Installing a warm water floor makes life in an apartment much more comfortable in winter. If the rooms have an area exceeding 50 sq. m, then a pump will be needed to ensure the movement of the coolant. When choosing, you need to consider the design features, only then can you count on reliable and trouble-free operation of the pump.

Installation of a pump for heated floors Source bouw.ru

Video description

Pump in the heating system.

The coolant is heated using a boiler. The liquid then moves through the pipes, gradually releasing heat as the floor warms up. When it passes the entire circuit, the temperature is already lowered. Thus, during natural movement through the pipes, the heating of various parts will be uneven.

Design of a wet rotor pump Source bouw.ru

The situation changes when using a pump for water heated floors. Then the increase in heating occurs not due to an increase in the boiler temperature, but due to accelerated circulation. At the same time, heating of the entire area will become more uniform.

Heated floor pump Source teplowood.ru

Advantages of using collectors as part of underfloor heating

Devices that are installed assembled with all additional elements provide the following advantages:

How to assemble a manifold for a heated floor

- energy savings compared to traditional heating systems (on average 30-50%);

- high safety due to the absence of open elements that could become a source of fire hazard;

- The duration of operation of the collector group is several decades. Only pipelines are subject to periodic replacement;

- Optimal microclimate parameters in the heated room are ensured.

Is it necessary to install a pump?

For some types of heated floors, you can do without installing a water floor pump. However, there are situations when it is necessary. This happens, for example, in the following cases:

- The installation of a heated floor requires ensuring the optimal location of the pipes. It is important that the heating of the floor, air and objects in the house is uniform. If this rule is violated, materials may be damaged. For example, exposure to heat can deform parquet. The connected pump will increase the circulation rate of the coolant and prevent overheating in certain places.

- If the pipes for fluid circulation have a small cross-section, this increases energy losses. A pump for a water heated floor will speed up the movement of water, and this will ensure a more uniform heat transfer. If this is not done, the boiler will overheat, which will lead to increased wear and tear.

- Rooms may have floors made in different ways. For example, one room may have laminate flooring, while another may have parquet. Their heat capacity will differ, which will ensure uneven heating. Increasing the rate of fluid circulation will lead to a more harmonious distribution of heat between rooms.

If the rooms have a large area, then if the water flows slowly, it will give off heat too quickly. If you install a pump, this will increase the speed of its circulation.

How and why to bleed air when the circulation pump is running can be found in the video below.

Purpose

The main function of the circulation pump is to ensure optimal pressure in the pipeline so that the circulation of coolant in the line is uninterrupted. This will minimize disruptions in the operation of the warm water floor due to airing of the pipes.

Refusal of the unit in order to save money when constructing heated water floors (in any of the rooms - kitchen, bathroom) will affect the efficiency of their operation.

Video description

How and why to bleed air from the circulation pump.

A decrease in coolant temperature may depend on the following:

- Usually, when considering pumps for a warm water floor, it is assumed that the characteristics are taken for a temperate climate, typical of the European part of Russia. If we are talking about a region with colder conditions, then the coolant will cool faster. The power reserve of the device should be greater the further north it is planned to be used. Usually it is enough if it is 25%-30%.

- The longer the pipes for underfloor heating, the greater the difference between the initial and final temperatures. If there are several circuits in the house, each of them must be considered.

- Having good insulation prevents heat leakage. The smaller it is, the weaker the coolant cools during operation. For example, when the floor was made with technological violations, the temperature decrease can become significant.

If a pump is installed, it increases the speed of water flow. As a result, the heat distribution will be more uniform in each floor contour.

You need to consider what kind of power supply is needed for the purchased device. In this regard, the most common are those designed for 220 V. If the motor runs on a three-phase voltage of 380 V, it is more efficient and reliable. However, this pump can operate on a warm floor only where such a network is available.

Dry rotor pumps Source teplowood.ru

Malfunctions and how to fix them

Problems may arise during operation of the circulation pump. One of them is salt deposits on the impeller when water is used as a coolant. The process is especially activated when water is heated above 55 degrees. Therefore, most models have a thermostat; it turns off the device so that the water cools down to the required degree.

But even so, salt will still accumulate a little. When the system is operating, this fact does not significantly affect the pump. But when you turn on the warm water floor after a long period of inactivity, the pump may fail because the salt clogs the rotor. The problem is easily solved; you need to manually rotate the impeller.

Another point that may arise is airing. The reason for the formation of air plugs in a pipeline or unit lies in improper installation or operation of the equipment. There are several ways to avoid this:

- By removing air plugs in the main pipes, this is done before the heating is turned on;

- By installing separators or air valves;

- Carrying out periodic maintenance of equipment - this is especially important to do when unheated zones appear.

To avoid air locks, sudden changes in the temperature level and pressure in the system should not be carried out.

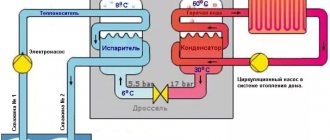

Pump operating principle

If a pump is installed in the system, it helps push water through the pipes. This mechanism is not intended to create excess pressure. The speed of fluid passage depends on how strong the heating should be. Therefore, it is more profitable to install pump models on heated floors in which this parameter is adjustable. For example, three-speed models meet such conditions.

The video below describes in detail the features of the GRUNDFOS ALPHA brand pump.

Criteria for proper selection of equipment

All installation efforts will be reduced to zero if the equipment is selected incorrectly. In order not to make a mistake, it is necessary to first analyze all aspects of a particular heating system and make the necessary calculations.

Main types of pumps

According to their design features, all devices are divided into 2 categories: with a wet and dry rotor.

Wet type pumps. This option is suitable for private homes. The unit is compact, almost silent and has a modular structure that is convenient for maintenance and repair.

But, unfortunately, it does not have high productivity - the maximum efficiency of modern models reaches 52-54%.

Circulation devices for heating networks should not be confused with similar devices for hot water supply. The heating pump does not require an anti-corrosion bronze or stainless steel housing and additional protection against scale - accordingly, it is cheaper

Pumps with a dry rotor are productive, unpretentious to the quality of the coolant, capable of operating under high pressure and do not require a strictly horizontal position on the pipe. However, they are noisier, and their operation is accompanied by vibration. Many models are installed on a foundation or metal support frame.

For installation of console, monoblock or “In-line” models, a separate room is required - a boiler room. It is advisable to use them when a flow rate of more than 100 m³/h is required, that is, for servicing groups of cottages or apartment buildings.

Brief overview of technical characteristics

When choosing a pump, you should definitely study the technical characteristics and compare them with the requirements of the heating system.

The following indicators are important:

- pressure that covers hydraulic losses in the circuit;

- productivity - volume of water or supply over a certain time interval;

- operating coolant temperature, max and min – for modern models on average +2 ºС… +110 ºС;

- power – taking into account hydraulic losses, mechanical power prevails over useful power.

Structural details are also important, for example, the inlet/outlet diameter of the pipes. For heating systems, the average parameters are 25 mm and 32 mm.

The number of electric pumps is selected based on the length of the heating main. If the total length of the circuits is up to 80 m, one device is sufficient; if more, additional devices will be required

An example of a unit for equipping a residential heating network with an area of 100 m² is a Grundfos UPS pump with a 32 mm pipe connection, a capacity of 62 l/s and a weight of 3.65 kg. The compact and low-noise cast iron device is inaudible even behind a thin partition, and its power is sufficient to transport liquid to the 2nd floor.

Pumps with built-in electronics allow you to quickly switch equipment to a more convenient mode depending on changes in temperature or pressure in the network. Automatic devices are equipped with digital displays that provide maximum information on the operation of the pump: temperature, resistance, pressure, etc.

Additional information on the calculation and selection of a circulation pump for heating is presented in the articles:

- How to calculate a heating pump: examples of calculations and rules for selecting equipment

- Selection of a circulation pump: device, types and rules for choosing a heating pump

- Circulation pump for heating: ten best models and tips for buyers

How to choose a pump for heated floors

When purchasing, it is important that the performance and pressure force match the floor design. How to calculate the pump power for a heated floor will be discussed below. Most often, heated water is used as the working fluid. Calculation of a pump for a heated floor includes determining the performance using the following formula:

Q = 0.86 x (P/(TN-TK))

The following notations are included here:

- P is the heating power of the heated floor, which is measured in kilowatts;

- TN is the initial temperature when the coolant enters the system;

- TK is the temperature of the water after passing through the entire circuit.

If several circuits are used, the values for each must be summed. In most cases, the temperature difference does not exceed 5 degrees.

Markings used for pumps Source teplowood.ru

You also need to make sure that the circulation pump you purchase for underfloor heating creates the required degree of pressure. This characteristic is important when using various types of pipe connections. The fact is that not only the pipe itself, but also each of them creates resistance to the movement of water.

The video will help you choose a pump.

Which method should I choose?

It is important to pay attention to the specifics of your technical conditions

Selecting a connection option is a task that is usually solved by comparing technical capabilities and system performance. If you have your own heating boiler, the best option is a scheme with a mixing unit. If there is no boiler, it is most convenient to use a heat exchanger heated from the central heating network. You can feed a heated floor directly from the boiler if it produces coolant at a low temperature.

In any case, the main selection criterion is the reliability and stability of the ETP. Being left without heating your home in winter in our country is an extremely undesirable situation, therefore, you should choose the most workable option. In addition, it is recommended to have an additional option for heating the house in case of problems with the main heating circuit.

Video description

Water heated floor.

Choosing a pump for heated floors. The technical documentation indicates the resistance of each meter of pipe. Before calculating the pump for a heated floor, this parameter will need to be multiplied by the length of the pipe. To take into account the influence of various parts, appropriate numbers are used. For the valve, a value of 1.7 is taken. For each connection point the coefficient is 1.2. When using a powerful boiler, a mixer can be provided. For it the parameter is 1.7. To determine the pressure required for underfloor heating, the following formula is used.

H= (P x L + K)/1000

The formula contains the following notations:

- N represents the desired pressure force;

- P is the hydraulic resistance force of the pipes specified in the technical documentation;

- K is the power reserve factor.

When choosing a suitable model, it is necessary that the calculated parameters are in the middle of the characteristics. For example, if the pump is three-speed, then the indicated capacity and pressure must correspond to the second. Correct calculation of the circulation pump for a heated floor will allow you to choose the most efficient model.

In what position should the pump be installed Source teplowood.ru

When choosing, you need to consider the type of pump. The following varieties are used for domestic purposes:

- An advantageous solution is to use a wet rotor pump. The name reflects the fact that the blades are immersed in coolant. This solution is effective in cases where the area of the serviced floors does not exceed 400 square meters. m. Features of such pumps are quiet operation, low energy consumption and high reliability. During the pumping process, the rotation of the blades sucks in water and sends it further.

- The user can select a pump that uses a dry rotor. It is mounted in a separate container, which must be hermetically sealed. To ensure trouble-free operation, regular cleaning and lubrication is necessary. In such models, the rotor does not have direct contact with the liquid. It does not suffer from the hardness of the water used. Typically, such devices produce noticeable noise when operating.

Connection to an individual heating boiler

The presence of an individual heating boiler in an apartment or private house eliminates all organizational problems in permitting the installation of water heated floors. In this case, connecting a warm water floor does not require any permits. Depending on the location and operation conditions of the facility, boilers can be of various types:

- on gas fuel;

- on liquid fuel (diesel, fuel oil);

- solid fuel: firewood, pellets, coal;

- electrical;

- combined.

In apartments in multi-storey buildings, gas or electric heating boilers are most often used; connecting a heated floor circuit to the central heating system is not required. In this case, the diagram differs slightly, but the functional purpose of the main elements remains the same.

Diagram of a water heated floor system in a private house with an autonomous boiler

Essential elements:

- boiler;

- expansion tank;

- pressure gauge;

- circulation pump;

- manifold for underfloor heating;

Unlike the case with central heating, connecting a heated floor to a boiler does not require installing a three-way valve to regulate the temperature of the coolant. Its installation is not necessary; the temperature can be changed from the boiler control panel. Temperature control sensors are also located on the external control panel.

The expansion tank serves to maintain stable pressure in the system; when heated, the volume of liquid increases. To prevent the underfloor heating collector, pump and other expensive elements in the pipeline system from collapsing, the tank compensates for the expansion of the coolant volume. The pressure gauge shows the pressure in the pipes. The main thing is that before pouring the solution into a warm floor, you need to check the functionality of all components.

Control panel on the boiler body

Regardless of the modification of the device and its manufacturer, all panels have basic options, and some additional programming functions:

- buttons or regulators for increasing and decreasing the supply coolant temperature;

- button for automatically setting a comfortable, economical temperature mode, room temperature – 20-22 ̊C;

- It is possible to program control, set the modes “winter”, “summer”, “vacation”, “function of protecting the system from freezing of liquid”.

How to make specific settings for boilers with different control panels is described in the operating instructions. Filling a water heated floor with a solution for a separate boiler is done in the same way as for central heating.

Remote control panel

How the pump works

Before choosing a circulation pump for a heated floor, you need to study this device in more detail. This mechanism is designed to pump coolant through underfloor heating pipes. It consists of the following elements:

- The main part of the structure is the body. It must have significant mechanical strength. For its manufacture, stainless steel, bronze or cast iron are most often used. Recently, the use of plastic housings has become increasingly common.

- The device has connections for connecting pipes. Industrial models use flange connections with a diameter of 40 mm or larger.

- Rotating blades are used to work with coolant. An impeller made of technopolymer is often used. This material is known for the fact that it practically does not wear out.

- The impeller is driven by an electric motor. It is usually mounted on the side of the body. It determines all the main characteristics of the pump.

When installing a circulation pump for a warm water floor, it is recommended to place it in such a position that the motor shaft is horizontal. If this rule is violated, the device may lose up to 40% of its power.

Connecting a floor pump Source lucheeotoplenie.ru

Main types of collectors

A stainless steel manifold lasts longer than brass or metal ones.

The operation of the device is as follows: water from the boiler flows into a storage tank. Such a tank is located at a height above the “comb”. The coolant enters the distributor with shut-off and control valves. From the distributor, the flows diverge into separate branches. The output pipes are collected at the bottom of the “comb” to be sent to the boiler for heating.

Usually the unit is a piece of pipe with a certain number of bends. As the technical specifications become more complex, the complexity increases tenfold, the complexity of setting up the automation and installation become many times more complicated.

Made of stainless steel

Stainless steel manifolds are stronger than brass. They have a large flow area that equalizes the pressure of the flows of different coolant consumers. The Valtek heating collector is designed for an average of 50 years of operation at a pressure of 10 atm. and temperatures up to 130 degrees.

Branded models are reliable - even the appearance of a weld does not lead to corrosion. When buying models from cheap manufacturers, you can end up with low-quality metal and surface corrosion.

Made from polypropylene

You can assemble a polypropylene manifold with your own hands from pipes and fittings.

The polymer comb is made from polypropylene pipes. This lightweight material is not as durable as steel, but it will successfully last for many years. Plastic manifolds are extremely cheap. The use is justified when circulating coolant in several heating devices. If your main goal is to save money, this option is suitable.

The stores offer models with fittings and manifolds with shut-off valves.

To switch to a metal product with threads, combination fittings are used.

Plastic combs are common in Ukraine. To strengthen the structure, up to 30% glass fiber is added to the PA66 polyamide in factory technopolymers to increase strength.

The disadvantage of polymer products is their thick walls. They narrow the cross-section of the passage with the same dimensions of the part. Steel components are stronger, the walls can be made thinner - the internal cross-section increases and passes several percent more liquid per unit of time under the same conditions.

Another disadvantage of polymers is oxygen permeability. Fiberglass reinforcement reduces this to a minimum. But oxygen diffusion is present.

The advantages of polymer products are resistance to aggressive environments, electrochemical corrosion, and low thermal conductivity. For the same tube length, polymer loses less heat than steel or brass.

Made of brass

It is recommended to buy brass manifolds with a nickel coating.

This material is a leader in the manufacture of combs. For production in Europe, a hollow brass rod is made. For dozens of years, products were made from it - cut to the required length, holes drilled for flow meters, valves, and threads cut. There are also stamped models on the market.

Due to rising prices for brass, manufacturers switched to cheap materials - steel and plastic. However, brass models are still preferable. They have one drawback - leaching of zinc. But it is leveled out by chrome or nickel plating of the surface.

In low-temperature conditions, the advantages of low expansion of brass are leveled out and are relative.

Features of installation and use

When using the floors in question, the coolant is usually low temperature. This makes it possible to install the pump both on the inlet and on the branch after the boiler. If we are talking about a private house where there is more than one floor, it is recommended to install the unit on each of them. If the system uses a mixing unit, you need to install the device after it. This will ensure the correct temperature for the pump to operate. Before choosing a pump for a heated floor, you need to decide where to install it.

Correct installation will ensure high-quality operation of the device Source nicespb.ru

After installing the pump, before starting it, you need to bleed the air from the system. This will avoid the formation of traffic jams. Some designs provide for the use of a special valve for this purpose. If the pump has not been operated for a long time, it is recommended to disassemble it and thoroughly clean it of deposited salts.

Installation of the pump on a heated floor must provide a place where there is easy access to the equipment. In this case, the owner will be able to easily maintain and repair the device. If you are using a motor that makes a lot of noise during operation, it is recommended to install it in a technical room.

It is recommended to bleed the air regularly, every 1-1.5 months. If traffic jams occur more often, it means that errors were made during installation. The unit must be lubricated annually. It is sufficient to descale a wet rotor once every three years.

For floors larger than 50 sq. m pump installation is necessary Source b2b-instrument.ru

Operation and care

To extend the service life of pumping equipment in heated floors, during installation, operation and maintenance, a number of rules must be followed:

- Do not tighten the connecting parts tightly, since modern models are made of alloys that do not have great strength. To ensure the tightness of the system, it is not recommended to use tow, but it is better to use modern tapes that can withstand high pressure well, and do not require tight tightening of the connecting nodes.

- Install the device in an accessible place so that in case of breakdown it can be easily replaced. Also, it needs constant preventive maintenance, which consists of inspecting the oil seal. When there are large amounts of impurities in water, they harden and cause damage. These deposits must be removed, and to reduce the amount of their formation it is better to install a filter.

- Bleed the air before starting the system, and prophylactically once a month, by opening a special tap. Air in the line complicates the movement of water, and this provokes the formation of cold spots. At the same time, the automation sends a command to the pump, and it is switched on unexpectedly, thereby starting it more often. This reduces its resource, and accordingly the service life decreases.

- Lubricate the mechanism once a year, especially the “dry” type device.

It is not recommended to suddenly switch pressure or temperature in the system. And when it freezes, or after summer, the temperature should be increased gradually.

In conclusion, we can say that water floors will not function effectively without circulation equipment. It’s up to you to decide which pump to choose for underfloor heating. But if you are not sure that you can install the equipment yourself, it is better to invite professionals.

Let's learn how to select a pump and a three-way pump for a heated floor! Warm floors from A to Z - part 3

Possible faults

With use over time, the user may encounter problems. The most common of them are described below.

Tap water is often used as a coolant. During operation, salts will be deposited on the blades. This gradually leads to a decrease in the quality of work and increased wear. Often this problem is encountered with the onset of autumn.

After a long break in operation, deposits appear on the blades. This may result in the pump not starting one day. After switching on, it will begin to hum, but there will be no movement of water. If you turn the impeller manually several times, it will begin to rotate and the pump will be ready for operation.

Internal structure of a floor pump Source prouteplenie.com

Where to install the circulation pump in the heating system: heated floor

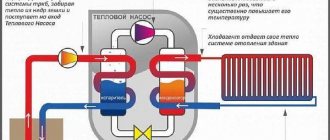

Heating a home by heating floors is gaining increasing popularity. To operate the system, it is equipped with a mixing unit and a circulation pump, which ensures the movement of the coolant along the contours (loops) of the heating pipeline. This is due to the fact that the water temperature should not exceed the set value normalized for the floor covering used.

The “circulator” is installed between the three-way valve and the underfloor heating manifold. Only this arrangement will ensure the functionality of the system. If you mount the pump unit between the connection to the radiator network and the three-way valve, the mixing unit will be non-functional, and the heated floor will not heat up. The supercharger is secured to the flanges with threaded nuts. If the wiring is done correctly, there will be no problems with installing the pump unit.

Data for calculations

Calculations and design are based on several characteristics of the room, as well as the choice of heating option - main or additional. Important indicators are the type, configuration and area of the room in which the installation of this type of heating system is planned. The optimal option is to use a floor plan indicating all the parameters and dimensions necessary for calculations. You are allowed to take the most accurate measurements yourself.

Heated floor calculation schedule

To determine the amount of heat loss, you will need the following data:

- the type of materials used in the construction process;

- glazing option, including type of profile and glass unit;

- temperature indicators in the region of residence;

- use of additional heating sources;

- exact dimensions of the room area;

- expected temperature in the room;

- floor height.

In addition, the thickness and insulation of the floor, as well as the type of floor covering to be used, are taken into account, which has a direct impact on the efficiency of the entire heating system.

When performing calculations, you should take into account the desired temperature for the room being equipped. Consumption of underfloor heating pipe depending on the loop pitch

Consumption of underfloor heating pipe depending on the loop pitch

| Pitch, mm | Pipe consumption per 1 m2, m p. |

| 100 | 10 |

| 150 | 6,7 |

| 200 | 5 |

| 250 | 4 |

| 300 | 3,4 |

Water floors in wooden houses

Features of heating a wooden floor

Water-heated floors under wooden floors, and even more so on a wooden base, are not installed so often. There are several reasons for this:

When working with wooden bases, it is necessary to compensate for the heat capacity of wood using reflective elements

- Thermal conductivity of wood. On the one hand, this is a plus - the wooden base acts as a heat insulator. On the other hand, the floor will take quite a long time to warm up. In addition, there is a risk that a significant portion of the energy will be spent on heating the subfloor, and only part of the heat (relatively small) will enter the room.

- Temperature deformation. Laying hot water pipes in the thickness of a wooden floor can lead to uneven changes in the linear dimensions of its individual sections. As a result, the stability of the structure is significantly reduced - primarily due to the appearance of cracks in both the rough flooring and the frame.

Wooden bases are subject to temperature and humidity deformations - this feature will have to be taken into account

- Exposure to moisture. Of course, water heated floor systems are made airtight, trying with all their might to avoid leaks. But when laying under a wooden covering, even condensation caused by temperature differences can cause the wood to swell.

Pipes must be hidden under supporting elements, otherwise they will be damaged when walking on the floor

- Significant thickness of heating elements. If water heated floor pipes are laid in a screed, their thickness can be easily compensated by pouring the required layer of concrete. When installing on a wooden base, you have to solve these problems differently, since simply laying a finishing coating over the pipes will not work.

The traditional option of pouring screed (pictured) will not work here - the load is too great

However, everything that I noted above does not mean that a wooden water floor system is unrealizable in principle. If we take into account all these shortcomings and use modern materials, devices and technologies in our work, then a warm floor on joists or planks will work to the envy of our neighbors.

How can you make a base?

When planning the installation of a heated floor in a house with a wooden floor or a joist system, we need to solve the main question - where to hide the pipes?

When laying on a wooden base, pipes must be protected from load using spacer inserts made of wood or chipboard

The difficulty here is not only to protect them from the load. This is not difficult to do - just raise the level of the finishing coating by a few centimeters. But in this case, we greatly lose in the efficiency of heat transfer: an air layer is formed above the pipes, which acts as a heat insulator. That is, we heat anything, but not the floor itself.

That is why, when assembling a heated floor system, they try to lay the coating exactly at the level of the upper edge of the pipe.

For this purpose the following devices are used:

| Illustration | Method of laying a water heating system |

| Milled prefabricated bases. To lay pipes deep into the floor at the required level, particle boards (chipboards) with grooves made on a milling machine are used. We select the depth and configuration of the grooves in such a way as to ensure the most rational distribution of pipes with coolant. Disadvantages of modular chipboard flooring:

| |

| Rack structures. This option is a cheaper alternative to a modular base with milled grooves. Slats are placed on the subfloor, the gap between them corresponds to the diameter of the pipe being laid. The thickness of the slats is selected in such a way that the gap between the upper edge of the pipe and the finished floor is minimal - this reduces heat loss. The downside is that the gaps on the sides and in the places where the pipes turn are large, so some of the heat is still lost. | |

| Polymer mats. To solve a significant part of the problems associated with heat loss, deformation and wetting, polymer mats with grooves for laying pipes can also be laid over the subfloor. They function in the same way as milled chipboard panels, but the efficiency of these products is higher. The downside is the high price, which is only partially offset by savings on heating. |

Any of these options is suitable if we need to lay a heated floor on plywood or other wooden base. I am a supporter of polymer mats, but milled models made of chipboard, and even simple designs made of slats packed onto the floor, have a right to exist.

Prefabricated laminated chipboard base, ready for pipe laying

What should be the flow rate and pressure?

Based on the experience of creating underfloor heating, we can say that the pump performance for sufficient heating of a “moderately insulated building” in a central climate should be approximately the following.

Those. – for an area of 100 sq. m. a private house in the middle zone will require a pump group with a capacity of 1.5 m3. at one o'clock.

For example, 7 heating circuits are used, if the flow rate is divided approximately equally, then it is a little more than 0.2 cubic meters per hour in each circuit.

The plate shows approximate data on the pressure drop in underfloor heating circuits using a 16 mm pipe.

Probably, loops with a length of 70 - 80 m are installed. The flow rate in each circuit is about 3 liters per minute (0.18 cubic meters per hour), respectively, the maximum pressure according to the table is about 2 m. Art.

Therefore, for 100 sq.m. For this “medium-cooled” area, we need a pump that would provide a flow rate of 1.5 cubic meters at a pressure of 2 meters of water column.