A warm blind area is necessary in regions where the soil freezes to a depth of 50-80 cm. The water inside the soil freezes and increases in size, causing deformation called soil heaving.

Pressure from earth masses has a detrimental effect on the foundation, cracks appear, and pieces of cladding fall off. In addition, the thermal insulation of the room suffers.

The first floor of the house becomes cold, the floors freeze, and dampness forms in the underground. Heating a building requires more resources, and heating costs are rising.

According to research, the presence of an insulated blind area increases the temperature inside the building, allows you to preserve its integrity for a long time and significantly saves the heating budget. Most often, the blind area is insulated if the house has a shallow foundation or there is a basement floor.

We will tell you in the article how to make an insulated blind area around the house with your own hands.

When can you insulate yourself, and when should you turn to professionals?

The blind area is one of the simplest elements in the construction of a private house. Any homeowner who knows how to work with their hands can handle it themselves. The main thing is to follow the technology of the device and correctly create a “layer cake” from building materials inside the structure.

There are 3 types of blind area:

Tough. It is based on pouring concrete or paving. The participation of specialists is recommended here, since the technology is labor-intensive and will require hiring equipment and auxiliary tools.- Semi-rigid. The final covering here is made of paving slabs, which lie on a concrete base.

Laying out the material and pouring the base require certain skills; it is not always possible to carry out the process efficiently the first time on your own. - Soft blind area. The technology does not involve concrete, so this process is easier to do yourself.

Accordingly, you can insulate the blind area with your own hands with a soft coating that does not require the participation of equipment and concrete work. For other types of coating, the intervention of professionals may be required, but if you act carefully and according to the instructions, insulation and installation of the coating yourself is possible for everyone.

Use of extruded polystyrene foam

If a private house has a warm basement or basement, the blind area can be insulated with extruded polystyrene foam. Thus, you will insulate the foundation walls and with your own hands will ensure a warm and dry atmosphere in the basement.

Expanded polystyrene is produced in slabs of various sizes and thicknesses, has low thermal conductivity, is resistant to mold, does not rot, and in the absence of mechanical damage can last up to 40 years.

Insulating a blind area with foam plastic has one drawback - the presence of seams between the slabs. Moisture can seep through these seams, and if the insulation gets wet, it will not be able to fully perform its functions.

Requirements for insulation

There are a great variety of thermal insulation materials on the market today. The best options for insulating a blind area should have the following properties:

- Coefficient of thermal conductivity . The operating conditions in a particular region matter. The lower this indicator, the better the insulation performs its main function.

- Humidity and biostability . The material must be dry, the amount of moisture inside is minimal, since otherwise it will affect the integrity of the blind area itself. Its physical properties should not change due to temperature changes. The presence of moisture in the pores directly affects the proliferation of microorganisms.

- Ability to absorb water . The less water the insulation absorbs, the lower its thermal conductivity. High-quality material for the blind area should not be susceptible to moisture, the indicator is indicated as a percentage. When choosing between the same insulation from different manufacturers, the water absorption indicator should be decisive. It is recommended to choose the one with the lower percentage.

- Density. For the blind area, you should choose materials with high density, since it will be in conditions of high humidity and under the influence of atmospheric conditions. The marking is displayed in kg/m3, the maximum value is 400.

- Strength. Affects susceptibility to mechanical stress. Soil heaving should not affect the physical properties of the insulation. For the blind area, insulation with a strength above 5 MPa is chosen. This also affects integrity during transportation.

- Durability and frost resistance . For blind area insulation, these are the two most important indicators that directly affect the safety of the building’s foundation and the structure itself. The indicators show what temperature the insulation can withstand and how long it will last under operating conditions.

For the blind area, solid types of insulation are used, elastic and frost-resistant. Also, they should not shrink, as this could cause the entire structure to deform.

Example of calculation of foundation thermal insulation

Here, as an example, we will calculate a thermally insulated shallow foundation (TFMZ) for a house without thermal insulation of the floor on a strip reinforced concrete foundation in Smolensk.

| Fig.1. Scheme of thermal insulation of the foundation of a building without thermal insulation of the floor. 4 and 5 - horizontal and vertical thermal insulation |

Load per 1 l.m. foundation tape is determined in accordance with SNiP 2.01.07-85. A calculator program for calculating the load on a foundation can be found by following this link.

Using this calculator, we will determine the load on the foundation strip and the width of the foundation base.

Next you need to determine:

- dimensions of vertical and horizontal thermal insulation;

- thickness of the soil cushion.

- As a heat insulator we take thermal insulation boards made of extruded polystyrene foam (XPS) grade 35;

- The material for constructing a soil cushion and filling the pit sinuses is crushed stone with a density p

= 2040 kg/m3 and deformation modulus

E

= 65000 kPa. - The base soils are represented by silty sands with a density p

= 1800 kg/m3 (18.0 kN/m3) and a deformation modulus

E

= 18000 kPa.

Step 1. Definition of MI.

We find the specified parameter for the construction site (Smolensk) using the schematic map of IM (see below). MI = 50000 degree hours.

Step 2. Determining the parameters of vertical and horizontal thermal insulation.

In Table 1, the frost index IM = 50,000 degree hours corresponds to the following thermal insulation parameters:

- thickness of vertical thermal insulation b y

=0.06 m; - thickness of horizontal thermal insulation along the perimeter of the building b h

=0.061 m; - thickness of horizontal thermal insulation at the corners of the building b c

=0.075 m; - width of the thermal insulation skirt D h

=0.6 m; - length of sections near the corners of the building L c

= 1.5 m.

Step 3. Calculation of the thickness of the soil cushion.

The thickness of the soil cushion for heated buildings with indoor air temperatures in winter not lower than 17 °C is taken to be at least 0.2 m.

Answer.

Based on the calculations performed, we finally accept:

- thickness of vertical thermal insulation from slabs b y

=0.06 m; - thickness of horizontal thermal insulation along the perimeter of the building made of slabs b h

=0.061 m; - thickness of horizontal insulation at the corners of the building made of slabs b c

=0.075 m; - width of the thermal insulation skirt D h

=0.6 m; - length of sections near the corners of the building with enhanced thermal insulation L c

= 1.5 m; - the thickness of the soil cushion is 0.2 m.

In this case, the depth of the pit under the TFMZ will be: 0.4 m +0.2 m = 0.6 m.

Which material to choose?

Since the material is subject to rather stringent requirements, only a few are suitable for insulating blind areas. Each of them can be installed independently.

Expanded polystyrene

A type of foam plastic, it is used more often than other materials due to its versatility and low cost.

Advantages:

- low thermal conductivity and moisture absorption;

- high strength;

- frost-resistant;

- flexible;

- service life reaches 80 years.

Disadvantages: flammable, it is important to securely lock it under the top layer of the blind area and cover it with the plinth facing material.

Suitable for all types of blind areas, ideal for concrete coverings , but it is necessary to lay it with additional insulating material (film or geotextile) to eliminate mechanical impact and the possibility of fire.

Penoizol

It is sprayed on the base of the building and on the bottom of the trench, under the blind area, where a cushion of clay, sand and geotextile is laid.

Advantages:

- applied without joints, in a uniform layer from a special machine with a sprayer;

- dense, does not absorb moisture;

- low thermal conductivity;

- does not allow oxygen to pass through.

- durable, non-flammable.

Flaws:

- application requires the participation of specialists with equipment;

- toxic, respiratory protection is required for all those present and isolation of the neighboring area (so that the plants are not damaged).

Penoizol is not recommended for regions with high humidity and places where there is heavy rain. The material cannot withstand excess water levels and its application is expensive. Sold in various forms, including sliced.

Styrofoam

One of the most famous materials, elastic, is suitable for strengthening expansion joints.

Pros:

- low thermal conductivity;

- affordable;

- easy to lay and model to the desired shape.

Minuses:

- easy to damage mechanically (reinforced mesh is required during installation);

- subject to combustion;

- if the density is low, moisture absorption is high.

Polystyrene foam lasts much less time than other insulation materials. But it is simple to replace and easy to install yourself.

Expanded clay

The most harmless, environmentally friendly, natural material. It is created from a mixture of clay and slate.

Advantages:

- to use, you don’t need anything other than a shovel - it’s simply poured into a trench;

- non-toxic;

- It's inexpensive.

Disadvantages: not recommended for hard blind areas. Lightweight material is intended for insulation of structures covered with crushed stone, gravel, and lawn.

Concrete composition for blind area – M250

- 1 bucket of cement M400

- 2 buckets of sand

- 4 buckets of crushed stone fraction 5-25

- 0.6-0.7 buckets of water.

It is worth noting that the sand may be wet, and then the amount of water added to the concrete will have to be reduced. For a more plastic (liquid) state, add a plasticizer to the concrete. It would be more correct to mix the plasticizer with water, and only then add it to the dry components (crushed stone, sand, cement).

Try to avoid excess water in concrete as it reduces the strength of the concrete.

How to calculate the required amount of building materials?

If polystyrene foam is used as insulation, it is laid in several layers, since the standard thickness of 5 cm is not enough to maintain the temperature in the ground.

For central Russia, 2 layers are enough, that is, 10 cm thick. For northern regions 3 layers. The quantity is calculated by square meters, taking into account overlaps on the wall of the building.

Example : the perimeter of a building is 8*4 meters = (8+4)*2 = 24 m. With a standard blind area width of 1 m, it turns out that only this part requires 24 m2 of polystyrene foam. The overlap on the wall is equal to the same perimeter, but its height is 30 cm.

We count 24*0.3 = 7.2. With a reserve of 8 m2. A total of 32 m2 of polystyrene foam is needed for laying in 1 layer. For a double bottom layer you need 24+24 = 48 m2. And 8 m2 for the walls. A total of 56 m2 of polystyrene foam will be required.

For foam plastic, the calculation follows the same scheme , but depends on the thickness of the material.

If the tiles are initially larger than 10 cm, then the insulation is placed in one layer. This means, if you look at the example above, 32 m2 including the walls. Penoizol is calculated based on consumption per 1 m2. The layer thickness should not be more than 25 cm; at standard air temperatures and normal winter (not northern or southern regions), up to 15 cm is sufficient. According to manufacturers’ calculations, 1.3 liters per 1 m2 is required.

Example : similar to the previous calculation. The blind area itself requires 24 * 1 * 1.3 = 32 liters of mixture. On the wall 24*0.3*1.3 = 10 l. Total 32 l. Here it is also recommended to take with a reserve of 35 liters. Expanded clay is sold in cubic meters, consumption is calculated based on the height of the layer.

Example: a layer of expanded clay is 10 cm, the building parameters are still the same. 0.01 m3 is consumed per 1 m2. We calculate 10*24 (area of the blind area)*0.01 = 2.4*1000 = 2400 liters. Total: according to the given parameters, you will need 2400 liters of expanded clay. It is packaged in 50 liter bags. Divide 2400 by 50. This means you need 48 bags of expanded clay.

To each calculation you need to add a few more units in case of errors or omissions. If the building has a porch, near which there is no blind area, then its length must be subtracted from the perimeter.

How to make an insulated blind area around the house, instructions

The blind area is a necessary element of the house, and to understand this, you need to find out what tasks it performs. For example, we have a house on a strip foundation; rain and melted snow fall into the soil near the foundation and moisten it. When frost sets in, water in the ground turns into ice and expands, creating frost heaving, which has great destructive power.

Even if the foundation is laid below the freezing depth, the tangential forces of frost heaving still act on it. That is, wet frozen soil sticks to the foundation and, when heaving, lifts it.

For shallow foundations, an insulated blind area is mandatory, and for a buried strip and monolithic slab it is desirable.

The insulated blind area performs the following tasks:

- Removes moisture from the foundation.

- Reduces freezing depth.

- Significantly reduces the forces of frost heaving.

- Is a path around the house.

- Reduces heat loss through the foundation.

What is required to create a warm structure?

To build a blind area outside the house you will need:

- shovels, shovels and bayonets;

- gloves;

- vibrator;

- plumb line, tape measure, thread, pegs;

- sharp knife;

- boards for formwork;

- rule.

Materials:

- sand;

- crushed stone;

- clay;

- waterproofing;

- thermal insulation;

- geotextiles;

- covering: concrete, paving slabs, granite chips, lawn, etc.

Depending on the type of blind area, some of the listed materials and tools may not be needed.

Correct insulation technology

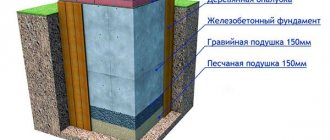

The first steps in the process of building a blind area are the same:

Dig a ditch with a depth of ½ the depth of soil freezing (approximately 30-40 cm). The width is 20 cm greater than the width of the roof overhang. Treat the bottom with chemicals that prevent plant growth and the appearance of insects.- Form the bottom at an angle from the building of about 10 degrees. Dig a groove along the outer edge of the trench for the drainage pipe.

- Pour moistened clay or sand up to 10 cm high into the bottom. Compact with a vibrating machine.

- Place waterproofing with an overlap of up to 20 cm on the wall.

- Pour 10 cm of crushed stone on top as drainage.

- Compact another 10 cm of wet sand.

Next, a layer of thermal insulation is laid . Each uses its own technology:

- Expanded polystyrene is laid in slabs.

- Penoizol is applied with a sprayer (special machine) evenly over the entire area of the blind area with a small backdrop on the wall. It does not form seams and creates another additional layer of waterproofing.

- The foam is laid in tiles evenly. If necessary, the material is cut and formed into the required area.

- Dronite is poured before and after expanded clay. The expanded clay itself is 10 cm thick.

There should be 2-3 cm of free space between the blind area and the wall of the building; it is called an expansion joint. It is left in case of shrinkage of the building and seasonal expansion of natural building materials (wood).

After this, the process is completed with a finishing coating:

- Pouring concrete. A blind area is installed around the entire perimeter. A reinforced grid is laid on the heat-insulating layer. Next, damper joints are installed along the entire perimeter in increments of 2 meters - boards 2.5 m thick. Concrete is poured in one layer at an angle of up to 10 degrees from the house. Ironing is carried out, complete drying with periodic moistening.

- Paving slabs are made according to the same principle, only the layer of concrete is 2 times thinner and tiles are laid on top.

- The soft blind area is laid out without reinforcement or concrete. A layer of sand and gravel is poured onto the insulation and covered with geotextiles. And the final layer is placed on this coating: gravel, granite chips, drainage with lawn and others.

A layer of thermal insulation is also laid on the lower part of the wall, its height is up to 30 cm. It lies inside the expansion joint and serves as a softening elastic stop. At the final stage of construction, the insulation layer is covered with the finishing of the base.

The video will tell you about insulating the blind area with polystyrene foam:

Stages of construction of an insulated blind area:

- First you need to vertically waterproof the foundation strip.

- Next, insulate the foundation strip from the outside with sheets of expanded polystyrene 50 mm thick.

- Around the house, all grass and fertile soil layer, which is usually 20-30 cm, is removed.

- Next, a layer of sand 20-35 cm thick is poured, spilled with water and compacted well, for example, with a vibrating plate or vibrating foot.

- Next, the sand layer is carefully leveled.

- It is better to organize the required slope using sand so that the thickness of the concrete is uniform throughout.

- You can level the plane and slope of the sand using wooden guides or beacons.

- Next, lay the EPS sheets on a sandy base.

- Maintain a 5mm gap between the sheets and fill the gaps with polyurethane foam.

- The hardened foam is cut off with a knife.

- Next, a removable wooden formwork is installed, which will hold the concrete and act as a guide for the rule.

- The formwork must be firmly fixed by driving pegs into the ground for support.

- Next, a reinforcing mesh with a rod diameter of 5 mm and a cell of 100 by 100 mm is laid on the insulation sheets. Overlap 20 cm.

- The reinforcing mesh is laid on pebbles, which lift it by 3-4 centimeters, creating a protective layer of concrete.

- The last stage is pouring and compacting concrete grade M200-M250, which you can make yourself, or order ready-made concrete at the factory.

To prevent the concrete from drying out, the concrete should be shed with water for the first seven days, or even better, covered with film.

Note that if expansion joints are not provided in the blind area, cracks in the concrete are almost inevitable. The lack of insulation under the blind area also significantly increases the likelihood of cracks.

There are two options for making seams:

- Using thin wooden lintels in the blind area.

- Cutting joints in concrete with a grinder and a concrete disc.

The blind area segments are divided into sections of 2-3 meters, and the seams are filled with flexible sealants.

What mistakes can there be and how to avoid them?

Main mistakes:

- laying polystyrene foam in one layer - there is no need to save money, the more reliable the thermal insulation, the more durable the entire structure will be;

- the overlap on the wall is done for greater thermal insulation efficiency and protection of the foundation from freezing - you should not forget about it;

- The lamellar insulation is laid in even layers, the seams are connected as tightly as possible - if you put the material overlapping, cracks will form.

Insulation is recommended for all types of blind areas in Russia, since most regions experience severe winters.

The absence of this detail is detrimental to the foundation of the building; the cold quickly destroys it, making the house uninhabitable. If errors occur with the installation of insulation, the blind area is completely disassembled and the procedure is repeated correctly.

Insulation

If the house is placed on a pile-screw foundation (which is often done in areas with moving soils), the blind area is not so rigid. Since with small displacements of the soil, the protective strip located around the building and the decorative elements of the basement of the structure will inevitably begin to collapse. To prevent this from happening, you need to make a special expansion or expansion joint about 3 cm wide. It is made from DSP, penoplex, roofing felt or bitumen-impregnated boards. Thanks to the blind area, the foundation of the house can be reliably protected.

However, when making it, you need to remember that to ventilate the underground space of the plinth, you need holes with a diameter of about 100 mm. Holes are made at a height of 50 cm from the blind area. They are covered with decorative grilles that protect the subfloor from rodents and other insects.

To organize a good blind area, take into account the type of foundation of the house, and ensure that a number of mandatory requirements are met. Then the structure will protect the base for a long time and effectively.

Expenses

Average prices for insulation in Russia:

Expanded polystyrene. The price depends on the thickness and volume of purchase. Piece by piece 2 cm - from 55 rubles/piece, 5 cm - from 115 rubles/piece, 10 cm - from 250 rubles/piece. The standard plate size is 118.5*58.5.- Styrofoam. 1 cubic meter from 220 rubles.

- Penoizol. The work is carried out by specialists from 140 rubles/cubic meter. They bring the mixture ready for application and spray it, creating a thermal insulation layer.

- Expanded clay. Bag 50 l from 120 rub.

You will find a lot of important and useful information about insulating the blind area around the house in this section.