The under-roof space is used in different ways; living rooms or storage systems are equipped here. Thermal insulation work, which requires little labor and financial investment, makes it possible to get additional living space that will never be superfluous. More than half of developers use mineral wool as a thermal insulator. Let's talk about the process of insulating an attic from the inside with your own hands using mineral wool, and the video at the end of the article will help you better understand this issue.

Mineral wool: definition and manufacturing technology

Among the existing methods of insulating an attic from the inside, mineral wool comes first as an economically advantageous and technically convenient material. Its price is significantly lower than other insulation materials, and installation is easy and simple.

Mineral wool is a reliable insulation material

Mineral wool is fiber obtained from the melt of volcanic rocks, waste from glass and blast furnace production. Depending on the base, insulation is divided into basalt, slag or glass wool.

*

Types of mineral wool insulation

To obtain it, the same technology is used:

- Glass, molten rock or blast furnace slag is loaded into a shaft-type furnace.

- At temperatures above 1500ºС they are heated to a liquid state. Fibers are obtained directly by blowing or centrifugal method. They make up the structure of the material.

- The fibers are bonded with phenol-formaldehyde resins followed by polymerization.

- Heat treatment.

- Package.

Technological scheme for obtaining mineral wool

*

Mineral wool is hygroscopic; with prolonged contact with water, it loses its thermal insulation properties. To prevent moisture from entering, the material is sealed in plastic film.

Signs of a “correct” pitched roof

High-quality materials, coupled with compliance with insulation technology, guarantee a long service life of the roof without “crying” walls in the attic, mold and mildew. A properly insulated pitched roof provides a comfortable microclimate in the attic without the need to increase the power of the boiler in winter or the air conditioner in summer. You can technically verify the effectiveness of roof insulation by examining it with a thermal imager. The device will show the absence or presence of zones through which owners “drown” the street. But even without equipment in winter, the main sign of mistakes made can be seen with the naked eye - “garlands” of icicles. On a roof where the insulation is done correctly, the snow lies in a uniform mass, without melting, and there is nowhere for icicles to come from.

Advantages and disadvantages of mineral wool

Advantages and disadvantages of mineral wool

After heat treatment, mineral wool acquires the following qualities:

- low heat conductivity, which makes mineral wool an excellent insulation material;

- fire safety, the production of wool from non-flammable components allows it to resist fire;

- resistance to various temperature conditions, sudden changes do not cause deformation of the insulation;

- resistance to chemically aggressive environments;

- the ability to resist the appearance and development of microorganisms inside the insulation;

- excellent vapor permeability;

- ease of installation.

Among the disadvantages are excessive hygroscopicity and a tendency to form dust. The last property appears only during work. Compliance with all safety regulations during installation work helps to avoid the appearance of dust.

Preparatory stage

Insulating the attic from the inside with thermal insulation material - mineral wool - begins with preparatory measures.

Preparing for insulation

Preliminary work:

- Inspection of surfaces for fixing mineral wool.

- Coating wooden surfaces with an antiseptic, and metal with anti-corrosion compounds.

- Replacing damaged areas, drying damp areas.

- Inspection of the rafter system and repair.

- Removing the packaging film from the cotton wool so that the material takes on the desired shape.

- Preparation of protective clothing for safe installation: suit, gloves, respirator, goggles.

Manual calculation

The next step in insulating a cold attic of a house with mineral wool is calculating the thickness of the layer.

Errors when choosing the thickness of the mineral wool layer

*

Manual calculations are carried out in accordance with the set of rules “Thermal protection of buildings”. The given formulas and calculations will require special training from a non-specialist.

It is impractical to understand the nuances of manual technology for calculating one individual attic. It is recommended to use free calculator programs from the Internet.

Calculation using the program

When choosing a calculator program to calculate the thickness of the thermal insulation layer, the region of residence is taken into account. Otherwise, the result will not reliably reflect the real picture. For a one-time determination of the insulation thickness, it is recommended to use an online service.

Calculation using the program

How to properly insulate an attic

The insulating structure is a kind of pie of several tiers, where each layer performs its own function. Let's figure out why insulation consists of several layers and what they are needed for.

Waterproofing

The first layer is a waterproofing membrane. It is this that will protect the insulation from moisture penetration. It cannot be laid without waterproofing protection. Moisture from the roof will get onto the insulation, and wet insulation loses its protective properties, freezes and collapses.

Thermal insulation

High-quality thermal insulation will retain heat inside the room in cold weather and prevent overheating of the air in the attic in the summer. In addition, the insulation performs the function of noise protection. The optimal insulation thickness for most regions of Russia is 20 cm.

Vapor barrier

The purpose of a vapor barrier is to prevent steam generated as a result of vital activity from penetrating into the inner layer of the insulating cake. And also prevent insulation components from getting inside the room.

Features of insulation

Nuances taken into account when insulating

Before starting work on laying thermal insulation material, pay attention to the following important features of insulation:

- The attic will be a living space, and therefore will require more thorough thermal insulation than roof insulation.

- The rafter system and floors are not designed for great forces, so the insulation should have a small mass. Taking into account the specific gravity, mineral wool is ideal.

- Heat leaves the attic not only through the roof, but also through the walls and floor; they also require careful insulation.

- Warm air, due to its physical characteristics, promotes the formation of dew drops, so the thermal insulation layer should be covered with a vapor-proof film.

Preparing the attic roof for insulation with mineral wool

Most of the preparatory work consists of performing two procedures:

- Laying a vapor barrier membrane on the walls with fixation by horizontal slats;

- The second step is to install a wooden frame made of timber onto the walls of the attic.

It is clear that in the case where the roof slope will serve as the wall of the attic space, a roof counter-lattice can be used to lay the mineral wool. In any case, there should be a vapor barrier between the roofing and the insulation.

Which mineral wool is best for the attic

According to experts in the field of private housing construction, mineral wool is considered the best thermal insulation material.

In order to verify this, we will perform a comparative analysis of cotton insulation on different bases.

Slag wool was popular in the former USSR more than 30 years ago. Its disadvantage is its high hygroscopicity. This quality is unacceptable in insulation for rooms with high humidity. Modern builders prefer modern glass and basalt products.

Comparison of mineral wool on different basis

*

On the Russian market we can distinguish the TOP of 7 manufacturers whose high quality products best correspond to the price:

Rockwool basalt wool

The leader is the Danish company Rockwool, which produces basalt-based thermal insulation. According to reviews from builders, it maintains a high standard of 10 points out of 10 possible, and ensures maximum quality without unnecessary unjustified overpayments.

Paroc basalt wool

Three companies occupy second place. Their performance is 9.9 out of 10:

- Paroc is a manufacturer of basalt mineral wool from Finland. His rating is 9.9 out of 10.

Mineral wool ISOVER

- The French concern Saint-Gobain is an international concern. He began producing his own thermal insulation materials 80 years ago. Products are manufactured based on glass and basalt rocks.

Mineral wool Knauf

The German group of companies Knauf produces insulation from glass and stone fibers.

Glass wool URSA

An international company from Spain, URSA, was formed relatively recently, after the URALITA Group concern acquired the German company Pfleiderer, or rather, its insulation business. Mineral wool is made from glass. Factories are scattered throughout Europe, and there is a representative office in Russia. The company's rating is 9.8 out of 10.

TechnoNIKOL basalt wool

The TOP is completed by two companies TechnoNIKOL from Russia and Beltep from Belarus. Their products are made from volcanic rocks and are of high quality and reasonable prices. Rating indicators 9.5 out of 10.

Beltep basalt wool

Having become familiar with the best mineral wool manufacturers, the builder makes his own choice. There is no consensus which of the listed brands is the best. When choosing, take into account the structural features of the roof, the climatic conditions of the region and the price.

Stone wool for attic insulation

One of the most common insulation materials in pitched roofs is stone wool, as the optimal material in terms of performance and cost. It has such properties as:

- low thermal conductivity;

- biostability;

- fire resistance;

- non-flammability;

- sound absorption;

- minimal hygroscopicity;

- durability;

- practicality (and ease of installation, and preservation of the original parameters for the entire service life).

When vapor passes through the fibers, the stone wool is not moistened, its thermal conductivity and volume remain unchanged, that is, during operation the insulation remains dry and effective and does not lose its properties.

ra093FORUMHOUSE Member

Please give advice on how best to insulate the attic of a 10x10 m timber house, Middle Urals. The pie is now standard: flexible tiles, ventilation gap 50 mm, membrane, rafters 200x50 mm. The attic is quite low, I don’t want to lower the ceiling too much.

I see options:

- 200 mm stone wool. Then straight finishing. The rafters look like cold bridges. But how much heat do they take away, considering that 200 mm, and my house itself is made of 190 mm timber, essentially like a cold bridge.

- 50 mm gap between the wool and the membrane, 150 mm of wool, there is already a 30 mm pier plate on the rafters. It turns out more expensive, but it seems to me it should be warmer than 200 mm of wool. The downside is that the ceiling will be lowered a little more.

What other options are there that are not too expensive? Of course, I would like to blow out everything with 150-200 polyurethane foam or lay it all out with slabs, but the price turns out to be very high. Can he handle the entire feast with 100 mm slabs? Judging by the advertised thermal conductivity, it will be like 200 mm of wool.

Anatoly Zemlyanko Technical specialist of ROCKWOOL company

Definitely the first option. 200 mm stone wool, which is the most effective vapor-permeable and breathable material. All other materials will act as a vapor barrier, so it is not advisable to mix these insulation materials. Logs are not cold bridges, since the thermal conductivity coefficient of wood is quite low, which indicates its effectiveness.

Properties and features of mineral wool cladding

*

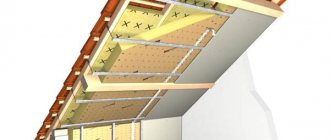

Mandatory requirement: when insulating, the insulating material should be laid in two layers. This design most closely matches the thickness of the rafter system and provides better thermal insulation for the attic. It will be warm here in winter and cool in summer.

Roofing pie

Insulation of the attic from the roof side is carried out according to the following scheme:

- slate or metal tiles;

- sheathing;

- roofing felt as a waterproofing material;

- mineral wool insulation;

- vapor barrier film.

Features of thermal insulation of the attic floor

The technology for insulating a mineral wool attic from the inside involves creating an obstacle to the outflow of heat and reducing air exchange with the cold street. This is a feature of the isolation process. As a result, warm, moist steam remains inside the room. In such conditions, it is necessary to reliably protect the cotton wool from moisture, otherwise it will quickly get wet and lose its properties.

Another problem is the dew point shift. If you insulate an attic roof from the outside, the dew point will be on its outer side. In this case, the resulting condensate will evaporate into the atmosphere. But if the insulator is laid from the inside, this does not happen. Therefore, it is very important to leave an air gap of 50-100 mm between the roof and the insulator. It is necessary for the evaporation of condensate.

For effective insulation you need a roofing pie of five layers. If you look from the roof, they are located in the following sequence.

TechnoNIKOL Rocklight stone wool

Layers of roofing cake

- Ventilation gap 50-100 mm.

- Vapor-permeable membrane, moisture and wind insulation.

- The insulating layer is laid between the rafters.

- Vapor barrier film or membrane.

- Attic ceiling.

For vapor barrier, it is best to choose special membranes. On one side they are rough, the other side is smooth. Thanks to this feature, condensation does not form on them. If there is no membrane, lay a film of polypropylene or polyethylene, glassine. For moisture and wind protection, other membranes are chosen: double-layer film, porous and superdiffusion. The last option is considered the best.

Instagram ekovata58

Instagram doktor.khlus79

Instagram aliancess_ryazan

Materials and tools necessary for insulating the attic

If mineral wool is chosen as the thermal insulation material, and you plan to do the insulation process yourself, then you cannot do without special tools and materials:

- glass or basalt wool;

- waterproofing film;

- vapor barrier fabric;

- wooden planks;

- timber 50×50, maybe less, but not less than 25×25;

- plane;

- axe;

- chisel;

- hammer;

- stationery knife;

- stapler;

- marker;

- measuring instrument;

- fastener

Laying the base for finishing.

For the inner lining of the attic, you can choose OSB sheets, lining, plywood or plasterboard. If you installed an additional beam for thermal insulation, nail the sheathing close to the beam. If there is no timber, we recommend using slats to make a gap of at least 20 mm and install the sheathing.

The warm attic is ready! Now your home is reliably protected from cold and heat, and there is much more space.

Algorithm for insulating the roof and walls of the attic: step-by-step instructions

*

Checking the evenness of rafter legs

- Before starting work, check the levelness of the rafter legs. This can be done using a long building level.

Measuring the distance between rafters

- Measuring the inter-rafter distance. It should be a multiple of 58 or 118 cm. Ideal option: maintain this size at the stage of design and construction of the roof. In this case, you can use standard mineral wool slabs with a width of 60 cm. The distance of 58 cm is calculated for one slab, which will simplify its fastening. A margin of 2 cm will allow the plate to be installed in the spacer and held in place without additional fasteners. This scheme will help to avoid gaps between beams and insulation slabs.

Fixing the insulation

- If the distance does not correspond to the specified dimensions, then the slabs are held in place with synthetic twine and counter-lattice. When cutting the material, a margin of 2 cm is provided.

Installation of a waterproofing layer

- Insulation of an attic roof begins with the creation of a waterproofing layer. A special film is used as a hydrobarrier. It is secured along the rafters with planks so that it envelops the frame beams.

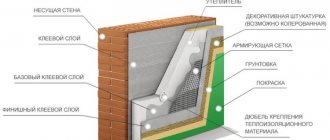

Installation of insulation boards

- Installation of mineral wool slabs occurs by compressing them and installing them in the space between the rafters. To avoid the formation of cold bridges, the insulation is laid in two layers. Each layer of mineral wool is secured with synthetic twine. Horizontal and vertical seams are staggered. It is important to prevent creases and wrinkles on the surface of the insulation. Where roof windows are installed, pay attention to the quality of the mineral wool laid. Here you need to use non-standard pieces of insulation and mount them along the frame.

- They begin to insulate the end walls of the attic. A frame with a distance between posts of 58 or 118 cm is installed on the gables. In order to save time and get an accurate result, the thickness of the insulation for the walls is calculated using a calculator program. This will save time and give an accurate result.

- After the insulation is installed, you need to check the presence of all places where cold bridges can form. To insulate them, sealant or polyurethane foam is used. Particular attention is paid to the joints between the outer rafters and the wall.

Vapor barrier membrane fastening

- Installation of a vapor barrier layer. For insulation, you can use polyethylene film, but it is better to use a vapor barrier membrane. It will protect the insulation from condensation and will not interfere with air exchange in the room.

Gluing the vapor barrier with special tape

- For fastening to the rafters, a construction stapler and staples are used. The fastening pitch is 150-200 mm. The membrane is overlapped with a margin of 100-150 mm. After installation, all joints are carefully taped with a special tape; it will provide maximum protection of the insulation from steam.

Installation of lathing for finishing

- The bottom sheathing is made of 50×50 timber; it will hold the insulation in its original position and will serve as the basis for attaching the ceiling and wall sheathing.

A detailed article about insulating a frame house with mineral wool.

Roofing pie composition

External roof insulation of an attic has few differences from the internal method of thermal insulation. The only difference is that before installing the mineral insulation, the inside of the roof remains bare.

Option with a residential attic

If the space under the roof allows you to equip an additional living room in this place, then the owners of private houses almost always take advantage of this advantage. A popular option is the vertical arrangement of the attic walls.

Vertical arrangement of the partition

Firstly, this allows you to increase the usable area, and secondly, it is possible to create a better thermal insulation cake. But more often there are sloping walls repeating the slope of the roof. With this method, external laying of insulation is used.

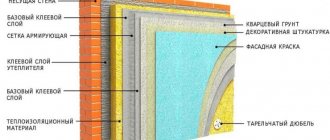

When insulating an attic internally, the following pie is used:

- A vapor barrier is laid on the sheathing.

- The second layer is laid mineral sheets, the thickness of which corresponds to the climatic conditions of the region.

- Next, the slats are filled horizontally, and the last 50 mm layer of thermal insulation is laid on top.

- At the final stage, a vapor barrier layer is filled.

Important! To reduce pressure from air flows, it is recommended to stuff slats over the vapor barrier.

What to pay attention to

When positioned vertically, there is free space between the roof and walls that needs to be insulated. In this case, the vapor barrier is installed from the roof side and on vertical structures. You should not ignore the installation of insulation on this section of the roof. If neglected, the indoor temperature may decrease or heating costs may increase.

Space behind the wall

Since cotton wool is afraid of high humidity, it needs enhanced protection. To do this, a vapor barrier is laid on both sides of the thermal insulation cake. Builders recommend using an auxiliary layer of polystyrene foam insulation. It will create a repulsive obstacle to a humid environment, preserving the quality of the mineral wool.

Insulating the ceiling of a cold attic of a house with rolled mineral wool

Pie of the attic floor

Insulating the attic floor with mineral wool is done in the same way as with wall cladding. It happens in two layers, but the algorithm for performing the work is different.

Stages of insulating the attic floor with mineral wool:

- Attaching the vapor barrier membrane.

- Insulation of the attic floor on wooden beams with rolled mineral wool.

- The final stage of insulating the attic floor is attaching the water barrier. You can use roofing felt, plastic film or a vapor barrier membrane.

The above recommendations will help even a novice builder to insulate an attic with mineral wool. As a result, the usable area of the house will almost double.

Tips and tricks

- Follow the rules for storing stone wool. The room should be dry and cool.

- It is not permissible to store the material without packaging or in a space unprotected from precipitation.

- After storing mineral wool, cover it with plastic wrap. This will create additional protection from moisture.

- The material is unpacked before direct use.

Unboxing

- As soon as the installation is completed, you need to fix the vapor barrier, without leaving the work for tomorrow.

- The joining parts of the vapor barrier layer must be fixed with double-sided tape.