Residents of private houses often get very cold in winter. After all, heat escapes through windows and doorways, cracks in the floor, as well as walls. To solve this problem, mineral wool for insulating the ceiling helps a lot.

Below in the article a video of do-it-yourself ceiling insulation with mineral wool is published, as well as the main nuances of installing this building material.

Selection of mineral wool

Among materials for insulation, mineral wool is in increasingly growing demand. This is no coincidence. Let's start with the fact that this is an environmentally friendly material, safe for the environment and humans. Mineral wool has a high heat retention class, absorbs sounds well, is not afraid of rotting, open fire, and is not interesting to rodents and insects. Increased elasticity and dimensional stability predetermine easy installation without fasteners. Mineral wool does not break, crumble, or slide over time, providing reliable thermal protection for up to 50 years.

These characteristics are fully inherent in insulation based on Izover Profi mineral wool. It consists of long slabs in rolls, which are equally suitable for the entire house - ceiling, walls, flat (in frame structures) and pitched roofs (attics), balconies, interior partitions, ceilings above the basement. The improved thermal conductivity coefficient (0.037) will save up to 67% on heating costs when compared with uninsulated spaces. As is known, ordinary mineral wool suffers even when slightly wet - drops of water displace air from the fibers and are difficult to weather, which can lead to a decrease in thermal insulation properties over time. Thanks to the special AquaProtect technology, Izover Profi repels water well and dries much faster due to optimal vapor permeability.

Insulation with mineral wool

Buy at isover market

A nice bonus is savings on transportation and storage due to the increased compression ratio in the packaging - it can be easily loaded into a passenger car, taking up 3 times less space compared to conventional basalt slabs (35 sq. m Isover Pro versus 6 sq. m of ordinary mineral wool, The same amount can be placed on the roof rack if you load an Isover module from several packages there, compressed with high-strength film at the factory). We will consider insulation technology in detail below.

Polyethylene foam and polyplex

In addition to attaching mineral wool to the ceiling, thermal insulation of the ceiling can be done using other materials:

- Foil polyethylene foam. This insulation is made of polyethylene foam in a special way and then glued to aluminum foil. It is sold in rolls, the width of which is standard and reaches one meter, and the thickness varies from one to 20 centimeters. The material is used both independently and together with mineral wool to improve the thermal barrier.

- Polyplex is produced by extruding polystyrene foam. It is sold in the form of sheets measuring 60x120 centimeters, the thickness of which varies from one to 20 centimeters. Among the advantages, it should be noted the increased density, due to which polyplex is used as insulation and a rough base for laying putty.

Both types have advantages and work such as gluing insulation to the ceiling can be done with your own hands. Polyethylene foam is fixed using special glue or dowels, widely used in construction. Polyplex is secured with dowels or holders that look like the letter P.

Features of ceiling thermal insulation with mineral wool

The stages of insulation and thickness directly depend on which ceiling needs to be insulated: under a heated or unheated room, in contact with external cold (in the attic, attic). In addition, the climatic zone of the region and the building structure (floors, walls) are important. Taking these parameters into account, before calculating the cost of mineral wool insulation, its thickness is selected.

Insulation thickness

For a ceiling inside a heated building, as a rule, 50-100 mm is sufficient, and if the ceiling is directly adjacent to a cold attic or roof covering with a slight slope, it is better to focus on 150-250 mm. In the northern region, this figure will have to be increased to 2 times, but in any case, before making the final choice, you need to check whether the planned insulation thickness meets the requirements of your region (in the next section we will look at how this can be done). In the case of reinforced concrete floors, the recommended value is at least 100-150 mm. The Izover Profi packaging contains two slabs, each 50 mm thick, 1220 mm wide, 4100 mm long, which will allow you to vary the degree of thermal protection at your destination based on one product. There is Izover Profi, already cut in half during production: the package contains 4 long slabs 610 x 4100 x 50 mm.

The Isover smart calculator will help you calculate the quantity and required thickness of the material that is optimal for insulating your home.

Material calculation

The peculiarity of the calculator is that it will help you calculate the required amount of insulation, and at the same time the benefits that await you in the short and long term. You only need to fill in the design parameters of the house, its location (region), heating source, and comfortable temperature. As a result, you will receive a detailed calculation of the cost of thermal insulation and how you will save on heating (monthly and annually) and how quickly you will recoup the costs. For example, just by changing the thickness of mineral wool, you can increase the energy efficiency and comfort of staying in your home: from class B with a layer of 50-150 mm (comfort in the off-season, protection from overheating in summer) to the highest class A+++ (at 200 -250 mm), adopted in Norway and Finland for permanent residence and allowing to minimize heating costs. Using the Isover calculator you can easily calculate the thermal insulation of floors, walls, roofs, ceilings, as well as apartments and balconies. In this case, the calculator will redirect you to the online aggregator, where you can place an order from the official distributor.

Brief overview of manufacturers

Nowadays it is easy to purchase products for any construction purpose, and mineral wool for the ceiling is no exception. Most likely, the supermarket will offer you several options that differ little from each other.

Brands known for excellent product quality and leaders in the thermal insulation products market:

- Knauf (Knauf - an international company); Isover (Isover - an international group); TechnoNIKOL (Russian corporation); Ursa (Ursa - a subsidiary of the Spanish group Uralita); Rockwool (an international group of companies headquartered in Denmark).

For insulating ceilings, both stone wool, produced on the basis of basalt rocks, and glass wool, which is produced after processing quartz sand and glass production waste, are suitable.

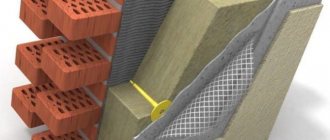

Diagram of one of the options for insulating the attic floor

Ceiling insulation technology

How to insulate a ceiling correctly? The process of thermal insulation of a ceiling in a wooden house consists of three main stages.

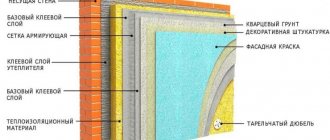

Waterproofing

Since wooden floors and the insulation itself can be damaged by moisture, it is first necessary to prevent their contact with water. To do this, all wooden surfaces are first treated with an antiseptic or a complex fire-bioprotective composition with mandatory drying. Then a vapor-permeable barrier is created under the roof - it will become waterproofing, which, without letting in drops of water from condensation or possible leaks, should freely release steam into a ventilated gap of 40-50 mm. Thus, wind-hydroprotection Izover Vetranet (AM), thanks to its three-layer structure, will reliably protect the structure from external moisture, the building from heat loss (blowing), and will not allow condensation to accumulate due to a special “breathable” membrane between the two protective layers. If you are sure that the roof will be used in a cold version (that is, the attic space is low, suitable only for storage), then you can use Isover Hydranet (D) vapor barrier as a moisture barrier, but do not forget about sufficient ventilation and a high-quality vapor barrier installed with sides of the lower warm floor. If you plan to insulate the roof in the future, then vapor-waterproofing (D) will not suit you and can cause harm; for waterproofing a warm roof, it is permissible to use only a “breathing” membrane - Vetranet (AM). It is waterproof and will last at least 50 years. The roll rolls out from left to right. Laying is carried out from below with an overlap (10-15 cm), a construction stapler will be useful. Easy cutting is ensured by convenient factory markings. To prevent water from leaking in, the joints are sealed with specialized adhesive tapes.

Laying mineral wool

Izover Profi in the 610 by 4100 mm format is ready for installation with a standard frame pitch of 600 mm in clearance. When choosing a product with a width of 1200 mm, you will need to cut the roll in half or to the desired dimensions. With a standard beam spacing, installation does not require fasteners - the long slab stands securely in place without cold bridges for at least 50 years. The product is produced in thicknesses of 100 mm or 50 mm (in a package there are either 2 or 4 slabs), allowing you to change the number of layers depending on the location of the ceiling - under a heated room or under the roof. A prerequisite for proper installation is that the width of the slab should be 1-2 cm wider than the pitch of the rafters/beams. Then it will not sag or, conversely, will not be overly compressed. Long slabs mean fewer gaps, joints, and cracks (after all, they increase heat loss by up to 50%). If necessary, the slabs are cut into the required sheets with a knife with a blade length of 15 cm. As a result, insulating the ceiling with Izover Profi mineral wool will take 2 times less time than installing conventional basalt slabs. And its installation can be carried out by one person per work shift.

Vapor barrier

The ceiling is the most vulnerable place to moisture, because this is where all the steam in the room accumulates. Moisture, as we already know, negatively affects the heat-shielding properties of mineral wool, and the structure itself as a whole. Therefore, after installing thermal insulation, reliable insulation technology requires a sealed vapor barrier layer. The Izover Paranet membrane serves these purposes. It is placed overlapping (10-15 cm), completely covering the mineral wool, attached to the rafters with a construction stapler, and then fixed with pressure bars. The joints are sealed (glued) with special adhesive tape Isover Paranet (CL). As a result, the ceiling will be protected from moisture, as well as from the possible formation of mold and mildew.

Please note that insulation with mineral wool should begin on the side farthest from the exit. Gradually move towards the door. Try to avoid gaps, cracks, and a large number of joints. Bends and pinching are fraught with a decrease in the working thickness of the thermal insulation layer, which can lead to heat loss and further freezing of the structure.

Tips from a pro

To ensure that the insulation of the ceiling surface is highly effective as a result of your actions, pay attention to the useful tips of experienced craftsmen:

- To work with metal sheathing, it is better to use self-tapping screws made of hardened steel. They will fix the insulating material well.

- Avoid pressing or compacting mineral wool during installation. This approach will significantly reduce its ability to retain heat.

- If the thickness of the selected material exceeds the width of the equipped sheathing, you can fill additional wooden blocks on top of the main boards.

- When the sheathing profile is installed and the mineral wool is placed in the cells, blow in the corners of the ceiling with polyurethane foam. This way you will eliminate the risk of cold air entering from the outside through the thickness of the ceiling.

DIY ceiling insulation

There are three methods of insulation depending on the building design:

- external (from the attic or attic);

- internal (in the presence of high ceilings, since it can take away from 150 to 350 mm of the room’s height);

- combined method (used more often for baths, saunas, where exits and communication openings are provided in the ceiling).

If it is necessary to insulate the space under the summer attic (cold or insufficiently insulated), and the ceiling height is small, it is better to thermally insulate not the ceiling, but the floor in the upper room (make sure in advance that the vapor barrier layer on the ceiling of the warm room is present and sealed). The process follows a pattern already familiar to us. You must first clean the floor and, if necessary, cover it hermetically with a vapor barrier (do not forget to seal the joints with special adhesive tape). Then comes the mineral wool between the additionally installed joists. On top there is a waterproofing film and a subfloor.

Installation of sheathing

An important process in thermal insulation is considered to be the reduction of thermal conductivity of ceilings. This stage is not skipped and is performed when the roof has not yet been assembled. Stages:

- The vapor barrier film is attached to the ceiling beams.

- Then the boards are nailed onto a film 2.5 cm thick, divided into 0.5 m squares.

- Thermal insulation is fixed on the resulting canvas. Mineral wool should be laid across the entire width of the ceiling.

On a note!

If you do not use the attic, then there is no need to install the film. In this case, you can attach the material directly to the sheathing.

If it is not possible to insulate the ceiling from above, above the beams, then you need to perform internal thermal insulation. To do this, simply attach the material to the ceiling. Afterwards it is sheathed with film and plywood.

Insulation from the inside

If it is necessary to thermally insulate the ceiling with mineral wool inside the house, we proceed according to the scheme described in the previous chapter, from top to bottom: waterproofing - mineral wool - vapor barrier. Under a heated floor, a minimum layer (100-150 mm) is often sufficient, including for basic sound insulation of rooms (a greater sound insulation effect is achievable if the frame space is completely filled and both sides are covered with sheet panels - GSP and moisture-resistant plywood or OSB). Under a cold floor or attic you will have to construct a serious barrier. The order of work and materials for insulation are the same, from top to bottom: waterproofing membrane - special frame (in the absence of beams) - increased layer of mineral wool (determined by calculation) - vapor barrier on the side of the warm room. After this, the ceiling is covered with any sheet panels (for example, Aqua Strong gypsum board) - now it is ready for finishing work.

Safety precautions

When working with mineral wool insulation in a private house, it is necessary to take into account the features of its structure. The material is made of tiny fibers that can separate and enter the human body. To prevent harm to workers and residents of the house, you need to pay attention to the following points:

- gloves, masks and overalls for workers to prevent material fibers from getting into the skin and lungs;

- preventing contact of air flows entering the ventilation system with the surface of the insulation to prevent danger to residents.

Mineral wool

Mineral wool is a fiber made from textiles.

It can be purchased in the form of rolls or blocks. The one made in the form of a path has greater thermal insulation. It not only has better performance properties, but it is also much easier to work with.

How to attach insulation to the ceiling using mineral wool? Let's look into this issue.

Thanks to cotton wool, it becomes possible not only to insulate, but also to protect the room from excessive noise, as it has excellent sound insulation properties. The installation itself is carried out using dowels with a wide head. Additional means for more durable fastening can be self-tapping screws and self-adhesive tapes.

Mineral wool on the ceiling

The installation instructions include the following work steps:

Measurements are taken from the ceiling on which installation is planned. Preparation of the slabs. They must correspond to the measurements taken and be completely identical. Holes for dowels are drilled in the ceiling. In this case, it is better to use plastic ones. With their help, metal profiles are installed on the base. Mineral insulation is applied to the profiles. After applying mineral wool, the entire structure is secured with dowels. Sheets are laid on top.

They also need to be secured as best as possible. This can be done using wooden slats and nails that resemble mushrooms in appearance. They received this name because of their wide cap on top. During installation, cracks and openings may remain, which it is advisable to fill with polyurethane foam.

Fastening mineral wool insulation has its advantages, such as:

- This material has high environmental parameters. It is hypoallergenic. Durable in use, thanks to the high quality of the products used. It is not subject to deformation. It is a fireproof material, which expands the range of its use. Application is possible even in bathhouses or saunas. High percentage of vapor permeability.

One of the important aspects in installation is that during installation the material itself must be placed tightly, but in no case be subject to deformation. Otherwise, it may lose its performance properties.

For a longer period of operation, it is advisable to coat the surface with an antifungal agent upon completion of installation work. This will allow further dust collection.