"Technoplex" and "Penoplex" are insulation materials that have high technical properties. They appeared on the market not so long ago, but have won the recognition of many. Let's figure out what the advantages and disadvantages of these materials are, what their features and differences are. Let's find out which insulation is better to choose and what to pay attention to, and compare several options.

Wall insulation Source optimole.com

Technoplex

Technoplex insulation is an extruded synthetic material that has proven itself well in construction. It is made from polystyrene granules: under high temperature and pressure they are mixed with graphite (it gives the sheets a gray-silver color) and a foaming composition. The mixture is poured into molds and pressed. After hardening, the sheets are cut to standard sizes.

The material is available in 2 versions:

- 118*58 cm;

- 120*60 cm.

The thickness varies - from 2 to 10 cm. The edges of the sheets have a special edge, thanks to which the parts fit together better and do not form gaps.

The result is a homogeneous structure with closed gas cells. Since almost all 100% of the pores are closed, the material has good technical characteristics: being light in weight, it is resistant to deformation and bending, retains heat well and almost does not absorb moisture.

"Technoplex" is used in a variety of areas:

- During the construction of private houses, for example, if the external cladding is made of sandwich panels, as well as when insulating the foundation;

- When arranging outbuildings;

Technoplex Source krov-m.ru

- For insulation of balconies and loggias, floors, including when installing “warm floors”;

- When insulating roofs, attics, interior, internal and external walls.

In addition, insulation is often used in the construction of railways and roads, and in the construction of refrigeration chambers.

Advantages and disadvantages

"Technoplex" is used in various fields of construction and repair due to its high technical characteristics. But, like any material, it has its pros and cons. It is important to know about them when analyzing how penoplex differs from technoplex.

The advantages of insulation include:

- Has high thermal insulation rates. Technoplex is 1.5 times more effective than polystyrene foam and 2 times more effective than glass wool.

- It tolerates temperature changes well and does not deform due to heat or frost. The sheets can withstand from -70 to +75 degrees.

- It practically does not absorb moisture, and therefore does not swell or rot. It can be used in conditions of high humidity.

- Does not shrink and can be used for a long time. Bacteria and mold also do not develop inside the material.

- The insulation is not susceptible to rodent attacks.

Technoplex is easy to cut Source cstor.nn2.ru

- The material is easy to use and process: it does not fray or crumble, the proposed shape and size are most convenient to use. Its installation does not require special skills or the use of special equipment.

- It has low weight and thin thickness. When used, it does not increase the weight of the building and does not reduce the usable area inside.

- The average service life is 50 years. At the same time, the characteristics of the material do not change over time.

Also, Technoplex is an environmentally friendly material. It does not contain substances hazardous to health and, subject to operating conditions, the insulation is completely safe.

Its disadvantages include:

- Flammability. "Technoplex" has a flammability class of G4, it is highly flammable and emits acrid smoke when burned.

- The material is easily destroyed by ultraviolet radiation. Open packaging should not be stored under the sun; keeping the insulation outdoors for a long time is not recommended at all. Installation is best done on a cloudy day.

- When working, do not use organic solvents, as the sheets begin to collapse.

Foundation insulation Source remontnik.ru

It is also noted that the price of Technoplex is higher than that of other popular insulation materials. If the volume of work is large, the cost of the material may be too high.

See also: Catalog of companies that specialize in home insulation

Material properties

The main characteristics of the insulation meet the requirements of building regulations:

- Low thermal conductivity coefficient. The average level corresponds to 0.027–0.031 W/m. The indicator is the best in the class of insulation. At the same time, its difference from related materials, for example, mineral wool, is not so significant. But the combination of low thermal conductivity with increased structure density provides noticeable advantages. An important factor is the constancy of the indicator; significant fluctuations in different conditions are not recorded, therefore the use of penoplex is allowed without an additional moisture-proof layer both on roofs and attics, and on foundations, floors, and basements.

- Fire resistance. Fire resistance is characterized by categories G3 or G4, which means a moderate level that exceeds the properties of foam plastic that supports combustion. Operating temperatures from -50° to +70°C are acceptable for polystyrene foam. In open fire conditions, the material is destroyed. The melting process begins, but not combustion. Some types of penoplex are characterized by enhanced treatment with chemical reagents to exhibit self-extinguishing. This improved quality corresponds to complete fire safety under extended operating temperature conditions.

- Moisture resistance. Water absorption of extruded polystyrene foam is 0.4% of the volume over a period of 28 days. Moisture enters only into the external pores of the insulation, which are opened when cutting and installing the slabs. Closed cells are kept unchanged. In fact, it can be argued that the material does not allow moisture to pass through. For insulation of facades and roofs of buildings, such moisture resistance indicators are very significant.

- High compressive elasticity. This figure is 25-35 kg/m3 and is unsurpassed among polystyrene foam insulation. Compressive resistance is achieved through the uniform distribution of tiny cells with good adhesion, improving the strength characteristics of the material. Penoplex does not change dimensions even under heavy loads. The slabs are very difficult to break. Only material with a small thickness of 20 mm is subject to damage, but there is no crumbling or crushing along the fault line, unlike other related insulation materials.

- Weak vapor permeability. Increased resistance is reflected in equal indicators of penoplex with a height of 2 cm and a layer of roofing material.

- Long service life. The warranty period for use is 50 years, taking into account atmospheric exposure. Under favorable climatic conditions, the slabs will last much longer while maintaining all their characteristics.

- Environmental friendliness. The use of freon in the manufacture of insulation is absolutely harmless: this type is non-flammable, non-toxic, and does not cause destruction to the ozone layer. Environmental properties are interconnected with the biostability of the insulation and the absence of toxic substances. The material is not subject to biological decay, therefore it does not require special storage conditions; the slabs can be placed on sites without shelter from precipitation or temperature changes.

- Availability of installation and processing . You can cut the slab with a regular stationery knife. The low weight allows you to cover the walls yourself without additional effort in constructing special frames. The material adheres well to glue. Weather conditions do not interfere with installation.

- Resistance to aggressive substances. Most construction mixtures and preparations are not capable of damaging penoplex, which does not react with them. These include organic and inorganic acids, alkalis, water-based paints, salt solutions, ammonia, cement or concrete mixtures, alcohols and oils, bleach. Extruded polystyrene foam has virtually no chemical activity. Attention! The exceptions are ethers, gasolines, formaldehydes, and oil-based paints.

- High sound insulation. In private housing construction, the noise insulation factor is very important. Penoplex solves this problem.

Penoplex

“Penoplex” is a heat-insulating extruded polystyrene foam, which is produced by the same name, and is distinguished by high technical properties, thanks to which the material has become extremely popular.

Its production is similar to that of Technoplex: polystyrene granules are heated at high temperatures and mixed under pressure with a foaming agent until a homogeneous structure is obtained. The mixture is passed through extruders, cooled and cut into sheets.

The plates are orange. The material consists of small cells filled with air. They are firmly closed and do not allow heat and air to pass through.

"Penoplex" is used:

- For floor insulation (under or on a screed, when installing a floor on joists or when installing a “warm floor”);

- When insulating a non-residential basement, thermal insulation of internal walls or facade;

- On roofs (for flat or green roofs);

- For insulation of wells and septic tanks;

- When installing platforms and paths, when constructing a blind area around the house.

Using Penoplex Source avrora-sm.ru

When using Penoplex, it is important to remember that it does not conduct moisture, and therefore it is necessary to have a good ventilation system, otherwise problems may arise. It is also necessary to select the thickness of the insulation so that the dew point falls on the material itself, and not on the wall.

"Penoplex" is available in several versions:

- " Wall ". They are distinguished by a rough surface on which finishing materials adhere better.

- " Comfort ". The edge is made in the shape of the letter "G". During installation, this guarantees stronger adhesion and the absence of gaps.

- " Foundation ". Used where structures are subject to high loads (for screeds) or where fire resistance requirements are lower (for floors or foundations).

- " Roof ". They have a “U”-shaped notch, which makes the connection more durable.

These types differ in thickness, density, elasticity and bending strength. For example, “Penoplex” “Foundation” and “Roofing” are more dense and elastic, their tensile strength is higher.

Advantages and disadvantages

It is impossible to decide how penoplex differs from technoplex and which is better without analyzing the pros and cons of the material. Both insulation materials are very similar to each other.

Penoplex Source ko-online.com.ua

On the walls: yes or no?

Insulating walls with Penoplex is permissible only if you agree to make an effective ventilation system that will regulate the humidity in the house.

In this case there are two options:

- Insulate the walls with EPS from the inside. With this solution, moisture practically does not enter the enclosing structures (the material from which the walls are made) due to the low vapor permeability of the material. In this case, the Penoplex layer for walls can be of small thickness. Specifically, it is necessary to count, since it depends on the material and thickness of the walls, and the region of residence. But, with such insulation, it is necessary to select the external finishing of the facade so that moisture is not trapped inside the wall. Ventilated facades are most suitable for this purpose.

- Stick the EPS on the outside. But at the same time, it is necessary to make an effective vapor barrier inside the room. It is needed to prevent moisture from entering the walls. Since there is EPS on the outside, it will not come out. To prevent moisture from accumulating in the wall, a vapor barrier is required. In this case, the thickness of Penoplex will be large. So large that the dew point is not in the wall, but in the thickness of the insulation. That is, in this case it will be necessary to insulate EPS walls with a thickness of 100 mm or more.

As you can see, there are options for using extruded polystyrene foam for wall insulation, but they are far from the best. Despite the fact that the material itself is good, it is poorly suited for this purpose.

And we must also take into account that the second option is only for non-hygroscopic materials. Such a scheme is very undesirable for wooden, frame buildings; it is poorly suited for foam blocks. The fact is that no matter how good the vapor barrier is, some of the moisture will still get into the walls. If the material is non-hygroscopic, moisture will gradually be removed from the wall during the dry season. With hygroscopic materials this process is more complicated. As a result, the wood rots and the foam block walls “bloom.”

Comparison of Technoplex and Penoplex

It is easy to see that both materials have the same pros and cons. Their production technologies are also similar.

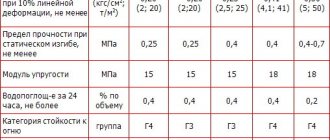

Using the table, you can compare the physical characteristics of both materials and clearly see whether penoplex or technoplex is better.

| Comparison options | Technoplex | Penoplex |

| Density (kg/cubic meter) | 26-35 | 25-47 |

| Flexural strength (Mpa) | 0,30 | 0,4-0,7 |

| Compressive Strength at 10% (Mpa) | 0,24-0,25 | 0,25 |

| Thermal conductivity (W/m*K) | 0,029-0,030 | 0,030 |

| Vapor permeability (mg/m*hour*Pa) | 0,005-0,011 | 0,007-0,008 |

| Water absorption (max) | 0,2 % | 0,4% |

| Temperature Range | From -70 to +75 degrees | From -50 to +75 degrees |

It is easy to see that the technical characteristics of both insulation materials are almost the same. Minor differences in density and water absorption may play a role in the choice, although the difference is too small. The difference is noticeable only in bending strength: Penoplex is much stronger and can withstand greater loads.

Video description

A comparison of both insulation materials is clearly shown in the video.

Since both insulation materials have the same source material, they are harmless to the environment and humans, and are not afraid of almost any building mixtures or solutions. Throughout the entire service life, subject to operating conditions, no harmful substances are released. The flammability of both insulation materials is the same: they easily ignite and release asphyxiating substances. It is recommended to pre-treat the sheets with fire-retardant compounds.

Installation of both materials is similar and does not require special knowledge; a novice master can easily handle it.

Despite the strong similarity, most often the choice is made in favor of Penoplex. There are several reasons for this:

- Price . Penoplex is about 10-15% cheaper than Technoplex. For large volumes of work, the difference in cost can be significant.

- Sheet size . Both insulation materials have similar widths (58 and 60 cm) and thickness (from 2 to 15 cm), only the length differs. "Penoplex" is sold in slabs 120 cm long, less often 240 cm (only at maximum density). "Technoplex" is produced in the form of sheets of various lengths: 120, 240, 300, 400, 450 cm.

Insulation from outside Source avrora-sm.ru

Comparison with other insulation materials

Other materials are also used as insulation. They all have certain features and disadvantages that are worth remembering.

Below we compare Penoplex and:

- Expanded polystyrene . It is produced using a non-press method, due to which the strength and density are reduced. Almost all technical characteristics of polystyrene foam are lower in comparison with Penoplex. The exception is vapor permeability: it is much higher, and therefore it is better to use insulation in rooms with high humidity.

- Styrofoam . Its characteristics are similar to expanded polystyrene.

Foam insulation Source tildacdn.com

- Styrex . Stirex and Penoplex have almost identical characteristics.

- Mineral wool . Made from mineral raw materials by heat treatment. It has different densities (up to 300 kg/cubic meter) and high vapor permeability, can absorb up to 1% moisture. At the same time, mineral wool can withstand temperatures up to +450 degrees. It is best used in rooms with high humidity and in fire hazardous places (workshops, garages, industrial facilities).

- Extrol . It has the same characteristics as Penoplex, but is produced not only in the form of slabs, but also in the form of cylinders or semicircular segments. It is convenient to use for thermal insulation of pipes.

When choosing a material, it is important to pay attention not only to the properties of the insulation, but also to the form of release and the ease of working with them.

Installation technology

When laying on horizontal surfaces - floors, flat roofs - the slabs are simply laid on a flat surface. The surface should be without sharp changes, the maximum deviation is 2-3%. This requirement must be met so that voids do not form. When laying, we monitor the joints; it is advisable to glue them (you can use tape) or fill them with the same foam/glue on which the slabs are attached.

If two layers of thermal insulation are laid, it is positioned so that the EPS slabs of the second row overlap the seams of the lower one. They also say that the slabs are laid with alternating seams or “staggered”.

When mounting on vertical surfaces, double fastening is used:

- Glue or adhesive foam is applied to the plane.

- Additionally fixed with umbrella dowels.

According to the technology for installing slab insulation on facades, umbrella dowels are installed at the junction of two sheets (any two sheets) and two additional fasteners in the plane of the sheet. That is, there are at least 8 fasteners per sheet (indicated in red in the figure). More is possible. Less - no. Unless, of course, you want the insulation and finishing to come off. If the winds in the region are strong, it is better to put more. To insulate the inside, you can install less.

Evgeniy Filimonov

Ask a Question

During installation, on the outer slabs and around openings, we install fasteners more often: three to four elements per slab. To keep the insulation rigid in the corners of the openings, a mesh is attached to it before plastering. It is attached at an angle of about 45°, securing the joint. Under such conditions, there will be no problems with finishing inside or outside.

If plaster, facade tiles, finishing stone and other heavy materials are subsequently applied to Penoplex, before installation, care must be taken to improve the adhesion of the material to the wall and to the finish.

Even if you are installing a Penoplex Wall with stripes, it is better to add roughness to the slab using a metal brush. And from both sides. If the wall is smooth, it also doesn’t hurt to add roughness - for better adhesion.

To work with Penoplex, a special adhesive mixture is recommended: Ceresit ST 84, illbruck PU 010, Titan 753, Ceresit CT-85, Kreisel 210 and 220, Baumit ProContact, STO Baukleber, Soudal Soudabond, Penosil Fix and Go, Den Braven, Krass.

Briefly about the main thing

Insulation plays an important role in construction and renovation. You can find a huge number of insulation materials on the market, each of which has its own characteristics and disadvantages.

“Technoplex” and “Penoplex” are similar in technical characteristics. Both materials have high density and can withstand significant weight, and are characterized by low vapor permeability and thermal conductivity. They also have similar disadvantages. Both insulation materials ignite easily and release hazardous substances.

The choice is most often made in favor of Penoplex. This is due to the low price and the ability to use sheets for external insulation.

Other materials can be used for insulation: mineral wool, polystyrene foam and others. Each of them has its own characteristics.