The task of the circulation pump is to drive the coolant along the entire line of pipes through the boiler with the most efficiently configured operating parameters. An incorrectly selected device will reduce the efficiency of the system, the water circulation will be less efficient, and the heating will be weak and slow. If the device is too powerful, excessive consumption of electricity is possible. It is necessary to pay attention to noise level, acceptable level of complexity of maintenance and repair. The pump must be installed and adjusted correctly. Let's look at how circulation pumps are selected, characteristics, stages and installation requirements, and how to install them.

Heating system pump

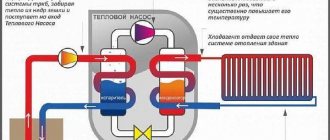

Circulation pumps (CP) are hydraulic equipment that provides forced circulation of coolant through the boiler through a closed pipe line with radiators. The device can be adjusted to different pressure modes.

The heating pump is a mandatory, default part of the circuit. Only an expansion tank (hydraulic accumulator) will not be able to ensure the full functioning of the equipment. The exception is systems with natural circulation, but pumps are often recommended for them as well to ensure safety and improve performance if necessary.

Pump value

The quality of heating depends on the circulation parameters provided by the pump. If the circuit is longer, with rises to the upper floors, then increased technical capabilities of the product will be required; more intense heating requires an increased flow rate.

The pump is installed in the heating system to ensure:

- circulation;

- uniform distribution of the resource with a given intensity, for the most efficient, effective heating.

The pump increases the intensity of the flow, heat flows faster to the radiators, and accordingly, heating occurs more quickly, its level is higher, and the room is heated in less time. At the same time, the load on the boiler is reduced, since the water is processed more quickly. With circulation pumps, there was no need for bulky, inconvenient pipes of significant diameter, and it became easier to disguise contours under finishing and place them inside walls.

When installing pumps in heating

Installation of a pump in the heating system will be required in the following cases:

- to increase the efficiency of boiler systems. In our case - for heating systems (autonomous individual) for an apartment or private house. Schemes with natural circulation are used less often, but they often require a supercharger for backup;

- when the natural movement of the coolant is impossible or too weak. And also to overcome the inertia of the scheme;

- if the heat generator does not have a pump unit;

- for circuits with two-pipe wiring, making it possible to adjust the heating of each individual battery.

The heat-releasing liquid must flow through a closed line (circuit), with certain adjustable speed parameters for effective heating for different conditions.

Requirements for installation of a circulation pump

There are a number of standards that regulate at the legislative level the installation of a circulation pump in a heating system. Some of the rules are set out in SNiP 2.04.05 “Heating...”. For example, it talks about the priority of schemes with forced circulation in heating networks.

Almost all requirements are justified by the operating efficiency of the system as a whole and the circulation device in particular. For example, the shaft of a device with a wet rotor must be installed on the pipe strictly horizontally in level so that there are no air pockets inside and the pump parts do not wear out prematurely.

A filter for dirt and abrasive particles is needed in any case, even when installing monolithic models. Filtered coolant will cause much less damage to pump parts than liquid with sand and suspended matter.

The mudguard is installed with the plug down in the direction of water movement to reduce resistance and facilitate system maintenance.

Some rules are dictated by manufacturers. For example, it was customary to install old models of certain brands exclusively on the return line, since they could not withstand high temperatures.

Now pumps have become more versatile and can be installed in any suitable location, but subject to power parameters.

Types of circulation pumps, design

The devices in question are similar to the same products for pumping water for other purposes, the operating principle is similar, but in this case the device is created taking into account the nuances of heating: for high temperatures, their differences, as well as for the characteristics of the system, the need to regulate pressure, speed in a wide range range. The product is manufactured for insertion specifically into pipes and bypass (a whole unit with it and taps is often sold), taking into account their specifics.

Wet pump:

Dry type:

There are 2 types used: with a wet and dry rotor. The latter are more productive, but are less often used for home and domestic use, since they are noisy, with noticeable vibration, and more expensive.

The main disadvantage of all pumps is their dependence on electricity. If the facility has frequent power outages, then backup batteries are installed; a stabilizer is recommended to level out voltage surges.

As standard for a heating pump, for all types, manufacturers provide stepwise speed settings: you can select the optimal mode and control energy consumption.

A brief description of the disadvantages and advantages of the varieties is as follows. Dry type products are noisier, create vibration, are expensive, but more productive, the purity of the pumped resource is not significant. Wet - quiet, cheaper, more compact, but limited in pressure, the transported substance must be free of impurities.

There are dual models on the market used for backup in emergency situations.

Which heating batteries to choose for a private home and cottage

It is not difficult to select batteries for a private home, because the autonomous heating system operates without significant overloads, which a centralized system experiences. Here you can connect any radiators, focusing on the required power, quality, efficiency, and cost of the device.

Many owners of private houses prefer aluminum radiators. They are cheaper than cast iron, more economical to operate and have higher heat transfer rates, and the sensitivity of aluminum devices to water hammer in an autonomous heating system can be neglected.

If you want to choose batteries based on the brand name, then you can take into account the unspoken rating of aluminum heating radiators for a private home. The top positions here belong to the brands Calidor, Global, Rifar, STI, which are well suited for operation in Russian climatic conditions.

Steel radiators are no less common, which is not surprising, because they are reliable, affordable, able to warm up quickly and have good heat dissipation. Here, in the ranking of steel heating radiators for a private home, the leading places are occupied by Kermi, Purmo, Zehnder, Sunerzha.

Among the worthy brands producing bimetallic radiators are the Russian Rifar and the Italian Global. Those who decide to purchase cast iron heaters should pay attention to Konner (Russia), Guratec (Germany), Retro Style (Russia).

As a result, all radiators are universal, which means posing the question of which heating radiators are best for a private house with a gas boiler is not entirely correct, because when choosing, they are mainly guided by the required power, the features of the room and the possibilities of the budget.

Wet rotor pumps

In wet modifications, the shaft and impeller are in contact with the pumped resource, and it also serves as lubrication and cooling.

The stator is separated by a special flask that seals parts of the electric motor, otherwise voltage would be transmitted through water to all metal elements of the system.

Components and how they work

Wet central pump design:

- housing that can withstand high pressures is made of cast iron, steel, aluminum. For standard home conditions, this is a small block that is attached directly to the pipe, bypass;

- a shaft (moving segment), also known as a rotor made of steel, ceramics with a bearing unit, a working disk with blades. The latter is fixed motionless, it consists of 2 wheels with holes connected by blades: on one - for moving the resource, on the adjacent one - for securing to the electric motor shaft;

- a stator (fixed unit) on the rotor with an excitation winding (inductor) to stabilize the rotation speed and flow, for which it has small blades at a certain angle. This part prevents flow stalling. This part consists of a core and a frame. In the grooves of the first there is a winding. The stator is also a magnetic circuit and a supporting structure;

- control chip, power terminals. On models without the first element there is a capacitor, and on the contact block there is a speed selector.

When starting, the blade disk rotates, a vacuum is created inside the pipe, the coolant is drawn in and moved by the rotor further along the equipment (from inlet to outlet). Fence and ejection are carried out. Centrifugal force helps move the resource throughout the circuit. The resulting pressure creates the required force on different segments of the pipe line and creates circulation on its rises.

Nuances, pros and cons

Wet circulation pumps, however, like everything else, are usually modular. The devices are selected according to the parameters of the circuit (pressure, required maximum amount of pumped volume). An important plus is that the device is prefabricated, which simplifies its repair; broken parts are replaceable.

Wet central heating systems are installed on the vast majority of home systems, this is the standard, and here’s why:

- the device is almost silent, which is suitable for living, for better comfort;

- compactness, light weight - the device is a small box that does not require special fastening, partitions, or space on the floor. The product simply crashes into the pipe and “hangs” on it;

- there is no need for additional cooling (unlike dry models), this function is performed by the water flowing inside;

- There are fewer spare parts, the ability to replace them, easy repairs, dismantling, minimal maintenance frequency;

- wide range of settings;

- long-term performance if there is a filter and working fluid without fine particles;

- cheaper if the device is for low standard productivity.

Disadvantages for home heating with a wet pump:

- if the water contains fine abrasive particles (lime, iron, etc.), then the impeller and other parts (hydraulics) in contact with the liquid will wear out relatively soon and fail. For such products, a closed system with a purified resource is recommended; a dirt filter is mandatory;

- low efficiency - about 55%;

- the performance range is more limited than dry options. But it is enough to service the average private home, therefore, and also because of the low price, it is often used for housing.

Hydraulic separator

If there is a need to install an additional pump, then another device must be included in such a heating system - a hydraulic separator. In the list of terms used, a hydraulic separator can also be called an anuloid or a hydraulic arrow.

- The pump shaft must be in a horizontal position relative to the floor surface;

- The movement of water flow in the system must coincide with the direction of the arrow on the device;

- To prevent liquid from entering the pump terminals, the box should be installed on the top or side of the equipment.

Correct installation of an additional pump in the home heating system

According to some users, it is better to install the pump on the return pipeline. Here the coolant temperature is minimal, which will increase the service life of the device, but not all experts agree with this statement. The fact is that the pump is designed for operation in a coolant environment whose temperature can reach 110 degrees.

Dry rotor pumps

The entire internal working unit of dry devices does not come into contact with water and is completely isolated. These products are slightly larger and heavier. There is noise and vibration. Here, more often there is a need for a separate place, a fence, installation on the floor with larger piping and wiring. But the devices can also crash in the standard way, like wet ones - directly into a pipe, bypass on the line.

“Dry” pumps are installed to transport significant masses of coolant along long-distance circuits, for example, for a large number of apartments in a high-rise building, for objects with several floors, entertainment centers, administrative and industrial buildings.

The design features are as follows. Between the electric motor and the hydraulic working segment there are sealing insulating gaskets (2 rings). There are 2 discs with a close fit. One is movable on the shaft, the other is static, firmly fixed inside the housing. A thin film of the pumped resource is created between the wheels, pressing on the elements, increasing the tightness.

The efficiency of dry pumps is 85%, according to this parameter they are the best, but they are used less often for home systems due to the noise and vibration created by the cooling fan.

Dry circulation pumps can be of the following sizes:

- monoblock - motor, all parts of the pump in a single body. Advantages: ease of maintenance and installation. But such devices, like console ones, are more often installed for MKD, on large objects, and these products are usually with a stand-foundation;

- console option. Assembled on a single base, the axes of the elements are on 1 line, but the shaft and pipes are remote from the drive;

- in-line. Compact, placed directly on the pipe. The pipes are on the same line (there are no snails, as in the previous version). There is automatic compensation for seal production. These are the popular options; they are usually used for not particularly demanding standard home heating.

In-line pump:

Advantages and disadvantages of dry circulation pumps Advantages of dry circulation pumps:

- productivity, higher power, efficiency 85%;

- more energy efficient;

- does not require horizontal positioning;

- low requirements for cleanliness of the coolant; abrasive particles will not damage the working parts of the mechanism, since they do not come into contact with it. Can be used on all systems - open, closed. The filter does not have to be mounted, although it is desirable;

Minuses:

- Dimensions and weight are slightly greater. For high performance, a typical installation option is on the floor (not directly on the pipe, as with most dry pumps). Accordingly, installation becomes more complicated and costs increase. But such a need does not arise often, since for home systems a compact, not particularly powerful model is sufficient; in most cases, the device is mounted directly on the pipe;

- Large devices require lubrication. For compact sizes, such a procedure may not be required or may be required extremely rarely, but this should be prescribed in the instructions;

- if the cooler breaks down, the device will overheat, with a high probability of failure;

- The cooling impeller is noisy and vibration occurs. A very significant drawback, since extraneous sounds, unnerving users, will nullify all the advantages. Sound insulation will be required, at least a box/fence with it or installation in a remote segment;

- repairs and replacement of spare parts are somewhat more labor-intensive: the design is complicated by the cooling impeller, there are features associated with the insulation of internal parts;

- expensive.

This type of equipment is productive, unpretentious to the coolant, works with high pressures, and does not require horizontal placement. But the device is noisy, with vibration, and is often made in overall sizes; this sometimes entails the need for installation on a foundation or a metal frame.

Pump device

Since the engine stator is energized, it is separated from the rotor using a glass made of stainless steel or carbon material

The main elements that make up the circulation pump are:

- housing made of stainless steel, bronze, cast iron or aluminum;

- rotor shaft and rotor;

- wheel with blades or impeller;

- engine.

Typically, an impeller is a structure of two parallel disks that are connected to each other by means of radially curved blades. One of the disks has a hole for liquid to flow through. The second disk secures the impeller to the motor shaft. The coolant passing through the engine acts as a lubricant and coolant for the rotor shaft where the impeller is fixed.

Since the engine stator is energized, it is separated from the rotor using a glass made of stainless steel or carbon material. The walls of the glass are 0.3 mm thick. The rotor is fixed on ceramic or graphite bearings for sliding.

Selection, calculation

Let's look briefly and clearly at how to choose a circulation pump for a heating system in specific situations.

What characteristics to pay attention to:

- pressure Must cover hydraulic losses on the line;

- productivity - max. pumped mass of resource per unit. time;

- working t°. Most modern models are designed for a range of +2...+110° C, which is enough for most circuits;

- power. Mechanical power, taking into account hydraulic losses, should prevail over useful power;

- The diameter of the pipes should be selected to match the existing pipes (25, 32 mm), however, adapters can also be used.

Circuit type

For open systems, wet devices are not desirable, since the coolant in them usually contains abrasive particles (sand, oxidized iron, lime, etc.): if they get between the rotor and stator, impeller, they will quickly damage the device. But in closed systems where the water is filtered, distilled, or another clean special coolant (propylene glycol) is used, such products will last for years without special maintenance. For units with a dry rotor, the quality of the working resource and the type of circuit do not matter.

Open circuit bypass pump:

Examples of schemes for one- and two-pipe circuits:

Another typical example:

Power calculation

There is a standard formula for calculating pump performance based on equipment characteristics: for every 10 meters of line there is 0.6 m of device pressure. For a small house with a contour of 80 m, we take a pump with a head of 4.8 m. It is advisable to add 15–20% of the reserve to the obtained result, especially if there are rises to the upper floors.

More complex equation:

R is taken as standard for the European region 100 W/m² for properties with 1 or 2 apartments and 70 W/m² for multi-apartment buildings.

Speed, noise

Modern average units are equipped with three speeds as standard. The selected unit must have adjustment; the wider its range, the better. The setting will allow you to quickly heat your home when it gets cold, and when it warms up, you can reduce heating and electricity consumption.

A dry pump cooler makes noise; if it is not possible to provide sound insulation and extraneous sounds are undesirable, then choose a wet version of the product.

Example of a circulation pump, manufacturers

Examples of popular brands with a good reputation:

As an example for a heating circuit for a house of 100 m², you can take the Grundfos UPS model, its characteristics are as follows:

- for pipe connection Ø32 mm;

- for productivity - 62 l/sec.;

- weight 3.65 kg;

- cast iron;

- The power is enough to raise the resource to the 2nd floor.

Central heating unit Wilo STAR-RS 25/6 180 (wet) can be considered as an average sample of a product for a not too demanding system:

There are electronically controlled devices that allow you to quickly, automatically switch the equipment to the desired mode depending on changes in pressure and temperature. Such devices are equipped with digital displays that display data on temperature, pressure, and resistance.

Dry or wet rotor

Wet pumps have the following features:

- if the pressure (meaning provided by the device, the calculation we described above) is more than 15–17 m, then for this parameter the products in question are rare on the market, they are expensive;

- used only for closed systems, where there is less need for high pressure, clean coolant;

- in terms of price, if the pressure is more than 10–14 m, it is often more expensive than a dry pump, and in addition, they have increased motor sizes;

- It is not recommended to place it on an open system where there may be dirt, sand and other abrasive particles. The pump will fail in a year or two, since water here acts as a lubricant, washes the internal parts, there is a constant circulation and friction of the abrasive, the gap between the rotor and stator quickly becomes clogged, and the graphite bearings wear out.

Up to 7–10 m of head for a productivity of 25–30 m³/hour, wet products are cheaper than dry ones. But the noise of the latter is much greater.

Tips on what to choose:

- at working requirements 1–10 m of water. Art., flow rate 1–25 m³/h, it is advisable to take wet products;

- at 12 m water. Art. and we select dry pumps for any performance. They are for particularly high consumption;

- in any case, if it is possible to make noise insulation, then a dry pump is a good choice;

- if less noise is required, then only wet types. You can use 2-3 such devices: they will cope with the increased requirements of the system, and at the same time there will be no noise, although the price of such a scheme may be somewhat more expensive. You can also install one powerful wet blower for heating, but such models, as we have already noted, are rare on the market and expensive.

External factors influencing work

The main factor is the temperature outside. The amount of heat required for heating, and therefore the operation of the device itself, depends on it. As an example: a pump that is “frozen” will not be as efficient as one that is already “warmed up”. One important point regarding the choice: the device often overheats if it is not selected correctly (it simply cannot cope). Therefore, it is so important to find out about the features of the system before purchasing.

Another important factor is the diameter of the pipeline. The larger it is, the more working fluid needs to be distilled, therefore, the more powerful the pump is required. Finally, it is not advisable to install a device designed for 2.5 centimeters into a pipeline with a diameter of 3.2 centimeters using connecting adapters. This often leads to a decrease in pressure.

Is the device model important?

There are a lot of pump models from different manufacturers on the market, but almost all of them have the same characteristics. The differences can only be in service life and degree of reliability. The most popular manufacturers are rightfully considered: Grundfos, Speroni, Wilo, Elsoterm and Wester. There are also many Chinese models, as well as outright fakes made in China. But the quality of the brands mentioned above is superior to them, as they are reliable, durable and almost silent. The only negative is the high cost (from 2500-3000 rubles ).

What to choose? Certainly not Chinese pumps. It is better to overpay for one of the above brands, but get really high-quality equipment.

Installation Basics

The inclusion of autonomous heating in the circuit and the presence of central heating there is regulated by SP 60.13330. According to this act, a heating system with forced circulation is considered priority (not with natural circulation, although this is also possible).

The installation process briefly consists of securing the assembled pump unit (with filters, taps) with union nuts to a pre-cut pipe in a certain place.

Peculiarities

For wet pumps:

- placed so that the position of the shaft is clearly horizontal (not necessary for dry options) - this will eliminate airing, spare parts will not break because of it;

- the filter is a standard mud trap; it is mounted with its branch downwards along the flow of water to reduce resistance and facilitate maintenance.

For older products, the factory can indicate the installation location; once upon a time only the return line was considered such, but modern pumps can be installed anywhere (on the supply side too).

Autonomous heating pump installation diagrams

Let's look at the basic diagrams of how to install a pump and embed it onto a pipe.

They put it on return/feed, there is no difference. You can cut it directly onto the main pipe or make a bypass (outlet) and place it on it. The last method is the best, it makes it possible to more conveniently dismantle/install the device for maintenance; when replacing, it is usually so familiar that it is assumed by default.

There are several options for the installation location; there is also a diagram for several pumps (manifold connection).

Let's consider the traditional option with installation on a bypass.

For modern models, the location - return or supply - is not significant. They choose at their own discretion, as is more convenient for the user.

But, undoubtedly, in all cases the best option is to tap into the bypass in these places.

Some specialists remain adherents of the old traditional rule, according to which the return is the best section for installation. Through this segment, the liquid that has given off heat returns to the boiler. A less warm, cooled resource does not have such an aggressive effect on the device. The described opinion has completely lost its relevance for modern models designed for high temperatures, however, we indicate it for a full disclosure of the topic. It is important to read the instructions, since for older products the manufacturer may recommend a return line.

If the device is cut into the supply segment, then not directly close to the boiler, but after the safety group.

Option for solid fuel boiler. NC is not installed on the supply section due to the risk of explosion, since with the specified type of unit the heating does not stop quickly. This is a boiler with great inertia. Even if you turn it off, the intensity of fuel combustion may increase for some time, there is a risk of water boiling, the liquid expands, the pressure increases, creating a steam bomb. Boiling water is mixed with steam, gets inside the device, reduces productivity, and the cooled resource in the circuit does not have time to refill the boiler in the required volume - the device becomes hot, and there is a high probability of an explosion.

When a cooled resource is launched into a heated TD boiler, condensation forms. To eliminate this phenomenon, the liquid is first heated on the small circuit to +55° C, and then the thermal valve slowly switches to the main circuit. Cool masses are mixed with already heated ones, the sharp difference in temperature is leveled out.

Pump in a natural circulation system

One of the options for autonomous heating is an open line, where the expansion tank is mounted at the highest point. The inclusion of a circulation pump in such a scheme will increase the performance and versatility of the equipment.

The natural circulation is always somewhat limited and unstable, so if you need an increased quality of heating, you can use a pump, and when weak heating is enough or in case of power outages, you can use gravity.

To switch from a forced circulation to a natural one, a particularly important installation is to install the heating pump on the bypass. When the pump is activated, the gravity pipe is closed with a tap. Let us add that installation on bypass is always recommended for all circuits.

Harness

First you need to decide how many superchargers there will be. For one simple line, one device is enough.

When two units are required:

- for a system with complex or multiple circuits;

- if “warm floor” is combined;

- an indirect heating boiler is used;

- two boilers are used, for example, TD and electric (a pump for each).

What is required for installation

What parts need to be prepared for strapping:

- Ball Valves. Mounted together with the pump. They are needed to cut off the flow of water during emergencies and repairs. Placed at the entrance and exit;

- thermostat for the pump (not mandatory, but a desirable element);

- check valve - brass, cast iron - for movement in one given direction. Placed after the pump in the direction of flow;

- a regular dirt filter (for the roughest cleaning). Devices for fine filtration are not installed on heating; if you need clean water, and this quality is always recommended, and especially for “wet” pumps, then it is cleaned before filling;

- air bleed valve to remove air pockets. The unit can be activated automatically, there are also manual products, and it may already be integrated into the device;

- American nuts (often included with pumps);

- bends - sections of pipes with threads at both ends for fitting, connecting pipeline segments when they cannot be rotated;

- tools: open-end wrenches, adjustable wrenches;

- pliers;

- tow, fum tape, sealant (Unipak).

If you need to install a heating pump with assembling the system and inserting it from scratch, then the procedure is not always accessible for you to do it yourself, since you will need to make a bypass, cut the pipe, prepare its ends, which will require welding, a grinder, dies for cutting threads for caps pump lead nuts, for American women.

American women are often included. Taps, adapters, bends (for connecting pipe sections) must be prepared. There should be no difficulties in selecting diameters: they are standard, usually 25, 32 mm.

Conclusions and useful video on the topic

Theoretical knowledge is quickly absorbed when accompanied by an interesting video that reveals the sequence and features of the work on installing devices.

Video review of the WILO pump – configuration and installation:

Practice shows that advanced home improvement enthusiasts can handle installing a circulation pump on their own.

However, if difficulties arise, it is better to turn to specialists: only qualified craftsmen know how to properly tie and install a heating pump, observing all the nuances of the chosen scheme.

Do you have personal experience installing a circulation pump? Do you want to share your accumulated knowledge or ask questions on the topic? Please leave comments and participate in discussions - the feedback form is located below.

Installing a circulation pump in homes with an individual heating system ensures uniform and high-quality heat distribution throughout all rooms of the house.

Installation instructions

So, we will describe the installation stages when circulation pumps are installed on the bypass. This scheme is used most often and is recommended by experts due to the following advantages:

- quick, convenient dismantling;

- convenient temporary shutdown.

For wet options, a horizontal, level position is critical:

There are various modifications of already assembled bypass loops on the market: for welding, for flanges, with segments for shut-off elements.

If it is not advisable to buy a ready-made assembly, for example, when all the parts are in stock or if there are specific features of the location, then the bypass piping is made from scratch. But you will need skills in working with pipes (welding, thread cutting).

A good, recommended location is between the membrane tank and the boiler. Below is a universal option: for open/closed circuits, for connecting using the collector method (several pumps).

Assembly order

Diagram showing the movement of water, please note: shut-off valves are mandatory - when removing the device for repair or maintenance, they are turned off:

They start by assembling a unit (module) with taps: one per inlet/outlet. pump, the third is part of the lower straight pipe. It is necessary to carefully measure the return segment in order to accurately weld the segment with the shut-off fittings.

The bypass section from the central station is assembled. The nuts are only screwed on, tightening is postponed until the final stage. The top is the pump part (in the photo below the GRUNDFOS UPS pump) with two already screwed in taps, a filter, at the ends of the module there are small sections of pipe with threads like squeegees, they serve as material for welding. Below is a shut-off valve for the supply pipe (main).

They try on a bypass loop, mark the welding points on the pipe, use a drill with special drills to make a hole for the diameter of the section being mounted, and weld the joint.

They cut in the entire assembly with the lower shut-off valve on the main pipe, in our case, on the supply from the gas boiler:

The last step is to connect the pump to power.

Connecting the pump to power

So, the system is completely assembled, the pump is selected, installed, and then the device is connected to the power supply. Before the procedure, the entire line is completely de-energized—the machine is turned off on the panel. The device may have a plug for a socket or without it - just wires of a certain length for connecting directly to the home network on the panel.

Procedure: The pump wires are connected, taking into account the polarity, to the line. The terminals are labeled and have standard colors. If the device does not have a cable with a plug for a socket and you decide to use just such a connection, then you can buy it in any store, you will need a three-core cable, usually a cross-section of 2.5 mm² is more than enough.

It is highly desirable to have grounding (three-wire wiring), since proximity to water creates a significant risk of current entering the equipment elements. It is recommended to connect the device via an uninterruptible power supply (UPS); you can also connect a boiler to it.

An excellent solution is to insert a thermostat into the system (see diagram below), it can also be immediately included in the unit, which will automatically switch off when the coolant temperature drops below the set limits.

It is also highly advisable to install the device with a connection to the network through a difavtomat (its analogue of an RCD + AB) or through the boiler automation system, on which all these measures should be taken by default. And also, if there is an automatic protective device on any line with an outlet and the pump is not too powerful, for example, 90 W, that is, it will withstand all the consumers hung on it, then separate individual wiring with RCBOs and RCDs under the pump may not be installed. The device can be connected to such an outlet and not bother.

Connections without grounding are allowed, for example, when the house is old with two-wire wiring, but then the presence of a difavtomat or RCD+AV in the diagram is vital.

Do-it-yourself pumping equipment installation diagrams and standards

Circulation pumps are installed in two ways. The first connection diagram for the unit is two-pipe. This connection method is described by a high temperature difference in the system and variable coolant flow. The second scheme is one-pipe. In this case, the temperature difference in the heating system will be insignificant, and the media consumption will be constant.

Installed circulation pump

Connect the pump yourself according to the instructions that come with the unit. It also indicates the installation procedure for the functional reinforcement chain. Before installing the pump, be sure to drain all water from the system. Often there is a need to clean it. During the operation of the heating boiler, a lot of debris accumulates on the internal surfaces of the pipes, which worsens the technical performance of the system.

Experts advise placing the circulation unit in front of the boiler - on the return line. This is done in order to eliminate the risk of boiling of an open type heating system due to the vacuum that is created when installing the supply pump. In addition, if you install a circulation unit on the return line, its trouble-free operation will be significantly increased due to the fact that it will operate at lower temperatures.

Bottom line

As you can see, the main difficulty of installation for a circulation pump is the need for welding, cutting pipes, and threading. The assembly itself is elementary: you need to carefully measure all the distances and screw in the elements. The connections are sealed with tow and sealant.

What to pay attention to during operation:

- it is necessary to periodically clean the filter and check the pressure gauge readings;

- The noise emitted by the device does not always indicate a breakdown; often the cause is air accumulating in the circuit. The problem can be solved simply - by bleeding with special valves;

- Dry pumps may require periodic lubrication.

Installation diagram

In practice, two schemes for installing a circulation pump are used in a single-pipe and two-pipe heating system. Before carrying out installation work, you must carefully study the attached instructions. At the preparatory stage of work, water is drained from the system and the pipes are cleaned of contamination by additional pumping of liquid. The pump is installed according to the attached diagram, then coolant is poured into the circuit and the unit is turned on.

As we have already said, it is best to install the pump on the return side using a tap or, as it is also called, a bypass. Such a device is necessary to shut off the water and replace the pump in case of breakdown. The diameter of the outlet pipe should be smaller than that of the central pipeline.

Installation diagram of an additional pump in the heating system

At each edge of the bypass, before entering and after exiting the pump, taps are installed for emergency shut-off of the coolant. Another valve is installed on the central line to direct the flow of liquid through the pump. Before entering the pumping equipment, a special filter is attached that will accumulate harmful particles in the water.