One of the methods of connecting heating devices - today it is considered the most modern - involves the presence of an element called a comb.

Below in the article we will talk about how a distribution comb for heating functions and how you can make it yourself.

Areas of application of heating combs

The main purpose of the heating comb is to optimize and rationally distribute the coolant.

Without a correctly designed and installed distribution manifold, the heating may not operate correctly. The comb allows you to use all the useful power of the boiler, while obtaining maximum efficiency of the entire system. Collectors also allow you to include several consumer points in the system and be sure that the temperature of the coolant in all sections of the main will be the same. If you do not use a distribution comb, it often turns out that the radiator near the boiler is very hot, and the radiator, for example, on the second floor, is lukewarm.

This happens because the coolant cools down while it reaches the last battery. This effect can be avoided and the path of the coolant to the end consumer can be reduced by dividing it into specific circuits.

Calculation of comb throughput

The calculation of the parameters of the distribution comb includes determining its length, the cross-sectional area of its cross-section and pipes, and the number of heat supply circuits. It is better if the calculations are done by engineers using computer programs; in a simplified version, they are only suitable at the preliminary design stage.

In order to maintain hydraulic balance, the diameters of the inlet and outlet manifold combs must match, and the total throughput capacity of the nozzles must be equal to the same parameter of the collector pipe (the rule of total sections):

n=n1+n2+n3+n4,

Where:

- n is the cross-sectional area of the collector4

- n1,n2,n3,n4 - cross-sectional areas of the pipes.

The choice of comb must correspond to the maximum thermal output of the heating system. What power the factory product is designed for is written in the technical data sheet.

For example, a distribution pipe diameter of 90 mm is used for a power not exceeding 50 kW, and if the power is twice as high, the diameter will have to be increased to 110 mm. This is the only way to eliminate the risk of unbalancing the heating system.

The 3-diameter rule is also useful (see picture above). As for calculating the performance of the circulation pump, the specific water consumption in the heating system is taken as the basis.

Each pump is calculated separately - per circuit and for the entire system. The figures obtained in the calculation are rounded up. A little extra power is better than too little.

Pros and cons of collector systems

The main advantage associated with the use of collector-type systems is the ease of control and operation. This is due to the fact that each of the elements can be controlled both centrally and individually. Consequently, it is possible to set the temperature for each specific room, and, if necessary, completely deactivate a device or group of devices. Moreover, this will not affect other parts of the system.

Video – Collector heating system

Each of the branches that make up the node must power only one battery (or, alternatively, a separate group of batteries), so the diameter can be insignificant. If necessary, using a collector, you can equip several circuits with different temperature parameters at once. This became possible thanks to the advent of a hydraulic arrow - a type of comb, which is a similar tube, but of a larger diameter.

This arrow is installed differently from a standard manifold - a kind of short circuit is created in the gap between the “return” and the supply. The liquid in the initial circuit will be permanently heated by the boiler and smoothly move inside the hydraulic arrow, as a result of which different temperature and coolant pressure indicators are demonstrated.

But there are, of course, disadvantages. First of all, buying a distribution comb is a very expensive pleasure and this is probably the only reason why these devices scare away potential buyers. The fact is that high-quality steel is used in the production process, which is why the products are much more expensive than steel pipes. In addition, for installation you will also need high-quality shut-off valves (the number of them depends on the number of circuits).

Another drawback is the mandatory presence of a circulation pump, without which the comb simply will not be able to function (read: additional electricity costs).

Setting up a comb for heated floors

After assembly, installation and connection, the comb for a warm floor must be configured - set the required level of temperature and water flow for each individual circuit. With the first parameter, everything is solved very simply - on the thermal head, located at the corresponding outlet in the “return” manifold, the required temperature level is set by scrolling.

With setting the flow rate, everything is much more complicated - each circuit has its own length, and there are no general patterns for adjustment. The fastest way to do this is to perform a hydraulic calculation of sections of heated floors using software that you can get on the website of one of the comb manufacturers.

The flow meter on the supply line in the manifold is equipped with an indicator flask. Under it there is a nut, by unscrewing or tightening which you can increase or decrease the coolant flow rate on the circuit

Hydraulic calculation of the heated floor circuit, on the basis of which you can calculate the flow rate and set it on the corresponding branch of the comb

But if for some reason you do not want to deal with adjusting the flow rate, then there is a simpler, but time-consuming method. It lies in the fact that the adjustment is carried out “by feeling” - if the room is too cool, then the flow rate at the collector increases, if the floor is too hot, then, on the contrary, it decreases. But due to the general inertia of the system, such a process can be seriously delayed. In addition, it must be taken into account that without a preliminary hydraulic calculation it will be impossible to immediately achieve an optimal result.

However, the process of adjusting the flow and temperature of a heated floor is not complicated in itself - you just need to twist the flow meter and thermometer on the supply and return manifolds in the right direction.

What you need to know about the cons?

After the advantages of using distribution combs in heating systems have become clear, it makes sense to dwell on some of the disadvantages:

- High price. Collectors are made of durable, high-quality metal, the cost of which is above average. High-precision locking equipment is also expensive. The more circuits a comb serves, the higher the cost of equipping it.

- Energy dependence. Collector heating without a circulation pump does not work. Therefore, you need to prepare for additional payments for electricity.

- High pipe consumption. The consumption of pipes in collector heating systems is several times higher than in conventional ones, since a separate loop must be pulled to each device. All this complicates and increases the cost of installation work.

The collector system, according to experts and those who already use it, is the most modern, reliable and efficient.

But at the same time, both its arrangement and operation are expensive.

Rules for connecting the distribution comb

The selection of the collector location must be based on the principle of equidistant location of the equipment from it. If this requirement is neglected, then high pressure arises at more extended nodes of the system, which will negatively affect this area. Therefore, the permitted difference in lengths of pipe sections from the comb to the batteries should not violate the 1:2 proportion.

Or, in other words, the length of the pipelines from the first radiator to the collector and subsequent batteries cannot be less than 2 times. If the specified characteristics are exceeded, it will not be possible to ensure accurate operation of the comb. If the house has many floors, the collector is installed on each of them. There are a number of methods for placing the distribution comb in the heating system: in a special installation cabinet or directly on the wall.

When installing the collector on the walls, specialized niches are made in them. To install the heating comb, determine a place above the floor level. In terms of dimensions, the niche must correspond to the dimensions of the comb, taking into account attachments and piping of heating pipelines. The space where the collector is located must certainly be dry. Usually, for these purposes, a corridor or an auxiliary room is chosen, where the distribution system will not disturb anyone.

In case the distributor is located in a transition, it is recommended to place a special metal cabinet with a door and holes for the input/output of pipelines in a niche. This design is usually equipped with special fasteners to securely fasten it.

Areas of application of heating combs

The main purpose of the heating comb is to optimize and rationally distribute the coolant. Without a correctly designed and installed distribution manifold, the heating may not operate correctly. The comb allows you to use all the useful power of the boiler, while obtaining maximum efficiency of the entire system.

Collectors also allow you to include several consumer points in the system and be sure that the temperature of the coolant in all sections of the main will be the same. If you do not use a distribution comb, it often turns out that the radiator near the boiler is very hot, and the radiator, for example, on the second floor, is lukewarm.

This happens because the coolant cools down while it reaches the last battery. This effect can be avoided and the path of the coolant to the end consumer can be reduced by dividing it into specific circuits.

Main manufacturers

On the heating systems market these days you can find a huge variety of models from manufacturers from literally all corners of the planet. However, among them there are also the most remarkable brands, whose products have earned many good reviews:

- Valtec. Valtek solutions are among the easiest to install. The products of this Italian company meet all the highest European quality standards.

- Rehau (Rehau). RehauHLV 5 collectors are designed for installation for dividing the circuits of a building's heating system, and RehauHKV are distinguished by the highest level of wear resistance and reliability. The combs are made of high quality stainless steel.

- HKVD. Collectors of this brand, unlike many, can be not only double-circuit, but 8- and even 12-circuit.

- Far heating combs are inexpensive, non-adjustable models.

- Danfoss. The main feature of this brand are special inserts that allow you to cover one or another contour depending on the need.

- Oventrop. Oventrop collectors are double-circuit and made from high-strength steel.

- Meibes. Stainless steel underfloor heating solutions.

What is a hydraulic arrow

If pumping equipment of significant power is installed in a multi-circuit complex heating system, then even it will not be able to cope with the different conditions and parameters of the network operation. Such inconsistencies in the operation of different circuits will negatively affect the operation of the heating boiler and shorten the service life of expensive equipment.

Branched heating networks cannot work harmoniously due to the fact that each circuit has its own performance and pressure. But even if each circuit is equipped with its own circulation pump, taking into account the parameters of the main line, the problem of system fragmentation will only worsen. This will lead to unbalancing of the networks, because each heating circuit will have its own parameters.

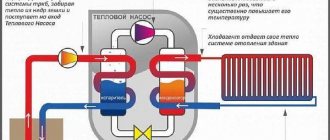

To solve the problem, one common boiler must heat the required amount of coolant, but each circuit must receive the required amount of heated liquid from the collector. In this case, the functions of the hydraulic system separator are performed by the manifold. A hydraulic separator is needed to separate the boiler flow from the general circuit. Another name for a hydraulic separator is a hydraulic arrow or HS (hydraulic arrow).

The name of the device comes from the analogy with a railway switch. Just as a railway switch directs trains in the required direction, a hydraulic switch distributes coolant flows across separate circuits. Externally, the device resembles a piece of round or rectangular pipe with end caps. The device is connected through a pipeline to the collector and boiler and has several pipes in the side.

DIY comb assembly

The collector assembly technology includes the following steps:

- In accordance with the dimensions specified in the project, the required amount of materials is prepared;

- The pipes are connected to each other as specified in the project;

- All pipes must be connected to each other using a suitable tool;

- The pipe connections must be thoroughly cleaned and treated with sealant;

- A manifold assembled by yourself must be checked for leaks by closing all pipes except one and ensuring the supply of water to it - the absence of leaks in the closed pipes indicates that the device has been assembled correctly;

- The finished distribution manifold is painted and dried;

- After the paint has hardened, the device can be installed in the location chosen for it.

Connection rules and installation features

Installation of the comb begins with attaching it with brackets to the wall, where it will be located openly or in a closet. Then you will need to attach the main pipes from the heat source to the ends and begin piping.

Option #1 – without additional pumps and hydraulic arrows

This simple option assumes that the comb will serve several circuits (say, 4-5 radiator batteries), the temperature is assumed to be the same, and its regulation is not provided. All circuits are connected directly to the comb, one pump is used.

The characteristics of pumping equipment must be correlated with the performance of the heating system and the pressure created in it. So that you can choose the best pump that is ideal in terms of characteristics and cost, we recommend that you familiarize yourself with the rating of circulation pumps.

A master with experience in manifold equipment knows how to correctly install a distribution comb and hide it in a cabinet so as to hide all the pipes

Since the resistance in the circuits is different (due to different lengths, etc.), it is necessary to ensure optimal consumption of the coolant by balancing.

To do this, balancing valves, rather than shut-off valves, are installed on the return comb nozzles. They can regulate (although not exactly, but by eye) the coolant flow in each circuit.

Option #2 - with pumps on each branch and a hydraulic arrow

This is a more complex option, which will be needed if necessary to power consumption points with different temperature conditions.

So, for example, in radiator heating, water heating ranges from 40 to 70 °C, a warm floor needs a range of 30-45 °C, hot water for domestic needs must be heated to 85 °C.

In the piping, the hydraulic arrow will now play a special role - a section of pipe that is blind at both ends and has two pairs of bends. The first pair is needed to connect the hydraulic needle to the boiler; the distribution combs are connected to the second pair. This is a hydraulic barrier that creates a zone of zero resistance.

For boilers with a power of 50 kW and above, it is recommended to use a distribution comb together with a hydraulic arrow. It is mounted vertically on the wall with separate brackets to avoid excessive horizontal overload

On the comb itself there are mixing units equipped with three-way valves - temperature control devices. Each outlet pipe operates its own pump independently of the others, providing the specific circuit with the required amount of coolant.

The main thing is that the total power of these pumps does not exceed the main boiler pump.

Both options considered are used when installing distribution manifolds for boiler houses. Everything you need is sold in specialized stores. There you can buy any assembly assembled or element by element (counting on savings due to self-assembly).

To further reduce future costs, you can make a heating distribution comb yourself.

The boiler room manifold is located in close proximity to the heating equipment and is exposed to high temperatures that only metal can withstand.

The local distribution comb is subject to less stringent requirements for heat resistance; not only metal pipes, but also polypropylene and metal-plastic pipes are suitable for its manufacture.

For a local distribution manifold, the easiest way is to select suitable scallops from those that are commercially available. In this case, you should take into account the material from which they are made - brass, steel, cast iron, plastic.

Cast scallops are more reliable, eliminating the possibility of leakage. There are no problems connecting pipes to the manifolds - even the most inexpensive models have threads.

Distribution combs assembled from polypropylene parts are attractive due to their low cost. But in an emergency, the joints between the tees will not withstand overheating and will leak

Craftsmen can solder a manifold from polypropylene or metal-plastic, but they will still have to buy threaded tips, so the product will not be much cheaper in terms of money than a ready-made one from the store.

Externally, it will be a set of tees connected to each other by tubes. The weak point of such a collector is insufficient strength at high heating temperatures of the coolant.

The comb can be round, rectangular, or square in cross-section. Here, the transverse area comes first, rather than the cross-sectional shape, although from the standpoint of hydraulic laws, rounded is preferable. If the house has several floors, it is better to install local distribution manifolds on each of them.

Design features of a heated floor without a mixing unit

Is it possible to do without a mixing unit? Experts believe that the heating system can function normally without a mixing unit, provided that the heating in the house is organized using low-temperature circuits. This is possible if the water is heated only to a certain point.

Features of laying warm water floors

Example: heating is powered by an air source heat pump. If you use the same boiler to heat your house and heat water for your shower, then you can’t do without a mixing unit.

The main disadvantage of such a heating system is the need to insulate the living space. In addition, thermal insulation work is also added. Flaws:

Water floor installation

- The floor is laid in close proximity to the heating elements;

- The maximum area should not exceed 25 m²;

- It is necessary to contact a specialist who will help calculate the power of the water floor and the cooling rate of the coolant in the water supply. If the temperature difference is too high, condensation will form. High humidity on the surface of pipes leads to rapid failure of the pipeline.

Thus, it is not necessary to install a mixing unit for a heated floor yourself if you plan to heat a small room of up to 40 m². Design features of this assembly:

Scheme of structural elements and equipment of a water heated floor

- A TP thermal relay is mounted on the reverse side of the collector, which in the future will be connected to a 220 V network. This connection allows you to slightly modify the direction of the coolant: the liquid begins from the boiler into the supply manifold, from where it is already heated and evenly distributed through the pipeline. The circulation of water through the pipes is carried out by a pumping motor;

- Having completed a full circle, the water returns to the collector. At this stage, the manifold detects the fluid temperature and turns off the pump motor. The movement of hot liquid gradually slows down, due to which the house is heated. The mechanism starts the pump motor again after the temperature drops, and the whole cycle is repeated - first the coolant enters the boiler, from where it is evenly distributed among the loops.

Experts believe that if you haven’t installed a mixing unit for a heated floor yourself, it’s better to play it safe by installing a relay. This device will completely disable the functioning of the water floor if the temperature sensor detects too high a temperature in the pipes.

Heated floor thermostat connection diagram

Note that modern plastic can withstand high temperatures without any problems. For example, even the cheapest pipe can easily withstand 80–90 degrees

Please note that laminate and linoleum are not designed to withstand overheating. 35–45 degrees is the maximum they can withstand. https://www.youtube.com/embed/l2NKVVPP8AE

Mixing unit for underfloor heating with three-way valves

Operating principle of the collector system

The manifold is a metal comb with leads for connecting pipes and devices. The collector heating system is two-pipe. Hot water is supplied through one comb, and pipes that collect cooled water (return) are connected to the other.

The collector heating system has a closed expansion tank and a circulation pump that moves the coolant. The minimum volume of the expansion tank is equal to at least 10% of the total volume of all heating devices. The pump is installed on any of the pipelines leading to the collectors.

The collectors are installed in special cabinets, which are mounted in wall niches or in a separate room. The collector cabinets should be located at approximately the same distance from each heating device. Pipes can be connected to radiators from above, from the side and from below. The most widespread is the lower pipe connection to radiators. This option provides the best opportunity to hide pipes in the floor. A shut-off valve is installed on each hydraulic circuit coming from the collector, which makes it possible to turn off any radiator without disturbing the operation of the heating system. A valve is installed on each radiator to release accumulated air - a Mayevsky valve, or on the manifold - air release valves. Heat meters and drain valves can also be installed on the collector.

Each hydraulic circuit located after the manifolds is an independent system. This made it possible to create heated floors. These are floors in which pipes are laid in parallel or in the form of spirals, which heat the floor surface. The pipes are laid on a heat-insulating pad, connected to the collector and, after checking the tightness of the pipelines, they are filled with concrete. The height of the screed should not exceed 7 cm. The laying pitch and diameter of the pipes are determined by calculation. The length of one heating spiral should not exceed 90 m. Basically, metal-plastic pipes are used for heated floors, which easily accept any curvature.

When heating a warm floor, the temperature decreases according to the height of the room, and when installing radiators, on the contrary, the higher, the warmer.

How to build a collector yourself?

Today, buying a factory-made comb is not a problem - there is a wide range of these products on sale. But the distributor, as has been shown, has an extremely simple device, so if desired, it can be made independently. As a result, you will not only save some money, but also get a collector that best suits your requirements.

Well, let's see in what order the home craftsman should act.

Collector heating system of a two-story house

Advantages of a collector heating system

The main advantages are the ease of control of the design, in particular:

- Each circuit element can be controlled independently and centrally. This means that in the house the owner sets the temperature of each room and has the opportunity to turn off the radiator or group of radiators from heating altogether.

- Reduced costs. Due to the supply of coolant to only one battery, smaller diameter pipes are suitable for forming a pipeline. Plus the ability to disconnect the battery from the heat supply - together you get some good savings. The liner is most often recessed into the screed, taking into account the minimum distance from the boiler and radiator.

- You can set up several circuits with different heating parameters, including temperature changes, using a hydraulic arrow.

Also, when installing a collector for a heating system, you need to take into account the disadvantages:

- increased energy consumption;

- difficulties in equipping beam distribution and recessing devices into the screed;

- increased hydraulic resistance in the system.

When arranging independent heat supply to different circuits, it becomes necessary to use circulation pumps for each circuit, which means that the system becomes energy-dependent.

Principle of operation of the collector

The main purpose of the device is to uniformly supply heat flows from the main line along the circuit circuits and to the heating radiators, as well as to supply return water to the boiler. The device acts as an intermediate distribution unit and consists of a supply and return comb. In this case, the supply element is responsible for supplying coolant to the circuit, and the return element is responsible for returning the liquid to the boiler.

From each comb there are leads for connecting circuits leading to heating devices. The distribution comb of the heating system with leads can be supplemented with shut-off valves, which help regulate the pressure inside the circuits and, if it is necessary to carry out repairs or reduce the heating intensity, shut off the coolant supply to a separate branch.

The principle of operation is simple - a thermal collector for heating a house transfers coolant through a supply comb to the circuits, while inside the intermediate unit the coolant circulation rate is reduced due to the increased internal diameter of the structure, and this ensures uniform redistribution across all outlets.

The coolant is directed through connecting pipes, enters separate circuits and is transported to heating radiators or to a heated floor grid. Then the structure is heated, and the liquid is redirected through another pipe to the collecting comb of the collector. From here the water flows to the heat generator.

Collector placement rules

A small one-story house usually has one distribution manifold.

In this case, they try to place it in the boiler room or close to it. In two- and three-story cottages, a heating system with several collectors is used - one for each floor.

In this case, collectors can be connected both in parallel and hierarchically, when the next collector is connected to one of the branches of the previous one.

Installing your own comb on each floor allows you to reduce the total hydraulic resistance of the system and use fewer pipes.

You should think about where exactly the collector will be located during the development of the house project.

Types and modifications of heating combs

Modern distribution manifolds can be of two main types. Due to differences in their structure, they are used in different cases.

- Radiator manifolds have found their application in small volume systems. They are well suited for heating systems of a two-story private house, which have several heating circuits and heated floors. Such collectors are available with various coolant supply options: bottom, top and side. Most often there are distribution combs with a lower coolant supply. This is due to the fact that pipes laid under the floor retain heat much better, and are also completely invisible and do not spoil the appearance of the rooms.

- Distributive hydraulic arrow. This heating device is designed for multi-storey buildings and large volumes of liquid. The fundamental difference in the structure of such a collector is the container, which is located between the distribution combs and combines them. This is necessary in order to equalize the pressure throughout the system, and also to prevent a sharp temperature change in the pipes. The efficiency of a hydraulic arrow can be maximized if there is a circulation pump for each individual circuit.

On the market you can find combs made of various metals and alloys: brass, stainless steel and polypropylene. Each material is designed for a specific type of heating system and has its own pros and cons.

Depending on the number of outputs, you can find models from 2 to 10 serviced circuits. Depending on the need, you can find manifolds equipped with circulation pumps, additional drain taps or holes. It is also not uncommon to find thermostats and sensors in the design of the comb.

What are air vents and what are they for?

Many owners of radiator systems have encountered a situation where, with hot pipes, some parts of the radiator do not heat well or are generally cold; similar problems arise with insulation with water floors. The main reason for this phenomenon is the presence of air in the pipes, which rises and impedes the movement of the coolant.

If in an open circuit air bubbles are sent to an unclosed expansion tank located on high floors of a building or attic, and bleeding is not so important, then in a closed system an air bleeder for the heating system is vital on all circuits and individual heat exchange devices.

When plugs interfere with the operation of the system, manual or automatic heating drain valves are used to remove accumulated air. One of the simplest devices is a regular valve installed at the top point of heating radiators. To bleed air from the batteries, open the valve and wait for the moment when the stream stops flowing jerkily along with the air - in radiators without air, the water flow will be uniform.

In individual heating lines of private houses, instead of ordinary valves, special locks are installed on the radiators, which function automatically or are manually adjusted. With their help, they remove not only air from devices in which gas formation occurs, but also, when necessary, oxygen from water, which causes accelerated corrosion of metal fittings.

Rice. 2 Air vent for venting air from the heating system - design

Types of heating combs

In stores you can purchase heating manifolds that differ in the number of connected circuits, materials of manufacture, the presence of thermal heads or flow meters, manufacturer and a host of other characteristics. However, in general they can be divided into three main groups:

- manifold for boiler room;

- hydraulic arrow;

- local combs.

Heating distribution manifold for boiler room

A manifold for a boiler room is usually mounted from large-diameter metal pipes and is equipped with several pumps to circulate fluid through the system. This collector system consists of a supply comb, through which coolant is supplied to the heating system of the entire house, and a comb, which receives the cooled liquid and sends it to the boiler for heating. Pumps with shut-off valves are installed on the supply comb, and shut-off valves are usually installed on the receiving comb.

A necessary element of complex heating systems is a hydraulic arrow, which maintains the best temperature difference in the supply and exhaust circuits. Thanks to this difference, the operation of the heat generator installation is maintained with the lowest energy consumption. We will talk more about the hydraulic gun later in the article.

The boiler room manifold is also equipped with pressure monitoring devices and temperature sensors to monitor the operation of all elements. Such an element has fairly decent dimensions and is usually installed in a special room.

Hydroarrow

A hydraulic arrow is a device that is used to equalize pressure and temperature in a heating system. In the simplest case, a heating boiler circuit approaches it on one side, and a radiator circuit on the other, thus performing the function of a distribution manifold.

For more complex systems, a hydraulic arrow is installed in the boiler room in front of the distribution manifold, performing the same function - equalizing pressure in the system.

Structurally, the hydraulic arrow is made in the form of a vertical pipe, at the ends of which elliptical plugs are installed. If the coolant leaving the boiler has a temperature, and therefore a pressure, higher than necessary, then when it enters the hydraulic arrow, part of it goes into the heating circuit, and part of it is mixed with the cooled coolant from the return. Thus, stabilization and self-regulation of temperature and pressure in the system occurs. Visually, various cases of fluid flow are shown in the diagram:

The hydraulic distributor allows you to:

- avoid sudden temperature fluctuations that reduce the service life of the system;

- maintain the volume of water in the boiler heat exchanger at a constant level;

- maintain thermal equilibrium by separating the hydraulic circuit of the heat generator from the general system main.

The most complete optimization of the operation of a system with an installed hydraulic arrow is achieved through the use of a separate circulation pump for each circuit.

Heating comb

The distribution manifold for heating, unlike the boiler manifold, has much more modest dimensions, however, it performs similar functions. With the help of such a comb, the coolant coming from the boiler room is distributed either to consumers on the floor, or to various groups of consumers (underfloor heating collector, heating radiator collector).

The principle of operation is also somewhat different. If in the boiler manifold assembly the cooled coolant is completely replaced with heated liquid, then in the distribution comb they are also mixed and fed back into the system.

The functions of the hydraulic arrow in the combs are usually assigned to an additional circulation pump. With its help, the local heat-carrying fluid moves in a circle, entraining an additional portion of the heated coolant due to the different temperatures of the flows. At the same time, chilled water or antifreeze enters the main line. In accordance with this operating principle, a dosed amount of coolant is distributed into one or another heating circuit.

The distribution comb of the heating system is usually installed when there are three or more thermal appliances in one room and when a heated floor is installed. It helps to optimize the functioning of the entire complex and reduce the energy consumption of the heat generator.

Both the collector unit in the mini-boiler room and the distribution comb at first glance perform overlapping functions, but it is their joint use that makes the operation of the entire heating complex highly efficient.

Installation of the collector block

The boiler manifold is installed as close as possible to the boiler. The pipes are laid along the floor surface, after which they are filled with a tightening compound and insulated. This method allows to minimize the loss of thermal energy. The block is located in a special niche or panel. In a high-rise building, such a system will be installed on each floor, which will allow heating any room.

Mounted block. Photo source: klivent.net

The coplanar boiler manifold distributes heat evenly over the entire floor area. The cooled liquid is returned, mixed with the hot liquid and goes to the next round. The device is used with hot and cold water, as well as glycol solution.

When installing the collector, the following requirements should be taken into account:

- installation of a pump and expansion tank;

- purchase of additional pipeline and automation elements;

- installation of collector groups in metal boxes;

- decoration of the structure;

- selection of premises (storage room, corridor);

- passing pipes through holes in the walls of the box.

It is better to entrust this work to a professional. The most effective heating option is considered to be connecting a heated floor collector to a (gas) boiler. Such units allow you to reduce utility bills, since electricity costs much more. Floor-standing boilers running on diesel fuel are used as alternative energy sources.

Types of connection of two boilers or more:

- Parallel. The water supply circuits are connected to 1 line, and the return circuits are connected to the other.

- Cascade (sequential). Assumes a balance of thermal load between several installations. Before connecting the system, it is recommended to install special controllers. Piping boilers is possible only if these devices are available.

- According to the scheme of primary-secondary rings. In the first of them water constantly circulates. The secondary ring in this scheme will be each circuit and the boiler itself.

Devices can be purchased at the store or made independently. To do this, you will need to carry out calculations and develop a wiring project. The best material to use is steel pipes with a square cross-section. When using polypropylene raw materials, you should make sure that there is a reinforced layer, since under the influence of high temperature the product is subject to deformation.

Properly selected parts will help make the structure more reliable and durable. In the absence of the necessary tools, it is recommended to assemble the comb from ready-made parts. It is best to purchase components from 1 manufacturer. A homemade device will cost the creator several times less than buying a ready-made device. Factory models often contain unnecessary elements.

Operating principle of a heating distribution manifold

It must be said that the distribution comb of the heating system is an element whose design is extremely simple. These are 2 collectors of increased diameter with fittings for connecting heating circuits, cut into its walls perpendicularly. All factory-made manifolds are made of steel, and the pipes can either be connected to each other or supplied separately.

For reference. Many supporters of heating systems made of polypropylene try to assemble a comb from it with their own hands, so as not to spend money on factory products. Such a decision has the right to life, but may not always be applied, as will be discussed below.

The task of the comb is to ensure the supply of the required amount of coolant to several circuits with different hydraulic resistance and flow rate. A simple situation: a two-story cottage with a radiator heating system plus an extension with a swimming pool and a separate house for staff. Here you cannot do without division into branches - this is the first point. If 2 floors can be heated with one system, then it will not be possible to cover extensions and additional houses with it.

The second point is that no matter where the boiler room is located, the hydraulic resistance of the branches will be too different due to the different lengths and thermal loads.

This means that they need to be connected to a device that can solve the problem - a collector. Its operating principle is as follows: the coolant coming through the main line from the boiler enters a large cross-section pipe, as a result of which its speed is significantly reduced, as is the resistance of this section. Since the connecting pipes have a cross-section three times smaller than that of the collector, the coolant has the opportunity to flow equally well into each circuit and move to the radiators. If the diameter of the comb pipe was equal to the supply line from the boiler, then the lion's share of water consumption would fall on one branch, and the circulation in the rest would be insufficient.

As a rule, a factory heating distribution manifold is a single structure, where the connecting elements are long return pipes passing through the supply comb. In this case, both coolants do not contact each other, as shown in the diagram of the comb device:

The same principle is used to collect cooled water from all heating rings into one collector, from where it is successfully transported back to the heat generator. The minimum number of connected consumers is 2 (as in the diagram), the maximum is 8.

Design of different types of combs

The most affordable would be a distribution comb with manual shut-off valves made in China or Turkey. Metal-plastic pipes are put on the collet connectors located on it.

Threads at the ends are needed for connecting shut-off valves and central hot water supply/discharge. In general, such a comb will cope with its function, but its flawless service life will not be very long.

If disassembling the valves and replacing worn seals does not lead to initial tightness, you will have to buy a new manifold.

A more complex design would be a comb with plugs on the return manifold (and on the direct one too). Instead of them, flow meters and thermal heads can be installed in the future. The direct and reverse combs in such models are already connected by a bracket for mounting on the wall.

And finally, a complex and expensive, but the most effective distribution comb with factory-installed flow meters and thermal heads.

Flow meters regulate the uniform delivery of coolant to its destination, and thermal heads can adjust the temperature for each outlet separately, just like for a heating radiator. The types of thermal heads, their operating principles and installation features are discussed in more detail in our other article.

Even during the design process, it is necessary to make a choice between different types of combs, but in any case, the collector system is a preferable choice compared to conventional wiring based on such criteria as ease of use and durability.

How not to make a mistake when choosing a distribution comb

Before purchasing a device, it is important to consider every little detail. Correlate all the functions that will need to be performed in the future comb. In this case, special attention should be paid not to the material, unfortunately many people look only at it, but also to other important factors.

What to pay attention to first:

- The throughput capacity of the purchased device - it is important that it copes with the flow of water to all nodes.

- What pressure in the system is the comb designed for?

- Energy consumption based on each connection point.

- Possibility of expansion when new water supply units appear in the house.

Choosing the right distribution comb is an important job that is difficult to do on your own, especially if a person understands nothing at all about this difficult matter.

Heating distribution manifold design

Distribution combs for heating, depending on the connected devices, can have from 2 to 20 circuits, and the design allows this number to be increased if necessary. In the production of comb elements, materials with a high degree of resistance to water impurities and external factors are used. Typically the housings are made of stainless steel or brass.

Such elements are usually quite expensive, but their service life reaches tens of years. Simple and cheap analogues made of polypropylene are inferior in all respects to metal products. When choosing a manifold, you need to pay attention to the maximum possible pressure, throughput, number of connection points and the permissibility of installing auxiliary devices.

Each connection point can be equipped with outlet valves or shut-off or control valves. With their help, you can shut off the necessary branch during maintenance or repair without blocking the main flow of coolant.

To control thermal processes in individual rooms, air outlet and drain valves, heat meters and flow meters can be mounted on the comb body.

The collector system has a fairly simple operating principle. After the heating boiler, the heated coolant flows into the supply comb. In the inner part of the collector it slows down. This is ensured by the increased (relative to the main) diameter of the internal part of the device. Then the coolant is evenly distributed between the individual connection branches. Entering the connection pipes, which have a diameter smaller than the collector, the coolant continues to move to the devices that directly heat the room.

All elements, be it a heated floor mesh, a radiator or a water convector, receive a coolant of equal temperature; this is achieved by setting special flow meters that control the volume of coolant supplied to each branch. For example, in order to achieve the same temperature of the heated floor in the near and far room, it is necessary to configure the corresponding flow meters so that in the branch of the near room the coolant moves more slowly through the pipes, and in the branch of the far room faster.

After heat transfer, the liquid moves through the pipeline towards the return comb and then towards the heating boiler.

Whatever the type of heating system of any home, it almost always contains heating radiators. The most popular and popular type of collectors are devices that distribute heat flows to radiators.

The radiator distribution unit usually consists of two distribution combs connected to each other. The first directs the liquid to the radiators, the second returns it to the boiler. Such collectors, as a rule, are not equipped with additional equipment and instruments in order to save money.

Based on the type of connection, collectors can be divided into devices with top, bottom, side or diagonal connections. The lower connection method is used most often. In this case, it is possible to hide the contours under the decorative details of the floor, and make maximum use of the advantages of individual heating.

If the house has several floors, a collector unit for radiators is installed at each level. The installation location can be a special technological recess or shield that provides free access to the comb.

Ideally, all connection branches should have the same length. If it is impossible to maintain the same length of the circuits, then an individual pump can be installed on each of them to maintain coolant circulation. According to this scheme, warm water floors are usually equipped, each branch of which is equipped not only with its own pump, but also with automation.

Accurate flow measurement

In Danfoss FHF collectors, the coolant flow is regulated by special valve inserts, and not by flow meters. In addition to accuracy and ease of adjustment, this also increases the service life of the flowmeter.

In addition to distribution combs, ready-made manifold kits may include automatic air vents, wall mounting mounts and flow meters that regulate the volume of coolant in heating circuits. A manifold group for underfloor heating and radiators allows you to balance the heating and provide a higher level of comfort in every room of the house.

Features of narrow washing machines

Those who choose narrow washing machines are guided by the goal of saving living space, which is already small. And if this is a front-loading machine, then the lid also serves as a shelf, and its advantage is that it can be built into the kitchen work surface or under the bathroom sink. But narrow units with a vertical loading type allow you to add a forgotten item during the washing process.

Since the drum is not as large in diameter as in a standard machine, this affects the number of revolutions and, accordingly, the laundry may not be practically dry at the end of the process. Let's highlight machines of two washing classes and discuss them.

Class A

Good loading parameters for a narrow machine: 4.5 kilograms.

There is a choice of spin speed, delayed start, starching, the presence of a 3D-AquaSpar system and a FuzzyLogic control system.

No child protection. Lighting indicators indicate the washing progress.

Class B

Are there washing machines 55 cm wide? Yes, and one of these copies is DAEWOO DWD-CV701PC (height - 60, width - 55, depth - 28.7). Has a maximum load of 3 kilograms. The optimal choice for young mothers: it is almost silent and makes it possible to wash baby clothes at a temperature of 80 degrees. Energy consumption class - A. A washing machine with a height of 60 centimeters under the sink makes it possible to save space. It has an innovative design that will please the eye. The menu includes a shortened wash cycle.

Recommendations for choosing wisely

The main difficulty lies not only in the installation of the collector itself, but also in the correct choice of equipment.

When choosing a comb model, you should focus on the following parameters:

- Maximum permissible pressure for this model. It determines the type of material from which the hydraulic valve can be made.

- Node throughput.

- Availability of auxiliary devices.

- Number of comb outlet pipes. It must correspond to the number of cooling circuits.

- Possibility of additional connection of elements.

All operational parameters are indicated in the product passport.

To install floor-by-floor independent heating circuits equipped with autonomous control, combs must be installed on each floor of the house.

When selecting and installing floor distributors, they are guided by the parameters of the “subsystem” that they are intended to serve.

Thanks to the floor-by-floor arrangement of the combs, if necessary, you can always turn off the heating of both several individual devices and the entire floor

This greatly simplifies the maintenance and repair of the heating system.

Since a collector block is not a cheap pleasure, in order to protect yourself from disappointment when the system quickly fails, when choosing a model, you should focus on products from trusted manufacturers.

You can safely trust the following: “Rehau”, “Soletrol”, “Oventrop” and “Meibes”. In each series of leading European manufacturers you can select a complete set of necessary additional equipment.

Auxiliary elements and fittings for the collector block must also comply with GOST and TU.

As additional devices for connecting the manifold, you may need: 1 – automatic air vent, 2 – adapter, 3 – corner, 4 – tap, 5 – squeegee, 6 – another corner, 7 – pipe outlets

Each of the additional structural elements performs its own function:

- automatic air vent - installed if the unit and radiators are located on the same floor;

- adapter - required when installing an air vent with a diameter of ½ inch, provided that the manifold thread is ¾ inch.

- corner - will allow you to connect the pipes and direct the air vent upward.

- tap – necessary to connect the pipe coming from the boiler to the device;

- a squeegee equipped with a cap nut will allow, if necessary, to shut off the coolant supply and, by unscrewing the cap nut, disconnect the device.

If you intend to connect a water heated floor from the collector, you will additionally need to install a tap for refilling.

To fix the collector to the wall, you will also need clamps mounted on plastic dowels. When installing the structure, it is also permissible to use special brackets.

Such designs are convenient in that the upper manifold in them is pushed forward, so that the pipes of the unit do not interfere with the pipeline supply to the lower manifold.

How does the comb assembly work?

When pipes are laid out in different rooms, their ends still come together in one place. A comb is connected to them. This is a distribution center. He has the following tasks:

- Reducing the temperature of the water coming from the boiler. The temperature for supply to the floor should be a maximum of 45 degrees, and the heat generator usually heats the coolant much hotter.

- Providing the required amount of heat for each room separately. The comb here functions as an energy distributor and is responsible for the flow rate on each circuit separately.

There are two collectors in the comb - return and supply. They are horizontal, connected to consumers - these are heating circuits. Coolant from the main line enters them from the ends.

To regulate the volume of water entering the circuits, valves are installed on the manifold. They are equipped with a pressure rod. You can adjust manually or automatically. To control the volume of water, the outlets from the second collector are equipped with flasks that measure flow.

Another important detail is the circulation pump. Without it, nothing will work properly, because the pump regulates the water circulation.

Function of a two-way valve

The operating principle of a two-way comb is simplified when compared with a three-way mechanism. A two-way valve with a fixed remote temperature sensor is placed in front of the comb. The sensor is located together with the processing manifold.

The valve has 2 main modes - opening and closing. They determine the location of the stem. The rod is controlled by a thermal head.

The operating principle of the design is as follows: first, the two-way valve is in the open position, while hot liquid is supplied to the comb. It is mixed with cooled water from the check valve, only then it enters the manifold to enter the floor system. A remote sensor located at the outlet measures the temperature. When it is less than the required level, the two-way valve will open. After heating brings the water to the optimal temperature, the system closes and the coolant no longer comes from the main source.

As heat is transferred into the room, the water cools and its temperature becomes less than the established norm. The thermal head of the valve, receiving information from the sensor, raises the rod, opens the valve, then the hot water from the boiler is again mixed with the cooled water in the comb.

So, the two-way system is reliable, it minimizes the likelihood of breakdown and too hot water entering the system. This process is also controlled by a thermostat and the operating principle of the equipment.

It should be noted that the smoothness and accuracy of adjustment is worse in contrast to installing a three-way valve.

Operation of a comb with a three-way valve

When choosing a comb, you should study the structure of the three-way valve, its pros and cons. Unlike the two-way one, it is more optimized because the circuit has three inputs:

- 1 node – receives coolant from the boiler;

- Node 2 – receives water from the outgoing collector;

- Node 3 – line from the processing manifold.

Connecting this valve is not difficult, and the operating principle includes the following steps:

- At first the mixing line is closed, but the supply from the boiler is open. Heated water enters the comb.

- The sensor notifies that the temperature is exceeded. In this case, the lock in the valve shifts, at the same time the mixing unit opens, and the flow of coolant is closed.

- Now the temperature is normalized, and the locking structure does not change its location.

- When the water makes several cycles of movement, it cools down. The valve records this process and closes the mixing unit.

The operating principle of the three-way design is characterized by smoothness and the ability to more accurately regulate the temperature regime. Despite these advantages, the disadvantage is the lack of reliability of the system.

The most popular models

1. Oventrop Multidis SF.

An inch heating comb is designed to organize heating with a water heated floor. Made from tool steel, characterized by high wear resistance. Main characteristics:

- permissible pressure in the circuit – 6 bar;

- coolant temperature – +70 °C.

The series is produced with valve inserts M30x1.5, and can also be equipped with a flow meter for connecting circuits located in different rooms. A bonus from the manufacturer - soundproofed mounting clamps. The number of simultaneously serviced branches is from 2 to 12. The price, accordingly, is 5650-18800 rubles.

To work with high-temperature appliances, Oventrop suggests using a heating system distribution manifold made of Multidis SH stainless steel with a Mayevsky tap. The design can already withstand 10 bar at +95-100 °C, the comb throughput is 1-4 l/min. However, products with 2 circuits have slightly weaker performance. The cost of Oventrop SH hydraulic valves ranges from 2780-9980 rubles.

Plumbers: You'll pay up to 50% LESS on your water bills with this faucet attachment

- HKV – brass underfloor heating manifold. Maintains a pressure of 6 bar in the range of +80-95 °C. Rehau version D is additionally equipped with a rotameter and a tap for filling the system.

- HLV is a heating distribution comb designed for radiators, although its characteristics are identical to the description of HKV. The only difference is in the configuration: a Eurocone is already provided here and the possibility of a threaded clamp connection with pipes.

The manufacturer Rehau also offers to buy separate Rautitan combs with three outlets for pipeline installation using sliding sleeves.

Heating distribution manifold made of steel with anti-corrosion coating. It operates in systems with temperatures up to +110 °C at a pressure of 6 bar and is hidden in a special heat-insulating casing. The throughput of the comb channels is 3 m3/h. Here the choice of designs is not very rich: it is possible to connect only from 3 to 7 circuits. The cost of such hydraulic valves will range from 15,340 to 252,650 rubles.

Stainless steel manifolds are produced in an even more modest range - for 2 or 3 circuits. With the same characteristics, they can be purchased for 19,670-24,940 rubles. The most functional Meibes line is the RW series, which already comes complete with various connecting elements, thermostats and manual valves.

- F – a flow meter is built into the supply;

- BV – has quarter taps;

- C – provides for extension of the comb through a nipple connection.

Each Danfoss heating manifold allows a system pressure of 10 atm at an optimal temperature (+90 °C). The design of the brackets is interesting - they fix paired combs with a slight offset relative to each other for more convenient maintenance. Moreover, all valves are equipped with plastic heads with marked markings, which allows you to set their position manually without the use of tools. The price of Danfoss models, depending on the number of connected circuits and additional options, varies between 5170 - 31,390.

The heating manifold can be selected for a Eurocone with 1/2″ or 3/4″ outlets or with a metric threaded connection. Far combs can withstand pressure up to 10 atm at temperatures not exceeding +100 °C. But the number of outlet pipes is small: from 2 to 4, but the price is the lowest of all the products reviewed in our review (730-1700 rubles for an unpaired distributor).

Tips for choosing

Despite the apparent simplicity of the combs, they need to be selected based on several technical parameters:

1. Pressure in the system - this value determines what material the distribution manifold can be made from.

2. The throughput must be sufficient so that the connected heating circuits do not “starve” from a lack of coolant.

3. Energy consumption of the mixing unit - as a rule, it is determined by the total power of the circulation pumps.

4

Possibility of adding circuits - this parameter should be paid attention only when in the future it is planned to build additional objects that require heating

The number of pipes on the hydraulic distributor must correspond to the number of connected branches (heating devices). In some cases, it is better to install several collectors, for example, in a two-story house - one block on each level. It is also possible to install unpaired combs at different points: one on the supply, the other on the return.

Finally, experts and experienced installers in their reviews advise not to skimp on buying a good collector. In order for it to serve for a long time and not cause any problems, the name on the box must be known.

Floating installation

To install a float limiter, you should proceed according to the following scheme:

- First of all, you should accurately determine the place where the comb will be installed. It can be installed anywhere in the structure, since the handle is not involved.

- The limiter is screwed to the frame. For this purpose, a self-tapping screw is used, the length of which should be 1.3 centimeters.

- Using a pencil, when the sash is in the “closed” position, mark the position of the latch. It should be located opposite the comb, but should not interfere with opening.

- Screw the clamp to the sash, having first made a hole for it.

- Check how the limiter works.