Owners organizing the heating of their private cottages or dachas use various options for connecting heat exchange devices and heated floors; when organizing heating, the circuit is conventionally divided into two branches - supply and return. When installing it, it is important to correctly install not only the pipeline supplying the coolant, but also the return branch, and it is important to know the following - what is the return of the heating system.

In any heating system, the coolant moves cyclically along a closed circuit; if in the gravity version the movement of the liquid occurs due to a decrease in the density of water at high temperatures and displacing it upward by a low-temperature water column, then in a closed line it is pushed by the impeller of the circulation pump.

In both cases, the return flow of the heating system must be installed correctly - with the expansion tank open, slopes are maintained at a certain angle, and in a multi-circuit wiring with an electric pump, a separate return manifold is installed. It performs the functions of redirecting the cooled flow to the boiler and mixing incoming and outgoing heat carriers of different temperatures.

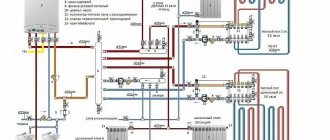

Rice. 1 Example of placement of heating equipment

What should be the operating pressure in the heating system?

But to answer this question in a nutshell is quite simple.

Much depends on what kind of house you live in. For example, for an autonomous or apartment, 0.7-1.5 Atm is often considered normal. But again, these are approximate figures, since one boiler is designed to operate in a wider range, for example, 0.5-2.0 Atm, and the other in a smaller one. This must be looked at in the passport of your boiler. If there is none, stick to the golden mean - 1.5 Atm. The situation is completely different in those houses that are connected to central heating. In this case, it is necessary to be guided by the number of floors. In 9-story buildings, the ideal pressure is 5-7 Atm, and in high-rise buildings - 7-10 Atm. As for the pressure under which the carrier is supplied to buildings, most often it is 12 Atm. You can reduce the pressure using pressure regulators, and increase it by installing a circulation pump. The last option is extremely relevant for the upper floors of high-rise buildings. The advantage of using automatic balance valves is also the ability to divide the system into separate pressure-independent zones and carry out their phased commissioning. Benefits of automatic balance valves include easier and faster system setup, fewer valves, and minimal system maintenance. Modern automatic balance valves are characterized by high reliability and improved control characteristics. Some are modular in design, meaning they can be upgraded or expanded in functionality.

How to make radiators hot - looking for solutions

If you find that the return is too cold, you should take a number of steps to find the causes and troubleshoot problems. First of all, you need to check that the connection is correct. If the connection is not made correctly, the down pipe will be hot when it should be slightly warm. The pipes should be connected according to the diagram.

To avoid air pockets that impede the flow of coolant, it is necessary to provide for the installation of a Mayevsky valve or bleeder for air removal. Before bleeding the air, you need to turn off the supply, open the tap and let out the air. Then the tap is turned off and the heating valves open.

Often the cause of cold return is the control valve: the cross-section is narrowed. In this case, the tap must be dismantled and the cross-section increased using a special tool. But it is better to buy a new faucet and replace it.

The reason may be clogged pipes. You need to check them for passability, remove dirt and deposits, and clean them well. If passability cannot be restored, the clogged areas should be replaced with new ones.

If the coolant flow rate is insufficient, you need to check whether there is a circulation pump and whether it meets the power requirements. If it is missing, it is advisable to install it, and if there is a lack of power, replace or upgrade it.

Knowing the reasons why heating may not work efficiently, you can independently identify and eliminate malfunctions. Comfort in the house during the cold season depends on the quality of heating. If you carry out the installation work yourself, you can save on hiring third-party labor.

Economical energy consumption in the heating system can be achieved if certain requirements are met. One option is to have a temperature diagram, which reflects the ratio of the temperature emanating from the heating source to the external environment. The values of the values make it possible to optimally distribute heat and hot water to the consumer.

High-rise buildings are mainly connected to central heating. The sources that transmit thermal energy are boiler houses or thermal power plants. Water is used as a coolant. It is heated to a given temperature.

Having gone through a full cycle through the system, the coolant, already cooled, returns to the source and reheats. Sources are connected to consumers by heating networks. Since the environment changes temperature, thermal energy should be adjusted so that the consumer receives the required volume.

Heat regulation from the central system can be done in two ways:

- Quantitative.

In this form, the water flow changes, but its temperature remains constant. - Qualitative.

The temperature of the liquid changes, but its flow does not change.

In our systems, the second regulation option is used, that is, qualitative. Here there is a direct relationship between two temperatures:

coolant and environment. And the calculation is carried out in such a way as to ensure the heat in the room is 18 degrees and above.

Hence, we can say that the temperature graph of the source is a broken curve. The change in its directions depends on temperature differences (coolant and outside air).

The dependency schedule may vary.

A specific diagram has a dependency on:

- Technical and economic indicators.

- CHP or boiler room equipment.

- Climate.

High coolant values provide the consumer with great thermal energy.

Below is an example of a diagram, where T1 is the coolant temperature, Tnv is the outside air:

A diagram of the returned coolant is also used. A boiler house or thermal power plant can estimate the efficiency of the source using this scheme. It is considered high when the returned liquid arrives chilled.

The stability of the scheme depends on the design values of fluid flow of high-rise buildings.

If the flow through the heating circuit increases, the water will return uncooled, as the flow rate will increase. Conversely, with minimal flow, the return water will be sufficiently cooled.

The supplier's interest, of course, is in the supply of return water in a cooled state. But there are certain limits for reducing consumption, since a decrease leads to loss of heat. The consumer’s internal temperature in the apartment will begin to drop, which will lead to violation of building codes and discomfort for ordinary people.

Where is the return route?

In short, the heating circuit consists of several important elements: a heating boiler, batteries and an expansion tank. In order for heat to flow through radiators, a coolant is needed: water or antifreeze. If the circuit is constructed correctly, the coolant heats up in the boiler, rises through the pipes, increasing its volume, and all excess ends up in the expansion tank.

Based on the fact that the batteries are filled with liquid, hot water displaces cold water, which, in turn, goes back into the boiler for subsequent heating. Gradually the water temperature increases and reaches the desired temperature. The coolant circulation can be natural or gravitational, carried out using pumps.

Based on this, the return can be considered a coolant that has passed through the entire circuit, giving off heat, and, already cooled, returned to the boiler for subsequent heating.

Differences between them

The difference between the described concepts is as follows:

- The supply is a coolant that flows through the radiators from the heat source.

- The return is a liquid that has passed through the entire circuit, and cooled down again to the heat source for subsequent heating. Therefore, occurs at the output .

- The difference is in temperature: the return is colder .

- The difference is in the installation. The water line that is attached to the top of the battery is the supply. What is attached to the bottom is the return line.

Important! Some tips need to be followed. The entire system must be completely filled with water or antifreeze . Maintaining fluid speed, circulation and pressure is equally important.

Temperature difference across radiators

The temperature difference should be 30 °C . In this case, the batteries will feel approximately the same to the touch . It is important to ensure that the difference in these values is not too large.

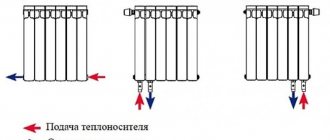

Photo 2. Heating diagram for 6 radiators: changes in flow and return temperatures on each of them are indicated.

Pressure regulator

The operation of the batteries and the pump is disrupted due to high or low pressure levels. Correct control of the heating system will help to avoid this negative factor. The pressure in the system plays a significant role, it ensures that water gets into the pipes and radiators. Heat loss will be reduced if the pressure is standard and maintained. This is where water pressure regulators come to the rescue. Their mission is primarily to protect the system from too much pressure. The operating principle of this device is based on the fact that the heating system valve located in the regulator works as a force equalizer. Depending on the type of pressure, regulators are classified into: statistical, dynamic. It is necessary to select a pressure regulator based on throughput. This is the ability to pass the required volume of coolant, in the presence of the required constant pressure drop.

Incorrect pipe connection

If the pipes are connected incorrectly, the efficiency of the radiator will decrease. Using the services of experienced craftsmen, such a problem does not arise. However, if you decide to connect the pipes yourself, then you may make a major mistake. When installing a radiator, the return pipe is often connected to the upper pipe, and the supply pipe to the lower pipe. This error causes the following problems:

- The efficiency of the system decreases and the water circulation is completely destroyed.

- The process of removing water from the battery is disrupted.

- Due to a decrease in battery efficiency and heat transfer, water cannot fill all sections evenly.

Water enters the radiator through the lower pipe. Then it flows in a circle and is discharged from the radiator. The work of the radiator is significantly reduced, since the sections do not warm up well. When connected to the upper pipe, liquid is not removed from the inside. This happens due to the characteristics of the radiator, which cannot create high pressure to remove water through the top.

Operating pressure in the heating system

Working pressure is considered to be the pressure whose value ensures optimal operation of all heating equipment (including the heating source, pump, expansion tank). In this case, it is taken equal to the sum of pressures:

- static - created by a column of water in the system (in calculations the ratio is taken: 1 atmosphere (0.1 MPa) per 10 meters);

- dynamic - due to the operation of the circulation pump and the convective movement of the coolant when it is heated.

It is clear that in different heating schemes the operating pressure will differ. So, if natural circulation of the coolant is provided for heating the house (applicable for individual low-rise construction), its value will exceed the static value by only a small amount. In forced schemes, it is taken as maximum permissible to ensure higher efficiency.

Numerically, the working pressure is:

- for one-story buildings with an open layout and natural circulation of water – 0.1 MPa (1 atmosphere) for every 10 m of liquid column;

- for low-rise buildings with a closed layout - 0.2-0.4 MPa;

- for multi-storey buildings - up to 1 MPa.

What does it depend on?

The temperature curve depends on two quantities:

outside air and coolant. Frosty weather leads to an increase in coolant temperature. When designing a central source, the size of the equipment, building and pipe size are taken into account.

The temperature leaving the boiler room is 90 degrees, so that at minus 23°C, the apartments are warm and have a value of 22°C. Then the return water returns to 70 degrees. Such standards correspond to normal and comfortable living in the house.

Analysis and adjustment of operating modes is carried out using a temperature diagram.

For example, the return of liquid with an elevated temperature will indicate high coolant costs. Underestimated data will be considered a consumption deficit.

Previously, for 10-story buildings, a scheme with calculated data of 95-70°C was introduced. The buildings above had their own chart of 105-70°C. Modern new buildings may have a different layout, at the discretion of the designer. More often, there are diagrams of 90-70°C, and maybe 80-60°C.

Temperature chart 95-70:

Temperature chart

Safety valves

Any boiler equipment is a source of danger. Boilers are considered explosive because they have a water jacket, i.e. pressure vessel. One of the most reliable and widespread safety devices that reduces the danger to a minimum is the safety valve of the heating system. The installation of this device is due to the protection of heating systems from excess pressure. Often this pressure occurs as a result of boiling water in the boiler. The safety valve is installed on the supply pipe, as close to the boiler as possible. The valve has a fairly simple design. The body is made of good quality brass. The main working element of the valve is the spring. The spring, in turn, acts on the membrane, which closes the passage to the outside. The membrane is made of polymer materials, the spring is made of steel. When choosing a safety valve, it should be taken into account that full opening occurs when the pressure in the heating system increases above the value by 10%, and full closure occurs when the pressure drops below the response value by 20%. Due to these characteristics, it is necessary to select a valve with a response pressure higher than 20-30% of the actual one.

How to protect the pump from malfunction

It is advisable to always maintain the required volume of coolant water in the pipes. Otherwise, the pump will wear out, both in case of excess water volume and in case of insufficient water volume.

To be on the safe side and avoid breakdowns of fairly expensive pumping equipment, it is recommended to adhere to some basic rules for operating equipment of this type:

- Do not allow the pump to turn on without coolant in the closed circuit. That is, if there is no water in the heating system pipes, then you should not “torture” the pump. This will cause your equipment to break down quickly.

- It is advisable to always maintain the required volume of coolant water in the pipes. Otherwise, the pump will wear out, both in case of excess water volume and in case of insufficient water volume. For example, if a pump can distill an amount of water from 5 to 105 liters, then the need to work with volumes from 3 to 103 liters will greatly wear out the working components of the unit, which will lead to its failure.

- In case of prolonged downtime of the pump (during the low heating season), it is necessary to run the unit in the operating position for at least 15 minutes once a month. This will avoid oxidation of all movable elements of the pump unit.

- Try not to exceed the coolant temperature above 65 degrees Celsius. A higher rate will negatively affect the working and movable parts of the structure.

- In this case, check the pump housing for leaks more often. If there is even the slightest leak somewhere, you should immediately identify the malfunction and carry out maintenance on the pump.

Features of the heating system of apartment buildings

When installing heating in multi-storey buildings, it is imperative to comply with the requirements established by regulatory documentation, which include SNiP and GOST. These documents indicate that the heating structure must ensure a constant temperature in the apartments within 20-22 degrees, and humidity must vary from 30 to 45 percent.

To achieve the required parameters, a complex design is used, requiring high-quality equipment. When creating a project for the heating system of an apartment building, specialists use all their knowledge to achieve uniform heat distribution in all sections of the heating main and create comparable pressure on each tier of the building. One of the integral elements of the operation of such a design is operation on a superheated coolant, which provides for the heating scheme of a three-story building or other high-rise buildings.

How it works? The water comes directly from the thermal power plant and is heated to 130-150 degrees. In addition, the pressure is increased to 6-10 atmospheres, so the formation of steam is impossible - high pressure will drive water through all floors of the house without loss. The temperature of the liquid in the return pipeline in this case can reach 60-70 degrees. Of course, at different times of the year the temperature regime may change, since it is directly related to the ambient temperature.

Why do the batteries in the apartment not warm up well?

Reason 1: air locks

Often the radiators in the apartment are cold or not warm enough due to air locks. As a rule, this problem is relevant for residents of upper floors, since the air tends upward through the pipes. In order to eliminate air jams, a Mayevsky crane is used. It allows you to release the collected air and ensure full circulation of the coolant in the pipes.

Reason 2: non-optimal connection of heating batteries

Design features of the heating circuit

Modern buildings often use additional elements, such as collectors, heat meters for batteries and other equipment. In recent years, almost every heating system in high-rise buildings has been equipped with automation to minimize human intervention in the operation of the structure (read: “Weather-dependent automation of heating systems - about automation and controllers for boilers using examples”). All the described details allow you to achieve better performance, increase efficiency and make it possible to more evenly distribute thermal energy throughout all apartments.

Purpose and principle of operation of the elevator unit

It was said above that the water in the heating system of a multi-story building heats up to 130 degrees. But consumers do not need such a temperature, and heating the batteries to such a value is absolutely pointless, regardless of the number of floors: the heating system of a nine-story building in this case will not be different from any other. Everything is explained quite simply: the heating supply in multi-storey buildings is completed by a device that turns into a return circuit, which is called an elevator unit. What is the meaning of this node, and what functions are assigned to it?

The coolant heated to a high temperature enters the elevator unit, which, in its principle of operation, is similar to a dosing injector. It is after this process that the liquid carries out heat exchange. Coming out through the elevator nozzle, the coolant under high pressure exits through the return line.

In addition, through the same channel, the liquid is recirculated into the heating system. All these processes together make it possible to mix the coolant, bringing it to the optimal temperature, which is sufficient to heat all apartments. The use of an elevator unit in the scheme makes it possible to provide the highest quality heating in high-rise buildings, regardless of the number of floors.

Types of heating systems

The amount of heat that the heating radiator will emit depends not least on the type of heating system and the selected type of connection. To choose the best option, you must first understand what kind of heating systems there are and how they differ.

Monotube

A single-pipe heating system is the most economical option in terms of installation costs. Therefore, this type of wiring is preferred in multi-storey buildings, although in private buildings such a system is far from uncommon. With this scheme, the radiators are connected to the main line in series and the coolant first passes through one heating outlet, then enters the input of the second, and so on. The output of the last radiator is connected to the input of the heating boiler or to the riser in high-rise buildings.

Example of a one-pipe system

The disadvantage of this wiring method is the impossibility of adjusting the heat transfer of radiators. By installing a regulator on any of the radiators, you will regulate the rest of the system. The second significant drawback is the different coolant temperatures on different radiators. Those that are closer to the boiler heat up very well, those that are further away become increasingly colder. This is a consequence of the serial connection of heating radiators.

Two-pipe wiring

A two-pipe heating system is distinguished by the fact that it has two pipelines - supply and return. Each radiator is connected to both, that is, it turns out that all radiators are connected to the system in parallel. This is good because the coolant of the same temperature enters the input of each of them. The second positive point is that you can install a thermostat on each of the radiators and use it to change the amount of heat it emits.

The disadvantage of such a system is that the number of pipes when laying out the system is almost twice as large. But the system can be easily balanced.

Types of radiator connections

The main methods of connecting heating system devices are several types:

- Lateral (standard) connection;

- Diagonal connection;

- Bottom (saddle) connection.

Side connection

Lateral radiator connection.

Connection from the end of the device - supply and return are located on one side of the radiator. This is the most common and effective connection method; it allows you to remove the maximum amount of heat and use the entire heat transfer of the radiator. As a rule, the supply is at the top and the return is at the bottom. When using a special headset, it is possible to connect from bottom to bottom, this allows you to hide the pipelines as much as possible, but reduces the heat transfer of the radiator by 20 - 30%.

Diagonal connection

Diagonal radiator connection.

Connection diagonally to the radiator - the supply is on one side of the device from the top, the return is on the other side from the bottom. This type of connection is used in cases where the length of a sectional radiator exceeds 12 sections, and a panel radiator is 1200 mm. When installing long radiators with side connections, there is uneven heating of the radiator surface in the part furthest from the pipelines. To ensure that the radiator heats up evenly, a diagonal connection is used.

Bottom connection

Bottom connection from the ends of the radiator

Connection from the bottom of the device - supply and return are located at the bottom of the radiator. This connection is used for the most hidden installation of pipelines. When installing a sectional heating device and connecting it using the bottom method, the supply pipe approaches on one side of the radiator, and the return pipe on the other side of the bottom pipe. However, the heat transfer efficiency of radiators with this scheme is reduced by 15-20%.

Bottom radiator connection.

In the case when the bottom connection is used for a steel panel radiator, then all the pipes on the radiator are located at the bottom end. The design of the radiator itself is made in such a way that the supply flows through the manifold first to the upper part, and then the return flow is collected in the lower radiator manifold, thereby not reducing the heat transfer of the radiator.

Bottom connection in a single-pipe heating circuit.

How to correct the situation when there is a drop

Everything here is extremely simple. First, you need to look at the pressure gauge, which has several characteristic zones. If the arrow is in the green, then everything is fine, but if it is noticed that the pressure in the heating system is dropping, then the indicator will be in the white zone. There is also a red one, it signals an increase. In most cases, you can handle it on your own. First you need to find two valves. One of them is used for injection, the second is used for bleeding media from the system. Then everything is simple and clear. If there is a shortage of media in the system, it is necessary to open the discharge valve and monitor the pressure gauge installed on the boiler. When the arrow reaches the required value, close the valve. If bleeding is needed, everything is done in the same way with the only difference being that you need to take with you a vessel into which the water from the system will be drained. When the pressure gauge needle shows normal, tighten the valve. Often this is how the pressure drop in the heating system is “treated”. Now let's move on.

They are widely used in constant flow systems. The main advantage of manual balance valves is their low cost. The main disadvantage is that every change in the installation must rebuild the system, which is labor-intensive and expensive.

Automatic balance valves Automatic balance valves allow you to flexibly change the parameters of the pipeline system depending on fluctuations in pressure and flow of the working medium. They are proportional regulators that maintain a constant differential pressure in the system and minimize disturbances caused by control valves. They are characterized by high performance, which allows them to maintain the established hydraulic conditions in systems, compensating for interference caused by the control valve.

Comparison with other types

In the lower insert, the supply line is laid from below, next to the return line, so the coolant is directed from the bottom up along the supply risers. Both types of distributions can be designed with one or more circuits, dead-end and associated flow of water in the supply and return pipes.

Natural circulation systems with connections at the bottom are used very rarely, since they require a large number of risers, and the point of inserting pipes in this way is to reduce their number to a minimum. Taking this into account, such structures most often have forced circulation.

Roof and floors - meaning

In the upper supply line, the supply line is above the radiator level. It is mounted in the attic, in the ceiling. The heated water flows to the top, then through the supply risers it evenly spreads over the radiators. Radiators must be located above the return line. To prevent air accumulation, install a compensating tank at the very top point (in the attic). Therefore, it is not suitable for houses with a flat roof without an attic.

The wiring from below has two pipes - supply and discharge - the heating radiators must be higher than them. It is very convenient for removing air pockets using Mayevsky taps. The supply line is located in the basement, in the basement, under the floor. The supply pipe must be higher than the return pipe. An additional slope of the line towards the boiler minimizes air pockets.

Both wirings are most effective in a vertical configuration, when the batteries are mounted on different floors or levels.

Pressure norm

Effective transfer and uniform distribution of coolant for the performance of the entire system with minimal heat loss is possible at normal operating pressure in the pipe lines.

The coolant pressure in the system is divided according to the method of action into types:

- Static. The force of influence of a stationary coolant per unit area.

- Dynamic. Force of action during movement.

- Maximum pressure. Corresponds to the optimal value of liquid pressure in the pipes and is capable of maintaining the operation of all heating devices at a normal level.

According to SNiP, the optimal indicator is 8-9.5 atm, reducing the pressure to 5-5.5 atm. often leads to heating interruptions.

For each specific home, the normal pressure indicator is individual. Its value is influenced by factors:

- power of the pumping system supplying coolant;

- pipeline diameter;

- remoteness of the room from the boiler equipment;

- wear of parts;

- pressure

Pressure control is possible using pressure gauges mounted directly into the pipeline.

Reasons for uneven heating of batteries

When approaching various types of repair work, it is useful to use the rule - go from simple to complex. Often the cause of a problem can be eliminated through preventative maintenance.

The answer to the question why heating radiators are cold from below and hot from above lies in the following:

- The shut-off valves are not fully open or closed;

- air entered the system and a plug formed;

- a lot of salt deposits and impurities have accumulated in the radiator, interfering with circulation;

- shut-off valves broke and the conditions for uniform movement of the coolant were violated;

- The radiator is not connected correctly;

- there is low pressure or coolant speed in the system;

- the room is too cold.

The radiator is clogged

Water in central heating systems contains impurities of salts, which settle in any convenient place (turns, bends, recesses, shells on the inner surface).

The coolant may contain various foreign impurities:

- metal shavings and rust;

- sand;

- pieces of gaskets and plumbing sealant for threaded connections.

Over time, a jelly-like mass accumulates at the bottom of the heating battery, clogging the fluid flow paths. Over time, the dirt substance can turn into a solid state.

Shut-off valves are not working properly

The taps installed on the inlet and outlet pipes to the battery must be open and freely allow coolant flows to pass through. A malfunction can lead to changes in pressure and circulation of the working fluid.

A breakdown is considered to be the incorrect operation of the faucet locking mechanism, the inability to turn it to the closed or open position.

Low system pressure

The coolant is supplied to the system under the influence of a set pressure. If its value is below normal, the working fluid will not be able to completely fill the radiator, and as a result there will be no effective heat transfer.

A decrease in pressure can be caused by a number of reasons:

- Malfunction in the central boiler room or main line.

- Insufficiently open shut-off valves on heat supply risers and pipes.

- Increasing the volume of heat exchangers, for example, installing radiator sections or equipment for “warm floors” beyond the norm.

Incorrect radiator installation

The batteries are connected to the heating system according to the established scheme. Changing the order of supply and removal of working fluid leads to disruption of its circulation or complete cessation of movement. The radiator can be connected incorrectly by “specialists” with low qualifications or by property owners who have taken on the functions of plumbers.

Low coolant circulation rate

Reducing the time it takes for liquid to move in the heating radiator will result in the effect of a warm top and a cold bottom.

The pressure drop in the system was already mentioned above as the reason for the decrease in circulation rate. Another factor influencing the movement of fluid in the heating network is disruption of the natural (gravitational) type of heating, that is, the creation of traffic jams, obstacles to movement, and so on.

Cold room

In a room with a low temperature, the coolant cools faster, and the battery below, closer to the outlet pipe, will be colder than in the area where the hot liquid is supplied.

Pipe diameter and degree of wear

It is necessary to remember that the size of the pipe must also be taken into account. Often, residents set the diameter they need, which is almost always slightly larger than the standard sizes. This leads to the fact that the pressure in the system decreases slightly, which is due to the large amount of coolant that will fit into the system. Do not forget that in corner rooms the pressure in the pipes is always less, since this is the most remote point of the pipeline. The degree of wear of pipes and radiators also influences the pressure in the heating system of the house. As practice shows, the older the batteries, the worse. Of course, not everyone can change them every 5-10 years, and it is not advisable to do this, but it doesn’t hurt to carry out preventive maintenance from time to time. If you are moving to a new place of residence and you know that the heating system there is old, then it is better to change it immediately, so you will avoid many troubles.

Hydraulic balance of hot water supply systems. The hot water temperature in hot water systems drops significantly when demand is low or absent. This leads to several problems: long waits for hot water, water overflow, and the possibility of unwanted bacteria developing. To maintain the water temperature at the required level, this is usually a constant circulation of water in the systems, through a circulation pump and a circulation pipe. Hydraulic balance in these systems is usually maintained using direct acting temperature controllers.

What to do if the bottom of the battery is colder than the top

If the battery is hot on top and cold on the bottom, it is not functioning properly. In this case, diagnostics are required not only by the battery itself, but also by the entire heating system. The cause of the problem may lie in recent work on the heating system and replacement of the radiator. As a rule, the “hot top – cold bottom” problem appears due to an air lock (99% of cases) or a clogged radiator valve (a consequence of improper start-up of the system).

This problem is solved in two ways. You can remove the air lock using a Mayevsky tap or a bleeder. First of all, turn off the coolant supply to the radiator and leave the return line open. Open the drain, wait until the air comes out, close the drain and open the coolant supply. As a rule, this is enough.

If this method does not work, and we are talking about an apartment building, it is better to call a specialist. For private houses there is another option. First you need to turn off the heating supply, open the drain at the highest point of the system and use back pressure to squeeze out all the air.

Each heating system may have its own characteristics, and therefore there is a high probability of atypical problems arising. These include incorrectly selected pipe diameters, incorrect coolant distribution, poor throughput, lack of pressure, problems with the circulation pump or expansion tank. In any case, only a specialist can fully understand all the nuances, so in case of difficulties in solving the problem, it is better to seek help.

The efficient operation of the heating system determines how comfortable the temperature in the house will be during the cold season. Sometimes situations arise when hot water is supplied to the system, but the batteries remain cold

It is important to find the cause and eliminate it. To solve the problem, you need to know the structure of the heating system and the reasons for cold return during hot supply

Where to put radiators

Traditionally, heating radiators are placed under windows, and this is no accident. The rising flow of warm air cuts off the cold air that comes from the windows. In addition, warm air heats the glass, preventing condensation from forming on it. Only for this it is necessary that the radiator occupies at least 70% of the width of the window opening. This is the only way the window will not fog up. Therefore, when choosing the power of radiators, select it so that the width of the entire heating battery is not less than the specified value.

How to place a radiator under a window

In addition, it is necessary to correctly select the height of the radiator and the location for its placement under the window. It must be placed so that the distance to the floor is around 8-12 cm. If you lower it lower, it will be inconvenient to clean, if you raise it higher, your feet will be cold. The distance to the window sill is also regulated - it should be 10-12 cm. In this case, warm air will freely go around the obstacle - the window sill - and rise along the window glass.

And the last distance that must be maintained when connecting heating radiators is the distance to the wall. It should be 3-5 cm. In this case, rising currents of warm air will rise along the back wall of the radiator, and the rate of heating the room will improve.

Radiator does not heat up

Most often, problems with normal heat transfer occur in heating radiators. This is explained by their specific design - the coolant does not move through one pipe, as in a transport line, but is distributed over several.

In what cases does the heating radiator not heat? There are several factors that directly affect the correct operation of the battery.

Air locks in heating

There are several reasons for the appearance of air locks in the heating system - excess temperature, water evaporation, etc.

It is important that the consequence of this is the appearance of places in the line that are not filled with coolant. Most often these are heating radiators. To eliminate them, it is necessary to install a Mayevsky valve - an air valve that releases excess air from the device

To eliminate them, it is necessary to install a Mayevsky valve - an air valve that releases excess air from the device.

How to determine why a radiator does not heat well? The simplest method is a temperature difference on the surface. At the point where the air lock forms, it will be significantly lower, thereby preventing the normal passage of the coolant. To eliminate it, you must perform the following steps:

- Using a screwdriver or a rotary lever, the Mayevsky tap is opened;

- Add water to the system until the coolant begins to flow out of the tap along with the air;

- Shut off the water supply.

After starting the heating system, the surface of the radiator should heat evenly. Otherwise, repeat the procedure.

Improper installation and limescale deposits in pipes

The efficiency of its operation depends on the correct installation of the radiator. It should not be inclined relative to the plane of the floor and wall. If this condition has not been met, then the question will inevitably arise - why the heating battery does not heat.

To check the correct installation of the radiator, you can take a standard building level. If the upper plane of the battery has deviations, re-installation should be performed. It is best to use new reinforced fasteners for this.

If after this the question of why the heating radiator does not heat remains unresolved, it is recommended to flush the heating system. This problem is relevant for old pipes and radiators made of steel and cast iron. Over time, a limescale layer accumulates on the inner surface, preventing the normal flow of coolant. There are several ways to perform the washing procedure:

- Hydraulic. A special pump is connected to the system circuit, which creates high water pressure. Under the influence of this force, the scale is broken into small fractions and retained in the pump filter;

- Chemical. Special additives act on limescale, which loses its uniformity and flakes off from the inner surface. Subsequently, hydraulic flushing is performed to remove residual debris.

Experts recommend using a comprehensive method to solve the problem in which the radiator does not heat up. After checking the correct installation, the system is flushed, and then filled correctly with the Mayevsky tap open.

If a two-pipe heating system does not heat due to clogged pipes, you need to carefully choose a cleaning technology. For pipelines made of polypropylene, chemical cleaning cannot be done.

About Leak Testing

It is imperative to check the system for leaks. This is done to ensure that the heating operation is efficient and does not have failures. In multi-storey buildings with central heating, the cold water test is most often used. In this case, if the heating system drops by more than 0.06 MPa in 30 minutes or 0.02 MPa is lost in 120 minutes, it is necessary to look for places where there are gusts. If the indicators do not go beyond the norm, then you can start the system and begin the heating season. Hot water testing is carried out immediately before the heating season. In this case, the media is supplied under pressure, which is the maximum for the equipment.

Their purpose is to maintain temperature and minimize water consumption in hot water circulation systems

An important feature of these valves is the presence of periodic disinfection of the DHW pipeline network. Tags: balancing valves Manual balancing valves

Autonomous heating systems

Today you may not ask for cold, but your heating system will do it for you. If you did not pay enough attention during the summer season, an unpleasant surprise can be expected at the beginning or during the heating season. Do you have a cold house because your radiators are as bad as ever before? Errors in maintenance or poor adjustment of some parts of your heating system may be a malfunction. It's best to use the summer months to maintain your heating system, but many people will only start doing it when they need to flood for the first time.

The battery does not heat up

If one or more radiators do not heat or heat poorly, then the first thing you need to do is check if there is air in them using air vents. If water flows from the drains, but the radiator still does not heat, then you need to make sure that both taps of this radiator are open (such inattention can often occur). The next step is to check if the radiator is clogged. To do this, other heating radiators that heat and are on the same branch as the non-working one must be shut off so that all the water flows through this radiator. If it starts to warm up, it means it is not clogged. In this case, it is necessary to hydraulically level the branch. In simple terms, it is necessary to cover the remaining radiators on the branch so that the one who is not working gets more. You need to be prepared that leveling will take more than one day, because the heating system may be slow to respond to changes in settings. If the taps in front of the radiator are completely open, and it is cold, then it is clogged (extremely low probability). Basically, the last radiators on the branch may not heat . But this can always be eliminated by hydraulic leveling. If someone tells you that “it’s not pumping there” or “the pump’s power is insufficient,” don’t rush to believe and touch the pump or pipes. In order to prevent the pump from pumping too much, you need to try very hard when installing the heating system. If one or more of the last radiators does not heat up even after working with the taps, then there may be an air lock in the pipes (see circulation disturbance in the heating system).

Control of operating pressure in heating circuits

For normal, trouble-free operation of the heating system, it is necessary to regularly monitor the temperature and pressure of the coolant.

To check the latter, deformation pressure gauges with a Bourdon tube are usually used. To measure small pressures, their varieties can be used - diaphragm devices.

Figure 1 – Strain gauge with Bourdon tube

In systems where automatic control and regulation of pressure are provided, various types of sensors are additionally used (for example, electric contact).

- at the inlet and outlet of the heating source;

- before and after the pump, filters, mud traps, pressure regulators (if any);

- at the exit of the main line from the thermal power plant or boiler house and at its entry into the building (with a centralized scheme).

Figure 2 – Section of the heating circuit with installed pressure gauges

Adjusting heat supply, what methods to use

During heating operation, the coolant in the system heats up and expands, that is, it increases in volume. That is why the owner sometimes needs to adjust the heating radiators in his private home, thereby controlling the operation of the heating supply. There are several types of devices that allow you to do this kind of work. All devices are usually divided into two categories:

- 1. regulatory;

- 2. controlling.

The first allow you to regulate the pressure and temperature in the system, and reduce these parameters up or down. They can be installed on individual sections of the pipeline and used to regulate individual parts of the network, or regulate the operation of the entire system as a whole. Control devices are all kinds of thermometers and pressure gauges installed separately from the control means in systems or together with them. They allow you to obtain information about the operation of the heating supply at any time and make a decision about the need to configure it.

To ensure that no difficulties arise with its adjustment during heating operation, when designing engineering it is necessary to provide for:

- installation of thermometers and pressure gauges before and after the heating boiler, in distribution manifolds (in the lowest and highest parts of the network);

- installing a pressure gauge before the circulation pump, if present in the system;

- installation of an expansion tank: leaky - in open networks and membrane - in closed ones;

- installation of safety valves and air vents necessary to prevent pressure in pipes from increasing to critical values.

During normal operation of the system, the water temperature in the pipes should not exceed 90 degrees, and the pressure should be within 1.5-3 atmospheres. Some heating networks can operate at higher temperatures and pressures, but they use special elements not found in standard home heating systems. The inability to regulate the battery with a conventional thermostat may indicate the formation of an air lock. To eliminate it, you will have to use the Mayevsky crane.

How to cut heating

How to refuse heating in an apartment building?

Documentation

We will only partially touch on the documentary part. The problem is quite painful; permission to disconnect from the central heating center is given by organizations extremely reluctantly, and often it has to be obtained through the courts. It is quite possible that in your case it would be much more useful not to read a technical article, but to consult a lawyer knowledgeable in the Housing Code.

The main steps are:

- Let's find out if it is technically possible to turn it off. It is at this stage that most of the friction will occur: neither housing and communal services nor heat suppliers like to lose payers.

- Technical specifications for an autonomous heating system are being prepared. You need to calculate the approximate gas consumption (if you use it for heating) and show that you are able to provide a temperature regime in the apartment that is safe for the building’s structures.

- The fire inspection act is signed.

- If you plan to install a boiler with a closed burner and exhaust of combustion products to the facade of the building, you will need a permit signed by the Sanitary and Epidemiological Supervision Authority.

- A licensed installation organization is hired to draw up the project. You will need a full package of documents - from instructions for the boiler to a copy of the installers’ license.

- After installation is completed, a gas service representative is invited to connect the boiler and start it up for the first time.

- The last stage: you put the boiler on permanent maintenance and notify the gas supplier about the transition to individual heating.

Technical side

Refusal of heating in an apartment building is due to the fact that you need to dismantle all heating devices without disrupting the operation of the heating system. How it's done?

In houses with bottom filling, it is worth considering two cases separately:

- If you live on the top floor, you obtain the consent of the lower neighbors and move the jumper between the paired risers to their apartment. Thus, you completely isolate yourself from the CO. Of course, you will have to pay for welding work, installation of an air vent, and cosmetic repairs to the neighbors’ ceiling.

- On the middle floor, only heating appliances are dismantled, with welding and cutting off the hoses. A jumper of the same diameter as the rest of the pipe cuts into the riser. Then the riser along its entire length is carefully insulated.

Sequence of actions when adjusting batteries

It should be noted that the adjustment of radiators in centralized heating systems comes down mainly to setting the control devices to a comfortable temperature regime. In autonomous schemes, this process is more labor-intensive, because It is not only the batteries that need to be regulated, but also the boiler. In addition, if several heating devices are connected to a closed heating circuit (one- and two-pipe systems with bottom wiring), it is necessary to achieve a balanced heating circuit.

To solve this problem, at the initial stage you should determine the coldest room in the house, because... Battery adjustment will begin with this. To do this, all taps are closed, and after the radiators have cooled, the temperature in each room is measured.

In the found room, the shut-off valve opens completely, and after reaching the required level of heating, they move to another radiator, adjusting the position of the valve, which ensures a comfortable mode. After all the batteries have been adjusted, begin setting up the boiler regulators.

There is another (simplified) option. To do this, it is necessary to determine the exact sequence of location of the radiators along the flow of the coolant. Then in the first battery the tap or thermal head is opened, for example, by one or two turns, in the next - by two or three, in the third - by three or four, etc. If the temperature in each room meets the needs, the adjustment process is considered complete. Otherwise, the procedure should be repeated, increasing or decreasing the number of turns of the tap.

When designing a heating system, measures must be taken to control temperature and pressure. To do this, it is necessary to install special fittings and devices. How to properly adjust the heating system: radiators, pressure and other elements? First you need to understand the principles of organization of these sections of the system.

Heating check valve

A complex heating system contains a fairly large number of auxiliary elements, the task of which is to ensure reliability and uninterrupted operation. One of these elements is the heating system check valve. A check valve is installed to prevent flow in the opposite direction. Its elements have very high hydraulic resistance. Due to this circumstance, there are restrictions on the use of check valves in a heating system with natural circulation. There is too little pressure in such a system. At minimum pressure, it is necessary to install gravity valves with a butterfly valve; some of them can operate at a pressure of 0.001 bar. The main part of the check valve is the spring, used in almost all models. It is the spring that closes the shutter when normal parameters change. This is the principle of operation of a check valve.

It is necessary to take into account the operating parameters in a particular heating system. Therefore, select a heating system valve that has the required spring elasticity. Shut-off valves used in heating systems are usually made of the following materials: steel; brass; stainless steel; gray cast iron. Check valves are divided into the following types: disc valves; petal; ball; bivalve. These types of valves are distinguished by a locking device.

The role of return and its difference from supply

Sometimes, when carrying out plumbing work on their own, the user does not know how to identify the supply and return pipes when the battery is connected. If you are completely unfamiliar with the design, you can use a thermometer, identifying the supply and return pipelines by the temperature difference, if you know the circuits for discharging coolant to the heating radiators, consider the following options:

- With diagonal and side switching, the supply is always at the top and the outlet at the bottom.

- In the lower connection, the direction of movement of the input and output flows is sometimes indicated by arrows on the supply unit (binoculars).

- In Leningradka, the return pipe is considered to be the one coming from the last radiator in the row.

- In the manifold distribution, the supply combs are equipped with adjustable supply sensors in the form of fittings with transparent caps and indicators placed inside; the shut-off valves of the return comb are closed with threaded plugs. Also, the color marking of the forward feed is red, and the return feed is blue.

Rice. 3 Organization of heating systems using an open expansion tank

The return line plays no less important role than the direct line for supplying media to heat exchange devices or heated floors, its purpose and installation methods:

In gravity flow structures with an open storage tank. The movement of water in open circuits occurs due to the difference in hydrostatic pressures of the cooled and hot water columns due to the fact that the hot liquid has a lower density.

Therefore, the return line is designed and installed taking into account the following rules:

- Heat loss in the return must be quite significant to minimize the cooling of the water, that is, the batteries must have significant heat transfer.

- As the distance from the bottom point of the radiators to the boiler inlet pipes increases, the length of the low-temperature column increases and, accordingly, it more effectively displaces the heated coolant. The high location of the boiler from the battery lengthens the section with a cooled return, while simultaneously shortening the section of the high-temperature column - as a result, a large temperature difference shifts the working fluid much further up the circuit and heating occurs more efficiently.

- The upper installation of the boiler is contradicted by the condition under which it must be at a height below the level of the last batteries in the chain for the gravity flow of the carrier into it at an angle. If the boiler is installed low in the basement, to ensure normal circulation during installation, slopes towards the heating unit should be observed (2 - 3 mm per linear meter).

It should be noted that both of the above schemes are working (the latter is used more often) and their choice is related to the convenience of installing boiler equipment in the house.

Rice. 4 Closed heating system - diagram

In closed circuits with an electric pump. In multi-circuit heating with heated floors, circular pumps are installed that create the required pressure in the main; in many cases, two circular pumps are used - one pumps water throughout the system, and the second supplies coolant to the floors or radiator heaters.

With collector wiring, the return temperature relative to the supply plays an important role; the difference should not exceed 10º C, standard differences are 55 - 45, 50 - 40, 45 - 35, 40 - 30 degrees. To achieve these parameters, the cooled coolant from the return manifold is partially mixed with the hot coolant coming from the boiler, and then supplied to the heated floors.

In boiler piping. When the boilers are put into operation, the initial difference between the supply and return temperatures is quite significant - this leads to the formation of condensation on the walls of the heating chamber and chimney pipes, which, entering into a chemical reaction with carbon dioxide and other combustion products, causes accelerated corrosion of their surface.

To prevent these negative consequences, a small circuit is created with an adjustable check valve, in which the temperatures of the coolant entering the boiler and the heated fluid are quickly equalized. After reaching the specified temperature threshold, the thermal valve automatically opens and the entire system line is connected to the small heating circuit.

Sometimes, to equalize the temperature parameters of the supply and return, a bypass jumper of small diameter is installed between them; the width of its passage channel can be adjusted with screw valves (ball valves are used only for completely closing and opening passages).

Pipeline layout in a multi-storey building

As a rule, multi-storey buildings use a single-pipe wiring diagram with top or bottom filling. The location of the forward and return pipes can vary depending on many factors, including even the region where the building is located. For example, the heating scheme in a five-story building will be structurally different from the heating in three-story buildings.

When designing a heating system, all these factors are taken into account, and the most successful scheme is created, allowing all parameters to be maximized. The project may involve various options for bottling the coolant: from bottom to top or vice versa. In individual houses, universal risers are installed, which ensure alternating movement of the coolant.

Why is a pipeline buried?

Backfilling of the pipeline is carried out after the final installation of the water supply system. Such backfilling is carried out in order to hold the laid pipes in a stationary position.

Fixing pipes with backfill is carried out in several stages.

- Manual filling with shovels. This is the initial stage. It is carried out on both sides.

- Backfilling after compacting and joining pipe joints.

- Sprinkling of pipes. This is also done on both sides.

Heating pipe temperature table

The heating temperature, including return pipes, directly depends on the readings of street thermometers. The colder the air outside and the higher the wind speed, the higher the cost of heat.

A standard table has been developed that reflects the temperature values at the inlet, supply and outlet of the coolant in the heating system. The indicators presented in the table provide comfortable conditions for a person in a living space:

| Pace. external, °С | +8 | +5 | +1 | -1 | -2 | -5 | -10 | -15 | -20 | -25 | -30 | -35 | |

| Pace. at the entrance | 42 | 47 | 53 | 55 | 56 | 58 | 62 | 69 | 76 | 83 | 90 | 97 | 104 |

| Pace. radiators | 40 | 44 | 50 | 51 | 52 | 54 | 57 | 64 | 70 | 76 | 82 | 88 | 94 |

| Pace. return lines | 34 | 37 | 41 | 42 | 43 | 44 | 46 | 50 | 54 | 58 | 62 | 67 | 69 |

Important! the difference between the supply and return temperatures depends on the direction of movement of the coolant. If the wiring is from above, the differences are no more than 20°C, if from below - 30°C

Warm like a battery

Let’s assume that the central network structures are reliably insulated along the entire route, the wind does not blow through attics, staircases and basements, and conscientious owners have insulated the doors and windows in the apartments.

Let's assume that the coolant in the riser complies with building code standards. It remains to find out what the normal temperature of the heating radiators in the apartment is. The indicator takes into account:

- outdoor air parameters and time of day;

- location of the apartment in the house plan;

- living or utility room in an apartment.

Therefore, attention: it is important not what the temperature of the heater is, but what the temperature of the air in the room is. During the day, in corner rooms the thermometer should show at least 20 °C, and in centrally located rooms 18 °C is allowed

During the day, in corner rooms the thermometer should show at least 20 °C, and in centrally located rooms 18 °C is allowed.

At night, air in the home is allowed to be 17 °C and 15 °C, respectively.

Types of radiators for heating apartment buildings

In multi-storey buildings there is no single rule allowing the use of a specific type of radiator, so the choice is not particularly limited. The heating scheme of a multi-storey building is quite universal and has a good balance between temperature and pressure.

The main models of radiators used in apartments include the following devices:

- Cast iron batteries

. Often used even in the most modern buildings. They are cheap and very easy to install: as a rule, apartment owners install this type of radiators themselves. - Steel heaters

. This option is a logical continuation of the development of new heating devices. Being more modern, steel heating panels demonstrate good aesthetic qualities, are quite reliable and practical. They combine very well with the control elements of the heating system. Experts agree that steel batteries can be called optimal for use in apartments. - Aluminum and bimetallic batteries

. Products made from aluminum are highly valued by owners of private houses and apartments. Aluminum batteries have the best performance when compared with previous options: excellent appearance, light weight and compactness are perfectly combined with high performance characteristics. The only disadvantage of these devices, which often scares off buyers, is the high cost. However, experts do not recommend saving on heating and believe that such an investment will pay off quite quickly.

Conclusion

The correct choice of batteries for a centralized heating system depends on the performance indicators that are inherent in the coolant in the given area. Knowing the cooling rate of the coolant and its movement, you can calculate the required number of radiator sections, its dimensions and material. We should not forget that when replacing heating devices, it is necessary to ensure that all rules are followed, since their violation can lead to defects in the system, and then the heating in the wall of a panel house will not perform its functions (read: “Heating pipes in the wall ").

Centralized heating systems demonstrate good qualities, but they need to be constantly maintained in working order, and for this you need to monitor many indicators, including thermal insulation, wear and tear of equipment and regular replacement of worn-out elements.

How does the heating of a residential building work? Rising tariffs encourage the transition to autonomous heating of apartments; but the refusal of central heating in an apartment building, in addition to a mass of bureaucratic obstacles, also means a number of technical problems. To understand how to solve them, you need to imagine a coolant distribution diagram.

Consumer choice: cast iron or aluminum

The aesthetics of cast iron radiators is the talk of the town. They require periodic painting, since the rules require that the working surface have a smooth surface and allow dust and dirt to be easily removed.

A dirty coating forms on the rough inner surface of the sections, which reduces the heat transfer of the device. But the technical parameters of cast iron products are excellent:

- are slightly susceptible to water corrosion and can be used for more than 45 years;

- have high thermal power per section, therefore they are compact;

- are inert in heat transfer, so they smooth out temperature changes in the room well.

Another type of radiator is made of aluminum. Lightweight, factory-painted design, does not require painting, and is easy to maintain.

But there is a drawback that overshadows the advantages - corrosion in an aquatic environment. Of course, the inner surface of the heater is insulated with plastic to avoid contact of aluminum with water. But the film may be damaged, then a chemical reaction will begin with the release of hydrogen, and when excess gas pressure is created, the aluminum device may burst.

The temperature standards for heating radiators are subject to the same rules as batteries: it is not so much the heating of a metal object that is important, but the heating of the air in the room.

In order for the air to warm up well, there must be sufficient heat removal from the working surface of the heating structure. Therefore, it is strictly not recommended to increase the aesthetics of the room with shields in front of the heating device.

Why doesn't the return work work?

There are many problems associated with return flow in a heating system.

Squeezes feed

The water temperature in the return pipeline is determined by the design of the heating system and corresponds to the value in the temperature chart approved by the service organization.

Often apartment residents are faced with a problem when the return flow squeezes the supply.

A common reason is the transition of hot coolant from the supply line to the return circuit through various parts (for example, jumpers) of the hot water supply pipeline or ventilation. With an automatic control device, as a rule, it is enough to configure it correctly.

The coolant does not drain well

If the circulation of fluid in the heating circuit is disrupted, the water in the return pipes does not drain well. Initially, check that the power of the circulation pump meets the requirements. The reason may be hidden in a banal pipeline leak . The situation with poor circulation is typical for apartment buildings located on the final section of a heating main with insufficient pressure drop .

Temperature

There are a number of restrictions and regulations related to temperatures inside a living space.

- SNiP sets the following temperature standards: living rooms - 20C, corner rooms - 22C, kitchen - 18C, bathroom and combined toilet - 25C. It is better to focus on them if you are planning to switch to autonomous heating.

- In no utility service inside a residential building should the temperature exceed 95 degrees. For preschool educational institutions, the norm is even lower - 37 degrees. This is why in kindergarten groups you can see batteries of such a terrible size.

However: in the heating main at the same time there may be 140C at the supply.

Elements

Now let's move on to a detailed acquaintance with the components of the systems that provide water supply and heating in apartments.

Elevator unit

Its heart is a water-jet elevator, in the mixing chamber of which hotter and higher-pressure supply water is injected through a nozzle into relatively cold return water. At the same time, it draws part of the coolant from the return pipeline entering through the suction (jumper between supply and return) into repeated circulation.

Direction of water circulation through the elevator unit

The pressure at different points of the elevator unit is distributed approximately as follows:

- Feed to the elevator - 6-7 kgf/cm2;

- Return - 3-4 kgf/cm2;

- The mixture (on the supply line after the elevator) is 0.2 kgf/cm2 higher than on the return line.

Let us emphasize once again: the entire coolant in the heating circuit is driven by a difference of only 1/5 of an atmosphere, corresponding to a pressure (read: height of the water column) of 2 meters. This explains the relatively slow circulation of the coolant, the absence of hydraulic noise in the radiators and the relatively large (15-25 degrees) temperature difference between the radiators in the house.

The mixture pressure is almost the same as the return pressure

There may be several elevator units in a house; however, usually only one of them is equipped with hot water connections. The tie-ins of the dead-end system are located on the supply and return lines to the elevator and suction and are connected to the general bottling. Only one of the tie-ins is open at a time: otherwise the bypass created by them between the supply and return will absorb the difference necessary for the operation of the elevator.

The simplest elevator with a dead-end hot water system

DHW with recirculation requires the distribution of two bottlings throughout the house.

In the elevator unit they can be connected in three ways:

- From supply to return. The water flow through the hot water system is limited by a washer (a steel plate with a hole of a fixed diameter) installed on one of the flanges of the return connection;

- From feed to feed. Two tie-ins are mounted on the supply line to the elevator. Between them, a retaining washer is placed on the flange with a hole diameter 1 mm larger than the diameter of the elevator nozzle;

Please note: the washer creates a minimal pressure difference between the taps, practically without affecting the operation of the water jet elevator.

- From back to back. The installation of taps and washers is the same as in the previous case, but on the return pipeline.

Please note: The DHW switches to the return pipe when the flow temperature reaches 80 degrees Celsius. The current SNiP temperature of hot water supplied from an open heating system is limited to 75°C.

In addition to the elevator and hot water supply connections, the elevator unit includes:

- Mud collectors (always at the supply inlet, optionally at the return) with waste dumps for flushing;

Mud trap at the feed of the elevator unit

- Control valves for measuring pressure. They can be equipped with pressure gauges, however, if the elevator unit is located in the basement for utility purposes, the pressure gauges are often removed to avoid theft;

Permanently installed pressure gauges

- Oil pockets for measuring temperature;

- Heating system resets. They open onto the floor of the heating unit or, which is much more reasonable, into the sewer. Discharges make it possible to completely dry the heating and water supply systems of apartment buildings. In addition, they are used for annual hydropneumatic flushing of heating;

Once a year, the heating system is flushed with a compressor

- Gate valves or ball valves at the inlet of the elevator unit, on heating after the elevator and on all hot water connections. Optionally, intermediate valves may be present at the heating point, allowing, for example, to drain the elevator to remove the nozzle without turning off the hot water supply.

Heating spills

If the heating and water supply scheme of an apartment building is implemented with the installation of heating outlets in the basement, they are mounted horizontally, without slopes. Typical bottling diameter is 32 - 50 mm. Connections of risers are made by welding, less often - by threaded connections, on tees.

Bottom heating distribution: two pipes are laid around the perimeter of the house in the basement

It’s interesting: in houses built by Stalin, galvanization was widely used for heating. Welding is contraindicated for galvanized steel, since the anti-corrosion coating in the weld area inevitably burns out. Therefore, all elements of the heating system were mounted only on threads.

Heating in Stalin: all connections are threaded

With top filling, the supply in the attic of the house is laid with a constant slope. An expansion tank with a vent to bleed air is installed at the top filling point.

What is the difference in installation? With the procedure for starting heating systems.

In the first case, when the vented circuit is started, it is transferred to the vent in order to expel the maximum amount of air from the risers; then the air pockets from the remaining cold risers are released through Mayevsky taps in each jumper. It is long, inconvenient and often involves searching for missing residents of the upper floors.

To start the heating, the air must be vented in each apartment on the top floor

But the instructions for starting a top filling house are much simpler:

- Fill the heating circuit by slowly opening the house (heating) valves on the return and supply;

- Go up to the attic and bleed the air through the expansion tank vent. Due to the slope of the supply, it will be forced out by water exactly there.

The expansion tank and air bleeder are located at the top filling point

Heating risers

The typical diameter of heating risers is 20-25 mm.

Steel heating risers. Size - DN 20

Let us clarify: steel pipes used to install heating and hot water supply in apartment buildings are designated by a nominal diameter (DN, or DN). It indicates the possibility of connecting the pipeline to a pipe thread of the appropriate size and approximately corresponds to its internal diameter.

The risers turn into connections to the heating device; A bypass jumper of the same size as the riser, or a step smaller in size, is usually installed between the connections. The bypass ensures circulation in the riser when the shut-off and control valves on the connections (chokes, thermal heads, ball or three-way plug valves) are completely or partially closed.

Three-way valve for adjusting the heat transfer of a cast iron battery

For bottom filling, a jumper is laid between paired risers:

- At the level of the upper collector of heating radiators;

Looping of paired heating risers on the top floor

- Under the ceiling of a top floor apartment;

- Around the attic.

DHW spills

The diameter of hot water supply bottlings varies from 25 to 100 mm. Spills with a cross-section of 50 mm or more can be found mainly in houses built before the 80s of the last century: they were designed taking into account the overgrowth of steel water pipes with rust and lime deposits.

In later buildings, the diameters were selected without reserve, taking into account the estimated service life of black steel for water supply of 15 years.

Hot water supply and heated towel rails in the basement of a Khrushchev building

Spills for water supply systems are laid only in the basement or subfloor.

The functionality of two DHW dispensers in a recirculation system can be:

- Identical (both bottlings are connected to hot water risers with water collection points and heated towel rails);

Both water points and heated towel rails are connected to the paired risers

- Separate (the supply bottling is connected to risers on which water points are mounted, and the return bottling is connected to risers with heated towel rails). Less often, a group of risers with mixers and towel dryers is combined with a single single (without attached appliances) return riser.

Curious: up to 7 DHW risers can be combined into groups. In the author’s practice, risers were usually combined into groups common to a separate apartment or entrance.

DHW risers

Typical diameters (DN) of hot water risers are 20-32 mm.

In apartments they can be installed:

| Image | Location of hot water risers |

| In the niche of the bathroom (open or closed). |

| At the entrance to the toilet or combined bathroom. |

| Closed niche with risers in the kitchen | In the kitchen niche (kitchen DHW riser with apartment-by-apartment combination of risers in a circulation circuit). |

The connection of modern heated towel rails in hot water circulation circuits is carried out in the gap of the riser and ensures their constant heating.

Useful: when installing a heated towel rail with your own hands, it is better to connect it not to the break in the riser, but parallel to it. Shut-off valves are installed at the inlet and outlet of the dryer. This circuit will help you turn off the heating in the summer heat.

Connecting a heated towel rail with shut-off valves and bypass

What type of wiring to choose

The choice of construction scheme depends on the expected operating conditions:

- In buildings above 2 floors, heating is installed with main risers in a vertical pattern.

- In areas with frequent or prolonged power outages, preference is given to gravity systems with non-volatile boilers.

- For large objects, systems with forced circulation are installed, built using a horizontal type of wiring. The most suitable scheme in is the Tichelman loop.

- For independent execution, inexperienced users choose a dead-end wiring with several arms.

- When pouring pipes into the floor, it is advisable to choose a radial scheme with collectors on each floor - in the event of an emergency pipe rupture, you can turn off 1 radiator, postponing costly repairs with opening the floors.

- Small country houses, bathhouses and utility rooms are equipped according to a dead-end scheme.

Each specific case must be considered individually, taking into account the advantages and disadvantages of the types and types of heating systems.

Elimination

If you notice that the bottom is significantly colder than the top, then urgent action is required. It is necessary to follow the following algorithm to find the cause:

- Checking the correct connection.

- Inspect the radiator, bleed and clean it.

- Assess the condition of the control valves.

- Check the pipes.

- Determine the type of heating system, install or replace the circulation pump.