In the context of the continuous increase in housing and communal services tariffs, saving on heating and hot water supply is a pressing issue for many households. With the development of technology, new alternative ways of obtaining energy from light are emerging, providing maximum effect with minimum heat loss. One such method is a vacuum solar collector. You can either assemble it yourself or purchase ready-made options from sellers.

Principle of operation

The idea of capturing and converting light energy is not new. Wind power plants and solar panels have been successfully operated in the world for quite a long time; the latter, in regions with a large number of clear days, make it possible to ensure an almost completely autonomous supply of homes, commercial premises and equipment.

A classic solar battery receives and converts the light falling on it into electricity. Next, the energy goes to the consuming devices. The vacuum solar collector is designed differently: it consists of strong glass tubes with air evacuated to form a vacuum. The tubes are combined into a system.

Inside such a glass tube there are one or two copper rods with a coolant enclosed in them. The rays falling on the copper heat it up, and the heat is transferred to the wearer. In this way, solar energy is captured and stored. The design allows for high energy efficiency with low losses. This happens thanks to a vacuum: since there is no medium that takes away heat, almost all of it remains in the carrier. Such a solar collector retains approximately 95% of the energy it captures.

Liquid or air can be used as a coolant. The first option is the most common.

The design also reduces dependence on weather and ambient temperature. In winter, the complex will work as efficiently as in summer. At the current rate of steady growth in prices for organic energy sources, a solar installation for heating a house will pay for itself, on average, in 3–5 years, and will last about 25. That is, its owner, after a relatively short time, will begin to receive energy for free.

We recommend reading: can you make a solar battery with your own hands from improvised materials?

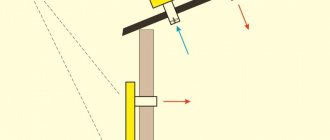

The operating principle of a vacuum tube type SKE.

The key to the operation of the solar system is the glass vacuum tube. Each vacuum tube consists of two glass flasks.

The outer bulb is made of extremely strong borosilicate glass that can withstand the impact of hail that falls at a speed of 18 m/s and has a diameter of up to 35 mm.

The inner flask is also made of borosilicate glass and covered with a special three-level coating with a gradual change in the absorption layers ALN/AIN-SS/CU. Through the use of new technologies, a high absorption coefficient and low repellency are achieved, which allows you to reach +380°C in the middle of the tube in direct sun, without harming the product itself.

Air is pumped between two glass bulbs to create a vacuum, which prevents reverse conduction and convective heat loss. In the middle of the glass flask there is a hermetic heat pipe (HEAT PIPE), made of pure red copper, in the middle of which there is a low-boiling and evaporating liquid, which performs the function of transferring heat to the coolant. The figure below shows the working principle of a vacuum tube.

The main intensity of solar radiation under terrestrial conditions is in the spectral range 0.28 µm – 3 µm. Borosilicate glass transmits solar radiation waves in the range of 0.4 microns - 2.7 microns. Penetrating through the outer transparent flask, the energy is retained in the second flask, on which a highly selective opaque absorber layer is applied.

As a result of the absorption of light by the absorber and its subsequent emission, the wavelength increases to 11 microns. Glass is an impenetrable barrier to electromagnetic waves of this length. Solar energy entering the absorber is trapped. By absorbing solar radiation, the absorber, even without an external flask, can heat up to a temperature of +80°C. The absorber heated to this temperature emits thermal energy, which, penetrating through the body of the second flask, is transferred to the HEAT PIPE. Due to the occurrence of the greenhouse effect, which is based on the accumulated energy under the glass, in the middle of the second flask the temperature rises to +180°C. This heat heats the low-boiling and evaporating liquid, which at +25°C - +30°C, turning into steam, rising, transfers heat to the working part of the HEAT PIPE, where heat exchange with the coolant occurs. The heat release causes the steam to condense and flow into the bottom of the HEAT PIPE, and the cycle repeats again.

The high heat transfer coefficient of an easily boiling and evaporating liquid, its small quantity and relatively small dimensions of HEAT PIPE provide effective thermal conductivity. HEAT PIPE works as a thermal diode. Thermal conductivity is very high in one direction (up) and low in the opposite direction (down).

In order to maintain a vacuum between two glass flasks, a layer of barium is applied to the lower inner part of the flask. It actively absorbs CO, CO, N, O, HO and H during tube storage and operation. The barium layer also provides a clear visual indication of vacuum status. White color means that vacuum conditions have been violated.

The ideal combination of vacuum and thermal copper tubes gives us the following advantages over flat-plate collectors:

High thermal efficiency. thanks to modern heat transfer methods, high-quality absorbent coating.

Wide range of work: thanks to the low thermal capacity, it is able to work in high clouds (in the infrared range of rays that pass through the clouds).

Each tube works independently of one another. Since antifreeze does not flow into the middle of the tube, and its access is limited by the heat exchanger, in the event of physical damage, the manifold continues to operate.

Less weight of the collector with better operating efficiency of the collector itself.

Better work efficiency in winter thanks to vacuum. The tube can withstand temperatures as low as -50°C.

Operating temperatures

Collectors are divided into types according to the temperature of the working environment:

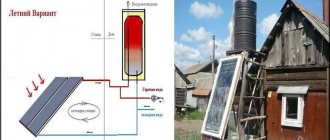

- low-temperature - in them the coolant warms up to 50 degrees. They are used for heating containers with water for irrigation, arranging summer baths and showers, creating comfort in cool spring or autumn, and other tasks that do not require high temperatures;

- medium temperature, heating up to 80 degrees. From this point on, the solar collector can be used for space heating (including in winter), and similar options are common in private house projects;

- high-temperature, where the media is heated up to 300 degrees. Such systems are used in commercial buildings, workshops and other similar places. High-temperature complexes require a complex mechanism for accumulating and transferring heat and take up a lot of space, which is why they are not suitable for private household tasks. In addition, they are labor-intensive to manufacture and install, requiring special tools and appropriate skills.

Scope of application

Vacuum solar collectors are used wherever it is necessary to provide heat and hot water in conditions of limited fuel, the impossibility of supplying traditional communications or the instability of their operation. They are installed at various sites:

- agricultural production;

- enterprises;

- medical institutions;

- sanatoriums and other health centers;

- kindergartens, schools, summer camps;

- tourist destinations and hotels;

- private and apartment buildings;

- office buildings;

- railway transport and the like.

A device such as a vacuum solar collector will work wherever there is daylight and a cold water supply to the facility. With its help the following problems are solved:

- organizing seasonal and year-round supply of hot water to facilities;

- modernization and optimization of existing water supply infrastructure;

- standby and full heating of premises;

- heating of swimming pools;

- heating for agricultural needs (nurseries, incubators, etc.);

- preparation of technical heated water, etc.

You can learn in detail how to use a solar collector to heat a swimming pool.

How does a solar collector work?

There are various options for implementing vacuum devices that convert solar energy. Main types of collectors:

- without the use of protective glass - it is tubular;

- device with reduced conversion;

- flat;

- with transparent thermal insulation;

- air device;

- flat vacuum.

All these devices are structurally similar and carry the following basic components:

- transparent vacuum tube;

- a heated pipe mounted in it, where the working coolant circulates;

- prefabricated distributors connected to larger diameter pipes. They contain the circulation circuit of the internal tubes.

In a simplified way, the design can be imagined as an ordinary thermos with transparent walls through which light falls on the inner flask. Thanks to the vacuum between the walls and the flask, the latter warms up well and transfers almost entirely the heat to its contents.

The correct operation of the complex can be controlled by a circulation pump. This element will ensure safe and coordinated interaction of all parts of the solar collector. An automated control system for the heating complex monitors the temperature and, if it falls below the permitted level (for example, at night), the pump stops. This avoids backheating and other related problems.

Flat-plate collectors

A flat solar collector heats the coolant using a plate absorber. It is designed quite simply. Essentially, this is a plate of heat-intensive metal, painted black on top with special paint. A serpentine tube is tightly adjacent (welded) to the bottom surface of the plate, through which the liquid circulates.

Black selective paint provides maximum absorption of sunlight, and their reflection is almost zero. The absorbed rays heat the coolant under the absorber, which, in turn, is fed further into the system. To minimize heat loss, thermal insulation of the absorber from the collector body and tempered glass, which contains almost no iron oxides, are used. It is installed above the absorber and serves as the top cover of the housing. In addition, the use of such glass allows you to create a kind of “greenhouse effect”, which further increases the heating of the absorber, and therefore the temperature of the coolant.

Classification by design differences

Vacuum collectors are divided according to the type of glass tubes and the parameters of heat channels. Tubes usually come in two categories:

- feathers;

- coaxial.

And the channels can be direct-flow U-shaped and heat pipe varieties (see below).

Coaxial Vacuum Tubes

This is a classic “thermos” - a flask in which a vacuum is created between double glass walls. In addition, the inner surface of the flask is covered with a special heat-absorbing layer. They are made from high-strength borosilicate glass with good light transmission. Such vacuum tubes for a solar collector must last at least 15 years, cope with a pressure of 1 MPa and not be afraid of bad weather conditions.

The absorber is a hollow copper rod filled with ether. When heated, the ether evaporates, rises, transfers the accumulated heat and falls down as condensation. The process is then repeated, ensuring continuous heat exchange inside the module.

Feather

Their walls are thicker than coaxial ones and consist of a single bulb. The copper absorption element is framed by a corrugated plate with a heat-absorbing layer. This allows the vacuum to be located directly in the module channel.

The efficiency of such a tube is higher, but the feather system is more expensive, and it is more difficult to replace it in the event of a copper absorber failure or a leak in the flask. But this option is considered the most reliable, efficient and durable among similar devices.

Heat pipe technology

Modules made using this technology contain tubes with evaporating liquid coolant. When heated by steam, it rises to the top and is collected in a manifold - a heat collector. Here the carrier gives off heat, settles, and the cycle repeats. From the manifold, the carrier transmits energy throughout the system, providing heating in heating and hot water circuits.

The working element of such a channel is made of copper, less often - of aluminum. The service life must be 15 years. The cost of a hit-pipe solution is relatively low and makes it the most popular option for creating modern tubular solar systems. If any component becomes damaged, it can be easily replaced without disassembling the entire complex. Repairs can be carried out on site with a minimum of tools.

Direct flow U-shaped exchangers

As the name implies, the tube of such a heat exchanger is similar to the letter U. Either the working fluid of the coolant or the water of the system circulates in it. In this case, one part of the component works with a heated medium, the other with a cold medium.

When heated, the composition expands and enters the storage tank; In this way, simple fluid circulation is ensured. An effectively heat-absorbing coating is applied to the internal walls of the storage tank.

These tubes are very effective, but have a drawback: they are structurally integral with the manifold and are installed only together with it. Replacing one damaged tube is impossible; to do this, you will have to remove the entire system.

Comparison of various modifications

In the manufacture of solar units, thermal channels and vacuum glass tubes for solar collectors are combined in a variety of combinations.

The most popular among consumers are coaxial models with a heat pipe. Buyers are attracted by the loyal price of the devices and very simple, affordable maintenance throughout the entire service life.

A vacuum solar collector with a heat pipe working channel can be easily repaired. Replacement of damaged tubes is carried out on site and does not involve dismantling the system or moving it to another location. However, heat transfer in these models is difficult, due to which the output efficiency is no more than 65%

Vacuum devices with heat pipe channels demonstrate high reliability and have no restrictions on use even in high-pressure solar thermal complexes.

Devices with a coaxial flask containing direct-flow U-shaped channels are also included in the list of popular ones. They are characterized by such parameters as low heat loss and efficiency of 70% and above.

To function correctly, a vacuum device with a U-channel must be installed correctly. It is desirable that the minimum tilt angle be at least 20⁰. Only in this way will it be possible to ensure maximum return

The situation is somewhat spoiled by: a complex repair process, specific maintenance during operation and the inability to replace an individual damaged unit. If something happens to the device, it is dismantled and a completely new collector is put in place.

Feather tubes are structurally a single cylinder made of glass with thickened, strong walls (depending on the manufacturer, from 2.5 mm and above). The feather absorbent insert contained inside tightly fits the working channel, made of heat-conducting metal.

Almost perfect insulation is created by the vacuum space inside the glass container. The absorbent transfers absorbed heat without loss and provides the system with an efficiency of up to 77%.

In the event of a malfunction, manifolds equipped with feather tubes must be repaired. There is no need to change the entire system; it is enough to find a damaged unit, dismantle it and put a new one in its place

Models with a feather element are somewhat more expensive than coaxial ones, but due to their high efficiency they provide complete comfort in the room and quickly pay for themselves.

The most efficient and productive are feather flasks with internal direct-flow channels. Their actual efficiency sometimes reaches record levels of 80%.

When installing feather tubes into the frame, a strong crimp nut with a ring and a heat-resistant gasket is placed on the rod of each part. This ensures the tightness of the entire structure and allows the collector to fully function in any conditions

The price of the products is quite high, and when carrying out repairs, it is necessary to drain all the coolant from the system and only then begin troubleshooting.

Advantages and disadvantages of vacuum manifolds

The main advantage of this class of devices is minimal operational heat loss due to vacuum, an ideal natural insulator. Among other advantages:

- efficient operation of heaters at temperatures down to −30 degrees and below, which makes them suitable for winter use;

- heat collection with heating up to 300 degrees inclusive (for large industrial designs);

- reliability and durability;

- absorption of both light energy and invisible thermal radiation;

- resistance to adverse weather conditions;

- small windage and the ability to pass air masses almost freely (due to which the systems are almost not afraid of wind);

- even in areas with a small number of clear days and cold climates they can show high operating efficiency;

- maintainability of common heat pipe solutions at a high level;

- the solar battery remains operational even without a controller (or when it is turned off).

Installing one or more such devices makes it possible to significantly save on heating and hot water supply to any objects and buildings that need it. On average, water heating costs are reduced by 60%, and heating costs by 30%. Optimization and reduction of costs for operation and support of communications is also achieved. The vacuum solar collector acts as an autonomous heat source and provides consumers with hot water even during gas or power outages.

Another benefit is extending the life of existing heating systems. The load on them is reduced, and the boiler, for example, can last up to two times longer: the solar collector reduces the load on it to 97% of normal. The same applies to gas boilers. At the same time, vacuum solar modules are easily integrated into existing communications. You can plan their installation at the planning stage of the facility being built.

An important bonus is environmental friendliness. The class of devices under consideration does not produce harmful emissions, does not pollute the environment and uses a virtually inexhaustible source of energy - sunlight. In this case, every joule entering the system is used optimally.

Interesting: it is believed that by 2022, about 20% of the world's electricity demand will be met by the sun. This is especially true for regions with intense solar radiation and a large number of clear days. On average, about 3 million solar energy systems are put into operation per year.

We also note its disinfecting properties: heat kills many harmful microorganisms, and the vacuum also makes it difficult for them to reproduce.

But there are also disadvantages. These include the high cost of purchasing components and tools for self-assembly, as well as the inability of inexpensive tubular complexes to self-clean from snow, ice and other contaminants that have stuck/frozen in winter. Although there are options with anti-freeze modes, and samples with other additional capabilities.

Types of solar panels

Solar systems are classified according to the design features of the tubes and the type of thermal channel used as a receiver:

1. The coaxial model of a vacuum solar collector for heating a house is a double glass flask, in the cavity of which air has been evacuated. An absorbent coating is applied to the surface, so energy transfer occurs from the tube itself.

2. The feather structure is single-walled; the void here is located in the space of the thermal channel, part of which, together with the storage device, is integrated into the flask.

4. In systems with forced circulation, a low-power pump is installed to promote the movement of the media. At the same time, the power consumption is significantly less than the energy received for heating a private home.

5. There is also a difference in the number of circuits. In the simplest collectors, water for heating is heated and consumed from a storage tank.

6. More complex ones consist of a vacuum tube and liquid selection elements. The device contains a non-freezing and non-toxic carrier with anti-corrosion and anti-foam additives. This method reliably protects the equipment from salts and scale and promotes longer operation during heating.

Review of models and their characteristics

At the moment, China holds the lead in the production of solar energy collectors. According to reviews from private home owners, domestic manufacturers also sell equipment with good characteristics. European devices are quite expensive, but over time the costs of purchasing and installing devices are justified. The most well-known companies produce the following collectors:

Plumbers: You'll pay up to 50% LESS on your water bills with this faucet attachment

Collectors Dacha and Universal are the most famous devices of the domestic manufacturer. SCH-18 has high efficiency with condensate temperatures up to 250°C. The flasks are made of red copper, the coolant is liquid. The absence of water in a vacuum ensures resistance to freezing. The durable body resists wind well. The pipeline is protected by a polyurethane manifold. Rubber anti-dust seals prevent dust and precipitation from entering.

They work effectively at temperatures down to -35°C, the type of functionality is a pressure system for heating. There is a controller for controlling the heater, tube size is 1800 mm, tank volume is 135-300 l, heating element power is 1.5-2 kW. The collectors are manufactured in accordance with international certifications, which ensures their safety and reliability.

Self-assembly

To begin creating a vacuum manifold, you need to assemble the frame. It is advisable to install it immediately where the future heating complex will be located. The dimensions of the frame depend on the planned characteristics of the future system and the model being assembled. As a rule, detailed instructions are specified in the instructions supplied with the components.

Important: there must be thermal insulation at the bottom of the box of the future collector.

Example project for assembly:

When assembling the frame on the roof, it is additionally reinforced with sealant in the contact areas. This is necessary to protect against water ingress through the mounting holes. Next, the storage tank is put in place and attached to the frame.

Next, the air vent, heating element and temperature sensor (if equipped) are installed. All components are installed on softening pads (must be included in the kit). After this, it is necessary to connect the building’s water communications to the system - for this, fittings and pipes made of polypropylene are usually used; such fittings are quite durable, durable and can be easily replaced if they fail. Pipes must withstand temperatures up to 95 degrees.

When the water supply is connected, water is poured into the storage tank and the tightness of the complex is checked for several hours. If leaks are found, they should be repaired immediately. The final stage is the installation of heating modules. A copper tube is placed in a vacuum glass flask, and the structure is fixed from below with a cup and a rubber boot. The tip of the copper tube is pushed into the brass condenser until it stops, then the locking mechanism snaps onto the bracket.

The installation of the remaining tubes follows the same principle.

After this, the mounting block (if provided) is connected to the system. It is supplied with power from a 220 V network. Auxiliary modules are also connected - temperature sensor, air exhaust and heating element. At the final stage, the control controller of the complex is installed (also if provided). The necessary settings are made into it, after which the new heating system starts working as usual.

All the main parts can be assembled yourself. But if you have no experience in plumbing and installation work, it is better to turn to factory components, since a complex assembled “from scratch” may contain significant flaws and not provide the required efficiency. On the Moscow market, a ready-made set of a heater for 30 vacuum tubes connected to a cold water supply with a tank with a volume of 260 liters costs about 90 thousand rubles.

Where is the best place to place it?

For effective and complete operation, the vacuum solar collector must be correctly placed and oriented to the cardinal points. In northern latitudes, it is advisable to install the device on the sunny side of the land or in the southern part of the roof. If it is not possible to orient exactly to the south, you should choose the most illuminated position in the direction of the west or east.

Important: the solar energy complex should not be blocked by trees, chimneys, decorative parts of the roof, neighboring houses or other buildings. This can significantly reduce efficiency. If positioned correctly, the heater will provide excellent heat transfer throughout the year, regardless of the season.

Model overview

Summer resident

Collector Summer Resident

This model costs about 18,500 rubles. This collector is capable of heating water up to 95 degrees and is perfect for country houses. Has a 12 month manufacturer's warranty. This time is enough to ensure its reliability.

This model has the following technical characteristics:

- The 100 liter tank is made of high quality stainless steel.

- The vacuum tube is 150 cm long.

- Tube diameter (external) 4.8 cm.

- The maximum possible pressure in the tube is 0.6 MP.

- The design is resistant to hail up to 0.5 cm.

- The tubes are made of borosilicate glass, which has an absorbing effect.

- The total weight of the collector is 45 kg.

Equipment:

- set of anthers (sealing) – 1 pc.;

- vacuum tubes – 16 pieces;

- frame and set of bolts – 1 pc.;

- expansion tank – 1 pc.;

- thermos tank 100 l. - 1 PC.;

CP-II-20-175 from ANDI Group

Manifold CP-II-20-175 from ANDI Group

The kit includes:

- Solar collectors

- water tank with a volume of 175 l., the internal circuit is made of stainless steel, and the external circuit is made of galvanized painted steel;

- vacuum tubes – 20 pcs.;

- TNC-2 (controller).;

The thermal insulation of the tank is made of polyurethane (50 mm). Internal diameter 36 cm, external 46 cm, steel frame 1.5 mm thick, galvanized. Net weight of the unit is 86 kg.

Homemade collector

Homemade collector

To make a collector you will need:

- Vacuum tubes - the quantity is determined by the designer. Industrial tubes are used.

- Block concentrator - depending on the number of tubes, one or another size of the device is selected. An industrial production unit is used.

- Materials for making the frame.

Manifold components

The collector frame is made; for this you can use lumber or metal profile elements. The concentrator and vacuum tubes are mounted on the frame in the following sequence:

- Heat-conducting plates and plugs are placed on the copper rod.

- The rod is installed in a vacuum flask.

- The fixing cups are put on.

- A protective boot is put on.

- The rod is placed in a block concentrator.

- The process is repeated with the next tube.

After assembly, the solar collector is mounted on a prepared plane, and the following conditions must be taken into account, such as:

- during installation, the collector should be oriented to the south;

- create conditions to prevent shading of the collector;

- create protection against overheating;

- securely fasten the collector to the prepared surface.