It is impossible to create a full level of comfort in a private residential building without a properly designed and installed water supply system. The best option is considered to be a radial water supply scheme in the house. To implement this, a water supply collector is used. After reading to the end, you will find out what kind of device this is. Let's consider why it is needed, design features and operating principle, existing classification, main installation points.

Installed collectors for water distribution Source platformalp.ru

Definition of the term “collector”

Water in the house always flows into the bathroom and kitchen. However, they still cannot do without it in a bathhouse, swimming pool, sauna, shower, and so on. Water supply must be ensured for all consumers, which are, for example, a sink, toilet, dishwasher and washing machine.

The water collector is a technical element. This part of the indoor water supply network is also called the comb. It is installed at the beginning of the system with cold and/or hot water. The installation of this important element is carried out, for example, in the boiler room of a private house or in a room where water treatment is carried out.

When choosing the installation location, free access to the water collector is ensured. It should not subsequently be cluttered with furniture and other objects. The comb cannot be tightly sewn into the building structures of the house. Often such a technical element is covered with a decorative false panel to improve the plumbing unit.

The presence of a collector in the water supply system of a house allows water to be delivered to each water distribution point. Their number is individual in all private residential buildings.

Mounted collectors in a private residential building Source oventrop-home.ru

A simplified version is two sinks, a bathtub and a toilet. Although modern houses have several toilets and bathrooms. Many homeowners combine such premises and install a large number of additional household devices, the operation of which is carried out only after connecting to the water supply.

Manufacturers

The production of water collectors is carried out by leading companies in the plumbing industry. However, when choosing components for plumbing, consumers rarely pay attention to this. It’s better to find out in advance which companies supply reliable and durable collectors. In this case, they will not require regular maintenance and frequent replacement. Manufacturers of the most popular and durable collectors include:

- Far. Italian brand of plumbing components. The cost of their collectors is affordable, while the quality is high. On average, you will pay 1000-1500 rubles for a comb for 2-3 outlets. The most expensive one - for a water supply system in the catalog costs 6300 RUR.

- Rehau. Another manufacturer of plumbing fixtures and everything connected with it. Often professional plumbers or people who are familiar with German quality turn to him. Despite the high cost, Rehau is actively purchased by the population. Models have nipples for clamping connections. This manufacturer selects exclusively safe and high-quality brass that can withstand high pressure.

- Tiemme. Another manufacturer of plumbing fixtures and accessories. This Italian brand produces inexpensive but high-quality manifolds. They are usually chosen by plumbers. The cost of a comb for a water supply system for 2 outlets is 500-700 RUR, for 3 - 800-1000 RUR.

- Stout. Russian brand with factories in Italy, Spain and Germany. Since 2014, it has been producing plumbing accessories. Stout is well known in the CIS countries. The products are valued for their quality and cost.

- Oventrop. Another European manufacturer of sanitary accessories. It is famous for its highly qualified employees who design manifolds. The cost is affordable.

- Valtec. A company engaged in the production of plumbing components since 2005. They specialize exclusively in plumbing fixtures.

Design and principle of operation of the collector

The main function of the comb collector is to distribute water to all plumbing fixtures. With the help of this element, the total flow is distributed into several parts that will not differ in pressure.

Manufacturers make combs with multiple outlets. Their number ranges from 2 to 4 pieces. When it is necessary to distribute water to more devices, then the devices are connected to each other. In this case, they focus on the required number of branches. If there are more of them, then unnecessary outlets are closed with plugs.

Comb with three branches Source leroymerlin.ru

The comb is made in the shape of a cylinder. Therefore, a collector is a pipeline whose diameter is larger than the cross-section of the connected pipes. At one end of this plumbing device there is an internal thread, and on the other side there is an external thread. This design allows the combs to be interconnected and connected to a supply line with hot or cold water.

The free end of the plumbing fixture is closed with a plug or an additional device is installed in this place. This is, for example, a device to prevent water hammer.

The cross-section of the comb inlet is always larger by 20% or even 40% of the diameters of the branches. Distribution devices with 3/4 inch inlet are often installed. Moreover, their outlets are 1/2 inch in size.

It is possible to mount a water supply manifold, whose outlet openings are equipped with taps or valve mechanisms. Both options allow you to shut off the flow in each branch. Using valves, you can also regulate the water supply power.

Water distribution device with four valves Source feko.com.ua

See also: Catalog of companies that specialize in water supply, sewerage and related work

Purpose

A warm floor is usually a system that includes several heating circuits - at least one for each room. With a large floor area or to control heating separately in different zones of the same room, two or more circuits are used.

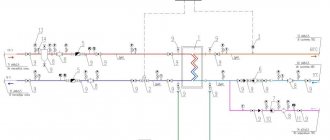

Heating comb, distribution manifold - names of the device that ensures the flow of coolant into the circuits of the floor heating system. The distribution unit consists of two combs - one of them is responsible for distributing the coolant heated by the boiler over the connected heating circuits, the second collects the cooled coolant and supplies it to the return pipe for return to the boiler.

Mounted distribution unit Source ad-cd.net

In addition to the main function of distributing and collecting coolant, the collector unit can solve a number of other problems. Depending on the configuration, it can:

- be responsible for deaerating the system;

- ensure regulation of the coolant supply in the required volumes;

- regulate the flow of circulating fluid using manual or automatic flow meters.

This allows you to maintain optimal temperature conditions in each room, depending on the requirements for the microclimate, and eliminate airing of the heating system, which results in a decrease in the efficiency of its operation. Shut-off valves are also installed on the supply and return manifolds - through them the circuits are filled with coolant, the system is pressure tested, and the liquid is drained.

Manifold group with automatic air vents Source tvo.by

Advantages of installing a collector device

Distributing water to each consumer according to the classical scheme using tees is cheaper than collecting water pipes. However, the use of combs has a number of advantages.

Distribution devices allow you to regulate the pressure in each branch. If you install a water supply system according to the classical scheme, then a decrease in pressure often occurs in an open mixer, for example, above a bathtub. This situation can occur when someone in the house uses the toilet, washes dishes in the kitchen sink, or turns on the washing machine.

The pressure difference will cause a change in water temperature. This leads to discomfort while taking a bath. A person can even get burned due to the increase in water temperature. A water collector for plumbing helps to avoid situations. It prevents pressure drops in the home system.

The use of a comb collector reduces the likelihood of a sharp change in water temperature in an open tap Source 299999.ru

Combs with valve mechanisms on the branches to regulate the water supply in each branch allow you to repair faulty plumbing fixtures. In this case, there is no need to shut off the entire water supply system.

The use of comb collectors also allows you to reduce the number of joints in the water supply. Thanks to this wiring scheme, the likelihood of leaks in the house is reduced. After all, a single pipeline can be laid from the collector to each water collection point.

In addition, combs allow you to quickly install additional plumbing if necessary. In this case, there is no need to redo the existing system.

However, the collector distribution of water supply pipes is characterized by high consumption of materials. Its implementation requires almost 8 or even 10 times more pipelines than for installing a water supply system according to the classical scheme. To reduce the cost of creating such a system, it is recommended to use pipes made of metal-plastic or polypropylene.

If there are collectors, separate water pipes are supplied to all plumbing fixtures Source kotel02.ru

Protection against water hammer in the apartment's water supply system.

To protect the apartment's water supply system from water hammer in the collector system, it will be necessary to install a water hammer compensator. Such a compensator is a kind of damper and the pressure surge is absorbed in it. The compensator consists of a piston and a spring; when the tap is suddenly closed, the excess pressure is compensated by the spring-loaded piston.

It's worth remembering, however. Such a compensator should be located where water will constantly circulate past it, otherwise water will stagnate in this area and pathogenic organisms will begin to develop. Those. It is impossible to remove the compensator on a blind pipe from the collector.

Classification of distribution manifolds

Manufacturers produce combs from various materials. They differ in design. Currently available on the market:

- Stainless steel devices that are lightweight, corrosion resistant, and able to withstand high temperatures and open flames. The attractive steel used does not pose any danger to humans.

- Polypropylene lightweight devices that do not rust.

- Durable brass combs are corrosion-resistant plumbing elements. They are expensive, but allow you to distribute even very hot water.

Manufacturers produce comb collectors in which the center-to-center distance between branches can range from 36 to 100 mm. The devices also differ in the way the pipes are connected to the branches. There are several options:

- thread;

- eurocone - for connecting most types of pipes through a special adapter;

- polypropylene bends - intended for soldering pipelines made of the same material;

- compression fittings - allow you to connect metal-plastic pipes.

Manifold with compression fittings Source bavariaplus-remont.ru

Criterias of choice

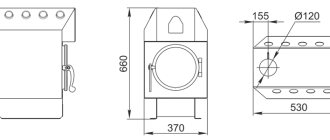

When choosing a heating distribution manifold for an underfloor heating system, you need to know in advance how many circuits you plan to connect. It is recommended to select devices with a reserve of one or two outputs in order to be able to adjust the system design and split an extended circuit into two branches or connect additional equipment (pressure gauge, thermometer). No more than nine loops can be connected to one collector; if there are more loops, two or more distribution blocks are installed.

Maximum comb size Source sgon24.ru

Next, you should pay attention to the material used to make the comb. Reliable and durable cases are made of stainless steel, chrome-plated or nickel-plated brass, and bronze. It is recommended to give preference to products manufactured in accordance with Russian GOSTs, or products from well-known manufacturers that have a certificate of compliance with European standards. Each comb should be carefully inspected to identify possible flaws - cracks, corrosion, surface defects.

The list of reliable brands includes: Kermi, Valtec, Rehau, Valliant, Rossini, FIV. When purchasing branded products, it is advisable to buy ready-made manifold blocks so as not to overpay for individual parts and to avoid problems associated with the incompatibility of elements from different manufacturers.

Cranes and other components

When choosing a collector for water supply, professionals will always help you determine which is best from the existing range. Specialists will take into account the allocated budget and the material of the pipes from which the wiring in the house will be created. In addition, simultaneously with the comb, all components are selected to create a full-fledged distribution unit of the water supply system:

- valves;

- pressure gauges;

- pumps;

- valves;

- fasteners;

- plugs;

- couplings;

- filters;

- counters;

- fittings.

Manufacturers also produce manifold cabinets. They are built into the wall or mounted on its surface. Their use allows you to improve the distribution unit and provide free access to it.

Combs are produced with and without taps. When using the latter option, you still have to install shut-off valves, but they can always be replaced when a breakdown occurs. If you choose a collector with built-in taps, you will have to completely change the distribution element of the water supply system.

Manifold-comb without taps on taps Source komsis.su

Video description

The capabilities of the collector, its configuration and operation are shown in the video:

Adjusting the supply of working medium

Flow meters (rotameters) make it possible to ensure uniform heating of loops regardless of their length, even if circuits that differ markedly in length and hydraulic resistance are connected to the comb.

For short pipelines, the fluid supply is regulated by reducing the passage opening; for long branches, on the contrary, the flow intensity is increased. This parameter is determined on the scale of the balancing rotameter for each circuit, after which the throughput of the flow valve is adjusted.

Adjustable flow meters are installed on the feed manifold only if it is equipped with manual valves for adjustment. They are not necessary if:

- branches of the same length are connected to the collector, and regulation of distributed flows is not provided;

- the collector block is equipped with automatic control valves with servo drives - in this case, the automation is controlled by an electronic thermostat and manual equalization of the heating of the branches is not required.

Installation Features

Before installation work, professionals always first determine:

- Number of consumers. The number of outlets on the comb may be greater, but not less than the water points.

- Type (material) of pipes to each device.

- Installation locations for additional components of the distribution unit. Their attachment points are marked on the wall.

- Necessary consumables and their quantities.

The collector installation process itself is carried out in stages:

- install shut-off valves on the inlet line;

- install check valves, meters and filter elements;

- connect and secure the switchgear;

- lay pipes to each water point;

- connect pipelines to the collector.

All work can be performed with high quality only by professionals. The whole process takes more time than installing a water supply according to the classical scheme.

Installation

Installing the collector is simple, but you need to know some features. It is necessary to prepare fittings and other components in advance: rubber gaskets, fluoroplastic sealing material, adapters. Try to purchase components from the same manufacturer, so the likelihood that you will have to change them will be reduced.

Install a water supply system for consumers in advance, think about where filters, check valves and meters will be installed. When everything is thought out, proceed with installation. Follow gradually, do not try to connect everything at once. Serial connection reduces the load on the joints, thereby reducing the risk of damage. Step-by-step installation instructions look like this:

- Installation of filters, check valves. This is the preparatory stage.

- Installation of distribution unit.

- Installation of shut-off elements that regulate water supply.

- Installation of a circular pump. It is necessary when water is distributed between floors.

- Fastening the comb to the surface using metal clamps.

- Installation of ball valves and meters to control water consumption.

- Attaching a membrane damper that protects against water hammer.

- Installation of fittings and adapters. Secure them to prevent future leaks and breaks.

The presence of the design increases the nominal cost of the water supply system. But it increases the comfort of its use. It is better to consult with a specialist who will select the optimal system and tell you what you need to purchase.

Briefly about the main thing

The manifold is used to distribute the flow evenly to each plumbing fixture. At the same time, the pressure remains constant, even if the flow of hot or cold water unexpectedly increases.

Combs are made of brass, stainless steel and polypropylene. They look like a pipeline with an increased diameter. It is equipped with several outlets with or without taps. The presence of shut-off valves allows you to turn off one of the water points at any time in order to carry out repairs. At the same time, in all other premises water can be used without restrictions.

The installation of the collector is carried out after installing the valve, meter, filter and shut-off valves on the inlet line. A fixed comb is connected to pipelines to each water point.

Tools, materials, dismantling old

Special tools for assembling residential pipelines are described above. To purchase materials, of course, you will need to calculate the footage, nomenclature and quantity locally. Dismantling old pipes is done in the usual ways. It is better to do this after installing and registering the water meter, so as not to turn off water to the floors for a long time.

We will give only one piece of advice: do not use valves with a lever. It is made of silumin or plastic and tends to break off at the most inopportune moment, just when you urgently need to close it. Take ball valves with a butterfly handle. The round, grooved handles also do not break, but wet or sweaty hands slip on them.

How to choose the right comb

In addition to the brand, you need to take into account the material from which the water supply manifolds are made:

- Stainless steel. Characterized by strength, corrosion resistance, low cost.

- Polyethylene. It costs even less than steel, but has one limitation. It cannot be used for installation of heating systems.

- Polypropylene. The material is good for everyone, and the only difficulty arises is that the connection involves soldering using specialized equipment.

- Brass. Strong, durable, versatile material for assembling a high-quality, reliable plumbing system.

You also need to pay attention to the fastening system. Threaded connections require the use of standard tools, which are found in almost every home. The difficulty lies in the need to cut threads on the pipes. Plastic elements require soldering. It is not practical to buy equipment for one-time use. Combined fastening methods involve the use of both tools.

Maximum operating temperature

This parameter indicates the maximum permissible coolant temperature at which normal operation of the collector is guaranteed. In a water heated floor system, the operating temperature reaches 55°C, in a heating system – 90-95°C.

The maximum operating temperature depends on the material used to manufacture the comb:

- brass manifolds – up to 150°C;

- steel collectors – up to 130°C;

- copper collectors – up to 600°C;

- polypropylene manifolds – up to 95°C.

Maximum working pressure

This indicator means the highest coolant pressure that the collector can withstand without deterioration in performance characteristics and premature failure. The operating pressure in the heating system does not exceed 2-5 bar, and in water heated floor systems - 3 bar.

The maximum operating pressure is determined by the material of the device:

- brass manifolds – up to 20 bar;

- steel collectors – up to 10 bar;

- copper collectors – up to 30 bar;

- polypropylene manifolds – up to 10 bar.

Tee distribution of water supply in the house is

Tee wiring of water supply in a house is otherwise called sequential wiring. It can be described as follows.

From the shut-off valves of the internal water supply, two pipes are drawn through the house, hot water supply and hot water supply. I will immediately note that in horizontal sections, the hot pipe is laid higher than the cold one so that condensation does not form.

In places where plumbing fixtures are installed, to their water outlets, branch pipes stretch from the main. The connection to the mains at the outlet points is made using plumbing fittings called a tee. This is where the name of the wiring method “tee” comes from.