With the onset of the cold season, every owner of a private home involuntarily thinks about how to increase heating efficiency and at the same time save on costs. Modern technologies that use the energy of sunlight to generate heat come to the rescue in this situation. Let's look at what a vacuum solar collector is, what its structure is, its operating principle and scope of application, what its pros and cons are, what types of devices exist, as well as what are the criteria for its selection and placement rules.

Solar collectors installed on the southern slope of the roof of a private house Source solntsepek.ru

Solar collector - what is it, device, principle of operation

Climate control equipment that directly converts the energy of sunlight into heat is called a solar collector in technical terminology. The device does not generate electricity like a classic solar battery, but only collects, concentrates and transfers heat to the heating system. The coolant is water, non-freezing liquid or air.

Based on their design characteristics and associated operating principles, solar collectors used for heating a house, including in winter, are divided into 3 main types - flat, vacuum and air. Structurally, the device is a set of series-connected coil-shaped tubes connected to the supply and return lines. A coolant circulates inside them - water, antifreeze or air.

Solar collector as part of a heating scheme for a private house Source ast75.ru

Any model of a vacuum manifold contains the following set of main components:

- External large transparent pipe without air.

- An internal small tube within which coolant circulates.

- A collector-distributor with connected large pipes, inside of which there are pipes of smaller diameter.

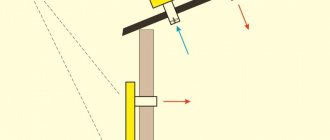

Schematically, this design is an analogue of a transparent thermos with maximum thermal insulation. Thanks to this, the small tubes warm up well and transfer heat to the coolant circulating inside them.

The principle of operation of the collector is based on the natural laws of changes in the properties of substances under the influence of temperature - the driving force that forces the coolant to circulate inside the tube system are natural processes such as changes in the density of the substance, convection, compression-expansion, etc.

Schematic design of a vacuum manifold Source avanten.ru

In this case, to enhance the intensity of absorption of thermal energy from the sun, special adsorbents are used, for example, metal plates with a blackened coating. Conversely, to maximize the passage of sunlight, the upper part of the installation is made of a material with high light transmittance.

Application

Installing a solar collector to meet the needs of a private home allows you to solve not only heating problems, but also an additional number of issues:

- Production of domestic hot water - for showering, bathing, washing, cleaning, washing dishes.

- Maintaining pool operating standards.

- Heating of greenhouses, greenhouses, greenhouses.

- Creation of an alternative standby heating system in case of an emergency.

- Optimization, reduction of costs for the operation of a traditional heating system.

- Preparation of technical hot water.

The solar collector can be used to heat water in a swimming pool Source 4pool.com.ua

Note ! The efficiency of the solar collector is so high that it can be used to heat a house even in winter - but only if a vacuum type model is installed. This is explained primarily by the design features of the equipment and the specifics of their operation in cold conditions. Unlike flat analogues, its tubes are not covered with snow, the material is strong enough to withstand even large hail, and the device, based on the principle of a thermos, allows you to bring the water inside to a boil in severe frost outside.

See also: Catalog of companies that specialize in engineering systems (heating, water supply, sewerage and others) and related work

From copper tubes

A collector with a copper coil, lined on the inside with sheets of the same material, is extremely effective. Perhaps the most effective one we found on the Internet. Tubes and strips are soldered with a special autogenous soldering iron at seams and joints, so the copper absorber was the most labor-intensive stage, taking 2 days.

Copper was blackened by placing it in a bath of potassium persulfate:

The case was insulated, and foil was attached to the back wall to reflect heat. All gaps were carefully sealed:

The structure was moved to its place, for this it was wrapped in ordinary cling film, and only after transportation and connection was the glass installed:

Result: in the hot southern climate, under direct rays, the copper became hot, the water heated to a boil, and there were even noticeable traces of melting of the polymer structural elements. It is advisable to add cold liquid to a shower with a solar absorber of this type, for which purpose provide a separate barrel with it or a supply from the tap.

Advantages and disadvantages

Depending on the design of the solar collector equipment, the heating system has a certain number of pros and cons. Thus, the advantages of flat varieties are manifested in the following:

- The most favorable ratio of “equipment price – heat production” is for regions with a temperate climate.

- Full autonomy of heating and hot water production.

- Maximum efficiency during the period of highest solar activity in comparison with solar panels and wind generators.

- Independence from standard energy resources and the constant rise in prices for them.

A solar collector on your site can be used to heat greenhouses and heat water for irrigation Source teplo.guru

- The average payback period is 3-5 years.

- Service life - at least 30 years.

- Self-cleaning function from snow and hail.

- Easy connection to the heating system.

- Absolutely harmless to the environment.

A flat-plate solar collector used to heat the heating fluid is not without some disadvantages:

- High cost of equipment, the need for installation costs and implementation in the heating system.

- The presence of sailing characteristics of the device, which creates the possibility of damage in strong winds.

- Low efficiency in cloudy weather, as well as during cold weather.

- Large heat losses due to imperfect design.

Vacuum varieties differ from flat ones for the better in terms of performance, as well as due to the following positive features:

- Wide operating temperature range, including cold temperatures down to -30-500C.

- Minimum windage parameters and likelihood of wind damage.

- Enhanced performance capabilities due to the ability to absorb radiation from the invisible part of the sunlight spectrum.

- Minor heat loss from the housing.

The more working panels the collector system has, the more efficient the heating system will be Source stroy-podskazka.ru

- High reliability in operation.

- Maintainability - in the event of a malfunction, it is necessary to replace one or more working elements, and not the entire structure.

- Possibility of heating the coolant up to 3000C.

- Insensitive design to precipitation.

The negative properties of vacuum models are associated primarily with the high cost of equipment and strict installation requirements.

Important! The efficiency of solar collectors depends not only on the weather, but also on installation conditions, landscape topography and the duration of sunshine. All these factors significantly affect the payback time.

What should the heat collector be like?

The heat collector is another very important working element of the vacuum manifold. Through this unit, accumulated heat is transferred from the tubes to the coolant.

The heat collector is located at the top of the device. One of its components, a copper core, receives energy and transfers it to the main coolant circulating in a closed tank-collector heat exchanger system.

Correct operation is guaranteed by a circulation pump connected to the system. The automation that controls the heating complex clearly monitors the temperature level in the channels and, if it falls below the permissible critical minimum (for example, at night), stops the pump.

This allows you to avoid backheating, when the coolant begins to take away the heat of the hot water collected in the storage tank.

Varieties

Modern solar collectors come in water and air types. The former use water, antifreeze or other liquid with suitable properties as a coolant. Circulating through the internal tubes, it transfers heat to the heat exchanger of the heating system. Inside the air modification, the air flow is heated in a similar way, which is then supplied for heating needs.

Schematic design of a flat solar collector Source tildacdn.com

Additional costs associated with operation

Using this does not imply any care or maintenance other than periodic cleaning of dirt and snow in winter (unless it thaws itself). However, there will be some associated costs:

- Repairs, everything that can be changed under warranty can be replaced by the manufacturer without any problems, it is important to buy an official dealer and have warranty documents.

- Electricity, very little of it is spent on the pump and controller. For the first one, you can install only 1 solar panel of 300 W and it will be quite enough (even without a battery system).

- Washing the coils will need to be done once every 5-7 years. It all depends on the quality of the water (if it is used as a coolant).

Video description

Video review of using a vacuum solar collector in your home:

- Due to the simplicity of the device, air modifications last longer and do not require special maintenance. Their main drawback is insufficient heat production during the cold season.

- The amount of heat generated by a vacuum device directly depends on the size of the tubes. Models with several tubes, with a length of at least 2 m and a diameter of 6 cm or more, are considered optimal.

- The equipment power indicator characterizes the amount of heat generated, expressed in kW, provided that the sun is at its zenith and there is complete cloudlessness.

On a note! The solar collector only works effectively during the day. To maintain heat in the room at night, it is necessary to install a heat accumulator. During the day it will accumulate heat and release it at night.

Do-it-yourself assembly of the unit

The process of assembling a vacuum manifold begins with the manufacture of a support frame for the working elements. It is installed immediately in the place allocated for the unit.

The size and dimensions of the frame depend entirely on the model that is planned to be made, and are usually prescribed in the instructions found among the accompanying documents for the components.

The finished frame for the collector is fixed to the roof so that it occupies a clear position and does not swing. If the roof of the building is slate, use sheathing beams and large-caliber thick screws. For other roofing materials, conventional anchors are used

I additionally fix the places where the frame meets the roof surface with sealant so that in the future water does not enter the house through the holes. Then the storage tank is delivered to the installation site and secured with screws to the top of the frame.

At the next stage, the heating element, temperature sensor and automated air outlet are assembled. All auxiliary components and related parts are placed on the included softening pads. To attach the temperature sensor, use a socket wrench.

Next, the supply of water supply communications is arranged. For this purpose, pipes are taken from any material that is resistant to low temperatures and can withstand up to 95°C. Polypropylene pipes and fittings have proven themselves well.

Polypropylene pipes are ideal for connecting the solar collector to the residential plumbing system. The reinforcement has good physical properties and operational endurance, serves reliably for many years and is easily replaced in case of cracks or tears.

Having connected the water supply, the storage tank is filled with water and tested for leaks. If leaks are found somewhere within 3-4 hours, they are repaired.

At the end, heating elements are installed. To do this, the copper tube is wrapped in aluminum sheet and placed in a glass vacuum tube. From below, a fixing cup and a boot made of durable, flexible rubber are placed on the flask.

The upper copper tip of the tube is pushed all the way into the brass condenser. Viscous thermal contact grease is not removed from the pipes. Snap the locking mechanism onto the bracket and mount all remaining glass tubes using the same principle.

Tubular solar collectors require regular maintenance and mandatory cleaning, especially during periods of active snowfall. If you follow these simple rules, they will work for a long time and maintain a high level of efficiency throughout their entire service life.

A mounting block is placed on the structure, a 220-volt power supply is supplied to it, and three auxiliary units are connected to the system - a heating element, an air vent and a temperature sensor.

The last thing to connect is a controller designed to correctly control the complex. The desired operating parameters are entered into the controller menu and the system starts in standard mode.

Step-by-step instructions for constructing a solar collector are given in this article.

Video description

Video example of the applied use of a solar collector for a country house:

- The light-absorbing panel should not be subject to shadows from nearby objects - houses, trees, pipes, fences, etc.

- When placing the device on the roof of a house, it is necessary to design a mount for it in advance.

- To avoid the accumulation of precipitation on the work surface, the device must be installed as close to a vertical plane as possible, but with minimal damage to capture sunlight.

- For optimal operation throughout the year, the device must be installed on the south side with an angle equal to the latitude of the area.

Reference! It will not be possible to create a completely autonomous heating system based on a solar collector. Since to ensure maximum efficiency, the circuit will need to be equipped with a circulation pump, automation and other equipment that runs on electricity. However, significantly reducing the consumption of the main energy resource - gas, electricity, coal - with its help is a completely feasible task.

Operating principle

All types of solar collectors can be used to heat a residential building or other facility, but the principle of their operation, regardless of the design and type of coolant, is the same.

The principle of operation of a solar collector is based on the ability of materials to absorb the energy of the sun in visible and invisible ranges to the human eye, and therefore, within a given material, physical processes begin, molecules begin to move faster, the material (substance) heats up. The heat generated by materials exposed to the sun's rays is transferred to the coolant for subsequent use.

Briefly about the main thing

A solar collector is a climatic device for collecting and transferring heat from solar energy to the coolant of a heating system. Devices of this type are liquid and air, flat and vacuum. The general scheme of their operation is that the coolant located in the internal tubes is heated by the heat of sunlight, and then enters the heat exchanger and transfers energy to heating or hot water supply.

The thermal collector can be used for various purposes - heating water for domestic needs, heating a house, greenhouses and utility rooms, maintaining the thermal regime of tanks, creating an alternative heating system, reducing the costs of the main heating system. The advantages of the equipment are profitable heat production, independence from external energy sources, high efficiency, quick payback, durability, operation in cold weather, harmlessness. Disadvantages - high cost of equipment and installation, possibility of damage by wind, probability of heat loss.

Solar collectors are classified according to a number of criteria:

- The structures are flat, vacuum.

- Coolant heating level – low, medium and high temperature.

- Method of application - active and passive.

- Heat transfer scheme - direct and indirect.

It is necessary to select and install equipment based on special rules, recommendations and specific conditions of use.

From a refrigerator radiator

There is a description on the Internet of a homemade solar collector with a refrigerator radiator. The manufacturing process as a whole is described above; let us briefly recall the main points:

- You can place reflective material (foil) in the inner surface of a tightly closed insulated box, but here it is fixed on a black rubber mat. This is also an effective option, since a dark color attracts rays better and accumulates heat.

- We place the coil inside the body, cover it with glass (you can use screws as stops), and place it so that the rays fall at right angles.

- We connect the PP pipes to the inlet for cold water and the outlet to the shower tank for warm water. And also the liner can be the most basic - from flexible, rubber hoses.

- Shower tank - any suitable container.

Classification by design differences

Vacuum collectors are divided according to the type of glass tubes and the parameters of heat channels. Tubes usually come in two categories:

- feathers;

- coaxial.

And the channels can be direct-flow U-shaped and heat pipe varieties (see below).

Coaxial Vacuum Tubes

This is a classic “thermos” - a flask in which a vacuum is created between double glass walls. In addition, the inner surface of the flask is covered with a special heat-absorbing layer. They are made from high-strength borosilicate glass with good light transmission. Such vacuum tubes for a solar collector must last at least 15 years, cope with a pressure of 1 MPa and not be afraid of bad weather conditions.

The absorber is a hollow copper rod filled with ether. When heated, the ether evaporates, rises, transfers the accumulated heat and falls down as condensation. The process is then repeated, ensuring continuous heat exchange inside the module.

Feather

Their walls are thicker than coaxial ones and consist of a single bulb. The copper absorption element is framed by a corrugated plate with a heat-absorbing layer. This allows the vacuum to be located directly in the module channel.

The efficiency of such a tube is higher, but the feather system is more expensive, and it is more difficult to replace it in the event of a copper absorber failure or a leak in the flask. But this option is considered the most reliable, efficient and durable among similar devices.

Heat pipe technology

Modules made using this technology contain tubes with evaporating liquid coolant. When heated by steam, it rises to the top and is collected in a manifold - a heat collector. Here the carrier gives off heat, settles, and the cycle repeats. From the manifold, the carrier transmits energy throughout the system, providing heating in heating and hot water circuits.

The working element of such a channel is made of copper, less often - of aluminum. The service life must be 15 years. The cost of a hit-pipe solution is relatively low and makes it the most popular option for creating modern tubular solar systems. If any component becomes damaged, it can be easily replaced without disassembling the entire complex. Repairs can be carried out on site with a minimum of tools.

Direct flow U-shaped exchangers

As the name implies, the tube of such a heat exchanger is similar to the letter U. Either the working fluid of the coolant or the water of the system circulates in it. In this case, one part of the component works with a heated medium, the other with a cold medium.

When heated, the composition expands and enters the storage tank; In this way, simple fluid circulation is ensured. An effectively heat-absorbing coating is applied to the internal walls of the storage tank.

These tubes are very effective, but have a drawback: they are structurally integral with the manifold and are installed only together with it. Replacing one damaged tube is impossible; to do this, you will have to remove the entire system.

Sequence of installation of a solar heating system for solar heating

After purchasing or making your own solar collector for heating your home, you can begin installing it.

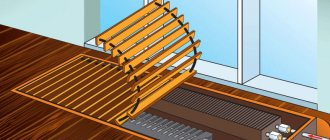

Installation begins with the installation of a storage tank with a capacity of 20-40 liters. You can also use several small tanks that are connected in a series chain using pipes. The tank should be insulated to avoid rapid loss of thermal energy. The storage tank is located at the highest point. It should be taken into account that when the system is filled with liquid, the structure will have significant weight, which will require reinforcement of the overlap at its location.

Next, you install a solar collector with your own hands for heating water, which is located on the south side of the building at an angle relative to the horizon of 35-45°. The system is then connected with pipes, which is necessary to obtain a closed hydraulic circuit. For this, inch or half-inch elements are used. Smaller diameter parts are used to organize the pressure part of the system. Pipes must be insulated, which will reduce the likelihood of heat loss.

In order for the collector to work efficiently, it is necessary to correctly assemble and install the structure

Important! The efficient operation of the heating collector depends on the tightness of all connections.

Upon completion of installation, the system is tested. It is filled through a pipe at the bottom of the collector, which will eliminate the possibility of air locks. The coolant enters the storage tank until the optimal level is reached, which is regulated using a float valve. The heated liquid will rise in the front chamber and enter the heating system. Natural circulation occurs until the temperature of the fluid entering the radiator and that leaving the manifold are equalized.

When arranging a hydraulic system, it is necessary to install shut-off valves that prevent the reverse circulation of the coolant into the storage tank from the manifold. This phenomenon occurs when the ambient temperature decreases, which is typical for the evening or night time.

We equip housing correctly

To preserve heat in the house, you should pay attention to the choice of interior doors. Where can you buy interior doors so that you don’t regret your purchase for a minute? How to protect yourself from possible counterfeits and unscrupulous manufacturers? What to do if you are ready to invest a sufficient amount of money to buy interior doors, but are not inclined to trust specialists with low qualifications? The conclusion in this case is simple - turn to the services of a company that sells a wide range of models of interior doors, represented by various design solutions and manufacturers. Our range is constantly expanding and updating, and the high qualifications of our staff are beyond doubt.

In our store you can always find interior doors designed in line with the main trends of traditional classics or corresponding to one of the many trends in modern interior design. Each product is not only equipped with reliable, functional and effective fittings, but also has a certificate of quality compliance with the main existing standards. By purchasing interior doors from us, you thereby give preference to absolutely harmless products made from environmentally friendly raw materials.