Heat pumps have been used for a long time and very successfully in domestic and industrial refrigerators and air conditioners.

Today, these devices have begun to be used to perform the opposite function - heating a home during cold weather.

Let's look at how heat pumps are used to heat private homes and what you need to know in order to correctly calculate all its components.

Heat pump. House heating design

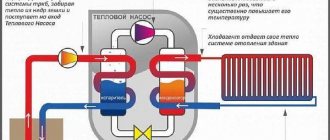

In a home heating system, a heat pump (HP) plays the same role as a boiler, that is, it is a heat generator.

The only difference is that the boiler burns fuel, and the heat pump “pumps out” thermal energy from sources that, at first glance, are not rich in it at all.

Soil and river water with a temperature of 5 - 7 degrees, or even frosty winter air, the temperature of which was generally below zero.

Such sources are called low-potential, and although they are in no way associated with the concept of heat, TN manages to “squeeze” an impressive amount of life-giving energy out of them. To this should be added the heat generated by the electric motor of the HP compressor: here, unlike a refrigerator and air conditioner, it is not wasted.

Otherwise, a heating system based on a heat pump is no different from a conventional one: a coolant is used - water or air, which is heated by flowing through a heat exchanger, and then distributes heat throughout the house. Circulation is provided by a pump (for water heating) or a fan (for air heating). Just like a traditional heat generator, a HP can be simultaneously connected to a hot water supply (DHW) circuit with or without a storage tank (boiler).

Did you know that you can heat your home for next to nothing? Geothermal heating: operating principle, advantages and disadvantages of technology, read carefully.

Read about how to independently install a double-circuit gas boiler for heating a private home.

In Russia, steam heating appeared earlier than water heating, but now such a system is rarely used. Here https://microklimat.pro/sistemy-otopleniya/montazh-sistem-otopleniya/parovoe-otoplenie-v-chastnom-dome-sxema.html you will find an overview of the main types of boilers and methods of steam heating.

Impact of VTN on the environment.

In addition to the financial benefits of installing a HVAC system, upgrading your HVAC system has a number of positive environmental impacts.

High conversion efficiency means you'll use less fuel to heat or cool your home. This means that power plants produce less energy from fossil fuels such as coal and oil, reducing the amount of greenhouse gases and other pollutants released into the atmosphere.

You can further reduce your carbon footprint by switching all your energy consumption from fossil fuels to solar energy. Installing solar panels on your roof allows you to power your VHP system (and your entire home) with free electricity with zero CO2 emissions.

Operating principle of heat pumps

Any HP contains a working medium called refrigerant. Usually freon acts in this capacity, less often ammonia. The device itself consists of only three components:

- evaporator;

- compressor;

- capacitor.

The evaporator and condenser are two reservoirs that look like long curved tubes - coils. The condenser is connected at one end to the outlet pipe of the compressor, and the evaporator is connected to the inlet pipe. The ends of the coils are joined and a pressure reducing valve is installed at the junction between them. The evaporator is in contact – directly or indirectly – with the source medium, and the condenser is in contact with the heating or hot water system.

Working principle of a heat pump

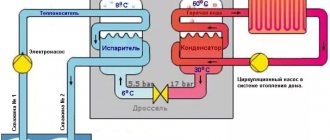

The operation of HP is based on the interdependence of gas volume, pressure and temperature. Here's what happens inside the unit:

- Ammonia, freon or other refrigerant, moving through the evaporator, is heated from the source medium, say, to a temperature of +5 degrees.

- After passing through the evaporator, the gas reaches the compressor, which pumps it into the condenser.

- The refrigerant pumped by the compressor is held in the condenser by a pressure reducing valve, so its pressure here is higher than in the evaporator. As is known, with increasing pressure the temperature of any gas increases. This is exactly what happens to the refrigerant - it heats up to 60 - 70 degrees. Since the condenser is washed by the coolant circulating in the heating system, the latter also heats up.

- Through the pressure reducing valve, the refrigerant is discharged in small portions into the evaporator, where its pressure drops again. The gas expands and cools, and since part of the internal energy was lost by it as a result of heat exchange at the previous stage, its temperature drops below the original +5 degrees. Following the evaporator, it is heated again, then pumped into the condenser by the compressor - and so on in a circle. Scientifically, this process is called the Carnot cycle.

The main feature of HP is that thermal energy is taken from the environment literally for nothing. True, to produce it, you need to spend a certain amount of electricity (for the compressor and circulation pump/fan). But HP still remains very profitable: for every kWh of electricity spent, you can get from 3 to 5 kWh of heat.

Making a heat generator with your own hands

List of parts and accessories for creating a heat generator:

- to measure the pressure at the inlet and outlet of the working chamber, two pressure gauges are needed;

- thermometer for measuring the temperature of inlet and outlet fluid;

- valve for removing air pockets from the heating system;

- inlet and outlet pipes with taps;

- thermometer sleeves.

Selecting a circulation pump

To do this, you need to determine the required device parameters. The first characteristic is the ability of the pump to operate with high-temperature liquids. If this condition is neglected, the pump will quickly fail.

Next you need to select the operating pressure that the pump can create.

For a heat generator, it is enough that a pressure of 4 atmospheres is reported when the liquid enters; this figure can be raised to 12 atmospheres, which will increase the heating rate of the liquid.

The performance of the pump will not have a significant impact on the heating rate, since during operation the liquid passes through a relatively narrow diameter of the nozzle. Typically up to 3–5 cubic meters of water per hour is transported. The coefficient of conversion of electricity into thermal energy will have a much greater impact on the operation of the heat generator.

Manufacturing of a cavitation chamber

But in this case, the flow of water will be reduced, which will lead to its mixing with cold masses. The small opening of the nozzle also works to increase the number of air bubbles, which increases the noise effect of the operation and can lead to bubbles starting to form already in the pump chamber. This will reduce its service life. As practice has shown, the most acceptable diameter is 9–16 mm.

The shape and profile of the nozzles are cylindrical, conical and rounded. It is impossible to say for sure which choice will be more effective; it all depends on the other installation parameters. The main thing is that the vortex process arises already at the stage of the initial entry of the liquid into the nozzle.

Types of heat pump designs

The type of heat pump is usually denoted by a phrase indicating the source medium and coolant of the heating system.

The following varieties exist:

- TN “air-to-air”;

- HP "air - water";

- TN “soil - water”;

- TN "water - water".

The very first option is a conventional split system operating in heating mode. The evaporator is mounted outside, and a unit with a condenser is installed inside the house. The latter is blown by a fan, due to which warm air mass is supplied to the room.

If such a system is equipped with a special heat exchanger with pipes, the result is an air-water heat exchanger. It is connected to a water heating system.

A HP evaporator of the “air-to-air” or “air-to-water” type can be placed not on the street, but in the exhaust ventilation duct (it must be forced). In this case, the efficiency of the HP will be increased several times.

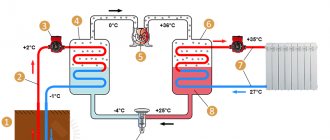

Heat pumps of the “water-to-water” and “ground-to-water” types use a so-called external heat exchanger or, as it is also called, a collector, to extract heat.

Schematic diagram of the operation of a heat pump

This is a long looped pipe, usually plastic, through which a liquid circulates, washing the evaporator. Both types of HP represent the same device: in one case, the collector is immersed in the bottom of a surface reservoir, and in the second - in the ground. The condenser of such a heat pump is located in a heat exchanger connected to the water heating system.

Connecting a VT according to the “water-water” circuit is much less labor-intensive than “ground-water”, since there is no need for excavation work. The pipe is laid in a spiral at the bottom of the reservoir. Of course, only a reservoir that does not freeze to the bottom in winter is suitable for this scheme.

Conclusions and useful video on the topic

The following video will introduce you to the principle of operation and design of a heat pump that processes wind energy:

A homemade air-to-water heat pump is one of the effective and inexpensive devices for additional home heating. Anyone can make and install this system.

Please write comments in the block below. Perhaps you have interesting information and photos on the topic of the article? Ask questions, share your own opinions and tips that are useful for site visitors.

Heat pump operation when operating according to the “ground-water” scheme

The collector can be installed in the ground in three ways.

Horizontal option

The pipes are laid in trenches in a “snake” pattern to a depth exceeding the freezing depth of the soil (on average, from 1 to 1.5 m).

Such a collector will require a fairly large plot of land, but any homeowner can build it - no skills other than the ability to work with a shovel will be required.

It should, however, be taken into account that constructing a heat exchanger manually is a rather labor-intensive process.

Vertical option

Collector pipes in the form of loops shaped like the letter “U” are immersed in wells with a depth of 20 to 100 m. If necessary, several such wells can be built. After installing the pipes, the wells are filled with cement mortar.

The advantage of a vertical collector is that its construction requires a very small area. However, there is no way to drill wells more than 20 m deep on your own - you will have to hire a team of drillers.

Combined option

This collector can be considered a type of horizontal, but its construction will require much less space.

A round well with a depth of 2 m is dug on the site.

The heat exchanger pipes are laid in a spiral, so that the circuit looks like a vertically installed spring.

Upon completion of installation work, the well is backfilled. As in the case of a horizontal heat exchanger, all the necessary work can be done with your own hands.

The collector is filled with antifreeze - antifreeze or ethylene glycol solution. To ensure its circulation, a special pump is inserted into the circuit. Having absorbed the heat of the soil, the antifreeze enters the evaporator, where heat exchange occurs between it and the refrigerant.

It should be taken into account that unlimited heat extraction from the ground, especially when the collector is located vertically, can lead to undesirable consequences for the geology and ecology of the site. Therefore, in the summer, it is highly desirable to operate HPs of the “soil-water” type in reverse mode - air conditioning.

A gas heating system has many advantages, and one of the main ones is the low cost of gas. The heating diagram for a private house with a gas boiler will tell you how to arrange heating of your home with gas. Let's consider the heating system design and replacement requirements.

Read about the features of choosing solar panels for heating your home in this topic.

Installation nuances

When choosing a water-to-water heat pump, it is important to calculate its operating conditions. If the line is immersed in a body of water, its volume must be taken into account (for an enclosed lake, pond, etc.), and when installed in a river, the flow speed

If miscalculations are made incorrectly, the pipes will freeze with ice and the efficiency of the heat pump will be zero.

What is a chiller and how does it work?

When sampling groundwater, seasonal fluctuations must be taken into account. As you know, in spring and autumn the amount of groundwater is higher than in winter and summer. Namely, the main operating time of the heat pump will be in winter. To pump and pump water, you need to use a conventional pump, which also consumes electricity. Its costs should be included in the total and only after calculating the efficiency and payback period of the heat pump.

A great option is to use artesian water. It emerges from deep layers by gravity, under pressure. But you will have to install additional equipment to compensate for it. Otherwise, the heat pump components may be damaged.

The only disadvantage of using an artesian well is the cost of drilling. The costs will not soon be recouped due to the lack of a pump to lift water from a regular well and pump it into the ground.

Calculation of a horizontal heat pump collector

The efficiency of a horizontal collector depends on the temperature of the medium in which it is immersed, its thermal conductivity, and the area of contact with the surface of the pipe. The calculation method is quite complex, so in most cases averaged data is used.

It is believed that each meter of heat exchanger provides the HP with the following thermal power:

- 10 W – when buried in dry sandy or rocky soil;

- 20 W – in dry clay soil;

- 25 W – in wet clay soil;

- 35 W – in very damp clay soil.

Thus, to calculate the length of the collector (L), the required thermal power (Q) should be divided by the calorific value of the soil (p):

L = Q/p.

The values given can only be considered valid if the following conditions are met:

- The area of land above the sewer is not developed, shaded or planted with trees or bushes.

- The distance between adjacent turns of the spiral or sections of the “snake” is at least 0.7 m.

When calculating the collector, it should be taken into account that the soil temperature after the first year of operation drops by several degrees.

Calculation formula

Ways of heat loss in the house

The heat pump is able to completely cope with space heating.

To choose the unit that suits you, you should calculate its required power.

First of all, you need to understand the heat balance in the building. For these calculations, you can use the services of specialists, an online calculator, or yourself using a simple formula:

R=(kx V x T)/860 , in which:

R is the power consumption of the room (kW/hour); k is the average heat loss coefficient of the building: for example, equal to 1 - a well-insulated building, and 4 - a barracks made of boards; V is the total volume of the entire heated room, in cubic meters; T is the maximum temperature difference between the street and indoors. 860 is the value required to convert the resulting kcal to kW.

In the case of a water-to-water geothermal heat pump, you also need to calculate the required length of the circuit that will be located in the reservoir. Here the calculation is even simpler.

It is known that 1 meter of collector produces approximately 30 W. In other words, 1 kW of pump power requires 22 meters of pipes. Knowing the required pump power, we can easily calculate how many pipes we need to make the circuit.

Example of heat pump calculation

We will select a heating element for the heating system of a one-story house with a total area of 70 square meters. m with a standard ceiling height (2.5 m), rational architecture and thermal insulation of enclosing structures that meet the requirements of modern building codes. For heating the 1st sq. m of such an object, according to generally accepted standards, it is necessary to spend 100 W of heat. Thus, to heat the entire house you will need:

Q = 70 x 100 = 7000 W = 7 kW of thermal energy.

We choose a heat pump of the TeploDarom brand (model L-024-WLC) with a thermal power W = 7.7 kW. The compressor of the unit consumes N = 2.5 kW of electricity.

Reservoir calculation

The soil in the area allocated for the construction of the collector is clayey, the groundwater level is high (we assume the calorific value p = 35 W/m).

The collector power is determined by the formula:

Qk = W – N = 7.7 – 2.5 = 5.2 kW.

Determine the length of the collector pipe:

L = 5200 / 35 = 148.5 m (approx.).

Based on the fact that laying a circuit longer than 100 m is irrational due to excessively high hydraulic resistance, we accept the following: the heat pump collector will consist of two circuits - 100 m and 50 m long.

The area of the site that will need to be allocated for the collector will be determined using the formula:

S = L x A,

Where A is the step between adjacent sections of the contour. We accept: A = 0.8 m.

Then S = 150 x 0.8 = 120 sq. m.

Vertical collector calculation

At a depth of over 15 m, the ground temperature remains stable at +10 degrees all year round. Therefore, the efficiency of a vertical collector is higher - on average, up to 50 W of heat can be removed from a meter-long area. To calculate the length of the heat exchanger, the type of medium must also be taken into account. So, from 1 meter of pipe it is possible to obtain the following thermal power:

- 20 W – when immersed in sedimentary soil (dry);

- 50 W – in rocky or wet sedimentary soil;

- 70 W – hard rocks (stone);

- 80 W – groundwater.

Application of vertical probe for heat pump

When constructing wells, the following condition must be observed: the distance between them must be at least 5 m.

To operate the heat pump from the above example, you will need a collector with a length of L = 5200 / 50 = 140 m.

Consequently, to equip the reservoir, it will be necessary to drill two wells with a depth of 70 m. In each of them, two U-shaped loops will need to be installed, for which it will be necessary to purchase 4x140 = 560 m of pipes.