The operating mode of a bathhouse differs from the maintenance of residential buildings. Most of the time, the bathhouse is not heated; if necessary, the interior space is heated to a temperature that allows you to steam, shower and be without outer clothing. The locker room should warm up to 25 degrees, the dressing room - to 27-29 degrees, these conditions are higher than the requirements for the maintenance of residential premises. In the steam room the temperature reaches 100 degrees or more.

The costs of heating a bathhouse and maintaining a comfortable temperature depend on the size of the building, building material and the effectiveness of insulation. Insulation is done in stages, divided into external and internal, and a separate insulation circuit is made in the steam room. Experts recommend: in a bathhouse made of timber with a cross-section of less than 180x180, internal insulation must be done. The decision on how to insulate a timber bathhouse from the inside and what material to use is made depending on the specific conditions.

When to start insulation and finishing work in a new wooden bathhouse

If the bathhouse is made of timber or is a log house, then you must immediately keep in mind that in the first three years after construction it will shrink noticeably (then less). On average, this is 20 cm in the first 3 years.

During shrinkage, cracks form - all this time you will be patching them. And the most important thing: if finishing was carried out immediately after construction, and it was nailed down firmly, then the lathing will not allow the bathhouse to sit properly.

Therefore, it is either left unfinished, or grooves are cut out in the sheathing so that the nails gradually slide into the grooves.

It’s better not to finish it, because you have to caulk the cracks both inside and outside, and the sheathing will get in the way. The bathhouse needs to be allowed to shrink (at least) for one year. And when its results are already visible, you can think about insulation and finishing work.

Inter-crown insulation and sealing of cracks

Over time, wooden buildings inevitably shrink, which causes gaps to appear between the crowns. Those, in turn, open the way for drafts, so the first stage of the fight is to seal them.

The initial stage of interventional insulation occurs during construction. Timber (including profiled) and round timber are laid with tow tape or jute. Subsequently, this will be internal interventional insulation.

In addition to the internal, there is also an external one, which has to be periodically updated. The resulting cracks can be filled with tow, jute, natural moss, or you can use modern materials, but only those designed for wood.

IMPORTANT! Plumbing sealants, putty and polyurethane foam are not suitable for sealing cracks in a bathhouse made of logs or timber. They are inelastic, designed for a constant gap size (while wood changes), they have poor adhesion to wood, insufficient heat resistance, harmful emissions, etc.

flaws. Over time they crumble out of the cracks

They are inelastic, designed for a constant gap size (and in wood it changes), they have poor adhesion to wood, insufficient heat resistance, harmful emissions and other disadvantages. Over time, they crumble out of the cracks.

The cracks on the outside of the beam or log are sealed with wood sealants in such a way that the sealants will dry from 2 to 5 weeks, and the walls must be protected from the sun and rain during this time.

Arrangement of thermal protection of walls and ceilings

Insulating the walls and ceiling of a bathhouse from the inside is similar to how it is done in other rooms, but special attention should be paid to the reliability of laying the vapor barrier layer.

Stage one - creating the lathing The procedure for how to insulate the ceiling in a bathhouse from the inside suggests that the distance from the lathing to the base of the wall or ceiling needs to be made slightly greater than the thickness of the material for thermal insulation

Stage one - creating the sheathing. The procedure for how to insulate the ceiling in a bathhouse from the inside suggests that the distance from the sheathing to the base of the wall or ceiling needs to be made slightly greater than the thickness of the material for thermal insulation.

When using galvanized profiles, this gap is adjusted using hangers, and the block is nailed down using a backing, which can be a piece of block. Galvanized hangers are also used for wooden sheathing.

The sequence for attaching the profile is as follows:

- A UD guide profile is fixed along the perimeter of the walls or ceiling, observing a 60-centimeter step. It is mounted to timber or logs with self-tapping screws, and to brick or concrete walls - with screws and plastic dowels.

- The axes of the CD profiles are marked, taking into account that the gap between them should allow the laying of heat insulation slabs without trimming. Then the hangers are attached to the wall, observing a step of 60-80 centimeters.

- To install and fix CD profiles to the hangers, use metal screws 9 millimeters long. The free edges of the hangers need to be folded.

Stage two - installation of insulation. Basalt wool in slabs is placed between the bars (profiles). The insulation of a ventilated façade or loggias is carried out in the same way. The work must be done in a respirator (gauze bandage) and special glasses. The fact is that the small fibers of this material are volatile and, when they get on the human mucosa, they greatly irritate it.

To cut the slabs, use a standard sharp knife. The insulation should not be crushed during installation. Regarding how best to insulate a bathhouse, you need to know that with a constant weight of the material, the smaller its volume, the worse its heat-insulating qualities will be.

Stage three – installation of steam and waterproofing. Strips of material are fixed horizontally from bottom to top, maintaining a 5-centimeter overlap. The foil side of the insulation should be facing inside the room.

The method of fixing the vapor barrier depends on the material from which the sheathing is made. So, before you insulate the steam room in a log bath, you need to stock up on a construction stapler. If there is a galvanized profile, the strips are secured with double-sided aluminum tape.

To create a high-quality vapor barrier, the insulation not only needs to be fixed, all existing joints must be taped with the same tape. Then moisture will not be able to penetrate the insulation.

Stage four – clapboard covering. To make the room cozy and beautiful after completion of insulation, it is necessary to finish the walls.

First, prepare the tools and materials necessary for the work, including:

- circular saw or electric jigsaw;

- drill - screwdriver;

- rasp (required when adjusting and processing the edge of the lining);

- construction square (necessary for marking boards);

- level and plumb line (they are in demand when checking verticals and horizontals);

- metal clamps for fixing wooden lining;

- copper or galvanized screws, which are needed for fastening the clamps to the bars;

- metal screws;

- wooden baseboards for finishing corners.

When carrying out work, you need to consider a number of points:

There should be a small gap between the lining and the vapor barrier layer. In addition, gaps (no more than 1-2 centimeters) are installed along the edges of the ceiling, as well as in the upper and lower parts of the walls.

The end boards in each row of the lining should be fastened with screws through and through, and their caps will be covered by the baseboard. All other boards will be held in place by clamps.

The above-described procedure for carrying out work allows you to both insulate an old bathhouse from the inside and a completely new building. Thermal protection of a bath structure is a very important stage, since the efficiency of the steam room depends on its quality. The main thing in the work is to take into account the slightest nuances and then the result will exceed expectations.

External insulation

Wooden structures

The process of thermal insulation of the room in which the bathhouse is located can be divided into two stages - external and internal work (see also the article Insulation of a bathhouse - materials and technologies). Below we will look at how to insulate a bathhouse made from different materials, and we will start, naturally, with the traditional option - a wooden frame.

By and large, wooden baths and saunas were previously not insulated at all. That is, to maintain maximum temperature in them, no additional structures were erected.

However, it is still possible to improve the heat-saving characteristics of a wooden log house:

The main source of heat loss is the gaps between the crowns of the bathhouse

It doesn’t matter whether the frame is made of round timber or timber, over time the wood will dry out and the gaps between the elements will reach several millimeters

We caulk the crowns

- To reduce heat loss during the construction of the bathhouse, we lay a special insulation between the crowns.

- Six months after construction (ideally, the bathhouse is not in use at this time), we additionally caulk all the cracks. To do this, you can use tow, moss or special materials.

- To seal cracks, use a hammer and a special spatula - “caulk”.

Brick structures

Brick baths are easier to insulate, although more expensive thermal insulation materials are used.

- When choosing how to insulate a bathhouse from the outside, many people prefer cheap polystyrene foam, although it is still better to use polystyrene foam boards. Although they are more expensive, they are more durable and durable.

- Before starting insulation, we prime the wall and then install the lower guide profile. We fasten polystyrene slabs on top of the brickwork with plastic dowels, after which we glue the seams with polyurethane foam.

- We glue fiberglass glass onto the polystyrene foam lining, after which we plaster the bathhouse.

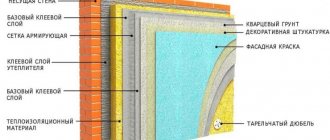

Possible external insulation scheme

This method is the simplest, and it is the one that is used most often when doing all the work with your own hands. However, this is not the only technology, and if time and finances allow, you can even install a multi-layer ventilated facade - a diagram of its design is given above.

Insulation of a brick bath

To begin with, it should be noted that building a brick bathhouse is much cheaper than building a wooden bathhouse. Based on this, many steam room lovers build a bathhouse from this material. However, you need to know that a brick bathhouse requires not only high-quality insulation, but also additional processing that protects the structure from the effects of water, steam and temperature changes.

The outside of the bath is insulated using various mineral wool insulation materials. This type of insulation is most often sold in rolls, slabs and mats. Rolled mineral wool insulation is used to cover the entire outer surface of the bathhouse walls. It is attached using ordinary wooden planks and slats. If the bathhouse is insulated using slabs, then metal corners should be installed between them, which must match the dimensions of the slabs.

When starting work, you need to take into account that not only the surface of the walls of the bathhouse, but also the entire perimeter of the foundation requires insulation. The finishing on top of the insulation is made from the material preferred by the bathhouse owner

At the same time, a small gap must be maintained between the insulation layer and the external finish - during operation it will serve as ventilation.

In order for the bathhouse to serve for a long time and fully insulate the roof of the building. This is most often done using clay or grass turf. The clay is diluted with water to the state of liquid sour cream and pour a thin layer over the roof surface. After waiting for the first layer to dry completely, pour in the second layer of clay mortar. Then the clay is carefully compacted and covered with material that has high thermal insulation characteristics, for example, sawdust. Tiles are laid on the floor of a brick bathhouse. Additional insulation of the floor is not required - the tile heats up quickly and retains the temperature perfectly.

Strip foundation

Such a foundation is installed when there is heaving soil on the plot.

The work on its construction is carried out step by step:

- Markings are made on the site and a trench is dug, the width of which is 40 centimeters and the depth is approximately 50 centimeters.

- The hole is filled with sand layer by layer until the ground level is reached, compacted each time and watered with water to ensure compact shrinkage.

- They construct formwork 50 centimeters high and 30 centimeters wide. For greater strength, it is reinforced using rods and metal pipes.

- Pour the concrete solution in several approaches (without allowing the previous layer to dry) or at a time.

- Roofing felt is laid on top of the concrete to waterproof the frame walls.

Projects and drawings of a two-story frame bathhouse provide for the provision of the most reliable support on any type of soil, with the exception of floating ones. The base is a prefabricated strip foundation.

Insulation of a bathhouse made of timber from the outside

External insulation of walls made of timber simultaneously performs the functions of wind and moisture protection:

- First, caulking is done, and the walls are treated with an antiseptic. Then lathing is made or metal guides are attached. Insulation is laid in the gaps. The next layer is wind and moisture protection. This should be a membrane. A counter-lattice or another way to create a ventilation gap of 3-4 cm. A layer of finishing.

External wall insulation (shown using a block wall as an example, but this can be done to insulate any wall).

Insulating a bathhouse made of timber from the outside with mineral wool may only be necessary, perhaps, if this bathhouse is a living space. Well, or if the bathhouse is made of very thin timber and is located in the Far North and is operated in severe frosts. Outside, it is permissible to use mineral wool with phenolic impregnation.

When does insulating a bathhouse from the outside make no sense and when is external wall insulation justified? How to do it?

But still, as a rule, insulation of a bathhouse made of timber from the outside is not required.

Just as in most cases a wooden bathhouse does not need any insulation other than sealing the cracks, its steam room is able to perform its functions without additional effort. Unless the owner sets the task of making a sauna out of a bathhouse, which differ in temperature and air humidity. But even in this case, it is enough to simply lay a layer of foil or foil-coated kraft paper without installing any insulation.

The foil is placed behind the lining, but never end-to-end, but with a ventilation gap so that the lining can dry out. There should also be an air gap between the foil and the timber wall. If a “thermos” is made from a steam room, you should not use coniferous wood in the lining, so as not to get burns from the resin. Let’s put it this way: insulating a steam room in a wooden bath, if we don’t talk about using foil, is a very strange event. The debate about foil will never end , she has many supporters and opponents.

But, as a fact, a steam room with foil becomes hotter, and the steam in it becomes harsher. Therefore, it is a matter of the owner’s taste. On the other hand, mistakes during its installation can be costly; if the wood gets wet, mushrooms and rot will develop. As experts say: try steaming without foil, you will always have time to put it on.

How to caulk timber

The properties of several natural materials are most suitable:

1. Since ancient times, builders have used tow to insulate Russian baths and Finnish saunas made of wood. Such popularity is ensured by the fact that tow is a cheap and easy-to-handle material. As it turned out, I myself am able (without having special experience) to insulate the timber walls from the outside using improvised means. Tow is sold in rolls, which further simplifies the installation process. In addition, they also sell improved tow with resin impregnation. It is more moisture resistant and has greater strength. The only drawback of the material is its short service life, so the insulation will have to be repaired from time to time.

2. You can also use moss, which is still used in Siberia. The lack of moss is a rather difficult installation process, which can take several days. In addition, moss that is not impregnated with special compounds can be destroyed by moths.

3. Experts consider the most profitable mixture of flax fibers with jute, called flax-jute felt. This is the most reliable insulation for timber walls. Among the advantages, we can emphasize the high density, which will allow for quick and even organization of seams. Also, one cannot ignore the ease of processing; insects and mold and fungi do not touch it. Jute insulation has excellent heat resistance.

In addition, you can use insulation of the beam with polystyrene foam from the outside, as the most inexpensive method, but the high fire hazard of the material has more than once led to tragic consequences, so this decision should be approached very carefully and only if no other insulation is possible.

Insulation made of synthetic materials for baths made of timber

Synthetic materials for insulating a log bathhouse

Before you start insulating a bathhouse, you should take into account the fact that the use of synthetic materials for these purposes is highly undesirable. This is due to the fact that the bathhouse loses its healing properties. Despite this, each material is worthy of more detailed information.

Mineral wool

The main advantage of this material is that it is completely non-flammable. The disadvantages of mineral wool are its complete lack of durability and too high sensitivity to moisture. It is used not only for thermal insulation of baths, but also in the construction of many other objects. Mineral wool is sold in rolls or sheets. Mineral wool is very convenient and extremely easy to use. The fairly low price also stands out.

Penoizol

Penoizol is an environmentally neutral material that does not accumulate harmful substances. It is very easy and convenient to use, it is durable and reliable. Penoizol is not subject to rotting or burning, and does not attract insects and rodents, which diligently avoid it. Sales are carried out in the form of rolls, crumbly crumbs or sheets.

Expanded polystyrene

This material stands out among others in that it retains heat perfectly, although the thermal insulation indicator strongly depends on the company that produces it. The disadvantage of polystyrene foam is its flammability. When burned, styrene is released, which has slightly toxic properties. The material is durable and quite easy to use. The price of polystyrene foam greatly depends on the manufacturer and the quality of the material.

Polyurethane foam

Among all synthetic materials, polyurethane foam is the leader in thermal insulation properties. That is why baths treated with polyurethane foam are considered warm. This material is extremely durable, but is also highly flammable, releasing highly toxic cyanide. The walls are covered with it in the form of pollination. The price of polyurethane foam largely depends on the manufacturer and quality of the material.

Application of foam plastic

Many home craftsmen are interested in whether it is possible to insulate a bathhouse with foam plastic. After all, this is a relatively inexpensive and easy-to-use material. However, it should be said that the bathhouse can be insulated with foam plastic from the outside or along the foundation.

When asked whether it is possible to insulate a bathhouse with foam plastic from the inside, most experts will answer negatively. This is due to the fact that foam is easily destroyed when exposed to high temperatures. The low moisture resistance of this material causes it to rot under the influence of high humidity. Therefore, for the interior of a bathhouse, foam plastic can only be used in rooms where there is almost no moisture.

Insulation materials

Insulation for a timber bath should have vapor permeability characteristics similar to wood. For this reason, all variations on the theme of polystyrene foam disappear - it does not allow moisture to pass through and condensation will form where it touches the wood.

Polyurethane foam emits harmful substances, so it is not suitable.

Mineral wools have suitable vapor permeability and can be freely used for external insulation, but the phenolic impregnations of most types of mineral wool during internal insulation of a bathhouse will evaporate at high temperatures, and these are carcinogens. There is basalt wool, to which no impregnation is added at all or very little is added - it is suitable.

Suitable insulation materials include flax fiber and soft fiberboard. The first consists of 85% flax, the second - from coniferous wood chips.

Both materials are vapor permeable, easily absorb and easily release moisture. Their characteristics are close to wood. But without fire retardant treatment, they are highly flammable.

But ecowool has already been treated with fire retardants, so it does not support combustion, it can be used in a wooden bathhouse.

By

Useful tips

The walls and ceiling of a bathhouse building must be insulated according to the following principles:

- Thermal insulators must be in close contact with the wall surface to reduce the risk of internal moisture and cold air entering.

- A ventilation gap is needed on top of the insulation to dry it.

- All floors and other wooden elements must be treated with an antiseptic composition to prevent premature destruction of the material.

- Materials with a low level of heat and moisture resistance cannot be used in the steam room.

- Insulation materials should be selected from those that do not deform under the influence of moisture and high temperatures and do not emit hazardous chemicals.

Necessary properties of insulation for a bath:

- heat resistance;

- moisture resistance;

- environmental friendliness;

- Fire safety.

Natural insulation materials require special treatment before use. Otherwise, mold, mildew and harmful insects may soon appear. In this case, it is more advisable to use artificial insulation.

Insulating a timber bath from the inside or outside, whichever is best

The answer to this question depends on what it should be better for: even after caulking, your bathhouse is so cold that no matter how much you heat it, it does not heat up to the required degree, or do you want to be able to steam in it for two days?

In the first case, you need to look for the reason where the heat goes. Alternatively, insulation from the inside can help, although there is an opinion that a wooden bathhouse should not be insulated in this way at all. In the second case, external insulation will help.

IMPORTANT! No matter which side you insulate the bathhouse, there you lose control over the condition of the wood, because it is hidden from view. You can only rely on proper installation of insulation

Wood breathes, takes in and releases moisture, so when insulating, you need to maintain the opportunity for it to “breathe.” And this means great limitations in the materials used.

Layout features

In the old rural baths, the exit from the steam room was almost immediately onto the street, which was well remembered by viewers of domestic films in which steamed heroes jump out of the steam room into the snowdrifts.

Modern owners make buildings more spacious, providing not only a steam room, but also a wash room, a dressing room, and a locker room. It is important not to overdo it in this matter, but to make the room after a preliminary calculation of the number of possible visitors. The extra space will increase heat loss, fuel consumption for heating and the volume of materials for insulating the room.

It is appropriate to place the steam room away from the entrance so that cold air does not enter it. At a minimum, you need to make a vestibule in front of the steam room if the area of other rooms at the entrance is planned to be small.

The doors in the bathhouse should not be very wide, but with a mandatory high threshold, because cool air always blows into the gap under the door.

Note! A square room with a stove near the entrance is best heated with steam.

With the correct structure design, insulating a wooden bathhouse is not difficult.

Bath insulation process

When building a sauna from timber, insulation is necessary if you plan to steam in the winter or the heat emanating from the stove is not enough to heat the steam room to the required temperature. To understand how to insulate a wooden bathhouse, you should study a large number of materials on this topic. This will help to avoid a large number of errors and problems that may arise directly at the stage of installation of thermal insulation materials, which may increase the work time.

The bath is insulated from the inside, outside and inside the wall. In-wall thermal insulation is installed as the walls are being built. A layer of mineral wool or other heat-insulating materials is laid between the inner and outer walls. The bulk of the work on internal insulation is carried out before finishing the interior. The exception to the rule is the floor and attic floors.

Bathroom floor insulation

Before you start insulating the attic floor, you should take care of the vapor barrier. To provide vapor barrier, glass hydroisol, roofing felt or polyethylene are used. The next layer is expanded clay, slag or fiberboard. The main requirements that should be presented to the insulation are: fire resistance, the quality of the thermal insulation layer should be equal to the same value as 25 centimeters of mineral wool. A screed of sand and cement, at least 3 centimeters thick, is laid on top of the heat-insulating layer, on top of which walking boards are laid.

Insulating the steam room of a log bath begins with insulating the walls from the inside. It is recommended to install heat and vapor barrier under materials such as gypsum fiber, plasterboard, magnesite. Undoubtedly, this will reduce the usable area of the room, but the amount of heat retained will significantly increase.

Insulation of the steam room of a bath

Insulation of a wooden bathhouse from the outside begins with insulation of its facade, at the stage of wall construction. To do this, inter-crown insulation is laid between the logs of the log house, which can be either ordinary tow or more modern insulation made from jute and flax. The thickness of the inter-crown for baths made of brace should not be less than 0.5-1 centimeters, and from a log house – 1.5 centimeters.

The optimal time to insulate the facade is mid-summer. During this period there are no sharp, abrupt fluctuations in temperature and humidity. Before you begin work on insulating the facade, it should be treated with agents that protect against rotting processes and prevent fire. If necessary, the inter-crown cracks are caulked. The façade is insulated with mineral wool, polyurethane foam, and polystyrene foam. Each layer of insulation must be secured with anchors, ensuring that the joint below the previous row overlaps the top one, resembling brickwork.

Bathhouse in the process of insulation

To prevent the formation of condensation during changes in temperature and air humidity, vents are provided under the sheathing and in the thickness of the foundation - special ventilation holes through which water vapor is discharged along with ventilation air flows.

To choose the right insulation, you should enlist the help of professionals and learn as much as possible on your own. Before you start insulating a wooden bath, you should plan everything carefully.

Having learned how to insulate a timber bathhouse as a whole, you should dwell in more detail on the most important part. Thermal insulation of the steam room is of greatest importance, because it is important to quickly create and constantly maintain high temperatures (from 60 to 130 degrees Celsius)

In a Russian bath, the optimal temperature is considered to be 60-90 degrees Celsius, since heat is achieved through high humidity, while a Finnish sauna requires higher temperatures, up to 130 degrees Celsius, due to dry air.

The importance of reducing heat loss is that a certain amount of fuel is needed to create the required temperature, and the more heat is lost, the more expensive it will be to light the bathhouse. In addition to this drawback, there is another, more global

Due to high heat losses and the use of large amounts of fuel, the service life of a bathhouse or sauna is significantly reduced, which entails additional costs for repairs and the purchase of fuel.

Ultimately, in some cases, heat loss can exceed heat output, and then the room will not warm up at all. In order to avoid home problems, you should arrange high-quality thermal insulation, which will retain all the healing properties of a real bathhouse, and will also warm up quickly and for a long time, giving warmth to its visitors.

: 2 289

Why do you need to insulate a bathhouse from the inside?

First of all, this is to ensure suitable conditions for the bath procedure. Next, sound insulation is provided and a solid basis for the finishing coating is formed. All this certainly increases the service life of the structure.

However, there are other privileges:

- Fuel costs for heating the room are reduced, regardless of what is used - coal or gas;

- A stable microclimate is formed that prevents drafts, dampness and cold. Thanks to this, everyone will feel comfortable;

- The air circulates properly, preventing moisture from settling on the surface of the room. The cladding remains dry, does not rot, does not succumb to mold and mildew, and always looks beautiful.

Wooden baths insulated from the outside

The most popular were and remain bathhouses built of wood. The walls of a wooden bathhouse have the ability to “breathe” and therefore perfectly regulate the air humidity in the room. To ensure that the wood from which the bathhouse is built retains its valuable properties, insulation is made using natural materials - flax wool, jute and flax felt, red moss or a mixture of the above materials.

Insulating the walls of a bathhouse from the outside does not require special professional skills. With the help of inter-crown insulation, cracks and gaps are caulked. The most convenient insulation materials are made from flax - they are soft and elastic, thanks to which they lie in an even layer. Insulation with jute will take a little longer - it is hard and brittle.

An important point is that the baths are insulated during the construction process, and not after its completion. The insulation is placed between the logs, which makes the structure not only warmer, but also much more durable and strong. After the roof of the bathhouse has been installed, the resulting gaps and grooves are re-insulated.

We recommend you read additionally: Insulating a brick bath.

Internal insulation

Floor and underground space

Foiled polyethylene foam, kraft paper or glassine can be used for vapor barrier. They protect the insulation layer from getting wet, in addition, a layer of metal foil reflects heat into the room.

We fill up the expanded clay

If you plan to insulate a bathhouse with your own hands, you need to start work from the floor:

- We lay sheets of roofing felt on the concrete base. On top of them we install supporting wooden beams, on which the logs will then be attached.

- Pour a layer of expanded clay onto the roofing felt. The thicker the layer, the warmer the floor in the sauna rooms will be.

- We fix the logs to the support beams, having previously leveled them on the plane using a level.

- Between the logs we lay insulation on the expanded clay - mineral wool or polystyrene foam. In some cases, it is possible to fill the underground space with ecowool, a heat-insulating material based on cellulose fibers.

All that remains is to make a vapor barrier, and you can lay the floors

We cover the heat insulator with a vapor-proof membrane, after which we lay the subfloor.