade.

Options for correctly applying glue to foam:

- along the perimeter in the form of stripes with a width of 4-6 cm. On the remaining surface of the insulation - dotted “bloopers” (from 3 to 8 pieces). The total area of the adhesive should cover at least 40% of the foam sheet;

- applying glue to the entire surface with a ridge spatula - used only if the walls are pre-plastered.

Note: the adhesive solution is applied only to the surface of the thermal insulation, never to the base.

Gluing mineral wool requires preliminary puttying of the surface of the slab. A thin layer of cement mortar is rubbed into the surface of the mineral wool.

Manufacturers

It is better to buy cotton wool from trusted manufacturers. Among them are both well-known brands and mineral wool brands that are unfamiliar to the mass consumer.

Rockwool. (Denmark) produces insulation from basalt and gabbro fibers at production facilities located in several countries, including Russia. Features of insulating mats are:

- low thermal conductivity;

- good absorption of air noise;

- resistance to open flame (flammability class NG);

- long service life;

- environmental cleanliness.

Paroc. A manufacturer of basalt wool from Finland () offers consumers mats for residential construction and acoustic insulation of recording studios.

The insulation is characterized by a low thermal conductivity coefficient, fire resistance, and durability. It is almost impossible to find counterfeit products on sale - the company very carefully monitors the market for counterfeits. Unfortunately, for the average consumer the price of insulation is too high.

Isover. The leader in sales of mineral wool in Europe is a transnational company registered in France, which has its production facilities in Russia. The product has the best balance between price and quality.

TechnoNIKOL. The brand of thermal and waterproofing materials "TechnoNIKOL" belongs to Russian business, but is produced in many European countries (Lithuania, Belarus, Czech Republic, England). Among the huge product line, mineral wool insulation occupies a significant place. Modern equipment and careful quality control allowed the company to enter the TOP 5 largest suppliers of mineral wool to the construction market of Europe and the CIS countries.

IZOVOL. produces basalt insulation in Russia. The product has an affordable price and good quality. The line of insulation products includes mats produced separately for facades, roofs, floors, and foundations.

All quality characteristics meet the requirements of EU and Russian standards. A slight shedding of fibers during the installation process blurs the impression of quality. The manufacturer knows about the problem, but cannot fix it yet.

In addition to the listed brands, it is worth paying attention to the products of the brands “KNAUF” and “URSA”. It is very often bought for insulation of timber houses. From the middle price sector, experts note the insulation "Beltep" (Belarus). It has excellent rigidity, good vapor permeability, easy installation, and an affordable price.

Advantages

Mineral wool has a number of advantages specifically for insulating wooden walls.

- One of the main things is vapor permeability. The material does not block air in wooden walls, which constantly accumulate and evaporate moisture. Thus, the tree continues to “breathe” and ventilate.

- The second important advantage is flammability.

Mineral wool is not flammable. In the event of a fire, it begins to smolder only if the temperature reaches 450-600°C. This is the best indicator of flammability among all types of insulation. Even fire-resistant isolon begins to burn at a temperature of 250°C. In addition, during a fire, mineral wool does not emit smoke and resin that is hazardous to health, unlike polystyrene foam, EPP and other plastic-based insulation.

Softness and plasticity make it possible to lay insulation on rebated walls, for example, log houses. Competition in this regard can only come from foil insulation made of foamed polyethylene.

Cotton wool in rolls bends well, following the contours of the structure.- In terms of thermal conductivity, mineral wool is not very different from its competitors, but in terms of water absorption, on the contrary, it is inferior. Although to a lesser extent, cotton wool can absorb moisture, unlike insulation based on polyurethane or plastic, which have water-repellent properties.

Required materials and tools

To carry out thermal insulation work on the facade, it is necessary to purchase basic and auxiliary (consumable) materials, assemble a set of tools and devices.

Materials you need to purchase:

- mineral insulation - you need to buy 10% more, since consumption increases due to pruning;

- vapor barrier (windproof) film;

- wooden block - usually 50 mm thick, width - depending on the thickness of the mats for the main sheathing;

- rail (distance bar) 20 x 50 mm for counter-lattice for siding, block house, imitation timber, etc.;

- plastic or metal corners for reinforcing corners;

- metal cornices for mats;

- primer;

- special fasteners for mineral wool (dowels with a large plastic head);

- glue “CERESIT CT190” for attaching mats to the wall and gluing reinforcing mesh;

Attention: CERESIT CT180 adhesive is intended only for glass wool. You can glue basalt wool with it only at your own peril and risk.

- reinforcing fiberglass mesh;

- wood screws when installing counter-lattice.

Tools and equipment you will need:

- scaffolding (needs rent) or trestles (just do it yourself). Working on stepladders or ladders is, firstly, prohibited for safety reasons, and secondly, it is inconvenient;

- hammer drill or electric drill;

- screwdriver;

- mixer attachment for preparing glue;

- wood hacksaw;

- a hacksaw or metal scissors (you can use a grinder);

- knife with removable blades;

- glue container;

- notched spatula;

- hydraulic level or laser level;

- building level;

- plumb line;

- chop cord;

- construction corner;

- roulette;

- hammer.

Preparatory work

Any repair and construction process begins with preparatory work. Facade insulation is no exception. The sequence of actions is as follows:

- everything unnecessary is removed from the wall: drainage systems, street lights, ebbs, window and door frames, various strips, etc.;

- the walls are subjected to a thorough inspection, during which the vertical is checked - a deviation of no more than 1.5 cm is allowed, and cracks, cracks, and drilled holes are also found;

- when the wall is collapsed, it is primed, followed by plastering and reinforcement, cracks and holes in wooden houses are clogged with flax tow, in all others they are covered with special mastics (there are universal ones for a specific type of wall material);

Attention: if plaster was used in the process of repairing walls or removing the vertical, further work can be continued only after the plaster solution has dried - 7-8 days.

- surface of brick, concrete, gas silicate, etc. the walls are cleaned of dirt and dust, mortar build-up from masonry joints;

- wooden walls are impregnated with fire retardants and antiseptics;

- the facade is primed with a deep penetration primer twice;

- A vapor barrier film (diffuse membrane) is attached to the walls with a 10-12 cm overlap, with the smooth side facing the insulation. For fixation, you can use the staples of a construction stapler. To ensure high-quality vapor barrier, it is better to glue the seams with regular tape;

Attention: many experts ignore the vapor barrier of the facade under the insulation boards. The existing experience of the site's editorial staff says no rather than yes - it is difficult to fix insulation boards with glue on top of the film. The membrane may simply not withstand it and the entire load will fall on the dowels.

- at the level of the joint between the wall and the foundation, a metal cornice is installed (builders sometimes call it a “profile”) which will support the mats from sliding down. Fixation is carried out using self-tapping dowels. The connecting joints at the outer corners are cut at an angle of 45o, after which they are fastened together with 2 plates.

If the foundation is wide, then the cornice is not installed, and the slabs are mounted directly on the base, previously covered with roofing felt, which acts as a waterproofing layer and damper.

The sheathing is placed on the fixed film.

Arrangement of sheathing

Those who carry out the insulation of the facade on their own, the need to install the sheathing is often linked to the fastening of mineral wool to the wall. But that's not true. The mats adhere perfectly to the wall surface with glue and dowels. So, before painting the facade, it is enough to strengthen the surface of the mats with fiberglass reinforcing mesh, and apply a layer of putty on top. The grille does not get stuck on frame walls either. Here the insulation is placed between the frame posts.

Lathing is needed when insulating walls outside with mineral wool for siding, block house, imitation timber, lining, etc.

Using the example of sheathing for siding, we will analyze step by step the technology for attaching it to the wall. To work you will need:

- wooden beam 40x40 or 50x50 mm. Dry, straight, with a smooth surface, without falling knots, dark spots and mold;

- metal hangers or bars for attaching the sheathing to the wall.

The work is performed in the following sequence.

Step 1. The distance from the wall surface to the outer plane of the frame is calculated. The thickness of the timber is subtracted from the result obtained. As a result, we get the size of the bar for the sheathing. When using direct hangers, calculations will help determine at what distance the beam should be attached from the wall surface.

Attention: under siding, block house, imitation timber, lining, two options for attaching the sheathing are possible: flush (the most rational option), in this case a counter-lattice is stuffed in, or protruding by about 4-5 cm to create a ventilation gap. Then the counter-lattice is not mounted.

Step 2. Using a tape measure, a plumb line and a marker, mark the beam attachment lines on the wall. The horizontal distance is 60 cm, vertical - 40 cm. But this is in theory. It is more practical to maintain a size of 390x590 mm. Mineral wool will fit into such cells very tightly, by surprise. The layout of the beam is shown in Fig. below.

Step 3. Bars are prepared to fit the obtained dimensions.

Step 4. Along the line of passage of the beam, the places where the beam is attached are marked: at the ends of the beam, and inside in increments of 40-60 cm.

Step 5. Holes for the dowel are drilled using a puncher or drill.

Step 6. Dowels are driven into the drilled holes.

Step 7. A block is attached to the wall.

Step 8. The sheathing is stuffed.

This method of fastening is simple in technology, but creates problems when laying mats: you will have to cut out part of the insulation under the block. Otherwise, the mineral wool will not be able to be attached to the wall with glue. Therefore, experienced specialists prefer metal hangers, despite the difficulties of attaching the timber.

Important: window and door openings around the perimeter are lined with additional timber.

General Tips

A few rules and notes for quality work.

How to choose and apply glue to mineral wool

Without the correct selection and use of glue, the insulation may sag and cease to act effectively. Stone wool is a rather unusual material, and not every adhesive can provide high-quality adhesion to the wall.

Polymer-cement compositions will provide the highest adhesion. They are sold as a dry mixture similar to cement. There are several well-known brands: “EK THERMEX”, “ERESIT CT190”, “ERESIT CT180”.

Following the instructions on the package, dilute the mixture with water and mix well (repeat after 5 minutes). The solution will retain its adhesive properties for 2 hours.

Apply the solution evenly onto a flat surface of the wall so that you get 7-8 glue circles. We also apply glue to the back side of the cotton wool (closer to the edges); the surface should be covered with the composition more than half. It is also better to coat the joints. The glue hardens for some time, so it is possible to lay the slab correctly. Attaching stone wool to a wall is simple.

Sometimes, for greater reliability, additional fastening may be required. Anchor bolts or slats secured to the sheathing can help here.

Installation of insulation

Insulation of the facade with mineral wool is carried out using several technologies. Here are instructions for the most common methods: insulation of frame walls, facades under siding and decorative plaster.

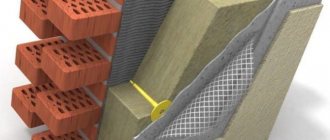

Insulation of frame walls

Insulation of frame walls has the following work algorithm:

- from inside the room, a para-insulating membrane is attached along the frame posts, with the smooth side facing the insulation;

- a block is placed on top of the membrane or a metal profile is screwed on to create a ventilation gap;

- OSB or plasterboard (gypsum plasterboard) is fastened onto a padded block (profile) for finishing;

- mats are installed between the racks. Here, home craftsmen often do not know how to attach mineral wool to the wall of a frame house. There is no need to be tricky - it is held between the posts due to its rigidity and slightly larger size;

- A windproof film (type A) is fixed on top of the insulation with staples;

Important: the outer layer of the vapor barrier cannot be stretched, as in frosty weather the film shrinks in size and may burst. There should be 1 cm of sag between the posts.

- the counter-lattice is filled with a block of 5.0x6.0 cm (according to SNiP, the ventilation gap should be 6 cm);

- the walls are sheathed.

Quite often, especially in cold zones of the country, double insulation of a frame house is carried out. In this case, a sheathing of horizontal timber is placed on the outside of the frame. Basalt wool mats are installed between the beams.

The insulation is covered with a windproof film, on top of which a counter-lattice is placed to create a ventilation gap. An OSB board 9 mm thick is laid over the counter-lattice if the façade will be finished with artificial or natural stone. The siding panels are attached to the counter battens.

Insulation under siding

Under the siding, mineral wool slabs are laid from bottom to top, as closely as possible to each other in the absence of a horizontal beam. In the cells - in space. Non-standard pieces in corners, near window openings and doors last. Cutting to size is done with a construction knife.

The top of the insulation is covered with a windproof film. A counter-lattice with a beam height of 2-6 cm is placed on it (violation of SNiP regarding the size of the ventilation gap does not lead to negative consequences). Cladding panels are attached to the padded slats.

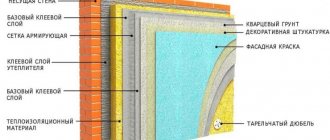

Insulation of facade under plaster

Applying decorative plaster to basalt wool requires rigid fixation of the mats to the wall. This makes changes to insulation technology. The process consists of the following operations:

- prepare the glue according to the instructions printed on the package;

- The adhesive mass is applied with a notched trowel to the mat over the entire surface, pointwise or along the perimeter and with a point in the center of the slab.

Important: some authors of works on construction sites recommend applying glue to the ends of the insulation, which is a serious mistake.

- the mat is pressed against the wall. The 1st row is pasted. The mats of the second row are attached with an offset of at least 150 mm (like brickwork);

Attention: it is impossible to accommodate all the subtleties of the technological process in one work. Therefore, we strongly recommend that all home craftsmen who perform facade insulation with mineral wool look at the works: “Wall insulation with stone wool” and “Wall insulation with foam plastic.”

- corner, top and mats adjacent to door and window openings are cut to size with a construction knife;

- in the corner the mats should overlap each other one at a time, in a checkerboard pattern;

- corner joints are reinforced with plastic or metal plaster corner;

- The plates are additionally secured with dowels with a large plastic head at 5 points: 4 in the corners, one in the center. Fastening between seams is allowed. In this case, the dowel fixes two mats at once;

- The insulation surface is reinforced with fiberglass mesh. The glue is the same as that used to attach the slabs. The mesh is overlapped, overlapping the previous strip by 20 cm. The top is covered with glue 2-3 mm thick;

- dried glue is primed twice;

- After the primer has completely dried, the facade is finished with decorative plaster.

Important: insulation of the outside walls of a wooden house with mineral wool is carried out using the same technologies as given above.

You can insulate the attic using thermal insulation technology under siding.

Why is it better to insulate a house from the outside?

Let's figure out what the alternatives are and why it is best to insulate a wooden house from the outside.

Why is internal insulation less preferable? Firstly, the usable area decreases, secondly, the dew point shifts inside the log house, which will greatly shorten the life of the house and disrupt the comfort for residents, thirdly, the log house begins to rot, collapse and cause mold, which becomes a health hazard.

Insulation from the outside, on the contrary, is protection against freezing of the log house, shifts the dew point to the outside, which removes condensation outside, outside the wooden structures.