"Technoplex" and "Penoplex" are insulation materials that have high technical properties. They appeared on the market not so long ago, but have won the recognition of many. Let's figure out what the advantages and disadvantages of these materials are, what their features and differences are. Let's find out which insulation is better to choose and what to pay attention to, and compare several options.

Wall insulation Source optimole.com

Installation features

The slabs can be laid on the ground under a concrete screed

To insulate your home yourself, you do not need any special skills. It is enough to study the technology of work on a specific site and follow the tips and recommendations. The TechnoNIKOL Technoplex insulation is fixed with special glue and plastic dowels.

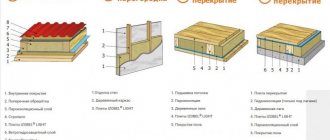

Floor insulation

Thermal insulation of floors with XPS slabs can be carried out on the ground and concrete screed. The first technology is used in rooms where the base will not experience high loads. Preparation begins with filling a layer of crushed stone. Sand is placed on top of it in a layer of up to 10 cm. Having compacted the base, sheets of expanded polystyrene are laid. Technoplex is poured with a concrete screed.

When insulating a concrete base, it is necessary to check its level. All differences are leveled with a solution. Expanded polystyrene is installed on a completely dry and clean base. In the basement, a layer of waterproofing is laid underneath it. The thickness of the sheets depends on climatic conditions, usually it is 50-80 mm. The insulation is covered with plastic film, and a damper tape is laid around the perimeter. Cement-sand mortar is poured.

If heating is provided by a water or cable electric floor heating system, heating elements and pipes are placed under the screed layer.

Thermal insulation of walls

The insulation is suitable for arranging a ventilated facade.

To fix the sheets on a vertical base, special adhesive mixtures Geresit or TechnoNIKOL are used. The insulation process begins with leveling, cleaning and priming the walls. Installation starts from the bottom. Each subsequent row is laid offset by half the length of the sheet. The adhesive composition is applied to the surface of the insulation, the plate is pressed against the wall for a few seconds. For additional fixation, 5 umbrella dowels are installed. They are placed in the corners and in the middle. The seams between the sheets are filled with polyurethane foam.

After the glue has dried, a reinforcing layer of fiberglass mesh is laid on the surface of the Technoplex. Finishing is done with plaster. After the solution has dried, the finishing coating is performed.

Foundation insulation

It is recommended to insulate the foundation from the outside. The surface is first covered with a layer of waterproofing. An adhesive mixture is applied to the expanded polystyrene boards around the perimeter and in the center. Pressing it to the foundation, hold it for 1 minute. The sheets are laid close to each other, and the subsequent rows are made with offset seams. The glue is given 2 days to dry, then the insulation is fixed with plastic dowels. The final finishing is done with plaster mortar over a reinforcing mesh.

Roof installation

Expanded polystyrene is suitable for roof insulation from the outside and from the inside.

Thermal insulation of the roof is carried out from the inside and outside. In the first case, it is possible after construction is completed. The slabs can be laid using frame and frameless technology. On a flat roof, the material is placed on a waterproofing sheet. The slabs are laid staggered, if necessary in two layers. The insulation is covered with a geotextile fabric. The finishing layer is a concrete screed or backfill with gravel.

The pitched roof is insulated along the sheathing. The bars are packed in increments of 600 mm, equal to the width of the slabs. Technoplex is laid in the sheathing, the joints are filled with polyurethane foam. The insulation layer is covered with a vapor barrier film. A counter-lattice is placed on top of the material for installation of finishing.

Technoplex insulation has all the necessary characteristics that ensure reliable and durable thermal insulation of the house.

Description and features of the material

Technoplex insulation is made from polystyrene granules, which, under the influence of high temperature and high pressure, are mixed with a special foaming composition and graphite. The viscous mass is sent into molds of a certain size, where it hardens and is cut into sheets of standard parameters.

The final product is smooth and dense. The structure of the sheet consists of a large number of small closed cells that do not allow air to pass through. Thanks to this, the characteristics of Technoplex (50 mm) are quite high. Graphite additives significantly improve the thermal insulation abilities and increase the strength of the slabs.

Products are sold in rectangular packaging, the size and weight of which depends on the size of the material.

Technical characteristics of Technoplex

High strength properties allow the material to be used where structures are subject to high loads. Being lightweight and thin, EPS boards nevertheless provide minimal heat loss compared to other analogues.

Important: Technoplex is chemically neutral (only gasoline and organic solvents are dangerous for it). The material is not susceptible to microorganisms, does not rot, and is not eaten by rodents. During operation, the insulation does not emit toxic substances.

The physical and technical parameters of Technoplex are given in the table.

Material advantages

To summarize, it should be noted that Technoplex is an improved modification of polystyrene foam. Here are the advantages of extrusion insulation.

- Strength. Gray EPS with graphite additives is 5-6 times stronger than expanded polystyrene. Polystyrene foam easily crumbles and breaks. It takes a lot of effort to break off a piece of extruded material.

- Density. Technoplex has a density and specific gravity that is 1.5-2 times higher. Therefore, it can withstand higher loads (it is not for nothing that it is used when forming a floor “pie”).

- Thermal insulation parameters. XPS retains heat better than foam products due to its smaller pores. With the same level of thermal protection, a Technoplex slab will be 25% thinner.

- Moisture resistance. Polystyrene foam absorbs water 5 times more actively: this is explained by its loose structure with numerous voids (although it should be noted that this figure is minimal). XPS with its minimal water absorption can remain in the ground for up to 50 years without losing its performance qualities.

The use of Technoplex is recommended wherever there are no increased requirements for vapor permeability. Installing the slabs of material is not difficult - the main thing is to fix them on the work surface and carefully foam the gaps.

What is technoplex? Features of insulation

Essentially, it is an extruded artificial polystyrene foam (XPS) material that is resistant to any external influences. Technoplex is produced in the form of plates that have a special edge for adhesion of the elements.

Manufacturing technology involves the use of polystyrene in the form of balls and a foaming agent. The components are heat treated and pressed under high pressure. As a result, the material has a porous structure, with evenly distributed cells.

The structure of technoplex withstands the effects of almost any chemical compounds. The exceptions are gasoline and organic solvents.

In addition, when producing technoplex, tiny graphite particles are added to the raw material, which significantly increases the strength of the material. Thanks to this feature, the finished insulation boards acquire a grayish tint.

Extruded polystyrene foam TECHNOPLEX 2cm

TECHNOPLEX 2cm extruded polystyrene foam is designed for thermal insulation of private houses, renovation of residential premises, including the installation of “warm floors”.

Description

Extruded polystyrene foam XPS TECHNOPLEX is a thermal insulation board that is used to insulate balconies, partitions, and in floor construction and “warm floors.” XPS TECHNOPLEX is one of the best thermal insulation materials for country house and apartment insulation. In the production of XPS TECHNOPLEX, nano-sized graphite particles are used. Nanographite reduces the thermal conductivity of the material and increases its strength. Thanks to the saturation with nanographite, XPS TECHNOPEX boards acquire a light silver tint.

Advantages

- Saves your money due to better thermal insulation properties per m². in relation to other thermal insulation materials;

- Retains heat 1.5 times more efficiently than conventional foam plastics and 2 times more efficiently than stone and glass wool;

- Not afraid of moisture;

- Does not shrink over time;

- Does not contain formaldehyde;

- Not susceptible to rodents;

- Convenient and easy to use. Provides high installation speed;

- Stable characteristics throughout the entire service life;

- Convenient packaging for transportation.

Characteristics

| TECHNOPLEX | Test method | TECHNOPLEX |

| Compressive strength at 10% linear deformation, kPa | GOST 17177 | 150-250 |

| Thermal conductivity at (25±5)0С, W/(m*K), no more | GOST 7076-99 | 0,032 |

| Thermal conductivity under operating conditions “A and B”, W/(m*K), no more | SP 23-101-2004 GOST 7076-99 | 0,034 |

| Flammability group | GOST 30244 | G4 |

| Water absorption, no more, % | GOST 15588 | 0,2 |

| Modulus of elasticity, MPa | ALLIANCES | 17 |

| Vapor permeability coefficient, mg/(m.h.Pa) | GOST 25898-83 | 0,010 |

| Specific heat capacity, kJ/(kg.оС) | SP 23-101-2004 | 1,45 |

| Bending strength, not less, MPa | GOST 17177 | 0,30 |

| Density, kg/m3 | GOST 17177 | 26-35 |

| Operating temperature, оС | 0t -70 to +75 |

Package contains 20 sheets, 14.4 m2

Geometric dimensions

| Geometric dimensions* | ||

| TECHNOPLEX | Test method | TECHNOPLEX |

| Thickness, mm | GOST 17177 | 20**,30,40,50,100 |

| Length, mm | GOST 17177 | 1180 or 1200 |

| Width, mm | GOST 17177 | 580 or 600 |

**- thickness 20 mm does not imply the presence of an “L” edge**

| Brand | TECHNOPLEX |

| Thermal conductivity (W/(m•k) | 0,034 |

| Quantity per package (m2) | 14.4 M2 |

| Application | Insulation of walls under siding, Insulation of baths and saunas, Insulation of walls under plaster |

| Insulation length (mm) | 1200 mm |

| Insulation width (mm) | 600 mm |

| Number of sheets per package | 20 pcs |

| Product type | Extrusion expanded polystyrene |

| Insulation density | 35 kg/m3 |

| Sheet thickness | 20 mm |

Buy with this product

Ceresit CT 83. Adhesive mixture for fastening polystyrene foam boards 25 kg Code: CN325 In stock: 999999 Notify when available 550 rub. Add Properties • can be used at temperatures from 0°C; • has a high…

Dimensions

When manufacturing a technoplex, certain standards for finished products are observed. Therefore, regardless of the manufacturer, the insulation has the same size and sheet thickness. It looks like this:

- Length – 1,180 – 1,200 mm .

- Width – 580 – 600 mm .

- Thickness – 20 / 30 / 40 / 50 / 100 mm .

It should be clarified that thick slabs are used only in the construction of industrial buildings and road work. Meanwhile, the characteristic L-edge profile is absent on products with a minimum thickness.

Installation of extruded polystyrene foam

The slabs are installed using polystyrene foam glue with additional fastening with dowel mushrooms if necessary. Technoplex is warmer than foam block and other building materials; 50 mm of extrusion insulation replaces 600 mm of foam block. If we compare Technoplex with URSA XPS and other foreign analogues, then its cost is lower, with the same thermal conductivity characteristics.

Insulation of buildings should be done from the outside; in this case, the area of the room will remain the same. Work should begin with cleaning and preparing the surface. The walls are cleaned of old paint or trim and then smoothed with plaster. Next, starting from the bottom, the insulation boards are installed. Many people install a base starting profile, which additionally protects the insulation from rodents.

The slabs are installed end-to-end so that there are no cold bridges. After finishing the entire surface, a layer of mastic or polystyrene foam glue is applied to the surface of the thermal insulation, onto which a reinforcing mesh is glued. After drying, the surface is primed and the facade of the house is finished with plaster. The façade can also be covered with vinyl siding or decorative PVC panels.

Penoplex or technoplex what is the difference

The scope of application of extruded polystyrene foam, due to its high strength and resistance to moisture, is very wide. XPS is used when pouring USP, insulating strip foundations and blind areas of houses. The material does not lose its original characteristics even in water, since the structure of the material consists of closed cells that do not absorb moisture, unlike Rocklight mineral wool.

Table. Penoplex or Technoplex, what is the difference in characteristics

Advantages and disadvantages

Any building material has its own strengths and weaknesses, which determine the area of application. Technoplex was no exception. The undeniable advantages of insulation include the following:

- Resistance to wet environments

- Reduced frost resistance coefficient, which eliminates the need to lay a layer of waterproofing

- Resistance to mechanical damage and dynamic loads

- Neutrality to most active substances

- Ease of installation

- Long service life without loss of original qualities

Among the disadvantages are the following:

- Material is burning

- When interacting with complex carbons, a conflict of materials occurs, which leads to destruction of the insulation structure. An unsuccessful example of a combination of components: insulation with Technoplex when facing with siding

- Sensitivity to prolonged exposure to direct sunlight

- Limited range of operating temperatures, which does not allow the material to be used for insulation of baths and saunas

The disadvantages include the high cost, which, however, is justified by the high technical characteristics and almost eternal service life.

Characteristics and properties of Technoplex products

The high strength of the material allows it to be used in construction areas subject to high loads. Light and thin XPS sheet does not load the structure, providing the lowest thermal conductivity coefficient among similar products.

Extruded polystyrene foam is resistant to most aggressive chemicals, except organic solvents and gasoline.

The insulation is not subject to rotting, shrinkage and deformation. It does not contain toxic substances, therefore it is safe for people. The low vapor permeability of the heat insulator, which prevents natural gas exchange, requires the installation of high-quality ventilation.

Performance properties

Technoplex ensures the safety of the home and the people living in it, thanks to its environmental friendliness. Extruded polystyrene foam is made from environmentally friendly materials and is non-toxic. In addition, when using the material, you need to take into account that it belongs to the group:

- flammability G4;

- flammability B3;

- smoke generating ability D3;

- toxicity of combustion products T2

The durability of Technoplext extruded polystyrene foam is ensured by:

- resistance to most aggressive environments, with the exception of petroleum solvents. In addition, the material does not deteriorate under the influence of solar ultraviolet radiation and atmospheric moisture;

- biological stability;

- maintaining properties during repeated defrosting and defrosting. It was experimentally established that even after 1000 times freezing and thawing, polystyrene foam did not lose its properties.

Application of extruded polystyrene foam, installation nuances

Technoplex products are effective thermal insulation of buildings in all areas:

- foundation;

- facades and interior walls;

- floors;

- screed floor, wooden flooring, “warm floor” system;

- balconies, garages, loggias.

High-density slabs of 45 kg/m3 are used in the modernization of roads.

For external installation, sheets with a thickness of 100 mm are used. Before fastening them, the walls are leveled and treated with a primer. The insulation is fixed with a special glue for polystyrene foam. The slabs are laid from below, tightly joining each other. Each subsequent row is performed with an offset of half a sheet. After the glue has dried, Technoplex is additionally secured with plastic dowels. The outside of the insulation is reinforced with fiberglass mesh and plaster is applied.

When performing internal thermal insulation, products of small thickness up to 40 mm are recommended. The material is fixed to the walls with glue; an air gap is left between the insulation layer and the finishing for ventilation.

Durable and moisture-resistant XPS boards are used to insulate floors on the ground under a concrete screed. When installing extruded polystyrene foam under a heated floor system, energy losses are reduced. The insulation boards are laid on the screed and covered with plastic film. A substrate with a layer of foil is laid on top of it, and cable mats are mounted. The entire system is filled with concrete screed.

When insulating the floor along joists, sheets of expanded polystyrene are laid on a layer of waterproofing placed between wooden blocks. The joints between the plates are covered with polyurethane foam.

Technoplex does not change its properties even in difficult operating conditions; it is installed as thermal insulation of the underground area of the blind area and the foundation of the house.

Application area

Technoplex is considered universal, therefore it is used in almost all construction sites. In particular:

- Foundations

- Interior of walls and facades

- Interior partitions

- Insulation of self-leveling floors and wooden floorings

- Arrangement of balconies and loggias

- Insulation of garages and outbuildings

It is worth noting that products with increased density can be used to modernize road surfaces.

Insulation of external walls

Builders, as a rule, perform insulation from the outside. In this case, the area of the room will remain the same. To perform the work, sheets of technoplex 100 mm thick .

If you take a thinner material, you need to use 2 layers of insulation, due to which heat loss will be reduced by 40–60%. Naturally, it is customary to begin external thermal insulation work using technoplex after surface preparation. To do this, the walls are cleaned and then leveled with plaster. Next, the insulation sheets are glued. To ensure they hold well, dowels can be used. In this case, the fastening is carried out end-to-end. Since the coating of techoplex sheets is smooth, the surface must first be roughened.

The slabs are glued starting from the bottom . Thanks to this, they will not mix while the glue dries. Then a layer of special mastic is applied to the surface and a reinforcing mesh is fixed on it, which will make the protective layer quite rigid. Next, treatment is carried out with a primer and finishing compound. As a result, the facade of the house will have an attractive appearance.

Experts recommend performing thermal insulation work in dry weather. It is also worth paying attention to the air temperature. It must be at least 5˚ C.

Description and features of the material

Technoplex insulation is made from polystyrene granules, which, under the influence of high temperature and high pressure, are mixed with a special foaming composition and graphite. The viscous mass is sent into molds of a certain size, where it hardens and is cut into sheets of standard parameters.

The final product is smooth and dense. The structure of the sheet consists of a large number of small closed cells that do not allow air to pass through. Thanks to this, the characteristics of Technoplex (50 mm) are quite high. Graphite additives significantly improve the thermal insulation abilities and increase the strength of the slabs.

Products are sold in rectangular packaging, the size and weight of which depends on the size of the material.

Internal wall insulation with technoplex

Similar work is carried out during the reconstruction of a home. It is also possible to insulate walls from the inside when the façade finishing has been completed recently. Preference should be given to technoplex sheets with a maximum thickness of 40 mm .

Since internal fastening is used in this case, the plates do not need to be fixed with dowels. Experts recommend leaving a small gap between the wall and the insulation itself. This will help reduce heat loss, but will lead to a reduction in living space. It is better to leave a distance, because this will provide natural ventilation. Accordingly, condensation will not penetrate inside, which means the humidity level in the room will remain optimal. This will help avoid rotting, and the walls of the house will dry out very quickly after rain.

When the insulation work using technoplex is completed, the wall surface must be finished . Wooden sheathing is often used for these purposes. It is also possible to use sheets of plasterboard, which are subsequently coated with paint or wallpaper.

Among the variety of modern insulation materials, special attention should be paid to technoplex. This material has excellent thermal insulation properties, thanks to which you can insulate your home both inside and outside. In this case, the help of professionals is not needed.

How Technoplex is used

The universal material can be easily cut with a knife, mounted on the sheathing or directly on the base, while laying vapor and waterproofing is not necessary. Installation on horizontal and vertical surfaces has its own nuances.

Facades

For them, 100 mm sheets of material are usually used. The walls are first leveled using a plaster mortar and impregnated with a primer. To fix polystyrene foam boards, special types of glue are used - Penosil, TechnoNIKOL, Cerezit, produced in the form of polyurethane foam. Technoplex is laid from the bottom up, tightly joining the elements together. Each subsequent row is shifted relative to the previous one by half the width of the slab. When the glue dries, the polystyrene foam is attached to the facade with plastic umbrella dowels for reliability. A layer of plaster is applied on top of the thermal insulation, and at the same time it is reinforced with fiberglass mesh.

Note: Expanded polystyrene can be glued to vertical and other planes using construction polymer-cement mixtures. The adhesive solution, prepared independently according to the instructions, has good plasticity and high adhesion to the base.

Insulation of external walls with Technoplex

Basement, foundation, blind area

Technoplex retains its technical characteristics even when in contact with the ground, so it is indispensable in the following situations:

- installation around the building with an indentation of 1.5 m - such a blind area prevents freezing of the basement floor;

- thermal insulation of underground communications;

- insulation of the foundation.

Internal thermal insulation

Indoor walls are insulated with Technoplex up to 40 mm thick. The plates are fixed with glue. For ventilation, be sure to leave a gap between the thermal insulation layer and the finish. Rooms lined with polystyrene foam require regular ventilation. You should not use the material for thermal insulation of a bathhouse or sauna.

Floor insulation

Moisture-resistant Technoplex XPS can be laid on the ground under a concrete screed. Another option is to install insulation on a subfloor, on top of which roofing felt or plastic film has been previously laid. If necessary, the joint lines of polystyrene foam boards are blown with polyurethane foam.

When installing a heated floor, Technoplex is mounted on a concrete screed, polyethylene or thin roll insulation coated with foil is laid on top of it, cable mats or another type of heated floor are installed. Finally, a finishing screed is laid on the mounted system.

Comparison

The main technical characteristics of insulation are its thermal conductivity, water absorption and operating temperature.

The flammability group for both insulation materials is G4 (highly flammable). Their prices differ by 10% (Technoplex is more expensive).

After comparing them, it is clear that there are no significant differences between these insulation materials.

Yes, Technoplex has slightly better characteristics, but the cost is also higher. Despite the fact that Penoplex is cheaper, with individual construction the savings are insignificant.

Cost of products

Penoplex wins this confrontation. It is about 10% cheaper than its brother. At large volumes, this minor difference becomes quite significant. Therefore, in order to save money, it is better to choose the first option. The price in each region of Russia may be different, this should be taken into account.

With all this, we can conclude: each of the insulation materials is an excellent option. They are similar in their characteristics, but, nevertheless, Penoplex is a little better. It turns out that for a lower price you get high-quality insulation material. It is versatile and can be used for different purposes. Technoplex or Penoplex, which is better? Reviews say that each of the materials is good.

The difference between foamed polystyrenes

As mentioned above, the use of liquid and powder gas-forming agents is better, so products obtained using this technology have stable thermal insulation characteristics. Although, this cannot be called the only reason why Technoplex and Penoplex do not contain freon. There are two more:

- Sealed cells of new material that have not yet been used have remnants of freon. Formally, it is called safe, but in reality it is better not to deal with it. It can cause lung problems in children.

- Over time, the gas will be forced out of the cells by air and humidity. And if dirty raw materials containing styrene were used in the manufacture of the material, then the contents will penetrate into the external environment.

And if technical grades of EPS, such as Penofol, are used to treat foundations, highways, and plinths, then the presence of freon in the composition does not affect the material in any way. But to insulate your home, it is better to use safe products. Therefore, the answer to the question: Penoplex or Penofol, which is better, can be answered - the first option.

How do you know which is better Penoplex or expanded polystyrene? After all, many recommend insulating with foam plastic, because it has a low price and excellent characteristics. To answer this question, you need to know how penoplex differs from expanded polystyrene. Let's start with production technology.

Technoplex, Penoplex and even Penofol are created during the extrusion process. This allows you to obtain a very dense linear structure, which affects the material’s resistance to water and humidity, as well as strength. Therefore, foam plastic is somewhat worse than materials created by extrusion methods.

Penoplex

“Penoplex” is a heat-insulating extruded polystyrene foam, which is produced by the same name, and is distinguished by high technical properties, thanks to which the material has become extremely popular.

Its production is similar to that of Technoplex: polystyrene granules are heated at high temperatures and mixed under pressure with a foaming agent until a homogeneous structure is obtained. The mixture is passed through extruders, cooled and cut into sheets.

The plates are orange. The material consists of small cells filled with air. They are firmly closed and do not allow heat and air to pass through.

"Penoplex" is used:

- For floor insulation (under or on a screed, when installing a floor on joists or when installing a “warm floor”);

- When insulating a non-residential basement, thermal insulation of internal walls or facade;

- On roofs (for flat or green roofs);

- For insulation of wells and septic tanks;

- When installing platforms and paths, when constructing a blind area around the house.

Using Penoplex Source avrora-sm.ru

When using Penoplex, it is important to remember that it does not conduct moisture, and therefore it is necessary to have a good ventilation system, otherwise problems may arise. It is also necessary to select the thickness of the insulation so that the dew point falls on the material itself, and not on the wall.

"Penoplex" is available in several versions:

- " Wall ". They are distinguished by a rough surface on which finishing materials adhere better.

- " Comfort ". The edge is made in the shape of the letter "G". During installation, this guarantees stronger adhesion and the absence of gaps.

- " Foundation ". Used where structures are subject to high loads (for screeds) or where fire resistance requirements are lower (for floors or foundations).

- " Roof ". They have a “U”-shaped notch, which makes the connection more durable.

These types differ in thickness, density, elasticity and bending strength. For example, “Penoplex” “Foundation” and “Roofing” are more dense and elastic, their tensile strength is higher.

Advantages and disadvantages

It is impossible to decide how penoplex differs from technoplex and which is better without analyzing the pros and cons of the material. Both insulation materials are very similar to each other.

Penoplex Source ko-online.com.ua

Comparing expanded polystyrene foam with other insulation materials

The main competitor for such materials are felt and fiber insulation. Some prefer to use mineral wool, others prefer Technoplex or Penoplex. Which is better, penoplex or mineral wool for insulation? Each of the materials has its own positive and negative properties. In the photo below you can see the features of expanded polystyrene foam.

Like mineral wool, they are durable, safe and environmentally friendly. True, the thermal insulation qualities and moisture absorption of mineral wool are worse.

Private one- and two-story premises are best treated with Penoplex. It is much more effective. Mineral wool is used for finishing high-rise buildings. The fact is that it does not burn at all. Fire retardant additives will not be able to protect EPPS 100%; mineral wool is better in this regard. However, it is not recommended to use it in damp and damp areas.

Another competitor for EPPS is isolon. This is insulation made from foamed and modified polyethylene. Some people ask, Izolon or Penoplex, which is better? Izolon is suitable for insulating internal walls and ceilings of a building. And the thermal conductivity coefficients of the materials are almost the same. Izolon can withstand heating up to 80 degrees Celsius throughout the day. The material has excellent sound and noise insulation. It is safe and environmentally friendly. When heated, it will not emit harmful substances. The main disadvantage is the softness and flexibility of Izolon. When laying it on the wall, it requires fixing with sheets of plasterboard or MDF boards. You cannot glue wallpaper or plaster on Izolon. This is why it is recommended to use it in conjunction with EPS insulation.

You can also find the following queries on the Internet: Ravaterm or Penoplex, which is better, Polyspen or Penoplex, which is better, or Stirex or Penoplex, which is better. It is impossible to answer the question unequivocally. All of them belong to XPS and have almost identical characteristics. The difference is the price and some additional nuances.

Manufacturers

There is fierce competition in the construction market, however, not as many companies are involved in the production of technoplexes as the consumer would like. Let's consider the list of the main suppliers of extruded insulation on the Russian market.

- TECHNONICOL . The company is among the TOP 100 largest enterprises in Russia, and has several production lines in the country. The manufactured products attract buyers with a relatively low price and high quality.

- URSA . A relatively young brand that appeared on the market in 2003. At the beginning of its development, the company was engaged in the production of mineral wool from fiberglass. After merging with the Spanish company URALITA, lines for the production of extruded polystyrene began operating. Now it is one of the leading European brands, actively developing the Russian building materials market.

- RAVATHERM . The trademark belongs to a Belgian company with production lines in the Moscow region. Finished products are subject to multi-stage quality control, so they invariably have high technical characteristics.

It is worth noting that the products of these enterprises have international certificates and are absolutely environmentally safe.